Professional Documents

Culture Documents

Installation Instructions For KLINGER Gaskets - Einbau - e

Uploaded by

stuartj01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions For KLINGER Gaskets - Einbau - e

Uploaded by

stuartj01Copyright:

Available Formats

Installation instructions for KLINGER gaskets

1. Gasket dimensions 2. Storage 3. Handling 4. Bolts/ Nuts/ Washers 5. Gasket installation KLINGER The global leader in static sealing

Installation instructions for KLINGER gaskets

1. Gasket dimensions

Correct size The gasket has to have the correct size. Inner diameter The inner diameter of the gasket should not be smaller than the inner diameter of the flange.

3. Handling

Protect the gasket All types of gaskets (metallic gaskets, PTFE gaskets, fibre reinforced gaskets etc.) should be handled with the same care and attention. Avoid carrying small gaskets in a pocket to protect the gasket from damage.

2. Storage

Ideal storage conditions The gasket should be stored horizontal to avoid tensions and permanent warpage. Ideal storage conditions are: temperature < 25C air humidity 50 - 60% Darkened storage room Store the gasket in a clean condition (ideally in a plastic bag). Carry ready cutted gaskets carefully, ideally in some form of protective cover. Protect the surface Do not bend the gasket and do not damage the surface.

Bolt holes Cut the bolt holes just a bit larger than the bolts to simplify the centralization of the gasket.

Installation instructions for KLINGER gaskets

4. Bolts/Nuts/Washers

Bolt properties Pay attention that all bolts which are designed for the flange are installed. Check if the used bolts are suitable for the given operating temperatures. Tighten the bolts cross-wise with the correct torque (calculation with KLINGER expert 5.1). Ensure that there is no corrosion on the bolts because this can effect the function of the bolt. Never Re-use bolts. Nut properties Use a nut which has a specified proof load 20% greater than the ultimate strength of the fastener. Use standard threads, rather than fine. Use the correct lubricant. Washers Use the same material for the washers and the nuts. Use washers to: bridge slotted or oversized holes even interface forces between joint componets reduce problems of fatigue by spreading the load placed by the fastener on the joint. Flange conditions Make sure that the flanges are parallel and report all irregularities.

5. Gasket installation

The tools At first make sure that the following tools are available and in good condition: the correct gasket chosen for the specific application a calibrated torque wrench a wire brush lubricants for the bolts. Cleaning of all flange surfaces Make sure that the flange surfaces are clean. Check the bolts and the flange surface if they are technically ok and free from any seriuos defects. Always brush in the direction of the grooves. To avoid damage on the flange surface please use a brass drift. Important for the gasket Insert the gasket carefully between the flanges. The gasket has to be centralized in the flange. Ensure that the gasket is installed in a dry state. It is important that the gasket is not pinched or otherwise damaged when bringing the flanges together.

Installation instructions for KLINGER gaskets

5. Gasket installation

Lubrication of bolts Apply lubricant to the bolt and the nut threads as well as to the face of the nut to reduce friction when tightening Pay attention that the lubricant does not contaminate the gasket or the flange surfaces. The recommended service temperature of the lubricant has to be within the process service temperature limits. Bolt tightening The required torque value can be calculated with KLINGER expert 5.1. Make at least 4 stages to the required torque as follows: finger tighten bolts use 30% of the required torque use 60% of the required torque use the full torque Close the torquing with one final pass in a clockwise sequence. Re-use of gaskets For safety reasons never re-use a gasket. The cost of a gasket is minimal compared with the costs which will come into being of a down time of the plant.

Re-Tightening If retightening is considered necesary, this should only be done at ambient temperatures before or during the first start-up. Never retighten compressed fibre gaskets at higher operating temperatures and longer operating times.

KLINGER expert 5.1 Powerful Sealing Calculation

Features: Easy, self-explaining flange selection Graphical analysis of gasket stresses QuickHelp Function Product documentation of the sealing materials included on the CD Step by Step selection to the most suitable gasket material Solution proposal of the program at calculation problems available in many different languages

We have devised a tried and tested method, to guide you step by step to the right gasket for your needs.

1. Applications overview: The gasket characteristics compared with the criteria to be met in typical application. 2. Product documentation: A separate data sheet is supplied for each gasket in our range. The pT diagrams are an invaluable aid to selecting the gasket most suitable for a particular application. 3. Data on chemical resistance: This section indicates the resistance of the individual Klinger gaskets to over 200 chemicals in common use. 4. Technical information by Fax: Let us have the details of your particular gasket requirements and you will receive a prompt reply, in some cases within 24 hours. 5. Sealing calculations on your PC: For the experienced specialist we have developed a powerful program which will answer all your questions on gasket construction, design and maintenance. We supply the software with on-line help. 6. Ideally you should run your own tests: We will supply the materials you need to carry out tests under your own operating conditions. 7. On-sit advice: With particularly difficult problems we shall be glad to advice you on-site. We can supply products adapted from our existing range or custom-formulated products.

