Professional Documents

Culture Documents

Al Sol HT TB

Uploaded by

Atri Basu ThakurOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al Sol HT TB

Uploaded by

Atri Basu ThakurCopyright:

Available Formats

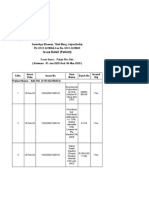

Technical Data

Aluminum Solution Heat Treatment

Alloys Some Aluminum Alloys are classified as heat treatable. Heat treatment is performed to change or improve mechanical properties. It should be noted that annealing can be performed on both types of alloys. When we speak of heat treatment we usually refer to Precipitation or Solution Heat Treatment. Briefly, the heat treatable alloys are generally Al / Cu alloys. Heat Treatment When Al / Cu alloys are heated above a certain temperature, the Cu in the alloy goes into what is known as Solid Solution. When held at this temperature long enough for the thickness of material all of the Cu will have gone into Solution. Hence Solution Heat Treatment. At this point the alloy is soft and malleable Left in this state the alloy will, over time, undergo a Precipitation of the solid solution, or Natural Aging. Some alloys do not need more than 4 to 5 days to attain most desirable properties. In many processes and alloys it is desirable and necessary to introduce a third heat treatment process in order to obtain a controlled Aging. Summary These are the processes in short form: 1. Solution Heat Treatment with these variables: a. Temperature b. Time c. Load temperature uniformity Quenching with these variables: a. Speed of transfer from furnace to quench tank b. Quenching media 1) Water 2) Polymers 3) Water / Polymer mixtures c. Quench media temperature d. Quench media temperature uniformity e. Quench media temperature rise during quench Aging with these variables: a. Temperature b. Time c. Load temperature uniformity

2.

3.

Equipment The most common types of batch processing equipment are:

Bottom Drop Furnaces that integrate solution heat treatment and quenching into one controllable operation.

Aging Ovens, which usually take the form of Walk-In, Circulation Type ovens.

Heat Treatment Specifications As most Aluminum or Magnesium products are used in Aerospace or Automotive applications which demand precise control of material properties, a number of Material Specifications have been developed. These specify the exact heat treatment procedures that have to be followed in order to attain desired material properties. Some examples are;

AMS 2750 Aerospace Material Specification Developed by Society of Automotive Engineers AMS 2770D Aerospace Material Specification Developed by SAE BAC 5602 Boeing Process Specification Developed by Boeing MIL-H-6088 Military Specification Developed by Naval Air Engineering Center

These specifications have many details in common and do provide a definitive guide for the capabilities of the heat treatment equipment and for the heat treatment programs to be followed for a great variety of alloys and material thicknesses and configurations. Final Notes This bulletin provides a very cursory introduction to the subject of heat treatments for Aluminum or Magnesium Alloys. For further information the reader is referred to the Specifications listed above and to the ASM Metals Handbook Volume 4 - Heat Treating.

KEITH COMPANY, 8323 Loch Lomond, Pico Rivera, CA 90660

800.545.4567 / 562.948.3636

www.KeithCompany.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- QM-I ManualDocument87 pagesQM-I ManualMuhammad Masoom AkhtarNo ratings yet

- Pub Breaking Out of Beginners SpanishDocument2 pagesPub Breaking Out of Beginners SpanishTuan TuanNo ratings yet

- Heating Catalogue 2019Document44 pagesHeating Catalogue 2019Zoran SimanicNo ratings yet

- t2 Chem Revision Ex 15 MSDocument29 pagest2 Chem Revision Ex 15 MSNicholas Ow100% (1)

- Influence of Test Equipment and Procedures On Obtained Accuracy in CPTUDocument26 pagesInfluence of Test Equipment and Procedures On Obtained Accuracy in CPTUalistuguiNo ratings yet

