Professional Documents

Culture Documents

Measure Met of Boundary On A Flat Plate

Uploaded by

MunJiwonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measure Met of Boundary On A Flat Plate

Uploaded by

MunJiwonCopyright:

Available Formats

Measurement of Boundary Layer

on a Flat Plate

Kay Gemba

California State University, Long Beach

March 25, 2007

Abstract

A basic understanding of ow characteristics over a at plate is es-

sential to a complete study of Aerodynamics. This experiment was

conducted in the California State University of Long Beach, CSULB,

windtunnel to gain a better understanding of the parameters and char-

acteristics of uid ow over a at plate. Readings of the boundary

layer were taken at four locations along a at plate at an average

free stream velocity U

of 19.1 0.3

m

s

giving Reynolds numbers cor-

responding to laminar through turbulent ows. The height of the

boundary layer ranged from around 3 mm to 29 mm. Displacement

thickness and momentum thickness values were calculated using the

velocity prole. The skin-friction coecients were determined using

three separate techniques all leading to similar, yet dierent results.

Comparing these results to a theoretical value of 0.0037, the best re-

sult for C

f

was calculated to be 0.00372 using an equation in terms of

Reynolds number for a turbulent section.

1 Objective

To become familiar with a boundary layer and its parameters.

2 Background and Theory

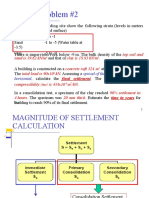

Boundary layer is a layer adjacent to a surface where viscous eects are

important. Figure (1) depicts ow of a uid over a at plate.

aerospace@gemba.org

1

Figure 1: Flow over a at plate

The uid particles at the at plate surface have zero velocity and they act as

a retardant to reduce velocity of adjacent particles in the vertical direction.

Similar actions continue by other particles until at the edge of the boundary

layer where the particles velocity is 99% of the free stream velocity. Bound-

ary layers can also be measured by more signicant parameters. The main

boundary layer parameters are as follows: The displacements thickness,

is

dened as the distance by which the external streamlines are shifted due to

the presence of the boundary layer:

=

_

(1

u

u

)dy (1)

The momentum thickness represents the height of the free-stream ow which

would be needed to make up the deciency in momentum ux within the

boundary layer due to the shear force at the surface. The momentum thick-

ness for an in-compressible boundary layer is given by:

=

_

u

u

(1

u

u

)dy (2)

The skin-friction coecient is dened as:

C

f

=

0

1

2

u

2

dy (3)

0

= (

u

y

)

y=0

(4)

2

The Reynolds number is a measure of the ratio of inertia forces to viscous

forces. It can be used to characterize ow characteristics aver a at plate.

Values under 500,000 are classied as Laminar ow where values from 500,000

to 1,000,000 are deemed Turbulent ow. Is it important to distinguish be-

tween turbulent and non turbulent ow since the boundary layer thickness

varies, as Fig. (2) shows.

Figure 2: Flow over a at plate

3 Procedure

Experiment 3 was conducted at California State University of Long Beach

with the Lab Wind Tunnel. The following procedures were used. The wind

tunnel was setup by the lab instructor with a pitot tube placed 12 from the

leading edge of a at plate. The wind tunnel was turned on and the digital

manometer was calibrated. The pressure dierential P at at least 26 points

was measured within the boundary layer with a y of 0.05 inches. At each

interval the mean pressure dierential was averaged over 10 data points and

recorded on the PC. The pitot tube was adjusted to 24, 36 and 48 and

above steps were repeated.

4 Data

The original data was recorded by a Computer using LABVIEW data acqui-

sition software. Mean values and uncertainties for each point are attached

to this report as Attachment No. 1.

3

5 Calculations

The basic assumption used in all following calculations is that the working

uid, air, is an incompressible uid. This is a reasonable assumption for

low speeds such as those involved in this testing. Standard day atmospheric

conditions of air are also used within these calculations. All calculated data

is presented within the Tables and Graphs section.

