Professional Documents

Culture Documents

PVEfea Assembly Analysis

Uploaded by

Anandh PsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVEfea Assembly Analysis

Uploaded by

Anandh PsCopyright:

Available Formats

PVEng

Design Conditions

Code: ASME VIII-1 Year: 2007 Addenda: 2009 MAWP: 1500 MEAWP: 0 Max. Temp.: 500 MDMT: -40 MDMT Press.: 1500 Min. Thk. (UG-16b): 0.0625 Corrosion Allowance: 0 Hydrotest: 2201 Impact Testing: None Impact Exemption: UHA-51(d) Radiography: None psi psi F F psi in in psi

Pressure Vessel Engineering Ltd.

ASME Calculations - CRN Assistance - Vessel Design - Finite Element Analysis

Finite Element Analysis Report - VIII-1

File: Desc: Dwg: Date: PVEfea-4472.0 Tri-Clamp FEA PVEdwg-4472.0 August 16, 2010

UG-22 Loadings Considered

Internal Press.: Yes External Press.: No Vessel Weight: No Weight of Attachments: No Attachment of Internals: No Attachment of Externals: No Cyclic or Dynamic Reactions: No Wind Loading: No Seismic Loading: No Fluid Impact Shock Reactions: No Temperature Gradients: No Differential Thermal Expansion: No Abnormal Pressures: No Hydrotest Loads: No

Author: Cameron Moore Reviewer: Laurence Brundrett

Conclusion: The Tri-Clamp meets VIII-2 design rules using VIII-1 allowable stresses and is acceptable.

www.pveng.com info@pveng.com Phone 519-880-9808

Pressure Vessel Engineering Ltd. 120 Randall Drive, Suite B Waterloo, Ontario, Canada, N2V 1C6

Table of Contents Description Cover Table of Contents Executive Summary Stress Limits Model Mesh Error Restraints Loads Bolt Loads Page 1 2 3 4 5 6 7 8 9 10 Description Reaction Area Reaction Forces Displacement Stress Clamp Stress Ferrule Stress Stress Linearization Bolt Stress Component Cycle Life

23-Aug-10

Page 2 of 20 Page 11 12 13 14 15 16 17 18 19

Rev 0 Release

Revision(s) Description

Date By 16-Aug-10 CBM

Executive Summary ver 4.00

Goal:

Page 3 of 20

The Tri-Clamp will be used under ASME VIII-1 service. This product cannot be calculated to code rules due to the complexity of its geometry. Instead the rules of ASME VIII-2 are used with ASME VIII-1 allowable stresses to determine its acceptability. Summary Conclusions: Materials Material strength properties used in this report are obtained from ASME IID, Table 1A, and are suitable for VIII-1 components. The rules of ASME VIII-2 are used to set the stress limits. Model Information The model used in the analysis represents 1/2 of the Tri-Clamp due to symmetry. A global mesh size of 0.09375" has been applied using 3D tetrahedral solid elements. The mesh size results in a reported error of less than 5%. Restraints & Loads A symmetry restraint is applied to compensate for the use of a 1/2 model. A single point on the clamp is fixed to prevent rigid body motion in all directions. Internal pressure is applied up to the pressure boundary and bolt loads simulated with a "bolt connector" feature. The resulting reaction forces closely match the theoretical reaction forces. The model is in balance and may be used for displacement and stress analysis. Results Through the FEA we found a 0.0009" maximum displacement as acceptable. A 22,817 psi peak stress results in an infinite cycle life. All general areas are within the allowable stress limits. Analysis Conclusion: The Tri-Clamp meets VIII-2 design rules using VIII-1 allowable stresses and is acceptable.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

