Professional Documents

Culture Documents

Collection of Standard Symbol ROUGH Assignment

Uploaded by

Hamza ShafiqOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Collection of Standard Symbol ROUGH Assignment

Uploaded by

Hamza ShafiqCopyright:

Available Formats

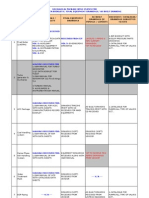

COLLECTION OF STANDARD SYMBOLS

General equipments:

Equipment Name

Conveyor

Symbol

Use

A conveyor is a common mechanical handling equipment that moves materials from one location to another. They are used in bulk handling industries as an efficient way to move semisolid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, and many others. A scraper conveyor is a material transportation device utilizing a continuous, driven chain circuit equipped with regularly spaced cross members.

Screw Conveyor

Scraper Conveyor

Overhead Conveyor

Feeder

Star Feeder

Overhead Conveyors can be used to moves materials from one location to another. When factory floor space is at a premium thus giving you the freedom and flexibility to have other machinery or production processes on the ground floor. They are used in pneumatic conveying systems, dust control equipment, and as volumetric feed-controls. It can be applied for the uniform feeding of powder in various industries. They are used in various industries for the metering of material into a production process. Weigh belt feeders are heavily used in the food industry for high-feed rates and to handle a wide range of materials, including fragile materials that might be damaged by a screw feeder. It a simple container for stirring, mixing and heating liquids commonly used in many laboratories. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Roll crushers are machines equipped with teeth and wheels that crush material up to one fifth its original sizes.

Screw Feeder

Weighing Feeder

Beaker

Crusher

Roll Crusher

Hammer Crusher

Ball Mill

Mixer

Kneader

Blender

Double Blender

Fluid Separator

Hammer crusher can be used to crush various semi hard and fragile materials, such as limestone, coal, salt, gypsum, alum, bricks, tiles, and coal gangue, and so on. It can crush materials of different sizes into small particles of relatively equal sizes. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics. Mixers are used in a wide range of industries to combine different materials together to form one final product from the mixing process. The mixed materials can be mixed from low to high viscosity, high to low viscosity, or mixed at a constant viscosity. Kneader are large volume, low shear, processing units that combine the intensive mixing and kneading necessary to process highly viscous, pasty, crust-forming materials, or materials that change phases. A blender is a laboratory appliance used to mix or emulsify substances. The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. It is used in removing particulates from an air, gas

Sand Filter

Dust Collector

Liquid-Liquid Separator

or liquid stream, without the use of filters, through vortex separation. Sand filters are used extensively in the water industry for water purification. A Dust Collector is used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Liquid-Liquid Separator can

separate any two immiscible liquids. We can separate fuel and water, or, oil and water, so efficiently that the effluent can contain 1 PPM or less of the unwanted liquid.

Filter

Rotary Filter

Screen

Electro-magnet

Cyclone

Filter may refer to a device to separate mixtures in chemistry, engineering, or household usage. Rotary vacuum filter drum consists of a drum rotating in a tub of liquid to be filtered. The technique is well suited to high solids liquids that would blind or block other forms of filter. It helps in the identifying or selecting members of a population based on one or more selection criteria. They can be used for the separation of magnetic ore particles and non magnetic gangue particles during the extraction of metals. A high speed rotating (air) flow is established within a cylindrical or conical container called a cyclone. They can be used for removing particulates from an air, gas or liquid stream,

Centrifuge

Briquetting Machine

Prill Tower

Dryer

Skip Hoist

Hoist

without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids. The method can also be used to separate fine droplets of liquid from a gaseous stream. A centrifuge is a piece of equipment, generally driven by an electric motor (some older models were spun by hand), that puts an object in rotation around. It is used to separate substances of greater and lesser density. Briquetting machine has been designed to produce a block of flammable matter used as fuel to start and maintain a fire( briquette) from a variety of granular or powdered material. such as: charcoal, coal, coke, iron oxide, iron concentrate, metal powder, iron powder, dried sewage sludge, steelwork dust, etc. Reactor used for producing prill agglomerates (From Latin means to wind into a ball). It is widely used in food, forage, chemical engineer, medicine, and mining industries. It is employed to reduce or minimize the liquid moisture content of the material. A basket, bucket, or open car mounted vertically or on an incline on wheels, rails, or shafts and hoisted by a cable; used to raise materials. Also known as skip. Any apparatus or device for hoisting (To move or lift

something by a rope-andpulley device).