Powerful sealing calculation with online help on CD-ROM

Certified according to DIN EN ISO 9001:2000

Subject to technical alterations. Issue: March 2006

Rich. Klinger Dichtungstechnik GmbH & Co KG Am Kanal 8-10 A-2352 Gumpoldskirchen, Austria Tel ++43 (0) 2252/62599-137 Fax ++43 (0) 2252/62599-296 e-mail: mueller@klinger.co.at http://www.klinger.co.at

You might also like

- Installation Storage Instructions Klinger GasketsDocument6 pagesInstallation Storage Instructions Klinger GasketsMoustafa HelmyNo ratings yet

- Gasket Installation Instructions: The Global Leader in Static SealingDocument4 pagesGasket Installation Instructions: The Global Leader in Static SealingFarhan TalibNo ratings yet

- Installation, Assembly and Test Procedure: Kamos Patented Kammprofil GasketDocument16 pagesInstallation, Assembly and Test Procedure: Kamos Patented Kammprofil Gasketjayhuacat7743No ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- Installation Procedure Kamos RTJ GasketDocument16 pagesInstallation Procedure Kamos RTJ Gasketekhwanhakim100% (3)

- Klinger Gasket CatalogueDocument118 pagesKlinger Gasket CatalogueArt James100% (1)

- Module 7 B1 MCQDocument5 pagesModule 7 B1 MCQNurannabi DipuNo ratings yet

- Cavaliere SV168&198 Series Wall Manual All CTRL (Rev.1016u.6b)Document32 pagesCavaliere SV168&198 Series Wall Manual All CTRL (Rev.1016u.6b)Euro-Kitchen, Inc.No ratings yet

- Flange Fitters Hand BookDocument52 pagesFlange Fitters Hand BookMohammed Abdul Sayeed100% (3)

- Cooker Hood Instruction Manual: Important: Retain For Future ReferenceDocument28 pagesCooker Hood Instruction Manual: Important: Retain For Future ReferenceAnkurNo ratings yet

- User's Manual: WS-4830SS WS-4836SSDocument16 pagesUser's Manual: WS-4830SS WS-4836SSMarco TosiniNo ratings yet

- Flange Assembly GuideDocument7 pagesFlange Assembly GuideYakdhan YaseenNo ratings yet

- Correct procedure for flange bolting installationDocument7 pagesCorrect procedure for flange bolting installationAkshay KalraNo ratings yet

- DometicRM53xx INM 4445102233 APAC (En) 04 2017-12Document36 pagesDometicRM53xx INM 4445102233 APAC (En) 04 2017-12carlNo ratings yet

- Transeals Identifying Hydraulic SealsDocument28 pagesTranseals Identifying Hydraulic Sealsvikram_007No ratings yet

- SealSDocument63 pagesSealSAnonymous fQAeGFNo ratings yet

- Construction Specification 97-Geomembrane Liner: 1. ScopeDocument6 pagesConstruction Specification 97-Geomembrane Liner: 1. ScopeLuis Rolando AguilarNo ratings yet

- Mosquito Magnet Defender InstructionsDocument18 pagesMosquito Magnet Defender InstructionsMrFixit1328No ratings yet

- 2023 01 Gasket-HandbookDocument216 pages2023 01 Gasket-Handbookrbnotosagoro100% (1)

- Installation GC1 Gunning Castables - Conventional PDFDocument2 pagesInstallation GC1 Gunning Castables - Conventional PDFLuis PullasNo ratings yet

- Installation Guide & User'S Manual: Pro-X SeriesDocument12 pagesInstallation Guide & User'S Manual: Pro-X Series123anthonyNo ratings yet

- Rubber Lining Application PDFDocument9 pagesRubber Lining Application PDFLasandu WanniarachchiNo ratings yet

- SV198B2-SPI30 SV198B2-SPI36 SV198Z2-SPI36 ManualDocument32 pagesSV198B2-SPI30 SV198B2-SPI36 SV198Z2-SPI36 ManualEuro-Kitchen, Inc.100% (2)

- Digeridoo Pulse Jet Engine PlansDocument4 pagesDigeridoo Pulse Jet Engine Plansjohn424No ratings yet

- Danby DAC 5110M Air Conditioner ManualDocument16 pagesDanby DAC 5110M Air Conditioner ManualRJ BodenNo ratings yet

- Amercoat 878 HSDocument4 pagesAmercoat 878 HSMario KoričanNo ratings yet

- Rubber Lining PrinciplesDocument5 pagesRubber Lining PrinciplesTushar MangratiNo ratings yet