Material Stress Limits ver 4.01 ASME VIII-2 Fig 5.1

Material Input Chart: 500 Temperature [F] Material 1 Material = SA-182 F316L Application = Clamps/Ferrules Sm [psi] = 14,800 Sy [psi] = 16,400 E1 = 1.0 E2 = 1.0 E [psi] = 25,900,000 v = 0.30 Coef [/F]= Cond [btu/hr-ft-F]= Pm [psi] = Pl [psi] = Pl+Pb [psi] = Pl+Pb+Q [psi] = Material = Application = Sm [psi] = Sy [psi] = E1 = E2 = E [psi] = v= Coef [/F]= Cond [btu/hr-ft-F]= Pm [psi] = Pl [psi] = Pl+Pb [psi] = Pl+Pb+Q [psi] = Comments Variable Descriptions: VIII-2 5.13 Sm (basic allowable) E1 (weld efficiency) E2 (casting efficiency) Cond (Thermal Conductivity) - IID Table TCD Stress Limit Equations: VIII-2 Figure 5.1 Pm = Pl = Pl+Pb = Pl+Pb+Q = Pl+Pb+Q+F = Comments:

(1) Sy material property is not required, more conservative Pl+Pb+Q limits might be computed without it. (2) The thermal expansion and conductivity coefficients are only required for studies including thermal stresses (3) Refer to VIII-2 5.15 Figure 5.1 and following for the Pm, Pl, Q and F stress limits (4) Refer to VIII-2 5.14 Table 5.6 for the correct application of the calculated stress limits (5) Use IID tables 5A and 5B for Sm for VIII-2 studies (6) Use IID tables 1A and 1B for Sm values (S) for VIII-1 studies (7) Use B31.1 Table A for Sm values for B31.1 studies (8) Use B31.3 Table A for Sm values for B31.3 studies

Page 4 of 20

Material 2 SA-403 316L Pipe Caps 14,800 16,400 1.0 1.0 25,900,000 0.30

Bolting 3 SA-193 B7 Bolts 25,000 88,500 1.0 1.0 27,400,000 0.30

Material 4

14,800 22,200 22,200 44,400 Material 5

14,800 22,200 22,200 44,400 Material 6

50,000 0 75,000 0 Material 7

Bolting 8

E (modulus of elasticity) - IID Table TM-1 v (Poison's ratio) - IID Table PRD Coef (coefficient of thermal expansion) - IID Table TE-1

E1*E2*Sm~~general primary membrane stress intensity limit 1.5*E1*E2*Sm~~local membrane stress intensity limit 1.5*E1*E2*Sm~~primary membrane + primary bending stress intensity limit Max(3*E1*E2*Sm,2*E1*E2*Sy)~~primary + secondary stress intensity Use fatigue curves~~peak stress intensity limit

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Model

Page 5 of 20

Fig-A An exploded view of the Tri-Clamp assembly. The clamp, ferrules and bolts will be analyzed in this report. Refer to drawing PVEdwg-4472.0 for details.

Fig-B Due to symmetry, a half model will be analyzed. Ferrules have been capped to simulate loads caused by a closed loop system. The nuts and bolts have been replaced by a "bolt connector" feature.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Mesh

Page 6 of 20

Fig-A A view of the mesh applied to the model. A global mesh size of 0.09375" is used with second order tetrahedral solid elements.

Fig-B A view of the mesh on the opposite side of the assembly. "No Penetration" contact sets are applied between the two clamp faces and the ferrule to clamp interaction. The caps are treated as bonded to the ferrules.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Error

Page 7 of 20

Fig-A A view of Error plot, capped at 5% error No general areas are observed in excess of 5% . Error results are acceptable, the mesh selected is appropriate.

Fig-B An alternative view of Fig-A.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Restraints

Page 8 of 20

Fig-A A view of the symmetry restraint applied. This condition restrains the sectioned faces to the "XY" plane wile permitting movement in the "X" & "Y" directions. This restraint compensates for the use of a half model and provides results identical to a full model.

Fig-B A close-up of Fig-A. A point is restrained from translation in the Y and X directions. The model is now restrained from rigid body motion in all directions.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Loads

Page 9 of 20

Fig-A 1,500 psi is applied to all internal faces up to the pressure boundary.