Heat exchangers:

Air Blown Cooler Air blown cooler is a heat exchanger. But, unlike a water heat exchanger which uses water as the cooling medium, an air blast cooler uses free ambient air as its cooling medium. A rise in the temperature controlled in order to optimize the performance of your system. Plate Type Cooler One is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. Finned Tube Cooler The two primary cooler designs are tube-and-fin style coolers. One can extract the heat through the tubes to the external fins where it is absorbed by the air flowing through the cooler. Double Pipe Heat Exchanger Double-pipe heat exchanger has high performance and comprising an inner pipe and an outer pipe which constitute a double pipe. Oil Burner An oil burner is a mechanical device that combines fuel oil

with proper amounts of air before delivering the mixture to the point of ignition in a combustion chamber. They are typically used in steamers, ovens etc. Boiler A boiler is a closed vessel in which water or other fluid is heated. Used to generate steam to drive turbines to generate electricity.

Fixed Heater

They are used in industry heating large scale industrial processes.

Tube Bundle Heat Exchanger

They are used in steam engine locomotives. Heat exchangers are widely used in industry both for cooling and heating large scale industrial processes. The type and size of heat exchanger used can be tailored to suit a process depending on the type of fluid, its phase, temperature, density, viscosity, pressures, chemical composition and various other thermodynamic properties.

Shell and Tube heat exchanger

In large power plants. Shell and tube bundle heat exchanger are used to condense the exhaust steam.

Condenser

A condenser is a device or unit used to condense a substance from its gaseous to

its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers. Automatic Stoker A device that supplies fuel to a boiler furnace by mechanical means. Also known as mechanical stoker. Refrigerator Refrigeration is a process in which work is done to move heat from one location to another. This work is traditionally done by mechanical work, but can also be done by magnetism, laser or other means. Refrigeration is used to liquify gases - oxygen, nitrogen, propane and methane. In oil refineries, chemical plants, and petrochemical plants, refrigeration is used to maintain certain processes at their needed low temperatures. Evaporation Condenser Evaporative cooling is a common form of cooling buildings for thermal comfort. It s only efficient when the relative humidity is low, restricting its effective use to dry climates. Oil Separators A means of controlling an oil level in the separator, which usually includes a liquid-level

controller and a diaphragm motor valve on the gas outlet. It utilizes the difference in density between oil or petroleum products and fluid to separate the oil from the fluid. They are utilized thoroughly in industry, typical industrial applications include: food processing equipment, heavy manufacturing, wastewater treatment, marine, water drainage and engine fuel systems. Chilling Evaporator They are often used in the plastic industry in injection and blow molding, metal working cutting oils, welding equipment, die-casting and machine tooling, chemical processing, pharmaceutical formulation, food and beverage processing, paper and cement processing, vacuum systems, X-ray diffraction, power supplies and power generation stations, analytical equipment, semiconductors, compressed air and gas cooling. They are also used to cool high-heat specialized items such as MRI machines and lasers, and in hospitals, hotels and campuses.

Air Cooling Evaporator

These heat exchangers are generally applied to control environmental conditions in holding freezer, dynamic blast freezers, stationary blast cells, refrigerated docks as well as other low temperature conditioned space found in food manufacturing and distribution facilities.

Extractor Hood

An extractor hood is a device containing a mechanical fan that hangs above the stove or cook top. It is used to remove airborne grease, combustion products, smoke, odors, heat, and steam from the air by a combination of filtration and evacuation of the air.

Fan Blades

A fan blade will often rotate when exposed to an air stream; often have designs similar to that of a fan. Their typical applications include climate control, vehicle and machinery cooling systems, ventilation, fume extraction, removing dust, drying and to provide draft for a fire.