Table 1: Nomenclature, SLS Conditions

C

d

drag coecient

F

D

drag force

air density

U

free stream velocity

dynamic viscosity

kinematic viscosity

P

free stream pressure

P

0

stagnation pressure

P pressure dierence

L Length of object

5.1 Eective Center

The eective center equation is used to measure the rst y distance on

which data is taken at each location. This is a function of the outer and inner

diameter of the Pitot tube. Measured values are D = 0.05 and d

i

= 0.025.

y

ec

= (0.131 + 0.82

d

i

D

) D = 0.69mm (5)

4

5.2 Free Stream Velocity

The recorded data for the experiment included Pressure readings with the

units of in-H

2

O. This data had to be converted into Pascals for velocity

calculations. Equations (6) and (7) were used for conversion and free stream

velocity calculations.

P

Pascal

= 249 P

H

2

O

(6)

U

P

Pascal

1

2

Air,SL

= 1.278

_

P

Pascal

(7)

Applying Equation (7), the free stream velocities for the conducted experi-

ments ranged between 18.7 .3

m

s

and 19.6 .3

m

s

.

5.3 Reynolds Number

Having found the free stream velocity earlier it is possible to calculate the

Reynolds number for all four ow conditions using the following relationship:

Re

=

U

=

U

(8)

The length L was measured from the leading edge of the at plate at which

the boundary layer distributions are being evaluated were measured in inches

and were converted to meters.

Table 2: Reynolds numbers and ow types as a function of L

Data Set Length L in meter Reynolds Number Flow Type

1 0.3048 3.4 10

5

Laminar

2 0.6096 6.9 10

5

Transition

3 0.9144 1.0 10

6

Turbulent

4 1.2192 1.3 10

6

Turbulent

5

5.4 Displacement Thickness

Once the free stream velocity and velocities at each y interval are known,

the displacement thickness

can be calculated according to equation (1).

The following formula is used to get a linear approximation of the displace-

ment thickness at all four pitot tube locations.

(1

u

u

)y (9)

The thickness of the boundary layer itself is a function of Reynolds num-

ber. The boundary curve for turbulent ow is much steeper. These are the

equations used to calculate for laminar and turbulent ow, respectively.

L

=

5 L

Re

.5

L

T

=

.382 L

Re

.2

L

5.5 Momentum Thickness

The momentum thickness for an in-compressible boundary layer is given by

equation (2). The following formula is used to get a linear approximation of

the momentum thickness at all four pitot tube locations.

=

u

u

(1

u

u

)y (10)

With displacement and momentum thickness found, H can be calculated:

H =

5.6 Skin friction Coecient

The skin-friction coecient can be evaluated using a variety of techniques:

5.6.1 Clauser Chart

By evaluating the Clauser chart, the skin-friction coecients can be found.

For all four locations the lowest values were taken for use in the Clauser

chart, corresponding to equation (5). The corresponding skin-friction values

C

f

were read from the Clauser Chart.

6

5.6.2 Reynolds Number

The skin-friction coecients can be calculated using Reynolds number with

these equations a laminar or turbulent boundary layer, respectively.

C

f,L

=

0.664

Re

C

f,T

=

0.0583

Re

0.2

5.6.3 Momentum Thickness

Another way to calculate the skin friction coecient is to calculate the slope

of vs the length L. With a zero pressure gradient,

u

du

dx

=

1

dP

dx

= 0

the Von Karman integral equation

d

dx

+ (2 +

)

1

u

du

dx

=

0

u

2

becomes, using the relationship of equation (3)

C

f

= 2

d

dx

(11)

Fig. (4) shows the approximated, linear value using this method.

Table 3: Summary of Skin Friction Coecients, 10

3

Data Set C

f

Clauser Chart C

f

Momentum Thickness C

f

Reynolds Number

1 6.0 2.4 1.10

2 6.0 2.4 4.02

3 4.5 2.4 3.72

4 4.5 2.4 3.54

7

5.7 Uncertainty Analysis

In order to get a condence interval of 95%, we can calculate the error around

the mean from our raw data and multiply it by a factor of 2, according to

equation (12). For all intervals for each Reynolds number, the maximum of

these intervals is chosen to be the condence interval.

CI = 2 = 2

_

n

i=1

(x

i

x)

2

n 1

(12)

The CI for P varies between 6.42 Pascal and 7.18 Pascal. To simplify

calculations, the value of 7.18 Pascals is used for all uncertainty calculations.

The P measured uncertainty is 1.25 Pascal.

