Professional Documents

Culture Documents

Horizontal Tie-In Systems - Low

Uploaded by

David tangkelangiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horizontal Tie-In Systems - Low

Uploaded by

David tangkelangiCopyright:

Available Formats

Horizontal Tie-in Systems

Horizontal Tie-In Systems

Horizontal Tie-in may be used for both first-end and second end tie-in of both flowlines, umbilicals and Jumper spools. The Termination Head on the line may be hauled in to the Tie-in point by use of a subsea winch, or parked on the subsea structure. Horizontal Tie-in may be made up by Clamp Connectors operated from a Tiein tool, by integrated hydraulic connectors operated through the ROV, or by non-hydraulic collet connectors with assistance from a Connector Actuation Tool ( CAT ) and ROV. Horizontal connections leave the flowline/ umbilical in a straight line, and is easy to protect if overtrawling from fishermen should occur. FMC Technologies has developed a range of Tie-in tools and methods to make any Horizontal Tie-in effective.

FMC Horizontal Connection Systems

FMC has developed Horizontal Tie-in Systems to handle anything from small fragile Subsea Umbilicals, to large 30 Export lines. Each Tie-in system has unique features to fulfill the clients specific needs. Either the lines Termination Head is directly parked in a position on the subsea structure ready for connection, or The pullin function is based on a subsea winch mounted on the Tie-in tool. By use of Horizontal Tie-in systems, the Tie-in Tool does not need to be retrieved to surface in between each connection operation. Consequently, the Tie-in tool may perform a series of tie-ins of pre-layed lines, jumpers or spools in one single subsea campain. This makes Horizontal tie-in a very efficient solution when several lines shall be connected continuously.

FMC Tie-in Experience

As development of Subsea fields reach the depth limit for diver operation, diverless Tie-in systems become an issue. FMC designed and operated the first diverless Tie-in & Connection system ever on the Gullfaks field for Statoil in the North Sea in 1986. Since then, many new innovative Tie-in solutions for deep and ultra-deep waters have passed through our work-shop to satisfy clients world-wide. FMC have now a family of Tie-in & Connection systems, all based on standard interfaces. These reach from the smallest hydraulic Flying Leads, to large bore Export lines in both Vertical and Horizontal, and Monobore or Multibore configurations.

Size & configuration table

Tie-in SySTem

ROVCON MK2 ROVCON MK1

Life of Field Service

mulTi-Bore Bore Hydr. Size lineS

10 + 3 6 + 2 6 + 2 14 14 14

HorizonTal HydrauliC/ Single Bore ColleT meCHaniCal max nom. max ConneCTor operaTion pipe Size Bore-Size

KC4 KC4 Mechanical Mechanical Mechanical 18 12 12 3/4 16 10 11

inSTallaTion Tool requiremenTS

Rovcon Mk2 + ROV Rovcon Mk1 + ROV Stabcon Mk1 + ROV

STABCON MK1 KC4

Tie-in SySTem

UTIS

HorizonTal HydrauliC/ Single Bore Clamp meCHaniCal max nom. max ConneCTor operaTion pipe Size Bore-Size

Mechanical Mechanical 30 14 27 12 KL3 2

mulTi-Bore Bore

Size

Hydr. lineS

9

inSTallaTion Tool requiremenTS

CAT + ROV CAT + ROV

Installation of advanced Subsea systems require skilled offshore personnel and high quality equipment. Testing of equipment and training of personnel onshore is vital to success in this offshore operation. FMC has developed a Subsea School for training of Clients representatives alongside training of own service personnel. The good chemistry developed during this training period has resulted in a unique track record of successful offshore operations. The Customer Support headquarter in Bergen is the single point of contact for all service expertise, personnel, systems and tools needed for installation and life-of-field management and support. We provide service and strategic life of field planning and solutions designed to deliver immediate and long-term satisfaction to operators worldwide.