Cooling Towers:

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or in the case of closed circuit dry cooling towers rely solely on air to cool the working fluid to near the dry-bulb air temperature. Common applications include cooling the circulating water used in oil refineries, chemical plants, power stations and building cooling

Following are the different cooling towers on the basis of their construction but all of them serve the same purpose Induced Draft Cross Flow Cooling Tower Induced draft cooling towers are constructed such that the incoming circulating water is dispersed throughout the cooling tower via a spray header. These towers make use of the forced and the induced draft fans. Forced Draft Counter Flow Cooling Tower Forced draft cooling towers are very similar to induced draft cooling towers. The primary difference is that the air is blown in at the bottom of the tower and exits at the top. Forced draft cooling towers are usually used for high resistance air due to centrifugal blower fan. Water distribution problems and recirculation difficulties discourage the use of forced draft cooling towers. Hyperbolic Chimney Tower Cooling Tower These cooling towers make use of the difference in temperature between the ambient air and hotter air inside the tower. Natural Draft Counter Flow Cooling Tower Natural draft cooling towers are particularly attractive as a cost-saving solution for larger power stations and industrial plants requiring greater quantities of cooling water. As this type of cooling tower operates without fans. The required cooling air is not

conveyed through the tower by natural draft thus fans nor is fan power required.

Pumps:

A pump is a device used to move fluids, such as liquids, gases or slurries. A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement, and gravity pumps. Their names describe the method for moving a fluid. A pump supported directly by In line pump the system piping (i.e., the piping carries the weight of the pump); usually mounted vertically to save floor space, with its weight centered over the piping. Positive displacement pump A positive displacement pump is one in which a definite volume of liquid is delivered for each cycle of pump operation. This volume is constant regardless of the resistance to flow offered by the system the pump is in. The positive displacement pump differs from centrifugal pumps, which deliver a continuous flow for any given pump speed and discharge resistance. A centrifugal pump is a rot dynamic pump that uses a rotating impeller to create flow by the addition of energy to a fluid. Centrifugal pumps are commonly used to move liquids through piping. Centrifugal pumps are used for large discharge through smaller heads.

Centrifugal pump

Vertical Centrifugal Pump

Horizontal Centrifugal Pump

Rotary pump

Reciprocating Pump

A rotary pump is a positivedisplacement pump that consists of vanes mounted to a rotor that rotates inside of a cavity. Common uses include high pressure hydraulic pumps and automotive uses including, supercharging, power steering and automatic transmission pumps. They are also often used as vacuum pumps for providing braking assistance in large trucks and diesel powered passenger cars (whose engines do not generate intake vacuum) through a braking booster, and in most light aircraft to drive gyroscopic flight instruments, the attitude indicator and heading indicator. Furthermore, rotary pumps can be used in low-pressure gas applications such as secondary air injection for auto exhaust emission control, and in vacuum applications including evacuating refrigerant lines in air conditioners, and laboratory freeze dryers, extensively in semiconductor low pressure chemical vapor deposition systems, and vacuum experiments in physics. A reciprocating pump is a positive plunger pump. It is often used where relatively small quantity of liquid is to be handled and where delivery pressure is quite large. An ejector/injector is a pumplike device that uses the Venturi effect of a convergingdiverging nozzle to convert the pressure energy of a motive

Ejector/injector

Sump pump

Progressive cavity

Screw pump

Gear Pump

fluid to velocity energy which creates a low pressure zone that draws in and entrains a suction fluid. It is used for delivering water to a steam locomotive boiler takes advantage of the release of the energy contained within the latent heat of evaporation to increase the pressure to above that within the boiler. A sump pump is a pump used to remove water that has accumulated in a water collecting sump pit, commonly found in the basement of homes. A progressive cavity pump transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned. Screw pump is a machine historically used for transferring water from a lowlying body of water into irrigation ditches. A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. Gear pumps are also widely used in chemical installations to pump fluid with a certain viscosity.