Fig-B A close-up of Fig-A.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Bolt Loads

Page 10 of 20

Fig-A Simulated bolt connectors are applied to the clamp. This simulates a bolt using beam elements rather than including the bolt in the model. An axial preload of 1,262 lb has been applied. Refer to the bolt results page for the preload calculation.

Fig-B A "No Penetration" contact set is applied. A friction factor of 0.7 for steel on steel is incorporated.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Reaction Area

Page 11 of 20

Fig-A The reaction normal to the XY plane is measured. This area is used to compute the reaction force acting in the Z-direction.

Fig-B The reaction area measured in the Z-direction is 6.977 sq. in. This area will be multiplied by the design pressure to determine the reaction force in the Z-direction.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53

Reaction Forces ver 4.08

Page 12 of 20

View showing Global Reaction Forces from analysis 'X' = -0.00158 lb, 'Y' = 0.0078 lb, 'Z' = 10467 lb Calculated Reaction Forces = Analysis Reaction Forces within 2% Model is balanced, results are valid. 1,500 P [psi] - Pressure X Axis: reaction forces on the YZ plane caused by loads in the X direction 0.000 0.0 -0.002 TReactionX [lbs] = XArea [in2] - Pressurized area on YZ plane XForce [lbs] - Added force in the X direction XReaction [lbs] - Reaction force in X direction reported by FEA program XArea*P+XForce ~~ Theoretical X reaction force 0*1500+0 = 0

Y Axis: reaction forces on the XZ plane caused by loads in the Y direction 0.000 0.0 0.008 TReactionY [lbs] = YArea [in2] - Pressurized area on XZ plane YForce [lbs] - Added force in the Y direction YReaction [lbs] - Reaction force in Y direction reported by FEA program YArea*P+YForce ~~ Theoretical Y reaction force 0*1500+0 = 0

Z Axis: reaction forces on the XY plane caused by loads in the Z direction 6.977 0.0 10467.000 TReactionZ [lbs] = ZArea [in2] - Pressurized area on XY plane ZForce [lbs] - Added force in the Z direction ZReaction [lbs] - Reaction force in Z direction reported by FEA program ZArea*P+ZForce ~~ Theoretical Z reaction force 6.977*1500+0 = 10,466

Resultant of reaction forces in X, Y and Z: TResultant [lbs] = sqrt(TReactionX^2+TReactionY^2+TReactionZ^2) ~~ Theoretical resultant SQRT(0^2+0^2+10466^2) = Resultant [lbs] = sqrt(XReaction^2+YReaction^2+ZReaction^2) ~~ Actual resultant SQRT(-0.002^2+0.008^2+10467^2) = Error [%] = 100*(TResultant-Resultant)/Resultant 100*(10466-10467)/10467 = CheckError = abs(Error)<2 ~~ Error should be less than 2% ABS(0)<2 =

10,466 10,467 0.0 Acceptable

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Displacement

Axial Elongation

Page 13 of 20

Radial Expansion

Fig-A A view of the displacement plot with superimposed original geometry. Results are magnified 500x. The ferrules elongate axially and displace radially outward. The clamps rotate about the center due to the pulling force of the ferrules.

Joint separation

Fig-B A alternate view of Fig-A. The maximum displacement is 0.0009". Note the clamp displacement in the bolt head region and joint separation begins to occur. The displacement direction is as expected and the magnitude is acceptable.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Stress

Page 14 of 20

Fig-A A view of the stress plot (von Mises) capped at the primary general membrane allowable of 14,800 psi.

Fig-B A sectioned view of Fig-A. `A peak stress of 22,817 psi is located on the clamp face in contact with the ferrule. This stress will be used to determine the cycle life of the design.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Stress

Page 15 of 20

Fig-A A view of the clamp only stress plot (von Mises) capped at the primary general membrane allowable of 14,800 psi.