STABCON MK2 KL4

22 + 2 + 2 + 2

Tie-in SySTem

FLYCON

HorizonTal HydrauliC/ mulTi quiCk meCHaniCal ConneCTor operaTion

MQC Mechanical

Hydr. lineS

13

inSTallaTion Tool requiremenTS

Torque Tool + ROV

www.fmctechnologies.com/subsea

Horizontal Tie-In Systems

Horizontal Tie-In Systems

www.fmctechnologies.com/subsea

STABCON Tie-in System

The Stab and Hingeover Connection System (STABCON) is designed to install and horizontally connect Rigid and Flexible Flowlines, Umbilicals and Rigid Spools in deep and ultra-deep waters. A hinged stab on the termination head enters a receptacle on the subsea structure before the termination head is moved into horizontal position for connection by the ROV carried Connector Actuating Tool ( CAT ).

UTIS Universal Tie-in System

UTIS Tie-in system is designed for both first-end and second-end tie-in of Flowlines and Umbilicals. The UTIS tool carries the clamp-connector to the tie-in area, and lands on the porch/inboard hub. The ROV attaches the pull-in rope to the Termination Head pre-laid some distance from the structure, and the Termination Head with the outboad hub is then pulled in, and the clamp is made up. UTIS may also connect pre-laid Rigid Spools. The UTIS tool is run on guidelines, and is controlled from the surface located control container. The UTIS Tie-in systems have connected hundreds of Flowlines and Umbilicals for major oil companies worldwide.

ROVCON Tie-in System

The ROV based Tie-in & Connection System ROVCON is designed for second-end tie-in of Flowlines and Umbilicals. ROVCON is attached underneath a Work class ROV. The Tie-in skid package perfoms tie-in using two winches. Final pull-in and closing of the connector is by using stroking cylinders. The system comes with a set of ROV operated tools for hub preparation prior to connection. Advantages of the ROVCON Tie-in system is that it is designed to perform a series of tie-ins and connections of prelaid lines without returning to the surface. The system is very compact, requires minimal mobilization, and is air transportable. The ROVCON Tie-in systems have connected hundreds of Flowlines and Umbilicals for major oil companies world-wide

FLYCON Tie-in System

The Flying Lead Connection System (FLYCON) is designed to install and connect Hydraulic and Electrical Umbilicals (Jumpers) between subsea modules and structures by use of a standard Work class ROV. Jumpers are launched to the location in tailor-made baskets. Various configurations of Hydraulic Jumpers and Flying Leads can be supplied to suit a variety of applications. The FLYCON connection system is very compact, requires minimal mobilization, and is air transportable world-wide. The FLYCON Connection systems have connected hundreds of jumpers for major oil-companies world-wide.

www.fmctechnologies.com/subsea

FMC Technologies April 2008 - 3D illustrations by ID - print by Prinfo Vanberg

www.fmctechnologies.com/subsea

FMC Technologies 1777 Gears Road Houston TX 77067 USA Phone: +1 281 591 4000

FMC Technologies P.O. Box 1012 NO-3601 Kongsberg Norway Phone: +47 3228 6700

You might also like

- HOW - Rovcon Tie-In System - High ResDocument4 pagesHOW - Rovcon Tie-In System - High ResZhiqiang GuNo ratings yet

- Vertical Tie-In Systems - Low PDFDocument5 pagesVertical Tie-In Systems - Low PDFgeorge kNo ratings yet

- FMC KL-Clamp ConnectorsDocument3 pagesFMC KL-Clamp ConnectorsBalamir YasaNo ratings yet

- Subsea Innovation Pipeline Repair PDFDocument7 pagesSubsea Innovation Pipeline Repair PDFamalhaj2013No ratings yet

- Buoyed Up: Proven in The Past, Prepared For The FutureDocument10 pagesBuoyed Up: Proven in The Past, Prepared For The FutureantidemosNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Autonomous Subsea Tie in SystemDocument8 pagesAutonomous Subsea Tie in SystemAnonymous YSxTGQmD5No ratings yet

- Monobore Sub SeaDocument9 pagesMonobore Sub Seacamilo777No ratings yet

- Ge Subsea Manifolds Connection Systems BrochureDocument7 pagesGe Subsea Manifolds Connection Systems BrochureRashesh ShahNo ratings yet