- Concrete Cutter Procedure Rev.2Document9 pagesConcrete Cutter Procedure Rev.2Jennifer JavierNo ratings yet

- Full-Faced Expansion Joints: InstallationDocument3 pagesFull-Faced Expansion Joints: InstallationChiranjeevi AnilNo ratings yet

- Checkmate II QD 2013 .22lr Manual.Document2 pagesCheckmate II QD 2013 .22lr Manual.Griffin Armament SuppressorsNo ratings yet

- Classic Inst Guide v10 - 4Document72 pagesClassic Inst Guide v10 - 4vins21No ratings yet

- Sears Kenmore Model 141 16321 1 ManualDocument31 pagesSears Kenmore Model 141 16321 1 Manualtomj0001No ratings yet

- Amt 612 Lesson 2 Ac Covering Approved MaterialsDocument25 pagesAmt 612 Lesson 2 Ac Covering Approved MaterialsCarl Vincent SurnitNo ratings yet

- Safety Policy For Garment 31-07Document5 pagesSafety Policy For Garment 31-07S.M. Shariful Islam100% (1)

- LG Washer WM2487hwm Owners ManualDocument48 pagesLG Washer WM2487hwm Owners ManualmgmorgNo ratings yet

- Laminating Troubleshooting FinalDocument25 pagesLaminating Troubleshooting FinalHabteyes AbateNo ratings yet

- Checkmate II .22lr Manual.Document2 pagesCheckmate II .22lr Manual.Griffin Armament SuppressorsNo ratings yet

- Snap SOP - 27 Feb 2022Document38 pagesSnap SOP - 27 Feb 2022Suresh KumarNo ratings yet

- Ap238 Ps29 Ps31 ManualDocument28 pagesAp238 Ps29 Ps31 ManualEuro-Kitchen, Inc.No ratings yet

- ArmaFlex Application UkDocument36 pagesArmaFlex Application UkDave StaelensNo ratings yet

- Commercial Refrigeration User ManualDocument7 pagesCommercial Refrigeration User ManualFranz Rogene Holaizza VergaraNo ratings yet

- CRSM Cable Repair Sleeve Installation GuideDocument10 pagesCRSM Cable Repair Sleeve Installation GuideglenysyaNo ratings yet

- 3DHS 95 EXTRA 330SC-E Assembly ManualDocument27 pages3DHS 95 EXTRA 330SC-E Assembly ManualMitchell SchnyderNo ratings yet

- 4HK1 & 6HK1 ManualDocument352 pages4HK1 & 6HK1 Manuallionkinghd94% (104)

- PG22 Maverick 22 Short Revolver Build GuideDocument6 pagesPG22 Maverick 22 Short Revolver Build GuideTimNo ratings yet

- Install Sweat FittingsDocument5 pagesInstall Sweat FittingsPeter BqkNo ratings yet

- Valve storage protection procedureDocument2 pagesValve storage protection procedurenisus4everNo ratings yet

- Method Statement - InsulationDocument2 pagesMethod Statement - Insulationjasonvent82% (11)

- User's Guide: Thanks For Buying A POWERSTEAMER PRO Deep CleanerDocument17 pagesUser's Guide: Thanks For Buying A POWERSTEAMER PRO Deep CleanerMarkMoore75No ratings yet

- Ultimate Guide to Basements, Attics & Garages, 3rd Revised Edition: Step-by-Step Projects for Adding Space without Adding onFrom EverandUltimate Guide to Basements, Attics & Garages, 3rd Revised Edition: Step-by-Step Projects for Adding Space without Adding onNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Weatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundFrom EverandWeatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundNo ratings yet

- Ultimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildFrom EverandUltimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildNo ratings yet

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- Measuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopFrom EverandMeasuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopNo ratings yet

- Family Handyman Quick & Easy ProjectsFrom EverandFamily Handyman Quick & Easy ProjectsFamily HandymanNo ratings yet

- Section Cutting and Staining: A practical introduction to histological methods for students and practitionersFrom EverandSection Cutting and Staining: A practical introduction to histological methods for students and practitionersNo ratings yet

- Minor Loss HandoutDocument24 pagesMinor Loss HandoutJosh ShortNo ratings yet

- Spirol Pins Bissel Pins Tension Pins SLTP - UsDocument8 pagesSpirol Pins Bissel Pins Tension Pins SLTP - Usstuartj01No ratings yet

- Welding Symbols Jk65Document5 pagesWelding Symbols Jk65stuartj01No ratings yet

- 5 Threaded FastenersDocument7 pages5 Threaded FastenerstmakauNo ratings yet

- Bs 980 1950 - Steel Tubes For Automobile PurposesDocument14 pagesBs 980 1950 - Steel Tubes For Automobile Purposesstuartj01No ratings yet