Fig-B An "ISO Clipped" view of Fig-A capped at 14,800 psi. The only stresses in excess of 14,800 psi are in peak areas. A fatigue life will be based on the maximum peak stress.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Stress

Page 16 of 20

Fig-A A view of the ferrule only stress plot (von Mises) capped at the primary general membrane allowable of 14,800 psi.

Fig-B An "ISO Clipped" view of Fig-A capped at 14,800 psi. Stresses in the hub region in excess of 14,800 psi will be further analyzed through a stress linearization study on the following page.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

Stress Linearization ver 2.37

Stress Classification Line

Page 17 of 20

Fig-A The stress classification line is taken through the ferrule hub. The membrane stress is 2,692 psi and the membrane plus bending stress is 13,376 psi. These stresses are within the allowable limits and are acceptable.

25,000 20,000 15,000 10,000 Stress 5,000 0 -5,000 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 von Mises with all Components

Sn St Sh Tnt Tnh Tth von Mises Pm Pm+Pb

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

-10,000

-15,000 Distance i to j

Peak

Stress Check: General Stress Classification SA-182 F316L Material Allowed Actual Check Pm [psi] = 14,800 2,692 Acceptable Pb [psi] = 11,727 Pl+Pb [psi] = 22,200 13,376 Acceptable Peak [psi] = 17,123

4 nodes found on the stress classification line 0.1533 units long - cubic spline interpolated to 71 equally spaced nodes.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Bolt Stress ver 4.10

Tri Clamp Bolt Description Inputs:

Preload + Operating

Page 18 of 20

Load type UNC Bolt Type 1/4 Dia [in] Nominal Bolt Size (UNC) 25,000 Sm [psi] Allowable Bolt Stress File Location 0.189 0.438 0.028 45,000 90,000 1,262 PVELookup("BoltDia","Lookup","Root Dia",Dia) ~~ Root Diameter PVELookup("BoltDia","Lookup","AF",Dia) ~~ Head Diameter (*RDia^2)/4 ~~cross sectional area (3.142*0.189^2)/4 = 2*0.9*Sm ~~ bolt preload stress 2*0.9*25000 = 45000/(SQRT(Dia)) ~~bolt preload stress per App. S 45000/(SQRT(0)) = if(Spl2<(2*Sm),Spl2*A,Spl1*A) ~~bolt preload force used for fea IF(90000<(2*25000),90000*0.028,45000*0.028) =

Bolt Stresses - All Connectors

J:\4000-4999\4400-4499\4472 PVE Tri Clamp\bolt data.csv

RDia [in] = HDia [in] = A [in^2] = Spl1 [psi] = Spl2 [psi] = PL [lb] =

80000 70000 60000 Stress (psi)

50000

Pm Pm+Pb

Pm-Pb

40000 30000 20000 10000 0

Max Conn Sm 2 x Sm 3 x Sm

1 Connector 2

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

All connectors are below the allowables Type X Y Z SF (lb) 0.00 0.00 -0.09 AF (lb) 0.00 1293.90 4.87 BM (lb-in) -1.58 0.00 0.00 Shear Stress: Maximum Stressed Connector SSx [psi] = SFx/A SSy [psi] = SFy/A SSz [psi] = SFz/A Axial Stress: Maximum Stressed Connector SAx [psi] = AFx/A SAy [psi] = AFy/A SAz [psi] = AFz/A

Resultant Connector 0.09 Shear Force 1293.90 Axial Force 1.58 Counterbore with Nut-1 Bend Moment 0/0.028 = 0 0/0.028 = 0 -0.09/0.028 = -3 0/0.028 = 0 1293.9/0.028 = 46,120 4.87/0.028 = 174