- EG50F8 EG50G8 SubseaIntegrity Week1 Lecture1 17sep2015Document4 pagesEG50F8 EG50G8 SubseaIntegrity Week1 Lecture1 17sep2015LesleyAnne RowandNo ratings yet

- Turret MooringsDocument3 pagesTurret Mooringsjo0% (1)

- Multiple Riser Configurations Top-Tensioned Risers Hybrid Riser SystemDocument104 pagesMultiple Riser Configurations Top-Tensioned Risers Hybrid Riser SystemFreddyNo ratings yet

- Oliveros, Kyle Gio M. Bspe 5B PTQ Riser SystemsDocument14 pagesOliveros, Kyle Gio M. Bspe 5B PTQ Riser Systemsglenn vincent floresNo ratings yet

- Oss Subsea Connectors BR PDFDocument12 pagesOss Subsea Connectors BR PDFDheeraj Chowdary DhanekulaNo ratings yet

- Advanced deepwater spool design optimizationDocument28 pagesAdvanced deepwater spool design optimizationhiyeonNo ratings yet

- Steel Catenary RisersDocument29 pagesSteel Catenary RisersZadeh NormanNo ratings yet

- Offshore Subsea Structures and Subsea Systems AssignmentDocument16 pagesOffshore Subsea Structures and Subsea Systems AssignmentGeorge Baby100% (2)

- Stabcon Tie inDocument4 pagesStabcon Tie invon18No ratings yet

- Subsea Presentation PDFDocument3 pagesSubsea Presentation PDFSInowritaNo ratings yet

- Exam Solution 2009-10gDocument9 pagesExam Solution 2009-10gConstAntinosNo ratings yet

- OTC 23177 Frontier Subsea TechnologiesDocument11 pagesOTC 23177 Frontier Subsea TechnologiesRasheed YusufNo ratings yet

- Advances in Steel Catenary Riser DesignDocument5 pagesAdvances in Steel Catenary Riser Designdfal13No ratings yet

- CVC SystemDocument55 pagesCVC SystemPanirChelvan RamanathanNo ratings yet

- The Safe Design of Hot On Bottom PipelinesDocument26 pagesThe Safe Design of Hot On Bottom PipelinesZadeh NormanNo ratings yet

- Inspection Test Record jacket pre-loadoutDocument1 pageInspection Test Record jacket pre-loadoutMomo ItachiNo ratings yet

- Handbook - Riser DesignDocument46 pagesHandbook - Riser DesignPhong Nguyen86% (14)

- Design Considerations For Subsea Metrology Measurements - Patrick Bruce and Chris BathDocument28 pagesDesign Considerations For Subsea Metrology Measurements - Patrick Bruce and Chris BathAlberto darianNo ratings yet

- API Subcommittee 17 Industry Standards For Subsea Equipment: John M. Bednar - BP API SC17 ChairmanDocument13 pagesAPI Subcommittee 17 Industry Standards For Subsea Equipment: John M. Bednar - BP API SC17 ChairmanSOURAV KARNo ratings yet

- Wet Tree Vs Dry TreeDocument12 pagesWet Tree Vs Dry TreeAndirama PutraNo ratings yet

- 5 Guidelines For Struct Integrity Assessment of Existing PlatformsDocument8 pages5 Guidelines For Struct Integrity Assessment of Existing Platformssreedevi gummadiNo ratings yet

- Subsea ManifoldsDocument5 pagesSubsea ManifoldsBrittny LourdeNo ratings yet

- OTC-25134 Final - WatermarkDocument15 pagesOTC-25134 Final - WatermarkgenmikNo ratings yet

- Subsea Equipment ListDocument8 pagesSubsea Equipment ListiskanderNo ratings yet

- T 36Document6 pagesT 36Hariprasad RajannaNo ratings yet

- Corrintec Subsea Brochure PDFDocument8 pagesCorrintec Subsea Brochure PDFraaaghaffarNo ratings yet