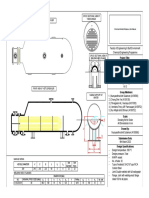

Vessels:

Vessel A vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the

ambient pressure. Vessels are used in a variety of applications in both industry and the private sector. They appear in these sectors as industrial compressed air receivers and domestic hot water storage tanks. Fluid Contacting Column In chemical engineering, such vessel are used when we have make two different fluids in contact for a short period for time for different purposes Reaction Vessel In chemical engineering, reaction vessels are such container which is designed to contain chemical reactions. Clarifier Clarifiers, the inclined parallel plate design used as part of a wastewater treatment system for solids settling. Closed Tank Closed Tank is a type of pressure vessel designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Gas Holder A gas holder is a large container where natural gas or town gas is stored near atmospheric pressure at ambient temperatures. Barrel A barrel or cask is a hollow cylindrical container

Gas Cylinder

A gas cylinder or tank is a pressure vessel used to store gases at above atmospheric pressure. High pressure gas cylinders are also called bottled gases.

Tray Column

Tray column is an essential item used in the distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in their volatilities. Fractionating columns are used in small scale laboratory distillations as well as for large-scale industrial distillations.

Storage Symbols:

Bin Bin is a pallet size box used for storage and shipping of bulk quantities. Storage Tank A storage tank is a container, usually used for holding liquids, sometimes for compressed gases (gas tank). The term can be used for reservoirs (artificial lakes and ponds), and for manufactured containers. Dome Roof Tank Dome roof tanks are meant for tanks having slightly higher storage pressure fluids. The dome roof tank comes in a single and double wall type. The single wall type is used to store heavy and light oil, etc. The double wall type is used

for low temperature liquids. Open Top Tank A tank is a container, usually for holding fluid. Open Tank is usually used to easier withstand hydraulic hydrostatically induced pressure of contained liquid. Cone Roof Tank Cone roof tank is designed for combustible products which have less tendency of evaporation. Double Wall Tank Double Wall Tanks are approved and designed for management of waste oil, generator fuel, transmission fluids, motor oil and other Internal Float Tank hazardous liquids. Floating roof tanks either internal or external is designed for very volatile products and flammable. Onion tanks are used for containing large volumes of water. The advantage of these tanks is they are totally collapsible and can be easily stored in its own storage bag. It can be easily stored in a truck or cargo hold in an aircraft. Other applications are Oil Spill, Fire Fighting, Water Relay, Water Storage, Mixing Tank, Hazardous Waste

Onion Tank

Drum

A drum is a cylindrical container used for shipping bulk cargo. They are also generally used for the transportation and storage of liquids and powders.

External Floating Roof Tank

An external floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate. External roof tanks are usually installed for environmental or economical reasons to limit product loss and reduce the emission of volatile organic compounds (VOC), an air pollutant.

Instruments:

Autoclave An autoclave is an instrument used to sterilize equipment and supplies by subjecting them to high pressure saturated steam at 121 C for around 1520 minutes depending on the size of the load and the contents Level Meter Level Meter can detect and measure the level of substances that flow, including liquids, slurries, granular materials, and powders. Pressure Gauges Typically, pressure gauges are devices used for measuring the pressure of a gas or liquid. Flow meter A flow meter is an instrument used to measure linear, nonlinear, mass or volumetric flow rate of a liquid or a gas.

Rota meter

A rota meter is a device that measures the flow rate of liquid or gas in a closed tube.

Venturi meter

Venturi meter is a device used for measuring the flow rate of fluids in a pipe. Tube sufficiently fine so that capillary attraction of a liquid into the tube is significant.

Capillary Tube

Reactors

Reformer Reaction Vessel A reformer is a reaction vessel based on steam reforming or auto thermal reforming and is used in chemical engineering, for conversion of petroleum refinery naphtha, typically having low octane ratings, into high-octane liquid products Hydro Desulphurization Rector Hydrodesulphurization (HDS) is a catalytic chemical reaction vessel widely used to remove sulfur (S) from natural gas and from refined petroleum products such as gasoline or petrol, jet fuel, kerosene, diesel fuel, and fuel oils.