Von Mises - Average Stress Across Bolt: Maximum Stressed Connector [psi] = SQRT(((SAx-SAy)^2+(SAy-SAz)^2+(SAz-SAx)^2+6*(SSx^2+SSy^2+SSz^2))/2) SQRT(((0-46120)^2+(46120-174)^2+(174-0)^2+6*(0^2+0^2+-3^2))/2) = 46,033 Check = <= 2*Sm ~~ ASME Section VIII-2 5.7.2(a) 46033<= 2*25000 = Acceptable Bending Stress: Maximum Stressed Connector M [lb-in] = 1.58 SB [psi] = M*(RDia/2)/((*(RDia/2)^4)/4) PmPb [psi] = Max(abs(+SB),abs(-SB)) = 2 2*(0.189/2)/((3.142*(0.189/2)^4)/4) = 2,381

MAX(ABS(46033+2381),ABS(46033-2381)) = 48414 CheckPmPb = PmPb<= 3*Sm ~~ ASME Section VIII-2 5.7.2(b) 48414<= 3*25000 = Acceptable

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Cycle Life ver 5.10

Page

19 of 20

Fig-A The 22,817 psi peak stress is used to determine the cycle life. An equivalent alternating stress of 12,465 psi is calculated which results in an infinite cycle life.

Stress Ranking

2.50E+04 2.00E+04 1.50E+04 1.00E+04 5.00E+03 0.00E+00 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Stress Differential

Rank

The above chart represents the top differential von Mises stresses. These stresses are determined according to the equations listed in ASMIE VIII-2 5.5.3.2. Stresses converging to infinity tend to lie at discontinuities and are not used for cycle life calculations.

9287 Node - first node of a consecutive set vlookup(nodeselect,stressresult,2,False) Spk [psi] = vlookup(nodeselect,stressresult,2,FALSE) = Not Linearized Stress result Table3.F.4CurveA Material coefficient table

22,817 .

Series 3xx High Alloy Steels, Ni-Cr-Fe Alloy, Ni-Fe-Cr Alloy, and Ni-Cu Alloy for temperatures not exceeding 800F Sa <= 28.2ksi, Curve A - Areas not heat, affected (Pl+Pb+Q) range <= 27.2ksi

Cycle Life ver 5.10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34

Page

20 of 20

Inputs: VIII-2, 5.5.3 1.00 Kf - fatigue strength reduction factor 14,800 Sa [psi] - material allowable 16,400 Sy [psi] - material yield strength 500 Tav [F] - average cycle temperature 25,900,000 Et [psi] - modulus of elasticity at Tav Alternating Equivalent Stress: VIII-2, 5.5.3.2 max(3*Sa,2*Sy) Sps [psi] = if(Spk<=Sps,1,"Linearize") Kek = if(Sn1k <= Sps, 1,"ERROR") Kek = (Kf*Kek*Spk)/2 Saltk = PVELookup("EgTable","Lookup","Eg","CL_Fig511022A") EG [psi] = Saltk*EG/Et Se [psi] = PVELookup("CL_Fig511022A","CycleLifeLookup",Se) Cycles =

MAX(3*14800,2*16400) = 44,400 1.00 1.00 (1*1*22817)/2 = 11,408 28,300,000 11408*28300000/25900000 = 12,465

100,000,000,000

Stress vs. Cycles

100,000

Stress

10,000 PVELookup("","CycleLifeLookup",Se)

1,000

1.0E+03

1.0E+10

1.0E+00

1.0E+01

1.0E+02

1.0E+04

1.0E+05

1.0E+06

1.0E+07

1.0E+08

1.0E+09

Cycles

1.0E+11

You might also like

- Post-Tension Flat Slab Design ExampleDocument17 pagesPost-Tension Flat Slab Design ExampleAwni Alkhteeb92% (12)

- Sample FEA ReportDocument13 pagesSample FEA ReportMario Tirabassi100% (1)

- Stainless Comparator PDFDocument14 pagesStainless Comparator PDFHarshal BendaleNo ratings yet

- Hechmer 1991Document7 pagesHechmer 1991rahulNo ratings yet

- In Elastic Buckling of Geometrically Imperfect TubesDocument16 pagesIn Elastic Buckling of Geometrically Imperfect TubesSiva RajNo ratings yet

- 861 Physics - Isc SpecimenDocument17 pages861 Physics - Isc SpecimenadityaNo ratings yet

