Professional Documents

Culture Documents

VII.P1e.polyolefin19 10674

Uploaded by

ShitalbioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VII.P1e.polyolefin19 10674

Uploaded by

ShitalbioCopyright:

Available Formats

3 Linde-KCA-Dresden: Polyolefin plants

Globally established polyolefin plants.

Competence in PE and PP projects opens markets.

02

Linde-KCA-Dresden: Polyolefin plants

Linde-KCA-Dresden: Polyolefin plants

03

Knowing what makes the market tick. Were familiar with the processes for PP and PE worldwide.

Polyethylene (PE) and polypropylene (PP) belong to the polymers with the highest demand and growth rates worldwide. More than 50 % of all ethylene produced is consumed in polymerisation processes for the production of PE and PP. More than 30 years of experience in the polyethylene and polypropylene market have given Linde a profound knowledge base in both engineering and project execution for such plants. Our experience of having constructed PE and PP plants in numerous countries around the world gives us, Linde, the capability to focus on the planning and project development required to provide a truly successful turnkey plant.

Integrating petrochemical complexes

Very few companies have the know-how to build turnkey integrated petrochemical complexes. Linde is in a unique position of being able to offer a complete spectrum of technologies along the olefin/polyolefin chain, such as gas separation, ethylene, propane dehydration, polyethylene and polypropylene, linear alpha olefins.

One-stop individual support

We offer the full range of engineering services for polyethylene and polypropylene projects, including: 3 Consulting services 3 Project development 3 Economical and technical feasibility studies 3 Licensing arrangements 3 Financing 3 Arrangement of premarketing and off-take 3 Support and documentation for authority engineering 3 Project management 3 Engineering and design 3 Procurement 3 Construction 3 Commissioning and start-up 3 Training of operational and maintenance personnel 3 After-sales support

04

Linde-KCA-Dresden: Polyolefin plants

Working hand in hand. Success through efficient coordination of the complexes.

Our approach is to structure typical polyethylene and polypropylene plants into separate complexes.

Complex 1

The PE or PP process plant forms the core of the entire unit, comprising the purification of raw materials, reaction system(s), resin degassing, vent recovery, additive handling and pelletising systems. These sections are typically covered by the licensors process design package.

Complex 2

Homogenisation and intermediate storage of the pelletised product take place in the blending and storage area. Finally, the product will be either loaded as bulk into container trucks or filled into bags the bagged product being stored on pallets in a warehouse.

Complex 3

Off-sites and utility systems must be provided in order to supply feedstock, raw materials and plant utilities at optimum operational parameters.

Linde-KCA-Dresden: Polyolefin plants

05

Investing safely. Integrated engineering for flexible reactions.

Superordinate data alignment

Linde-KCA-Dresden GmbH uses computer-based engineering tools linked to form an integrated system of in-house data exchange to perform the project task required by each discipline. This highly developed software is used for intelligent P&IDs for process engineering and 3D CAD modelling to develop plant design.

Accuracy through design reviews

It is one of the declared goals of Linde-KCA-Dresden GmbH to involve client engineering and operational staff to the maximum possible extent during the design phase. The client is invited to participate at regular plant design review meetings, in which all details of plant layout (equipment, piping, steel structure, buildings etc.) are openly discussed using the 3D CAD model.

Linde Integrated Management System (IMS)

The Linde IMS was developed in order to secure quality and timing through the entire engineering process. This business, quality and HSE management platform links activities and deliverables of all engineering disciplines during all stages of the planning process in a database, thus making the engineering and workflow efficient and transparent for our clients.

06

Linde-KCA-Dresden: Polyolefin plants

Technologies and processes with a future. Variable, flexible, safe.

Leading technology

Linde-KCA-Dresden GmbH is an Approved Bidding Contractor for the following technologies: 3 UNIPOL PE process of Univation Technologies 3 UNIPOL PP process of The Dow Chemical Company Upon specific client request, alternate technologies can be offered.

UNIPOL PE and PP the process chain

Raw material purification The raw materials are treated to remove poisons which could negatively affect the catalyst performance. Other specified chemicals are simply used as received, without further treatment. Reaction system A compressor circulates the reactor gas through a heat exchanger to fluidise the reactor bed and remove heat from the polymerisation reaction. The product is conveyed to the degassing system. Degassing The product is treated to remove residual hydrocarbons. The purged product is combined with additives and fed into the pelletising system. Pelletising The combined granular resin and additives are intensively mixed, kneaded and melted before being pelletised. After being dried, the pellets are conveyed to the product handling facilities. Product handling This process section is tailored to the requirements of the client. Therefore, the product handling is designed in close cooperation between the client and Linde-KCA-Dresden GmbH. We can offer all equipment required for dense and dilute phase conveying, elutriation, blending, bulk storage, bagging, packaging and pelletising facilities etc.