- Flexible Riser (Abdul Rahman)Document5 pagesFlexible Riser (Abdul Rahman)Subsea_TeamNo ratings yet

- Fusion-Bonded Epoxy Coatings, A Technology For Rebar Corrosion PreventionDocument13 pagesFusion-Bonded Epoxy Coatings, A Technology For Rebar Corrosion PreventionMuhamad Hafid ANo ratings yet

- OMAE2008-57487: Pipeline-Laybarge Interaction Model For The Simulation of S-Lay Installation ProceduresDocument10 pagesOMAE2008-57487: Pipeline-Laybarge Interaction Model For The Simulation of S-Lay Installation ProceduresdmlsfmmNo ratings yet

- Wet Tree Dry TreeDocument1 pageWet Tree Dry Treeasparagus1996No ratings yet

- Florida Guard Rail SystemDocument26 pagesFlorida Guard Rail SystemZaher Mhd SharafNo ratings yet

- Flexible Steel Pipe Applications: Dana FraserDocument15 pagesFlexible Steel Pipe Applications: Dana FraseraishahNo ratings yet

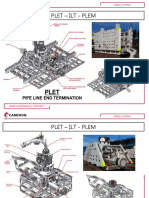

- Plet - Ilt - Plem: Pipe Line End TerminationDocument8 pagesPlet - Ilt - Plem: Pipe Line End TerminationEduardo Gomes100% (1)

- New Built VersusDocument40 pagesNew Built VersusKariem ZakiNo ratings yet

- Assignment #3 Subsea Manifold and TemplatesDocument6 pagesAssignment #3 Subsea Manifold and TemplatesGerald SantosNo ratings yet

- Subsea Control System SPC 18030e05Document39 pagesSubsea Control System SPC 18030e05Ahmad Rabie100% (1)

- Orca FlexDocument417 pagesOrca FlexAli Reza VatandoustNo ratings yet

- Process Pipeline Repair ClampsDocument4 pagesProcess Pipeline Repair ClampsHeru SuryoNo ratings yet

- L01 - Introduction To SPS PDFDocument39 pagesL01 - Introduction To SPS PDFariful islamNo ratings yet

- Offshore Oil Production Riser Desgn PDFDocument13 pagesOffshore Oil Production Riser Desgn PDFdndudcNo ratings yet

- Subsea Single Bolt ConnectorsDocument12 pagesSubsea Single Bolt ConnectorsPedro DutraNo ratings yet

- Supplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11Document81 pagesSupplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11maximusala83No ratings yet

- Introduction To Subsea Field ComponentsDocument57 pagesIntroduction To Subsea Field ComponentsMuhd SyahidNo ratings yet

- Parker Industrial Hose Catalog 4800Document258 pagesParker Industrial Hose Catalog 4800MROstop.comNo ratings yet

- Umbilical DescriptionDocument10 pagesUmbilical DescriptionIkhuosho AbodeNo ratings yet

- SHELL - Provision of FPSO Integrity and Specialized Pipeline Inspection and Maintenance Services On Bonga - 20221002Document4 pagesSHELL - Provision of FPSO Integrity and Specialized Pipeline Inspection and Maintenance Services On Bonga - 20221002Wale OyeludeNo ratings yet

- Flat-Bottom SilosDocument64 pagesFlat-Bottom Siloskhan_mmusaNo ratings yet

- Route Selection and Deepwater Pipeline DesignDocument19 pagesRoute Selection and Deepwater Pipeline DesignSampurnanand PandeyNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Vertical Tie-In Systems - LowDocument5 pagesVertical Tie-In Systems - LowMiguel PereiraNo ratings yet

- Cameron Subsea Systems PDFDocument49 pagesCameron Subsea Systems PDFasparagus1996100% (1)

- Specialist Tools and EquipmentDocument20 pagesSpecialist Tools and EquipmentDavid tangkelangiNo ratings yet

- Electrical Drawing 1 BinderDocument25 pagesElectrical Drawing 1 BinderDavid tangkelangiNo ratings yet