- Physics Chapt 19Document84 pagesPhysics Chapt 19catlinmwagner0% (1)

- ELEC 103: Week 3 - PressureDocument52 pagesELEC 103: Week 3 - PressurebharathaninNo ratings yet

- Method For Finding Stress in Cylinders With Radial NozzlesDocument10 pagesMethod For Finding Stress in Cylinders With Radial NozzlesmatodelanusNo ratings yet

- Thermal Ratcheting of A BeamDocument33 pagesThermal Ratcheting of A Beammilan44No ratings yet

- Stress Classification ASME DIV2 Sec5 V1Document13 pagesStress Classification ASME DIV2 Sec5 V1pajadhavNo ratings yet

- Stress Classification TechniqueDocument12 pagesStress Classification TechniqueAndrew FerrierNo ratings yet

- What Is Stress LinearizationDocument9 pagesWhat Is Stress LinearizationamlanfacebookNo ratings yet

- Hot Box Design PDFDocument8 pagesHot Box Design PDFAbu Anas M.SalaheldinNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonNo ratings yet

- Introduction To WRC 107 Concepts Limitations and FormulaDocument5 pagesIntroduction To WRC 107 Concepts Limitations and FormulamoryNo ratings yet

- Ligament Pressure Vessel AnalysisDocument8 pagesLigament Pressure Vessel AnalysisAnnie HillNo ratings yet

- Visual Vessel Design FAQDocument23 pagesVisual Vessel Design FAQsierthinNo ratings yet

- Effects of Thermal LoadsDocument12 pagesEffects of Thermal LoadshamadaniNo ratings yet

- Astm A 29 (1030)Document10 pagesAstm A 29 (1030)Rizki FebriyantoNo ratings yet

- ANSYS Stress LinearizationDocument15 pagesANSYS Stress LinearizationTiago CandeiasNo ratings yet

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDocument12 pages2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuNo ratings yet

- A Plastic Load Criterion For Inelastic Design by AnalysisDocument7 pagesA Plastic Load Criterion For Inelastic Design by AnalysisdogusNo ratings yet

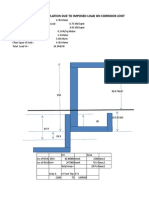

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitNo ratings yet

- Eq Base Shear CalculationsDocument9 pagesEq Base Shear Calculationsirshad313No ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Nonlinear Total Strain Vs Linear Strai1Document32 pagesNonlinear Total Strain Vs Linear Strai1Dasaka BrahmendraNo ratings yet

- Ansys Lug and Pin Stress AnalysesDocument30 pagesAnsys Lug and Pin Stress AnalysesAmm WillulNo ratings yet

- MESYS Shaft CalculationDocument28 pagesMESYS Shaft CalculationZoebairNo ratings yet

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackNo ratings yet

- Stress Fatigue PrinciplesDocument12 pagesStress Fatigue Principlesjinny1_0No ratings yet

- Aisi O1: Cold Work Tool SteelDocument7 pagesAisi O1: Cold Work Tool Steeltewiinaba777No ratings yet

- Wind LoadDocument45 pagesWind LoadglaydelleNo ratings yet

- Autofrettage in Pressure VesselsDocument28 pagesAutofrettage in Pressure Vesselssran1986No ratings yet

- FEA Tutorial by MITDocument28 pagesFEA Tutorial by MITSamson RaphaelNo ratings yet

- Plate Analysis: Floor and Deck SlabsDocument20 pagesPlate Analysis: Floor and Deck SlabsDobromir DinevNo ratings yet

- Proposed Design Criterion For Vessel Lifting Lugs in Lieu of ASME B30.20Document8 pagesProposed Design Criterion For Vessel Lifting Lugs in Lieu of ASME B30.20cpchonburi0% (1)

- Subroutine For Cohesive ElementDocument41 pagesSubroutine For Cohesive ElementBhushanRaj100% (1)