Simple processes

Both UNIPOL PE and PP are fluidised bed gas phase processes, each providing a maximum of operational safety and flexibility, combined with low capital investment, due to the relative simplicity of the technology derived from reliable equipment and moderate operating conditions.

A broad range of products

The UNIPOL PE and PP processes offer clients the unique opportunity to produce the widest range of products for the market requirements of today and tomorrow, providing for such product applications as film, pipe, tubing, blow moulding, injection moulding, roto moulding, fibres etc.

Linde-KCA-Dresden: Polyolefin plants

07

Planting seeds for the future.

Our customers success is our success. With innovative technologies and our employees extensive know-how, we are consistently turning our customers goals into our own in a fair, transparent and cost-conscious manner. Therefore, every plant we build is a reference for the next one creative in its concept, efficient in its implementation. As one of the leading companies in the planning and construction of chemical, gas, biotechnological and pharmaceutical plants, we offer our customers the security of consistently high quality standards. In cooperation with reliable business partners, we combine capacity and expertise in order to realise projects of any dimension. We regard every assignment as a chance to define a new market standard and to expand our strong international position. Driven by our own performance capability, it is our goal to make the name Linde a globally recognised seal of quality, with plants that speak for themselves and for us.

Linde-KCA-Dresden GmbH

Postal address: Postal office box 210353 01265 Dresden Germany House address: Bodenbacher Strasse 80 01277 Dresden Germany Phone +49.(0)351.250-30 Fax +49.(0)351.250-4800 lkca.dresden@linde-kca.com www.linde-kca.com Office Moscow: 115114, Moscow Letnikovskaja ul. 10 building 2, 8th floor Russia Phone +7.495.9871223 Fax +7.495.9871224 lkca.moskau@linde-kca.com

Linde-KCA-Dresden GmbH Bodenbacher Strasse 80, 01277 Dresden, Germany Phone +49.(0)351.250-30, Fax +49.(0)351.250-4800, www.linde-kca.com

VII.P1e.1005

You might also like

- AppSolution SimSci DYNSIMColumnReliefAnalysis 01-10Document6 pagesAppSolution SimSci DYNSIMColumnReliefAnalysis 01-10Yang Gul LeeNo ratings yet

- Global Benzene Production InsightsDocument3 pagesGlobal Benzene Production InsightsShitalbioNo ratings yet

- Pentair PSV Engineering HandbookDocument233 pagesPentair PSV Engineering HandbookAsad1001No ratings yet

- Global Benzene Production InsightsDocument3 pagesGlobal Benzene Production InsightsShitalbioNo ratings yet

- FA With OLGA ExercisesDocument35 pagesFA With OLGA ExercisesBehnam HosseinzadehNo ratings yet

- Design of Water Treatment PlantDocument77 pagesDesign of Water Treatment PlantNikhil89% (175)

- Flare For DesignDocument4 pagesFlare For DesignChem.EnggNo ratings yet

- Minimum Thermal FlowDocument4 pagesMinimum Thermal Flowdk4monjureNo ratings yet

- NORSOK P-001 Process Design PDFDocument26 pagesNORSOK P-001 Process Design PDFMarcelNo ratings yet

- Using The BJAC Properties Package With Aspen EDRDocument9 pagesUsing The BJAC Properties Package With Aspen EDRShitalbioNo ratings yet

- Flow Assurance 2005Document35 pagesFlow Assurance 2005Jiso ThomasNo ratings yet

- Flow Assurance 2005Document35 pagesFlow Assurance 2005Jiso ThomasNo ratings yet

- Learn how the Reboiler Wizard sizes column reboilers in Aspen PlusDocument2 pagesLearn how the Reboiler Wizard sizes column reboilers in Aspen PlusShitalbioNo ratings yet

- Air Cooled - VLL Enhancement Script - Rev2Document9 pagesAir Cooled - VLL Enhancement Script - Rev2ShitalbioNo ratings yet

- NORSOK P-001 Process Design PDFDocument26 pagesNORSOK P-001 Process Design PDFMarcelNo ratings yet

- Learn how the Reboiler Wizard sizes column reboilers in Aspen PlusDocument2 pagesLearn how the Reboiler Wizard sizes column reboilers in Aspen PlusShitalbioNo ratings yet

- Talibnanized Pakistan and Threat To Regional SecurityDocument7 pagesTalibnanized Pakistan and Threat To Regional SecurityShitalbioNo ratings yet

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- PPG FrontLine 2011Document4 pagesPPG FrontLine 2011ShitalbioNo ratings yet

- 2707027Document2 pages2707027ShitalbioNo ratings yet

- Aspen Plus Sulfuric Acid ModelDocument16 pagesAspen Plus Sulfuric Acid ModelStanley WoonNo ratings yet

- Maoist Insurgency and Guerrilla Warfare and State Response, Part-IDocument13 pagesMaoist Insurgency and Guerrilla Warfare and State Response, Part-IShitalbioNo ratings yet