- 11215-ELE-SPC-001 Rev. 0 Spec. For Cathodic ProtectionDocument8 pages11215-ELE-SPC-001 Rev. 0 Spec. For Cathodic ProtectionDavid tangkelangiNo ratings yet

- Gs35B Amplifier 144Mhz Tube Schematic: Original Drawing by Dj5Re - Cad Drawing by Dg2KbcDocument1 pageGs35B Amplifier 144Mhz Tube Schematic: Original Drawing by Dj5Re - Cad Drawing by Dg2KbcDavid tangkelangiNo ratings yet

- Part Book Genset 100 Kva Lovol NWB-1Document105 pagesPart Book Genset 100 Kva Lovol NWB-1David tangkelangiNo ratings yet

- MTU-interface Panel class 4000 Fuse CaptionDocument111 pagesMTU-interface Panel class 4000 Fuse CaptionDavid tangkelangiNo ratings yet

- Cable List - Seleraya (MIP - MMC)Document5 pagesCable List - Seleraya (MIP - MMC)David tangkelangiNo ratings yet

- Siemens 3TF ContactorsDocument15 pagesSiemens 3TF ContactorsDavid tangkelangiNo ratings yet

- Weekly Report Installation Production Flow Line Instrument and Piping - Week XX - Rev 2Document4 pagesWeekly Report Installation Production Flow Line Instrument and Piping - Week XX - Rev 2David tangkelangiNo ratings yet

- Yaesu FT 80C Service ManualDocument80 pagesYaesu FT 80C Service ManualRobert/YG2AKR82% (11)

- Lay Out Block Station Water TreatmentDocument2 pagesLay Out Block Station Water TreatmentDavid tangkelangiNo ratings yet

- User Handbook Genset 100 Kva Lovol NWB-1Document87 pagesUser Handbook Genset 100 Kva Lovol NWB-1David tangkelangiNo ratings yet

- Boiler Maintanance and Checked ListDocument2 pagesBoiler Maintanance and Checked ListAbdillah Fauzan AriefNo ratings yet

- Certificate of Conformity Genset 100 Kva Lovol NWB-1Document1 pageCertificate of Conformity Genset 100 Kva Lovol NWB-1David tangkelangiNo ratings yet

- Test Certificate Genset 100 Kva Lovol NWB-1Document1 pageTest Certificate Genset 100 Kva Lovol NWB-1David tangkelangiNo ratings yet

- Building Maintenance ChecklistDocument2 pagesBuilding Maintenance ChecklistDavid tangkelangiNo ratings yet

- Drawing Genset 100 Kva Lovol NWB-1Document8 pagesDrawing Genset 100 Kva Lovol NWB-1David tangkelangiNo ratings yet

- Inventarisasi Fasilitasi Produksi As of November 2016 Update 011216Document90 pagesInventarisasi Fasilitasi Produksi As of November 2016 Update 011216David tangkelangiNo ratings yet

- CS 3.11.3 (13) Building Maintenance ProceduresDocument8 pagesCS 3.11.3 (13) Building Maintenance ProceduresDavid tangkelangiNo ratings yet

- 0006 AllDocument137 pages0006 AllDavid tangkelangiNo ratings yet

- Boiler Maintanance and Checked ListDocument2 pagesBoiler Maintanance and Checked ListAbdillah Fauzan AriefNo ratings yet

- New Request Cable, 1-Feb - 2016Document1 pageNew Request Cable, 1-Feb - 2016David tangkelangiNo ratings yet

- Basic Principles of ElectricityDocument129 pagesBasic Principles of Electricityရန္ေနာင္ စိုးေအးNo ratings yet

- Chiller Maintenance and Energy ConsiderationsDocument80 pagesChiller Maintenance and Energy ConsiderationsDavid tangkelangiNo ratings yet

- Unit 6 Eletcrical and Electronic Principles PDFDocument16 pagesUnit 6 Eletcrical and Electronic Principles PDFDavid tangkelangiNo ratings yet

- BCBC Mandatory Prev MNT STDDocument41 pagesBCBC Mandatory Prev MNT STDjeffotNo ratings yet