- PV Enineering EHX - OutDocument144 pagesPV Enineering EHX - OutRAHUL KAVAR100% (1)

- Coke Drum Skirt ExampleDocument10 pagesCoke Drum Skirt Example2009tamerNo ratings yet

- Stress Concentration Factor - An Overview - ScienceDirect Topics PDFDocument20 pagesStress Concentration Factor - An Overview - ScienceDirect Topics PDFbhaskarrajusa8034No ratings yet

- ANSYS Workbench Report-TransientDocument13 pagesANSYS Workbench Report-TransientSathya GajjalaNo ratings yet

- Linearizing StressDocument6 pagesLinearizing Stressbo cambellNo ratings yet

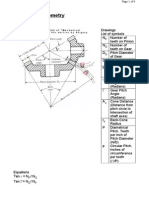

- Bevel GearDocument17 pagesBevel Gearparesh09No ratings yet

- Bevel ExplanationDocument4 pagesBevel ExplanationVarun VaidyaNo ratings yet

- BradleyDocument247 pagesBradleythomas duncan eelesNo ratings yet

- Simply Supported Rectangular PlateDocument17 pagesSimply Supported Rectangular PlateJoshua MagatNo ratings yet

- Welding Neck Flanges 1Document3 pagesWelding Neck Flanges 1bikkelbobNo ratings yet

- Free Span Oscillation Due ToDocument43 pagesFree Span Oscillation Due TotarekeeeNo ratings yet

- 6177-4 Hertz Contact StressesDocument10 pages6177-4 Hertz Contact StressesVictor GearNo ratings yet

- Pages From Hyundai Welding Handbook (2006)Document1 pagePages From Hyundai Welding Handbook (2006)tuatkNo ratings yet

- FatigueLife FEA PDFDocument43 pagesFatigueLife FEA PDFAbigail SommersetNo ratings yet

- Pveng: Pressure Vessel Engineering LTDDocument11 pagesPveng: Pressure Vessel Engineering LTDSivateja NallamothuNo ratings yet

- FEA Mesh Convergence and Singularity in Connecting LugDocument11 pagesFEA Mesh Convergence and Singularity in Connecting LugDarshanPatel100% (1)

- Analisis Fea Tanque Redondo Asme Viii - 1Document74 pagesAnalisis Fea Tanque Redondo Asme Viii - 1Calo AlcaloNo ratings yet

- 3 Analysis and Design of Deck SlabDocument14 pages3 Analysis and Design of Deck SlabAshish BhoiNo ratings yet

- CE 3100: Structural Engineering Lab: February 4Document12 pagesCE 3100: Structural Engineering Lab: February 4Sarankumar ThathuruNo ratings yet

- AISC 360-05 Example 002Document6 pagesAISC 360-05 Example 002Anitha Hassan Kabeer100% (1)

- APPENDjnklhIXW3 25 09Document9 pagesAPPENDjnklhIXW3 25 09Marimuthu AyyamperumalNo ratings yet

- Pressure Vessel Engineering LTD.: Finite Element Analysis Report - VIII-2Document23 pagesPressure Vessel Engineering LTD.: Finite Element Analysis Report - VIII-2rahulNo ratings yet

- Design of Crane Runway Beam With ChannelDocument9 pagesDesign of Crane Runway Beam With Channellatyrniang100% (3)

- Vessels PDFDocument2 pagesVessels PDFAnandh PsNo ratings yet

- Vaas CorrectionsDocument1 pageVaas CorrectionsAnandh PsNo ratings yet

- Show All Types of Ferrous MetalsDocument3 pagesShow All Types of Ferrous MetalsAnandh PsNo ratings yet

- Diff BWT Is 800 101Document96 pagesDiff BWT Is 800 101tops123No ratings yet

- Crane Design Basics: Beam CalculatorDocument13 pagesCrane Design Basics: Beam CalculatorAnandh PsNo ratings yet

- 05 Edge Welded BellowsDocument13 pages05 Edge Welded BellowsAbhishek BasakNo ratings yet

