Professional Documents

Culture Documents

3600 1

Uploaded by

shanmugasundaram_rOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3600 1

Uploaded by

shanmugasundaram_rCopyright:

Available Formats

UDC 621~791*6S~OS3~2 :689*14: S2O-l't2

Ct

First Reprint JUNE 1994)

IS:36OO(Partl)-1986

( Reaffirmed 1997 )

Indian Standard

METHOD OF TESTING FUSI0.N WELDED JOINTS AND WELD METAL IN STEEL

PART 1 CRUCIFORM FILLET WELD TENSILE TEST ( Second RwCslan )

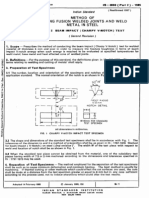

1. scope - Covers the procedure for carrying out the cruciform test to determine the reietive tensile strength under static loading of joints employing fillet welds between plates. This test should be preferably be supplemented by the use of macro examination of cross-sections of the joints covered in 1s : 3600 ( Part 9 ) - 1989 :Method of testing fusion welded joints and weld metal in steel: Part 9 iM acre and Micro examination. 2. Definitions - For the purpose of this srandard, the definitions of terms relating to welding and cutting of metals shall apply. given in IS : 812-1957 Gi6Bsery

- The test piece shall be made from plate of 3. Preparatian of Test Piooo and Test Specimens full thickness. The test piece and test specimens shall be prepared .according to the shape and dimensions given in Fig. 1. The plate thickness, fillet leg length, welding procedure, penetration, etc, however, shall be as specified in the appropriate appliCation standard. The length of the ~specimens shall be chosen as to suit the particular testing machine.

CENTRE LINES OF VERTICAL PLATtS SHALL BE IN THE SAME PLANE

o;I?Et~ll~A~ f

ACK WELDS

LENGTH TO SUIT TESTING MACHINE

1A All dimensions in millimetres.

1B

1A Test Piece and Method of Cutting Test Specimens 18 Method of Testing Specimens FIG. 1 CRUCIFORM TEST PIECE, SPECIMENS AND METHOD OF TESTING

4. Separation of Test Specimens - The method employed for the separation of the test specimens shall be such as to cause minimum deformation and min.imum heating. The best method is usually by machining. if thermal cutting or other method which could effect the cut surfaces are used, the ~ cuts shall be made at a distance from the test specimens greater or equal to 8 mm but in any case ~sufficient according to the process used, not to induce alterations which could alter the test results. 5. Heat Treatment - Test specimens shall be heat-treated only if the welded part they represent ii 1 heat-treated, in which case they shall, where possible, be heat-treated together with the welded part ~before the test. Where this is not possible, the specimens shall be heat-treated separately, the ~treatment and the rate of cooling being similar to that given to the part. ~6. Testing - The specimens shall be tested in tension with the load applied in the direction indicated in Fig. 1. Care shall be taken that the centre lines of the vertical plates are in the same plane. The inner edges of the outer discards should be prepared for macro examination.

Adopted

14 February 1985

I .. __.-- ---.

BUREAU MANAK OF BHAVAN,

0 May 1986. BIS

INDIAN g BAHADUR STANDARDS

Gr 1 I

SHAH ZAFAR MARG

NEW DELHI 110002

IS : 3600 ( Part 1 ) - 1985 7, Reporting of Results The following shall be reported as results of the test:

a) Thickness of parent metal; b) Throat thickness and leg length of weld; c) Location of the fracture, whether in the weld, in the heat-affected zone or in the parent metal. If the fracture is in the parent metal its appropriate distance from the weld junction shall be stated; and d) Description of the appearance of surfaces subjected to macro examination location of any weld flaws present. and the type and