- My Father Was A Patriot. He Died For Our CountryDocument6 pagesMy Father Was A Patriot. He Died For Our CountryShitalbioNo ratings yet

- Absorption of Aromatics CompoundsDocument9 pagesAbsorption of Aromatics CompoundsShitalbioNo ratings yet

- Shaojun Zhou - Gas Technology InstituteDocument29 pagesShaojun Zhou - Gas Technology InstituteShitalbioNo ratings yet

- The Vedic Wedding CeremonyDocument6 pagesThe Vedic Wedding CeremonyShitalbioNo ratings yet

- A Chance EncounterDocument1 pageA Chance EncounterShitalbioNo ratings yet

- Shame at Sharm Al Sheikh How Manmohan Succumbed To US & Pak BlackmailDocument10 pagesShame at Sharm Al Sheikh How Manmohan Succumbed To US & Pak BlackmailShitalbio100% (2)

- MR Antony, What's Your Agenda For India's DefenceDocument6 pagesMR Antony, What's Your Agenda For India's DefenceShitalbio100% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lattice VibrationDocument21 pagesLattice VibrationPandu lalNo ratings yet

- 10.1016/j.foodres.2014.01.057: Food Research InternationalDocument90 pages10.1016/j.foodres.2014.01.057: Food Research Internationaledywiyono2013No ratings yet

- Genie: Hot Water Driven Vapor Absorption MachineDocument39 pagesGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyNo ratings yet

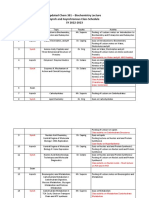

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchDocument3 pagesSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANANo ratings yet

- Methods For Diffusion Welding The Superalloy Udimet 700Document9 pagesMethods For Diffusion Welding The Superalloy Udimet 700Enary SalernoNo ratings yet

- Advanced PharmacognosyDocument13 pagesAdvanced PharmacognosyLisa DamayantiNo ratings yet

- Hooper David - The Colloidal Silver Hand BookDocument23 pagesHooper David - The Colloidal Silver Hand BookStarla ShermanNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- WokaStar - EN1Document8 pagesWokaStar - EN1Huang yen chengNo ratings yet

- Wieland CatalogueDocument40 pagesWieland Catalogueazb00178No ratings yet

- Pipebook ADocument2 pagesPipebook APRAKASH PANDEYNo ratings yet

- EDXRF Analysis of Polymer Films Thickness and CompositionDocument2 pagesEDXRF Analysis of Polymer Films Thickness and CompositionnadiarhNo ratings yet

- ENZYME KINETICSDocument11 pagesENZYME KINETICSDianne Villanueva100% (1)

- Cambridge IGCSE (9-1) : PHYSICS 0972/41Document16 pagesCambridge IGCSE (9-1) : PHYSICS 0972/41dowanahamidNo ratings yet

- RRLDocument5 pagesRRLSupremo Family100% (1)

- 14 CH242 Conjugated & UVDocument72 pages14 CH242 Conjugated & UVrizqiaNo ratings yet

- AKL10 Laser Technology LiveDocument49 pagesAKL10 Laser Technology LiveXin ChenNo ratings yet

- Recycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Document20 pagesRecycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Vijaykumar SharmaNo ratings yet

- Packaged Drinking WaterDocument4 pagesPackaged Drinking WaterSanjay JainNo ratings yet

- UV-Curing Screen InksDocument2 pagesUV-Curing Screen InksJavier RealNo ratings yet

- ATCO Gas STOPAQ-Vinylester Procedure Rev0Document45 pagesATCO Gas STOPAQ-Vinylester Procedure Rev0mkash028No ratings yet

- Entropy Changes in Thermodynamic ProcessesDocument33 pagesEntropy Changes in Thermodynamic ProcessesJessica AndersonNo ratings yet

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocument7 pagesFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuNo ratings yet

- Fulltext ClorometaDocument9 pagesFulltext ClorometakarkamalusNo ratings yet

- Practical of Chemistry PDFDocument377 pagesPractical of Chemistry PDFrajesh971No ratings yet

- RTS PS 2024ref2023ftsDocument3 pagesRTS PS 2024ref2023ftsmohitabochare2039No ratings yet

- Astm b571 97 R 13pdfDocument4 pagesAstm b571 97 R 13pdfkishor150688No ratings yet

- FTIR Analysis of Rapeseed Oil and Biodiesel Methyl EstersDocument2 pagesFTIR Analysis of Rapeseed Oil and Biodiesel Methyl Estersrgx1120% (1)

- Density Calculations Worksheet IDocument2 pagesDensity Calculations Worksheet Iapi-218999959No ratings yet

- June 2017 (v1) QP - Paper 6 CIE Biology IGCSEDocument12 pagesJune 2017 (v1) QP - Paper 6 CIE Biology IGCSEbandana dekaNo ratings yet