Table 4: Calculated Uncertainties

P 1.25 N/m

2

D 0.00005 m

U

0.3 m/s

0.3

Re .03

5.7.1 Sample Calculation

= f

_

(1

u

u

),

y

_

U

= [(U

U

)

2

+ (U

y

)

2

]

1

2

= [(0.00246)

2

+ (.05 2.54/100)

2

]

1

2

= 0.0028

8

6 Graphs and Tables

Calculated Pressure dierentials, velocity distributions, displacement and

momentum thicknesses, and skin friction coecients are attached to this

report as Attachment No. 2.1 to 2.4.

Figure 3: Velocity prole

Figure 4: vs. Length

9

Figure 5: Thickness of the Boundary Layer

7 Discussion of results

The Reynolds numbers for the ow are within the sub-critical Reynolds num-

ber regime. The ow transitioned from a laminar to a turbulent ow (Re =

500,000) prior to the second location, L = 24. The boundary layer thick-

nesses were in the expected ranges with respect to the L location along the

at plate. The data shows the thickness increasing along the length of the

at plate. Figure (5) shows the data and a logarithmic interpolation. The

results indicate that the behavior of a boundary layer is largely a function

of the Reynolds number. The Reynolds number is a function of the ow

speed, viscosity and density of the uid. Separation occurs earlier and with

more strength for higher Reynolds numbers. It is also useful to note that the

shape and the characteristic length of the surface make a big dierence in

the boundary layer parameters.

The mean velocity graphs from Fig. (3) visually show the velocity distribu-

tion within the boundary layer thickness. The graph shows that the boundary

10

layer grows as L is increased and the curves tend to have a greater tangent

as velocity increases. Also, the calculated displacement thickness and mo-

mentum thickness values were also in the expected ranges. The theoretical

values compared to the calculated values of skin-friction coecient did not

match up at all points. It could be concluded that at this location, x = 24,

the ow was in fact, still laminar or possibly in transition. This would help

explain the dierences in theoretical vs. calculated skin-friction coecients.

It may also be a fair assumption since the Reynolds number at this location

was just barely over the transition value. Due to this assumption, the calcu-

lated boundary later thickness is assumed to be the mean of the respective

laminar and turbulent calculated value.

8 Conclusions and recommendations

Windtunnel testing was conducted on a at plate to gain a better under-

standing of boundary layers and there parameters. Readings of the bound-

ary layer were taken at four locations along the at plate at an average ow

speed calculated to be 19.1 0.3

m

s

giving Reynolds numbers in the range

of 341,000 to 1,300,000. These values correspond to laminar through turbu-

lent ows and are within the sub-critical Reynolds number regime. Using

the data obtained the mean velocity proles were graphed at each location.

These graphs matched expected proles. The boundary layer thicknesses at

each location were determined and displacement thickness and momentum

thickness values were calculated using the data. The skin-friction coecients

were determined using three separate techniques. These values were not un-

reasonably away from each other, however they did vary. The discrepancy

between the skin-friction coecient of the second reading would lead us to

re-evaluate wether the ow at this location was truly turbulent. The calcu-

lated results suggest that this location was in fact still laminar or possibly

in transition. It might be useful not to use an open windtunnel for this ex-

periment since small disturbances can lead to fatal uncertainties, since the

desired calculated data is very sensible and small in magnitude. That might

explain some of the errors. Furthermore, it would be useful to take more

data within the laminar ow range to determine the curve of the boundary

layer more accurately. Other than that, the experiment was fairly successful.

11

References

[1] Dr. Hamid Rahai, MAE 440 Aerodynamics Laboratory Experiments, Cal-

ifornia State University Long Beach, Spring 2007

[2] John J. Bertin, Aerodynamics for Engineers, 4th edition, 2002

[3] Schlichting H. 1979. Boundary-layer theory. 7th ed. New York: McGraw-

Hill.