- 05 Edge Welded BellowsDocument13 pages05 Edge Welded BellowsAbhishek BasakNo ratings yet

- Bolts CatalogueDocument88 pagesBolts CatalogueAnandh PsNo ratings yet

- The Second Law of Thermodynamics: Conceptual ProblemsDocument84 pagesThe Second Law of Thermodynamics: Conceptual ProblemskolihaaaNo ratings yet

- Elasticity Applications 04 Beam TheoryDocument28 pagesElasticity Applications 04 Beam Theoryqaiserkhan001No ratings yet

- Metal Cutting QnsDocument8 pagesMetal Cutting QnsAsha DashNo ratings yet

- Dynamic Analysis of 3-3 Stewart PlatformDocument16 pagesDynamic Analysis of 3-3 Stewart PlatformehsanNo ratings yet

- FundamentalsofPhysics PDFDocument233 pagesFundamentalsofPhysics PDFMamdoh Al-QuthamiNo ratings yet

- Fulltext PDFDocument17 pagesFulltext PDFEl Youbi MohammedNo ratings yet

- ch25 PDFDocument11 pagesch25 PDFTomNo ratings yet

- Frisbee PhysicsDocument4 pagesFrisbee Physicsharsh100% (1)

- DIPPRDocument8 pagesDIPPROmar AlmonteNo ratings yet

- محاضرة نبتل بتاع الهيدروليك سيستم6Document8 pagesمحاضرة نبتل بتاع الهيدروليك سيستم6قطائف العواطفNo ratings yet

- Magnetic Field of A Moving ChargeDocument10 pagesMagnetic Field of A Moving ChargeGeeleegoatNo ratings yet

- Stress Distribution Around HolesDocument1,008 pagesStress Distribution Around HolesffontanaNo ratings yet

- Inbound 7181713037772966188Document15 pagesInbound 7181713037772966188keepersilent2No ratings yet

- Ideal Solution and Excess functions-Ch11-IVDocument32 pagesIdeal Solution and Excess functions-Ch11-IVmominhadiNo ratings yet

- IB PhysicsDocument8 pagesIB PhysicsAnthony Mercado LeonardoNo ratings yet

- Introduction To Boundary LayerDocument14 pagesIntroduction To Boundary LayerAyman KeirNo ratings yet

- Experimental Study On Failure Modes and Retrofitting Method of Latticed Transmission TowerDocument14 pagesExperimental Study On Failure Modes and Retrofitting Method of Latticed Transmission TowerMuhammad Irfan ButtNo ratings yet

- Confined Concrete Models PDFDocument4 pagesConfined Concrete Models PDFTushar SawaseNo ratings yet

- Science Reviewer 4TH QRTR Grade 9Document7 pagesScience Reviewer 4TH QRTR Grade 9Alex LovesmangoesNo ratings yet

- PE-209 Lecture-01Document34 pagesPE-209 Lecture-01Adeem AbbasNo ratings yet

- Case Method and The Pda PDFDocument73 pagesCase Method and The Pda PDFStephanie HaynesNo ratings yet

- Bubble Column ReactorsDocument22 pagesBubble Column Reactorslakshmivarthan83% (6)

- Single Phase Liquid Flow - Water Hammer and Surge Pressure Design GuideDocument11 pagesSingle Phase Liquid Flow - Water Hammer and Surge Pressure Design GuideCivil FriendNo ratings yet

- Semi-Detailed Lesson Plan in Physics Force, Motion and EnergyDocument16 pagesSemi-Detailed Lesson Plan in Physics Force, Motion and EnergyAly SobosoboNo ratings yet

- Wall Footing: Code ReferencesDocument4 pagesWall Footing: Code ReferencesSupun Aravinda JayawardhaneNo ratings yet

- EOCQ - Ans - 17 2Document1 pageEOCQ - Ans - 17 2Куаныш ЖанадилNo ratings yet

- M13 - L17 Grit ChamberDocument6 pagesM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)