Fluid Coking Reactor

A reaction vessel designed for carrying a thermal process utilizing the fluidized solids technique for continuous conversion of heavy, lowgrade petroleum oils into petroleum coke and lighter hydrocarbon products. A reaction vessel designed for Hydro cracking which is a catalytic cracking process assisted by the presence of an elevated partial pressure of hydrogen gas. Similar to the hydrotreater, the function of hydrogen is the purification of the hydrocarbon stream from sulfur and nitrogen heteroatoms.

Hydro cracking Reactor

Fluid Catalytic Cracking Reactor

It is designed for the conversion of the high-boiling, high-molecular weight hydrocarbon fractions of petroleum crude oils to more valuable gasoline, olefin gases and other products.

Mixing Reactor

The Batch reactor is the generic term for a type of vessel widely used in the process industries. Vessels of this type are used for a variety of process operations such as solids dissolution, product mixing, chemical reactions, batch distillation, crystallization, liquid/liquid extraction and polymerization. In some cases, they are not referred to as reactors but

have a name which reflects the role they perform (such as crystallizer, or bio reactor).

Valves:

A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically pipe fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. Valves are used in a variety of contexts, including industrial, military, commercial, residential, and transport. The industries in which the majority of valves are used are oil and gas, power generation, mining, water reticulation, sewerage and chemical manufacturing Valves play a vital role in industrial applications ranging from transportation of drinking water to control of ignition in a rocket engine. They are of different types which are discussed as follow Gate Valve A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. Globe Valve A globe valve is a type of valve used for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body

Screw Down Valve

Non return valve (or Screw Down Valve) can be stated as one way root. No return back to pump. In this case the fluid coming from delivery of pump presses the plate inside the non return valve along with screw. When the fluid generates back pressure the screw comes down and the return way is blocked by the plate A check valve, clack valve, non-return valve or one-way valve is a mechanical device, a valve, which normally allows fluid (liquid or gas) to flow through it in only one direction.

Check Valve

Stop Check Valve

A stop-check valve is a check valve with override control to stop flow regardless of flow direction or pressure. In addition to closing in response to backflow or insufficient forward pressure (normal check-valve behavior), it can also be deliberately shut by an external mechanism, thereby preventing any flow regardless of forward pressure.

Diaphragm Valve

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a "saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or steel.

Needle Valve

A needle valve is a type of valve having a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

Relief Valve

The relief valve (RV) is a type of valve used to control or limit the pressure in a system or vessel which can build up by a process upset, instrument or equipment failure, or fire.

Angle Valve

An angle valve is a flow control device that utilizes a piston seated within a metal casing in order to control the flow of fluid or gas through a system.

Float Operated Valves

Float Operated Valve is a valve used to control the flow of water into a cistern, the valve being controlled by the level of water in the cistern.

Butterfly Valves

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off.

Wedge Valve Ball Valve A ball valve is a valve with a spherical disc, the part of the valve which controls the flow through it. The sphere has a Motor/Hydraulic Ball Valve hole, or port, through the middle so that when the port

is in line with both ends of the valve, flow will occur. Relief Angle Valve These are automatically operated by system pressure. Outside control or operator is not required. Reducing Valve Pressure Regulator (or Pressure Reducing Valve) is a valve that automatically cuts off the flow of a liquid or gas at a certain pressure. Regulators are used to allow high-pressure fluid supply lines or tanks to be reduced to safe and/or usable pressures for various applications. Thus reduces pressure to a preset level downstream of the valve. Plug Valve 3-way Plug Valve Plug valves are valves with cylindrical or conically-tapered "plugs" which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug, so that fluid can flow through the plug when the valve is open. Plug valves are simple and often economical. Mixing Valve A Mixing Valve (TMV) is a valve that blends hot water with cold water to ensure constant, safe outlet temperatures preventing scalding.

Four Way Valve

The four-way valve (or fourway cock) is a fluid control valve whose body has four ports equally spaced round the valve chamber and the plug has two passages to connect adjacent ports. The plug may be cylindrical or tapered, or a ball.