EXPLANATORY

NOTE

This standard was first published in 1966 and subsequently revised in 1973 covering various tests on fusion welded joints and weld metal in steel. In view of the experience gained and in order to bring the test and test requirements in line with other International Standards published so for, it has been decided to revise the standard in the following parts: Part 1 Cruciform fillet weld tensile test Part 2 Beam impact ( Charpy V-notch ) test Part 3 Transverse tensile test on butt welds Part 4 Longitudinal tensile test on cylindrical weld metal test pieces on butt welds Part 5 Transverse root and face bend test on butt welds ( corresponding to IS0 5173-l Part 6 Transverse side bend test on butt weld ( corresponding Part 7 Longitudinal root and face bend test on butt welds Part 8 Nick break test and fillet weld fracture test Part 9 Macro and micro examination. In this revision free-bend test has been deleted as the ductility of the weld zone is being assessed more and more by other bend tests. Special tests such as tests for the susceptibility to lamellar tearing, reheat cracking, brittle fracture and creep fatigue will be covered in separate standards. The main purpose of this standard is to recommend test should be quoted or incorporated in engineering application tructions primarily for the qualification of welding procedures exist between application standards, the methods of test given procedures and test specimens that standards that deal with welded consand operators. Where differences still in this standard should be prefered. to IS0 5177-1981 ) 981 )

A general indication is given of the purpose served by the tests specified in this standard but this standard does not indicate the choice of test method nor a particular application nor the number of specimens to be tested or the repeat tests to be allowed in the event of failure. Such requirements are matters to be dealt with in the particular application standards where they exist or to be agreed between the manufacturer and the purchaser. It should be realized that variations in welding can give rise to variations in the test results. procedure and the preparation of test specimens

In preparing this part of the standard assistance has been derived from, BS : 709-l 983 Destructive testing fusion welded joints and weld metal in steel issued by British Standards Institution. In reporting the result of a tust on analysis made in acccordance with this standard, if the final value, observed or calculated, is to be rounded off, it shall be done in accordance with IS : 2-1960 Rules for rounding off numerical values ( revised ).

2

Reprog-.mhy Unit, BIS, New Delhi, India

You might also like

- ME355 NotesDocument147 pagesME355 NotesrogerfisicaNo ratings yet

- PT Outline Training LV IIIDocument2 pagesPT Outline Training LV IIITrung Tinh HoNo ratings yet

- Chapter 3 - Global Analysis EquationsDocument54 pagesChapter 3 - Global Analysis EquationsCarl Chester RagudoNo ratings yet

- Acoustics DissertationDocument63 pagesAcoustics DissertationNafish Alam33% (3)

- Calibrating Pressure GaugesDocument4 pagesCalibrating Pressure GaugesRonny AndalasNo ratings yet

- Ultrasonic Phased Array ApplicationsDocument26 pagesUltrasonic Phased Array ApplicationsLương Hồ VũNo ratings yet

- Specific Criteria For Non-Destructive Testing LaboratoriesDocument25 pagesSpecific Criteria For Non-Destructive Testing LaboratoriesKishore Nayak kNo ratings yet

- WPS at FormateDocument134 pagesWPS at FormateMohammad Rizwan100% (1)

- E428Document6 pagesE428valentinNo ratings yet

- Ruukki Hot Rolled Steels Ultrasonic Testing 2011 PDFDocument5 pagesRuukki Hot Rolled Steels Ultrasonic Testing 2011 PDFpvdang8453No ratings yet

- EN8 MaterialDocument2 pagesEN8 MaterialSwaran SinghNo ratings yet

- ASNTDocument5 pagesASNTshifaNo ratings yet

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- Process Specification For Ultrasonic Inspection of Welds PDFDocument14 pagesProcess Specification For Ultrasonic Inspection of Welds PDFFernandoi100% (1)

- Ultrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsDocument10 pagesUltrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsPetrNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- Hashemite University - NDT Overview PDFDocument7 pagesHashemite University - NDT Overview PDFgeorgescribd1103No ratings yet

- Sievert India Pvt. LTD.: Question PaperDocument10 pagesSievert India Pvt. LTD.: Question PaperPrabhuNo ratings yet

- Method of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardDocument5 pagesMethod of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardRicardo F.A.No ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- As 1817.3-2002 Metallic Materials - Vickers Hardness Test Calibration of Reference BlocksDocument4 pagesAs 1817.3-2002 Metallic Materials - Vickers Hardness Test Calibration of Reference BlocksSAI Global - APACNo ratings yet