12

You might also like

- Fluid Mechanics 101 Calculators & Tools GuideDocument11 pagesFluid Mechanics 101 Calculators & Tools GuideImran RasheedNo ratings yet

- Git Cheat SheetDocument1 pageGit Cheat Sheetkzelda100% (1)

- Lecture 5 - Reinforced Concrete - ColumnDocument52 pagesLecture 5 - Reinforced Concrete - ColumnChristopher PaladioNo ratings yet

- Low Speed Aerodynamics Piercy Aerofoil Lab ReportDocument7 pagesLow Speed Aerodynamics Piercy Aerofoil Lab Reportsilvia100% (1)

- ANSYS Tutorial: ContactDocument74 pagesANSYS Tutorial: Contacthailfreedom100% (1)

- Stress Relaxation and CreepDocument7 pagesStress Relaxation and CreepRaasik JainNo ratings yet

- R. M. Nedderman-Statics and Kinematics of Granular Materials-Cambridge University Press (1992)Document368 pagesR. M. Nedderman-Statics and Kinematics of Granular Materials-Cambridge University Press (1992)AndreaLopez67% (3)

- Selection of GasketsDocument53 pagesSelection of GasketsImtiaz Ali100% (2)

- Prasad1998 - Modelling of Hot Deformation FDocument16 pagesPrasad1998 - Modelling of Hot Deformation FUri SterinNo ratings yet

- Lab Report Bl2Document25 pagesLab Report Bl2Ahmad Hafizuddin83% (6)

- Band Gap Physics of PhotodiodesDocument622 pagesBand Gap Physics of PhotodiodesNgoc Phuc Le100% (3)

- Design of Lining of Tunnels Excavated in Soil and Soft Rock PDFDocument15 pagesDesign of Lining of Tunnels Excavated in Soil and Soft Rock PDFtradichon23No ratings yet

- Astm D 4439 00 Standard Terminology For Geosynthetics PDFDocument5 pagesAstm D 4439 00 Standard Terminology For Geosynthetics PDFDeyvi ManriqueNo ratings yet

- CFD Study of Air Flow over Two Side-By-Side Circular CylindersDocument11 pagesCFD Study of Air Flow over Two Side-By-Side Circular CylindersNirman MarioNo ratings yet

- Measuring Boundary Layer FlowDocument8 pagesMeasuring Boundary Layer Flowchantelle100% (1)

- Measurement of Boundary Layer On A Flat PlateDocument13 pagesMeasurement of Boundary Layer On A Flat PlateBehailu TarekegnNo ratings yet

- Chen 2610 Faculty CH 7 ADocument17 pagesChen 2610 Faculty CH 7 ASwamy RakeshNo ratings yet

- Lab Report Bl2Document25 pagesLab Report Bl2Raniero Falzon0% (1)

- FEEG2003 BL LabSheet 2024Document8 pagesFEEG2003 BL LabSheet 2024jiales225No ratings yet

- Title: Flat Plate Boundary LayerDocument17 pagesTitle: Flat Plate Boundary LayermuazadnNo ratings yet

- Flow Loss in Screens: A Fresh Look at Old CorrelationDocument6 pagesFlow Loss in Screens: A Fresh Look at Old CorrelationRakesh RanjanNo ratings yet

- FEEG2003 BL LabSheet 2024 HarbinDocument6 pagesFEEG2003 BL LabSheet 2024 Harbinjiales225No ratings yet

- Compressible Flow Over A Flat PlateDocument8 pagesCompressible Flow Over A Flat PlatefaseycisherNo ratings yet

- ENSC 283 Introduction To Fluid Mechanics: Chapter 7 - Flow Past Immersed BodiesDocument16 pagesENSC 283 Introduction To Fluid Mechanics: Chapter 7 - Flow Past Immersed BodiesArjun CpNo ratings yet

- Achenbach Smooth - Rough CylinderDocument15 pagesAchenbach Smooth - Rough CylinderVivek KantiNo ratings yet

- Z AIAAJournal2007Document5 pagesZ AIAAJournal2007engma3No ratings yet

- Leakage Calculation Through ClearancesDocument7 pagesLeakage Calculation Through Clearanceschandrasingh4564No ratings yet

- AE 342 Aerodynamics II Laboratory Sheet 3 Boundary Layer MeasurementsDocument5 pagesAE 342 Aerodynamics II Laboratory Sheet 3 Boundary Layer MeasurementsBanbona AlkurdshNo ratings yet