Pinch Valve

A pinch valve is a full bore or fully ported type of control valve which uses a pinching effect to obstruct fluid flow. There are a few types of pinch valves based upon application.

Knife Valve

Knife valve are similar to a gate valve, but usually more compact. They often used for slurries or powders on/off control. A bleeder valve works by releasing air, or gas through a valve opening to reduce the built up pressure inside a tank or remove excess air or gas in a system. The bleeder valve has a manually operated or automatic valve opening that serves as an exit point for air in a heating system, compressor or one of many other types of systems.

Bleeder Valve

Distillation Symbols :

Distillation column is a tall metal cylinder internally fitted with perforated horizontal plates used to promote separation of miscible liquids ascending in the cylinder as vapor. They also function to separate air into its various components, principally oxygen and nitrogen. For separating air in distillation columns these are taken into their liquid form rather than gaseous state.

Distillation columns are designed based on the boiling point properties of the components in the mixtures being separated. Thus the sizes, particularly the height, of distillation columns are determined by the vapors liquid equilibrium Tray / Plate Type(Bubble Cap , Sieve ,Valve) Distillation Tower This is also a tall, cylindrical column. Inside, a series of trays are placed, one above the other. The trays are used to bring the rising vapors and falling liquid into intimate contact. Tray towers do the same job as packed towers but they are very much more efficient in the separation process than packed towers and, they are also more costly. Packed Tower(Saddle , Ring) Distillation Tower As its name implies, the packed tower is a vertical, steel column which contains 'Beds' of packing material which are used to bring the rising vapors into intimate contact with falling liquid within the tower. The heat added to the mixture before entering the tower partially vaporizes the mixture and the vapors rise up the tower and begin to cool.

Compressor:

Centrifugal Compressor

Centrifugal compressors sometimes referred to as radial compressors. They have find their application in gas turbines and auxiliary power units, In automotive engine and diesel engine turbochargers and superchargers, In oil refineries, natural gas processing, petrochemical and chemical plants, air-conditioning and refrigeration and HVAC Centrifugal compressors quite often supply the compression in water chillers cycles etc

Centrifugal Vacuum Blower or Centrifugal Blower

A centrifugal blower is a mechanical device for moving air or other gases. They can generate pressure increases in the gas stream. Accordingly, they are well-suited for industrial processes and air pollution control systems. They are also common in central heating/cooling systems.

Axial Compressor

Axial compressors are rotating, airfoil-based compressors in which the working fluid principally flows parallel to the axis of rotation. They are widely used in gas turbines, such as jet engines, high speed ship engines, and small scale power stations. They are also used in industrial applications such as large volume air separation plants, blast

furnace air, fluid catalytic cracking air, and propane dehydrogenation. Axial compressors, known as superchargers, have also been used to boost the power of automotive reciprocating engines by compressing the intake air, though these are very rare. Reciprocating Compressor A reciprocating compressor or piston compressor is a positivedisplacement compressor that uses pistons driven by a crankshaft to deliver gases at high pressure. Applications include oil refineries, gas pipelines, chemical plants, natural gas processing plants and refrigeration plants. One specialty application is the blowing of plastic bottles made of Polyethylene Terephthalate (PET). Liquid Ring Vacuum A liquid ring pump is a rotating positive displacement pump. They are typically used as a vacuum pump but can also be used as a gas compressor.

Rotary Compressor

A rotary compressor is a gas compressor which uses a rotary type positive displacement mechanism. They are commonly used to replace piston compressors where large volumes of high pressure air are needed, either for large industrial applications or to operate high-power air tools

Rotary Compressor along with Silencer

Rotary Screw Compressor

such as jackhammers.

Drivers:

An electric motor converts electrical energy into mechanical energy. Motors are found in applications as diverse as industrial fans, blowers and Diesel Motor pumps, machine tools, household appliances, power tools, and disk drives. Agitator Or Mixer An agitator is a device or mechanism to put something into motion by shaking or stirring DC Motor DC motor is an electric motor that runs on direct current (DC) electricity. DC motors are commonly used where precise speed control is necessary, as in computer disk drives or in video cassette recorders, the spindles within CD, CD-ROM (etc.) drives, and mechanisms within office products such as fans, laser printers and photocopiers.