- SS96 Panel5 Paper08Document9 pagesSS96 Panel5 Paper08David tangkelangiNo ratings yet

- Basic ElectricityDocument16 pagesBasic Electricitylbsand100% (2)

- Building Inspection FormDocument3 pagesBuilding Inspection FormDavid tangkelangi50% (2)

- Attachment 2Document5 pagesAttachment 2David tangkelangiNo ratings yet

- Driving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorsDocument10 pagesDriving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorskellendadNo ratings yet

- New Brunswick CDS - 2020-2021Document31 pagesNew Brunswick CDS - 2020-2021sonukakandhe007No ratings yet

- Installation Instruction XALM IndoorDocument37 pagesInstallation Instruction XALM IndoorVanek505No ratings yet

- Common Size Analys3esDocument5 pagesCommon Size Analys3esSaw Mee LowNo ratings yet

- Fiera Foods - Production SupervisorDocument1 pageFiera Foods - Production SupervisorRutul PatelNo ratings yet

- Lanegan (Greg Prato)Document254 pagesLanegan (Greg Prato)Maria LuisaNo ratings yet

- The Changing Face of War - Into The Fourth GenerationDocument5 pagesThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozNo ratings yet

- Huawei WCDMA Primary Scrambling Code PlanningDocument22 pagesHuawei WCDMA Primary Scrambling Code PlanningZeljko Vrankovic90% (31)

- Modul-Document Control Training - Agus F - 12 Juli 2023 Rev1Document34 pagesModul-Document Control Training - Agus F - 12 Juli 2023 Rev1vanesaNo ratings yet

- Material Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008Document6 pagesMaterial Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008suckrindjink100% (1)

- Device Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayDocument2 pagesDevice Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayRohit Chouhan0% (1)

- ExpDocument425 pagesExpVinay KamatNo ratings yet

- Problems of Teaching English As A Foreign Language in YemenDocument13 pagesProblems of Teaching English As A Foreign Language in YemenSabriThabetNo ratings yet

- Identifying The TopicDocument2 pagesIdentifying The TopicrioNo ratings yet

- Jazan Refinery and Terminal ProjectDocument3 pagesJazan Refinery and Terminal ProjectkhsaeedNo ratings yet

- 27 MARCH 2020: Assignment 5 Question PaperDocument4 pages27 MARCH 2020: Assignment 5 Question PaperShadreck SandweNo ratings yet

- Human Resouse Accounting Nature and Its ApplicationsDocument12 pagesHuman Resouse Accounting Nature and Its ApplicationsParas JainNo ratings yet

- Key formulas for introductory statisticsDocument8 pagesKey formulas for introductory statisticsimam awaluddinNo ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakaRamli UsmanNo ratings yet

- Empowerment Technology Reviewer: First SemesterDocument5 pagesEmpowerment Technology Reviewer: First SemesterNinayD.MatubisNo ratings yet

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDocument7 pagesOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalNo ratings yet

- 00 CCSA TestDocument276 pages00 CCSA TestPedro CubillaNo ratings yet

- Modified Release Drug ProductsDocument58 pagesModified Release Drug Productsmailtorubal2573100% (2)

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocument11 pagesRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNo ratings yet

- 'K Is Mentally Ill' The Anatomy of A Factual AccountDocument32 pages'K Is Mentally Ill' The Anatomy of A Factual AccountDiego TorresNo ratings yet

- Colour Ring Labels for Wireless BTS IdentificationDocument3 pagesColour Ring Labels for Wireless BTS Identificationehab-engNo ratings yet

- Diemberger CV 2015Document6 pagesDiemberger CV 2015TimNo ratings yet

- The Effect of Dodd-Frank On Divorcing Citizens 1Document5 pagesThe Effect of Dodd-Frank On Divorcing Citizens 1Noel CookmanNo ratings yet

- TLE8 Q4 Week 8 As Food ProcessingDocument4 pagesTLE8 Q4 Week 8 As Food ProcessingROSELLE CASELANo ratings yet

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDocument12 pagesGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTORONo ratings yet