- Apth Unit4Document40 pagesApth Unit4Deepak GovindanNo ratings yet

- Fluid Mechanics II: B.S. Mechanical Engineering 4 SemesterDocument80 pagesFluid Mechanics II: B.S. Mechanical Engineering 4 Semesternaeema_58No ratings yet

- Boundary Layer Theory - P2Document19 pagesBoundary Layer Theory - P2alphascribeNo ratings yet

- DSMC Simulations of Rarefied Flow Over A Square CylinderDocument8 pagesDSMC Simulations of Rarefied Flow Over A Square CylinderThosh SanNo ratings yet

- 7.moin BFSDocument26 pages7.moin BFSpratikmitra30No ratings yet

- US08013FU1Document10 pagesUS08013FU1Vanco AdziskiNo ratings yet

- Blayer 4Document11 pagesBlayer 4muhammadasrafazmiNo ratings yet

- Experiments on Flow Past Spheres at Very High Reynolds NumbersDocument11 pagesExperiments on Flow Past Spheres at Very High Reynolds NumbersTeja DasariNo ratings yet

- Forced ConvectionDocument16 pagesForced ConvectionAleem AhmedNo ratings yet

- An Average Flow Model For Determining Effects of Three-Dimensional Roughness On Partial Hydrodynamic LubricationDocument6 pagesAn Average Flow Model For Determining Effects of Three-Dimensional Roughness On Partial Hydrodynamic LubricationKartik DuttNo ratings yet

- Numerical Simulations and Laboratory Measurements in Hydraulic JuDocument9 pagesNumerical Simulations and Laboratory Measurements in Hydraulic JuBabak mahmoudiNo ratings yet

- 2010 CiS Papers PDFDocument30 pages2010 CiS Papers PDFDigvijayNo ratings yet

- Homework 1Document4 pagesHomework 1Mohamed SaeedNo ratings yet

- Experiments With Biconvex Aerof6ils in Low-Density, and Double-Wedge Supersonic FlowDocument46 pagesExperiments With Biconvex Aerof6ils in Low-Density, and Double-Wedge Supersonic Flowaustin00012No ratings yet

- Chapter5 Direct-Numerical-SimulationDocument14 pagesChapter5 Direct-Numerical-Simulationshehbazi2001No ratings yet

- Aerodynamics 2 MEC 3706 Exercise Sheet 2 and SolutionDocument18 pagesAerodynamics 2 MEC 3706 Exercise Sheet 2 and SolutionJarvis AsiNo ratings yet

- Sand Liquefaction by Hypoplastic ModelDocument7 pagesSand Liquefaction by Hypoplastic ModelAnna SuuNo ratings yet

- Crossing Shockwave Boundary Layer Interaction Using Swept FinsDocument8 pagesCrossing Shockwave Boundary Layer Interaction Using Swept FinsArun KumarNo ratings yet

- Replace Implicit Equations With Signomial FunctionsDocument8 pagesReplace Implicit Equations With Signomial FunctionsnurudinsatharNo ratings yet

- CFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserDocument27 pagesCFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserK PedersenNo ratings yet

- 0207 Sin 2Document5 pages0207 Sin 2bogodavidNo ratings yet

- Solved Example of CH-3Document13 pagesSolved Example of CH-3Abubeker AreboNo ratings yet

- Friction FactorDocument79 pagesFriction FactorahmedNo ratings yet

- Presentation Cap 6 Heat II BWDocument20 pagesPresentation Cap 6 Heat II BWSean Crespo GomezNo ratings yet

- Experimental study on determining skin friction using boundary layer velocity profilesDocument12 pagesExperimental study on determining skin friction using boundary layer velocity profilesMC ANo ratings yet

- Assignment 6 With Solutions (2) FM WhiteDocument9 pagesAssignment 6 With Solutions (2) FM WhiteabNo ratings yet

- 1996 - An Adaptive Level Set Approach For Incompressible Two-Phase Flows - Sussman Et AlDocument44 pages1996 - An Adaptive Level Set Approach For Incompressible Two-Phase Flows - Sussman Et AlRodrigo AbdoNo ratings yet

- Matija SicDocument4 pagesMatija SicKamlesh SharmaNo ratings yet

- Finite Volume For Dam BreakDocument4 pagesFinite Volume For Dam BreakArnasli YahyaNo ratings yet