Motor

AC Motor

An AC motor is an electric motor driven by an alternating current. This type of motor is now used for the vast majority of commercial applications.

Turbine Turbines(Steam, Hydraulic, Gas Motor)

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.

You might also like

- Serverless Computing: Current Trends and Open ProblemsDocument20 pagesServerless Computing: Current Trends and Open ProblemsHamza ShafiqNo ratings yet

- A Spec RG Cloud Group'S Vision On The Performance Challenges of Faas Cloud ArchitecturesDocument4 pagesA Spec RG Cloud Group'S Vision On The Performance Challenges of Faas Cloud ArchitecturesHamza ShafiqNo ratings yet

- A Spec RG Cloud Group'S Vision On The Performance Challenges of Faas Cloud ArchitecturesDocument4 pagesA Spec RG Cloud Group'S Vision On The Performance Challenges of Faas Cloud ArchitecturesHamza ShafiqNo ratings yet

- Serverless Computing: Current Trends and Open ProblemsDocument20 pagesServerless Computing: Current Trends and Open ProblemsHamza ShafiqNo ratings yet

- Figure M 39 Ethanol Water MixtureDocument6 pagesFigure M 39 Ethanol Water MixtureHamza ShafiqNo ratings yet

- Chui 2019 Growing Old As A Member of An EthniDocument9 pagesChui 2019 Growing Old As A Member of An EthniHamza ShafiqNo ratings yet

- Blast Furnace Slag - Technical ReportDocument30 pagesBlast Furnace Slag - Technical ReportHamza ShafiqNo ratings yet

- Ligand Field TheoryDocument15 pagesLigand Field TheorydhimanprasNo ratings yet

- Study of Different Types of Pipe FittingsDocument17 pagesStudy of Different Types of Pipe FittingsIzi50% (2)

- E BooksDocument3 pagesE BooksHamza ShafiqNo ratings yet

- CV & Cover Letter Writing Tips CEO UET TaxilaDocument3 pagesCV & Cover Letter Writing Tips CEO UET TaxilaHamza ShafiqNo ratings yet

- Roll # 24 Leather IndustryDocument13 pagesRoll # 24 Leather IndustryHamza ShafiqNo ratings yet

- Evaporator Triple EffectDocument14 pagesEvaporator Triple Effectcocote161No ratings yet

- Evaporator Triple EffectDocument14 pagesEvaporator Triple Effectcocote161No ratings yet

- Comparisons of Map and DapDocument56 pagesComparisons of Map and Daphamzashafiq1No ratings yet

- FluidizationDocument20 pagesFluidizationHamza ShafiqNo ratings yet

- Studies On The Production of Chrome Free Vegetable Tanned Glaze Finished Shoe Upper Leather From Cow Hide.Document73 pagesStudies On The Production of Chrome Free Vegetable Tanned Glaze Finished Shoe Upper Leather From Cow Hide.singsaran100% (5)

- Solved PrecisDocument6 pagesSolved PrecisYehyaKhanNo ratings yet

- Assignment of Calcium Ammonium Nitate Single Super PhosphateDocument17 pagesAssignment of Calcium Ammonium Nitate Single Super PhosphateHamza ShafiqNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pipe Flow AdditionalDocument11 pagesPipe Flow AdditionalKefene GurmessaNo ratings yet

- Efisiensi Boiler CalculatorDocument13 pagesEfisiensi Boiler CalculatorSyarifuddin DjauNo ratings yet

- Atos Exproof Valves 16-19-6-E120Document10 pagesAtos Exproof Valves 16-19-6-E120francis_15inNo ratings yet

- LNGC Norman Lady Imo 7320344 Cargo ManualDocument260 pagesLNGC Norman Lady Imo 7320344 Cargo Manualseawolf50No ratings yet