- Selenium 75Document0 pagesSelenium 75vrapciudorianNo ratings yet

- Acs 03 UsfdDocument7 pagesAcs 03 UsfdPRAVIN DASSNo ratings yet

- Iso 17640-2010-UtDocument1 pageIso 17640-2010-Utsdmkl85No ratings yet

- Brinell Hardness of Metallic Materials: Standard Test Method ForDocument32 pagesBrinell Hardness of Metallic Materials: Standard Test Method ForJeffersonCruzNo ratings yet

- VT & PT - NotesDocument10 pagesVT & PT - Notessanjeev sahota100% (1)

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- Partial List of ISO SpecificationsDocument4 pagesPartial List of ISO Specificationsskynyrd75No ratings yet

- SB 548Document5 pagesSB 548Edson Julio S RNo ratings yet

- Visual InspectionDocument4 pagesVisual InspectiondomsonengNo ratings yet

- RT Standards NotesDocument4 pagesRT Standards NotesprabhuNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Liquid Penetrant InspectionDocument83 pagesLiquid Penetrant InspectionAzhar GulzarNo ratings yet

- G S Earth WireDocument10 pagesG S Earth WiresaratNo ratings yet

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 pagesLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANo ratings yet

- PipingDocument8 pagesPipingRajkumar ANo ratings yet

- Ultrasonic Testing - Wikipedia PDFDocument26 pagesUltrasonic Testing - Wikipedia PDFKarthicWaitingNo ratings yet

- Selection of Leak Testing Method PDFDocument3 pagesSelection of Leak Testing Method PDFdcsamaraweeraNo ratings yet

- Welder and Welding Operator Performance Qualification RecordDocument1 pageWelder and Welding Operator Performance Qualification RecordAsif HameedNo ratings yet

- 6082 T6 Aluminum Plate SuppliersDocument9 pages6082 T6 Aluminum Plate Supplierssanghvi overseas incNo ratings yet

- Norsok M101 Structural Steel FabricationDocument67 pagesNorsok M101 Structural Steel FabricationbreeeeezzzzzeNo ratings yet

- Casting Definitions and TerminologyDocument15 pagesCasting Definitions and TerminologyCharlie ChongNo ratings yet

- Visual TestingDocument1 pageVisual TestingAnonymous GE8mQqxNo ratings yet

- 6.4 - NDT-Magnetic Particle ExaminationDocument38 pages6.4 - NDT-Magnetic Particle ExaminationKatsaras SotirisNo ratings yet

- Introduction To UT Flaw DetectorDocument26 pagesIntroduction To UT Flaw DetectorNail Widya Satya100% (1)

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Aws D 1Document15 pagesAws D 1WagnerTarossiNo ratings yet

- SSIS Visual Examination Report FormatDocument1 pageSSIS Visual Examination Report FormatSalman KhanNo ratings yet

- Vacuum Box Test Procedure: PurposeDocument4 pagesVacuum Box Test Procedure: Purposesaravan1891No ratings yet

- Phased Array Practical ExamDocument2 pagesPhased Array Practical ExamMarcus AntoniusNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- ANSWER: Dye Penetrant Test Explanation:: No Explanation Is Available For This Question!Document4 pagesANSWER: Dye Penetrant Test Explanation:: No Explanation Is Available For This Question!shyamkumar rakoti0% (1)

- As 2168.2-2009 Non-Destructive Testing - Computerized Radiography Testing of Metallic Materials Using X-RaysDocument7 pagesAs 2168.2-2009 Non-Destructive Testing - Computerized Radiography Testing of Metallic Materials Using X-RaysSAI Global - APACNo ratings yet

- 28b. IS 3600 - 2 - 1985 PDFDocument2 pages28b. IS 3600 - 2 - 1985 PDFhhr2412No ratings yet

- BSI 709 DT Fusion WeldedDocument24 pagesBSI 709 DT Fusion WeldedbonnicoNo ratings yet

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- Astm D 897 - 01 - RDG5NWDocument3 pagesAstm D 897 - 01 - RDG5NWphaindikaNo ratings yet