- Fluid Mechanics 101: Calculators & ToolsDocument11 pagesFluid Mechanics 101: Calculators & ToolsHaseebPirachaNo ratings yet

- Natural Convection LatestDocument38 pagesNatural Convection LatestPradyumna Dhamangaonkar50% (2)

- Fluid Mechanics II (Chapter 2)Document16 pagesFluid Mechanics II (Chapter 2)Shariff Mohamad FairuzNo ratings yet

- Comparing Neutral Atmospheric Boundary Layer Simulation Methods for Building Pressure CalculationsDocument8 pagesComparing Neutral Atmospheric Boundary Layer Simulation Methods for Building Pressure CalculationsOkke BronkhorstNo ratings yet

- Drag ForceDocument7 pagesDrag ForceehsankotNo ratings yet

- Scale Up Design PabrikDocument17 pagesScale Up Design PabrikMochammad Arfy Adhaditia SasmitaNo ratings yet

- Achenbach1972 PDFDocument11 pagesAchenbach1972 PDFdyabrudyNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- ITNC 530 Cycle ProgammingDocument527 pagesITNC 530 Cycle ProgammingRahulNo ratings yet

- Eng Pcdmis 2022.1 CMM ManualDocument453 pagesEng Pcdmis 2022.1 CMM ManualRahulNo ratings yet

- Eng Pcdmis 2022.1 CMM ManualDocument453 pagesEng Pcdmis 2022.1 CMM ManualRahulNo ratings yet

- ITNC 530 Cycle ProgammingDocument527 pagesITNC 530 Cycle ProgammingRahulNo ratings yet

- Models - Chem.drug Release PDFDocument28 pagesModels - Chem.drug Release PDFRahulNo ratings yet

- Introduction To MatlabDocument45 pagesIntroduction To MatlabSivaraman ChidambaramNo ratings yet

- Avl DocDocument38 pagesAvl DocRahulNo ratings yet

- TB Ansys Maxwell Magnetic Field Formulation PDFDocument3 pagesTB Ansys Maxwell Magnetic Field Formulation PDFRahulNo ratings yet

- GFA Series PDFDocument1 pageGFA Series PDFRahulNo ratings yet

- SurveyDocument2 pagesSurveyRahulNo ratings yet

- Solving Ordinary Differential Equations With MatlabDocument22 pagesSolving Ordinary Differential Equations With MatlabMario ZamoraNo ratings yet

- WsDocument1 pageWsRahulNo ratings yet

- Fluid Structure Interaction Turek Benchmark Problem ResultsDocument12 pagesFluid Structure Interaction Turek Benchmark Problem ResultsRahulNo ratings yet

- Beam DeflectionDocument16 pagesBeam DeflectionPrashant MavaleNo ratings yet

- Halbach Array Electric MachinesDocument8 pagesHalbach Array Electric MachinesalexsurenderNo ratings yet

- Student Landing GearDocument1 pageStudent Landing GearRahulNo ratings yet

- 002.hydro-Magnetic Mixed Convection Flow in A Lid-Driven Cavity With Wavy Bottom SurfaceDocument12 pages002.hydro-Magnetic Mixed Convection Flow in A Lid-Driven Cavity With Wavy Bottom SurfaceRahulNo ratings yet

- AN INTRODUCTION TO HYDRODYNAMICSDocument109 pagesAN INTRODUCTION TO HYDRODYNAMICSVipul KumarNo ratings yet

- Scientific Method: Hypothetico-Deductive ScienceDocument1 pageScientific Method: Hypothetico-Deductive ScienceRahulNo ratings yet

- Jianan PartDocument69 pagesJianan PartRahul0% (1)

- Rankine HugoniotDocument21 pagesRankine HugoniotSaurabh KhandelwalNo ratings yet

- Assignment Register Form For Intern AE TUD v3 ProtectedDocument1 pageAssignment Register Form For Intern AE TUD v3 ProtectedRahulNo ratings yet

- OpenFOAM-3.0.1 Programmer's GuideDocument100 pagesOpenFOAM-3.0.1 Programmer's GuideCendhyLiestyariniNo ratings yet

- Comparison of Pressure and VelocityDocument7 pagesComparison of Pressure and VelocityRahulNo ratings yet