- PumpDocument82 pagesPumpkarthickNo ratings yet

- Instrumentation FOR P&ID'sDocument51 pagesInstrumentation FOR P&ID'sEvando Pereira dos SantosNo ratings yet

- Article 3 - Kalanit Pipeline System Air Slam Verification Study - Yiftach Rev 3Document15 pagesArticle 3 - Kalanit Pipeline System Air Slam Verification Study - Yiftach Rev 3anon_954581926No ratings yet

- Schedule of Grilles and Diffusers: Project: S.M.R.C DohaDocument4 pagesSchedule of Grilles and Diffusers: Project: S.M.R.C DohaSuchitKNo ratings yet

- As Built Drawing StatusDocument3 pagesAs Built Drawing StatuschennaimechNo ratings yet

- Control Valve Sourcebook Guide For Pulp and Paper Industry PDFDocument218 pagesControl Valve Sourcebook Guide For Pulp and Paper Industry PDFAmiroucheBenlakehalNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- Wellhead Plug Catcher (WPC)Document2 pagesWellhead Plug Catcher (WPC)Wade DavisNo ratings yet

- 1.0 Drainage System For Collection Pit For Spill Prevention: PipelinesDocument3 pages1.0 Drainage System For Collection Pit For Spill Prevention: PipelinesMonu SharmaNo ratings yet

- DJJ5123 Introduction of PneumaticDocument35 pagesDJJ5123 Introduction of PneumaticMigug SalamNo ratings yet

- Process Engineering Manual 005 IIDocument29 pagesProcess Engineering Manual 005 IIzoeNo ratings yet

- Fina Ponya-Model PDFDocument1 pageFina Ponya-Model PDFNursyarafina Binti SulaimanNo ratings yet

- Actuator-Hx Shut DownDocument6 pagesActuator-Hx Shut Downcoyarzun_12No ratings yet

- XPE2543 Rev GDocument2 pagesXPE2543 Rev Ggeofaxxxxxx100% (1)

- 11643Document16 pages11643dfvgdfvdfvdsvsfsdasdvNo ratings yet

- Mechanical Engineering Hydraulic Mechanics Important MCQ PDFDocument11 pagesMechanical Engineering Hydraulic Mechanics Important MCQ PDFGaneshNo ratings yet

- FORT VALE SuperMaxiReliefValve PDFDocument70 pagesFORT VALE SuperMaxiReliefValve PDFlorenzoNo ratings yet

- Specific Impulse: Overall PerformanceDocument4 pagesSpecific Impulse: Overall PerformanceRajeev GuptaNo ratings yet

- Rated Capacity, Gal/Min (Dm3 /min) Rated Net Head, Psi (Kpa) Approximate Power Required, HP (KW)Document2 pagesRated Capacity, Gal/Min (Dm3 /min) Rated Net Head, Psi (Kpa) Approximate Power Required, HP (KW)Mohamed KhaldiNo ratings yet

- O&M - Manual Index For ACBIL ProjectDocument10 pagesO&M - Manual Index For ACBIL ProjectMahendra Pratap SinghNo ratings yet

- CV H.Imran AliDocument3 pagesCV H.Imran Alimoj mastiNo ratings yet

- Task 5 - Refrigerator Valve PDFDocument3 pagesTask 5 - Refrigerator Valve PDFrivanmoehNo ratings yet

- Fluid Mechanics & Machinery LabDocument3 pagesFluid Mechanics & Machinery Labraghav dhamaniNo ratings yet

- Ring Joint Flanges For Use With Ring Joint Gaskets Per ASME B16.20 Shall Be Used ForDocument1 pageRing Joint Flanges For Use With Ring Joint Gaskets Per ASME B16.20 Shall Be Used ForRijwan MohammadNo ratings yet

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Document2 pagesNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'davidjsoulr0% (1)

- 1-D Mathematical Modeling and CFD Investigation On Supersonic Steam Ejector in MED-TVCDocument14 pages1-D Mathematical Modeling and CFD Investigation On Supersonic Steam Ejector in MED-TVCLucas RossiniNo ratings yet