- Worm Gear Sets enDocument30 pagesWorm Gear Sets enDimas Dwi HNo ratings yet

- Arc 1st Mod Arch 503 Building Services Question Bank 15 Mark QuestionsDocument33 pagesArc 1st Mod Arch 503 Building Services Question Bank 15 Mark QuestionsVictor Deb RoyNo ratings yet

- 01.blood & Body Fluids 2011 MBBSDocument70 pages01.blood & Body Fluids 2011 MBBSS.m. Chandrashekar100% (1)

- ME 6301 Engineering Thermodynamics QB - BY Civildatas - Com 12 PDFDocument62 pagesME 6301 Engineering Thermodynamics QB - BY Civildatas - Com 12 PDFAjay JNo ratings yet

- Inert Corrosion-Free Structural Repair and Protection SystemDocument16 pagesInert Corrosion-Free Structural Repair and Protection SystemLempira TorresNo ratings yet

- Rak ObatDocument5 pagesRak Obatkhilwa alfaynaNo ratings yet

- Biological Molecules: Grade 9 BiologyDocument28 pagesBiological Molecules: Grade 9 BiologyHeyitsyasi xoxNo ratings yet

- Investigation of Mechanical Properties of Rice Straw Fiber Epoxy CompositeDocument8 pagesInvestigation of Mechanical Properties of Rice Straw Fiber Epoxy CompositeAnson DsouzaNo ratings yet

- Rheology and Hydraulics: Rheology Is The Science of Deformation and Flow of MatterDocument36 pagesRheology and Hydraulics: Rheology Is The Science of Deformation and Flow of Matterhassan haddadiNo ratings yet

- Chem Ass 3084357142010Document2 pagesChem Ass 3084357142010kidaneNo ratings yet

- Stock Per 17 Okt 20 HargaDocument13 pagesStock Per 17 Okt 20 HargaLutfi QamariNo ratings yet

- Specification Glycine Ansun 2022Document2 pagesSpecification Glycine Ansun 2022Matt RatcliffeNo ratings yet

- Beets Take Home AssignmentDocument5 pagesBeets Take Home Assignmentapi-487667605No ratings yet

- SCK SeriesDocument17 pagesSCK SeriestahirianNo ratings yet

- Ingles Ensayo Causa Efecto DesnutricxionDocument2 pagesIngles Ensayo Causa Efecto DesnutricxionBrayan Murphy Crespo EspinozaNo ratings yet

- Gardex Catalogue 2010Document35 pagesGardex Catalogue 2010dongheep811No ratings yet

- Diaphragm Liquid Pump NF 1.30: Operating and Installation InstructionsDocument20 pagesDiaphragm Liquid Pump NF 1.30: Operating and Installation InstructionsplastiresaNo ratings yet

- PChem Manual Ed 2023Document73 pagesPChem Manual Ed 2023rebecca niilonga fotolelaNo ratings yet

- AlkalinityDocument33 pagesAlkalinityAinunNo ratings yet

- Mndy ParchiDocument858 pagesMndy ParchiPAN SERVICESNo ratings yet

- Engineering ChemistryDocument60 pagesEngineering ChemistryAditya ShindeNo ratings yet

- Assignment 1 - Chapter 3 AnswerDocument9 pagesAssignment 1 - Chapter 3 AnswerHarryzam MartelNo ratings yet

- Sta Apple (Chrysophyllum Cainito L.) : E. M. Ya Ia An F. G Tierrez-Rozco A To o o Su Ivers y Queretaro, MexicDocument7 pagesSta Apple (Chrysophyllum Cainito L.) : E. M. Ya Ia An F. G Tierrez-Rozco A To o o Su Ivers y Queretaro, MexicHannah Mae SarzaNo ratings yet

- MSDS Alpha PineneDocument6 pagesMSDS Alpha PineneAbdul RajabNo ratings yet

- Psa Nitrogen GeneratorDocument7 pagesPsa Nitrogen GeneratorFarjallahNo ratings yet