- Exploring Openfoam Source Code: There and Back AgainDocument72 pagesExploring Openfoam Source Code: There and Back AgainSantiago Márquez DamiánNo ratings yet

- HowTo Navigate OpenFoam MB PDFDocument72 pagesHowTo Navigate OpenFoam MB PDFRahulNo ratings yet

- Video Content EFMDocument8 pagesVideo Content EFMviggi657No ratings yet

- Aerospace Engineers AIAA 2010 531Document15 pagesAerospace Engineers AIAA 2010 531RahulNo ratings yet

- F 154 - 00 - Rje1nc0wmaDocument13 pagesF 154 - 00 - Rje1nc0wmajamaljamal20No ratings yet

- SAE Steel Bolts - Grades Ranging Grade 1 To 8.2 - Proof and Tensile StrengthDocument2 pagesSAE Steel Bolts - Grades Ranging Grade 1 To 8.2 - Proof and Tensile StrengthRuben GutierrezNo ratings yet

- Staad Pro Tutorial.Document79 pagesStaad Pro Tutorial.ArushiBiswasNo ratings yet

- W-Section Steel Strip Tension Test ReportDocument23 pagesW-Section Steel Strip Tension Test ReportZardarHussainNo ratings yet

- Density Functional Theory Investigations of Bismuth VanadateDocument7 pagesDensity Functional Theory Investigations of Bismuth VanadateNurSalahuddinNo ratings yet

- Ernesto GuadesDocument11 pagesErnesto GuadesAliNo ratings yet

- Magnetic Properties & CharacteristicsDocument9 pagesMagnetic Properties & CharacteristicsRogelyn JosolNo ratings yet

- International Journal of Heat and Mass Transfer: Sumit Malik, A.K. NayakDocument17 pagesInternational Journal of Heat and Mass Transfer: Sumit Malik, A.K. NayakvenkatadriKNo ratings yet

- LDC LP No. 01 Dtd 3rd April 2024Document12 pagesLDC LP No. 01 Dtd 3rd April 2024Gautam MishraNo ratings yet

- Sba 18 CifDocument2 pagesSba 18 CifAnonymous 1HlNy6nNo ratings yet

- Practice Problem #2: Spread of The Load of 2 Vertical To 1 HorizontalDocument21 pagesPractice Problem #2: Spread of The Load of 2 Vertical To 1 HorizontalFadli PunyeNo ratings yet

- IEEE Brown BookDocument488 pagesIEEE Brown BookJohn Adrian GalangNo ratings yet

- Wevo Folder Produkte Wevopur en Screen 230313Document4 pagesWevo Folder Produkte Wevopur en Screen 230313jason KlangNo ratings yet

- Facile Method of Prpeare Lotus-Leaf Like SHyrophobic PVC FilmDocument6 pagesFacile Method of Prpeare Lotus-Leaf Like SHyrophobic PVC FilmNiroshanNo ratings yet

- ENGR 313: Introduction To Materials Science and EngineeringDocument7 pagesENGR 313: Introduction To Materials Science and EngineeringTracey HowardNo ratings yet

- ACTIVITY#2 Group Activity PDFDocument5 pagesACTIVITY#2 Group Activity PDFAlfaro, Jeff SimonNo ratings yet

- Texture Profile AnalysisDocument2 pagesTexture Profile AnalysisKenesei GyörgyNo ratings yet

- In-situ stress assessment of concrete structures using different techniquesDocument25 pagesIn-situ stress assessment of concrete structures using different techniquesTony VrtonyNo ratings yet

- CHEM 17 - Freezing Point of Naphthalene and Boiling Point Elevation of Water.Document8 pagesCHEM 17 - Freezing Point of Naphthalene and Boiling Point Elevation of Water.Gerry Mark GubantesNo ratings yet

- Densolen - System AS39P / R20HT: Product InformationDocument2 pagesDensolen - System AS39P / R20HT: Product InformationCarlos PazNo ratings yet

- Development of High Strength Construction RebarsDocument13 pagesDevelopment of High Strength Construction RebarsK S RamakrishnaNo ratings yet

- Mechanical ScienceDocument12 pagesMechanical ScienceFernando EyzaguirreNo ratings yet