- BS 709Document17 pagesBS 709vuthuy94No ratings yet

- Is 3600Document5 pagesIs 3600marceloscarpariNo ratings yet

- b 557m - 02 عينة الشد المستطيلةDocument19 pagesb 557m - 02 عينة الشد المستطيلةMohamad Marwan HamwiNo ratings yet

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- Normal Modes of Vibration: One-Dimensional Model # 1Document51 pagesNormal Modes of Vibration: One-Dimensional Model # 1Edgar PuenteNo ratings yet

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarNo ratings yet

- Mechanics of Solids (CIE 1051) (Makeup)Document5 pagesMechanics of Solids (CIE 1051) (Makeup)Alok KumarNo ratings yet

- Flow Around A CylinderDocument17 pagesFlow Around A CylinderMatheus PauloNo ratings yet

- Mining Engineering SyllabusDocument8 pagesMining Engineering SyllabusRaju P SundaramNo ratings yet

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument13 pagesAluminium Alloy - Wikipedia, The Free EncyclopediajishnuNo ratings yet

- EM Paper 1Document1,156 pagesEM Paper 1sCience 123No ratings yet

- Calculation of Added Mass in The Proximity of The Seabed For An Oscillating DiscDocument64 pagesCalculation of Added Mass in The Proximity of The Seabed For An Oscillating DiscTNTNo ratings yet

- P-Y Curves For Group PilesDocument5 pagesP-Y Curves For Group PilessatyaNo ratings yet

- Instruction Manual: DS-2000 Series Reflecting and Refracting TelescopesDocument44 pagesInstruction Manual: DS-2000 Series Reflecting and Refracting TelescopesBrandon BohannonNo ratings yet

- Orifice Plate Flow Meter Data SheetDocument4 pagesOrifice Plate Flow Meter Data SheetTaimoor KhanNo ratings yet

- Refrigeration DryersDocument89 pagesRefrigeration DryersJairoQuirozGomezNo ratings yet

- CFD Study Heat PipeDocument8 pagesCFD Study Heat PipeSalman Chowdhury ShawonNo ratings yet

- Sgsits ManualDocument91 pagesSgsits ManualJoyita BiswasNo ratings yet

- Hasselblad 503cwDocument6 pagesHasselblad 503cweternal_harpyNo ratings yet

- Hopf Cole BrownDocument21 pagesHopf Cole BrownRoberticoZeaNo ratings yet

- Design and Analysis of Disc Brake System in High Speed VehiclesDocument9 pagesDesign and Analysis of Disc Brake System in High Speed Vehiclessavio pullkotilNo ratings yet

- Lecture 14Document14 pagesLecture 14Adam SurtiNo ratings yet

- Analysis of Axial Flow FansDocument7 pagesAnalysis of Axial Flow FanshonghieutrNo ratings yet

- Casting Process and Different Types of CastingsDocument31 pagesCasting Process and Different Types of CastingsTejas KumarNo ratings yet

- The Electric Potential: - The Potential Energy Per Unit Charge, U/q, Is The Electric Potential The Electric PotentialDocument29 pagesThe Electric Potential: - The Potential Energy Per Unit Charge, U/q, Is The Electric Potential The Electric PotentialMurtaza LokhandwalaNo ratings yet

- Vertical Turbine PumpsDocument18 pagesVertical Turbine PumpsazkNo ratings yet

- Footway Slurry Sealing Explanation, Bitumen Emulsion and Aggregate Chippings, Cost Effective Preventative Maintenance PDFDocument7 pagesFootway Slurry Sealing Explanation, Bitumen Emulsion and Aggregate Chippings, Cost Effective Preventative Maintenance PDFErick ChaitezviNo ratings yet

- The SunDocument503 pagesThe SunMichelle Miller100% (1)

- Module 7 - Complex and ERD Well PlanningDocument36 pagesModule 7 - Complex and ERD Well Planningchristianleal123No ratings yet

- Transverse and LongitudinalWavesDocument8 pagesTransverse and LongitudinalWavesDebasish TNo ratings yet

- Dry Gas Versus Wet Gas Compressor SealsDocument5 pagesDry Gas Versus Wet Gas Compressor Sealsasimozma100% (1)