- ASTM A231 - A231M - 10 Standard Specification For Chromium Vanadium Alloy Steel Spring WireDocument2 pagesASTM A231 - A231M - 10 Standard Specification For Chromium Vanadium Alloy Steel Spring WireMahmood Khan0% (1)

- Primary Design of A Tripod Supporting Structure For Wind TurbineDocument76 pagesPrimary Design of A Tripod Supporting Structure For Wind TurbineYangNo ratings yet

- Cyclone Fay Strikes Western AustraliaDocument3 pagesCyclone Fay Strikes Western AustraliaMukhotaru YanuarNo ratings yet

- Day Skipper Passage Planning: Boat SafetyDocument4 pagesDay Skipper Passage Planning: Boat Safetymaestromuzika100% (1)

- 3 Basic Question TypesDocument8 pages3 Basic Question Typesanisafiari0% (1)

- MANUAL INSTALLATION OF AMEX®-10 SealsDocument10 pagesMANUAL INSTALLATION OF AMEX®-10 SealsytserbetciNo ratings yet

- English8 Q4, W4 - Mod4Document16 pagesEnglish8 Q4, W4 - Mod4Rochelle EvardoNo ratings yet

- Those Winter SundaysDocument10 pagesThose Winter SundaysjesseNo ratings yet

- Direct and Reported SpeechDocument7 pagesDirect and Reported SpeechLittleLonely SoulNo ratings yet

- 2008-07-20 015947 tsb04-15-03 Rain Hat Repair Taurus SableDocument6 pages2008-07-20 015947 tsb04-15-03 Rain Hat Repair Taurus Sableecastro111No ratings yet

- Coal Bunker Design ReportDocument14 pagesCoal Bunker Design ReportVasanthakumarNo ratings yet

- Hills Like White ElephantsDocument9 pagesHills Like White ElephantsRohana FernandoNo ratings yet

- 02 Grounding of A Container ShipDocument13 pages02 Grounding of A Container ShipDnv BaileyNo ratings yet

- D 559 - 03 Standard Test Methods For Wetting and Drying Compacted Soil-Cement Mixtures PDFDocument7 pagesD 559 - 03 Standard Test Methods For Wetting and Drying Compacted Soil-Cement Mixtures PDFРадо МицевNo ratings yet

- C 1002 - 00 QzewmditmdaDocument4 pagesC 1002 - 00 QzewmditmdaHumberto GutierrezNo ratings yet

- Sizing The Control Transformer For A PanelDocument16 pagesSizing The Control Transformer For A PanelKishore KrishnaNo ratings yet

- Geology of Kubor Anticline PNGDocument164 pagesGeology of Kubor Anticline PNGstavros7100% (1)

- Kentucky BlastingDocument5 pagesKentucky BlastingYQPNo ratings yet

- Sae 3400 (Projct Report)Document19 pagesSae 3400 (Projct Report)Aishwary JainNo ratings yet

- KLM f70 CaseDocument4 pagesKLM f70 CaseDimitriosMonogiosNo ratings yet

- Carbon Credits-A Case Study On GFLDocument39 pagesCarbon Credits-A Case Study On GFLsudesh1992No ratings yet

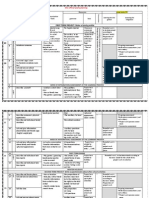

- 4levels Official Yearly Planning & Omitted Lessons PDFDocument16 pages4levels Official Yearly Planning & Omitted Lessons PDFSamir Bounab86% (7)

- Aashto T 308 (2013)Document8 pagesAashto T 308 (2013)Stuar TencioNo ratings yet

- Verbal Probability Expressions in National Intelligence EstimatesDocument124 pagesVerbal Probability Expressions in National Intelligence EstimatesKristan J. Wheaton100% (4)

- Full Report: Synthesis of AspirinDocument3 pagesFull Report: Synthesis of AspirinNor Ashikin IsmailNo ratings yet

- Fahrenheit 451 Script PDFDocument2 pagesFahrenheit 451 Script PDFRhonda20% (10)

- EG 15-14-1.1 Inspection and Testing of InstrumentsDocument3 pagesEG 15-14-1.1 Inspection and Testing of Instrumentsamin100% (1)

- 100 Welding Consumable Control ProcedureDocument10 pages100 Welding Consumable Control ProcedureAhmed Elsayed100% (3)

- How Tech Saves Lives in HurricanesDocument9 pagesHow Tech Saves Lives in HurricanescoachpriceNo ratings yet

- 2012 Examiners ReportDocument54 pages2012 Examiners ReportJonSeltinNo ratings yet