Professional Documents

Culture Documents

Product Design 1

Uploaded by

elango_mm3307Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Design 1

Uploaded by

elango_mm3307Copyright:

Available Formats

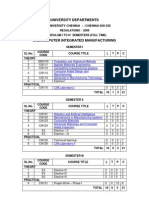

ANNA UNIVERSITY : : 600 025 CURRICULUM 2005 - FULL TIME MODE (4 Semesters) M.E.

PRODUCT DESIGN AND DEVELOPMENT SEMESTER I Code No. Course Title THEORY MA1606 Probability and Statistical methods PD1601 Integrated Product and Process Development-I PD1602 Concepts and Computer Applications in Design PD1603 Product Engineering Tools PD1604 Metals and Manufacturing Processes E1*** Elective-I PRACTICAL PD1605 Digital Product Development Lab SEMESTER II Code No. Course Title THEORY PD1651 Integrated Product and Process Development-II PD1652 Quality in Design PD1653 Non-metals and Manufacturing processes PD1655 Finite Element Analysis E2*** Elective-II E3*** Elective-III PRACTICAL PD1654 Design Studio Lab SEMESTER III Code No. THEORY PD1701 E4*** E5*** PRACTICAL PD1751 Course Title Design Paradigm Elective IV Elective V Project Work Phase I SEMESTER IV Code No. Course Title PD1751 Project Wok - Phase II * As per the Regulations 2005. L 0 T 0 P 24 M * L 3 3 3 0 T 0 0 0 0 P 0 0 0 12 M 100 100 100 * L 3 3 3 3 3 3 0 T P 1 0 0 0 0 0 0 0 0 0 0 0 0 3 M 100 100 100 100 100 100 100 L 3 3 3 3 3 3 0 T P 1 1 0 0 0 0 0 0 0 0 0 0 0 3 M 100 100 100 100 100 100 100

ELECTIVES FOR PRODUCT DESIGN AND DEVELOPMENT

Course Code CD1622 CD1623 CD1651 CM1651 ED1651 IC1672 IE1721 PD1621 PD1671 PD1721

Course Title Rapid Prototyping and Tooling Tribology in Design Mechanical Vibration Robotics and Sensors Optimization Techniques in Design Computational Fluid Dynamics Enterprise Resource Planning Reverse Engineering Advanced Mechatronics Supply Chain Management

L 3 3 3 3 3 3 3 3 3 3

T 0 0 0 0 0 0 0 0 0 0

P 0 0 0 0 0 0 0 0 0 0

M 100 100 100 100 100 100 100 100 100 100

MA1606

PROBABILITY AND STATISTICAL METHODS

3 1 0 100

1.

PROBABILITY AND RANDOM VARIABLE

Probability Random variables Binomial, Poisson, Geometric, Uniform, Normal, Exponential distributions Moments Moment generating functions and their properties Functions of random variables. 2. ESTIMATION THEORY 9

Multiple and Partial correlations Partial and Multiple regression Estimation of Parameters using Maximum likelihood estimator and Method of moments. 3. TESTING OF HYPOTHESIS 9

Basic definitions of statistical hypothesis Tests based on Normal, t, chi-square, and F distributions for mean, variance and proportion. 4. DESIGN OF EXPERIMENTS 9

Analysis of variance One way and Two way classifications Completely Randomized Design Randomized Block Design Latin Square Design 22 Factorial Design. 5. MULTIVARIATE ANALYSIS 9

An overview of multivariate methods, multivariate normal distribution, Eigen values and Eigen vectors. L-45 T-T-15 REFERENCES 1. 2. 3. 4. Gupta, S.C. and Kapoor, V.K., Fundamentals of Mathematical Statistics, Sultan Chand and Sons, New Delhi, 2001. Johnson, R.J., Miller & Freunds Probability and Statistical for Engineers, 6th Edition, PHI, 2002. Jay, L.Devore, Probability and Statistics for Engineering and Sciences, Thomson and Duxbury, Singapore, 2002. Dallas E Johnson, Applied Multivariate methods for data analysis, Thomson and Duxbury Press, 1998. Total = 60

PD1601

INTEGRATED PRODUCT AND PROCESS DEVELOPMENT I 3 1 0 100

OBJECTIVE To study about the successful product development strategies, product planning activities, specifications, various methods for concept selection and architecture planning. 1. INTRODUCTION 9

Characteristics of Successful Product Development-Who Designs and Develops Products-Duration and Costs of Product Development- Challenges of Product Development -Development Processes and Organizations-A Generic Development Process-Concept Development: The Front-End Process Adapting the Genetic Product Development Process- Product Development Process Flows-The AMF Development Process-Product Development Organizations-The AMF Organization 2. PRODUCT PLANNING 9

Product Planning Process- Identify Opportunities- Evaluating and Prioritizing ProjectsAllocating Resources and Timing- Pre-Project Planning-Reflect on the Results and the Process-Identifying Customer Needs- Raw Data from Customers- Interpreting Raw Data in Terms of Customer Needs-Organizing the Needs into a Hierarchy-Establishing the Relative Importance of the Needs-Reflecting on the Results and the Process 3. PRODUCT SPECIFICATIONS 9

What Are Specifications -When Are Specifications Established-Establishing Target Specifications-Setting the Final Specifications-Concept Generation-The Activity of Concept Generation-Clarify the Problem- Search Externally-Search Internally-Explore Systematically- Reflect on the Results and the Process 4. CONCEPT SELECTION 9

Concept Selection- Overview of Methodology-Concept Screening-Concept TestingDefine the Purpose of the Concept Test- Choose a Survey Population- Choose a Survey Format- Communicate the Concept- Measure Customer Response-Interpret the ResultsReflect on the Results and the Process 5. PRODUCT ARCHITECTURE 9

Product Architecture-Implications of the Architecture-Establishing the ArchitectureDelayed Differentiation-Platform Planning-Related System-Level Design Issues L : 45 T : 15 Total : 45

TEXT BOOK 1. Product Design and Development, Karl T.Ulrich and Steven D.Eppinger, McGraw Hill International Edns.1999 REFERENCE: 1. Concurrent Engg./Integrated Product Development. Kemnneth Crow, DRM Associates, 26/3,Via Olivera, Palos Verdes, CA 90274(310) 377-569,Workshop Book 2. Effective Product Design and Development, Stephen Rosenthal, Business One Orwin, Homewood, 1992,ISBN, 1-55623-603-4 3. Tool Design Integrated Methods for successful Product Engineering, Stuart Pugh, Addison Wesley Publishing,Neyourk,NY,1991, ISBN 0-202-41639-5 4. www.me.mit/2.7444

PD1602 CONCEPTS AND COMPUTER APPLICATIONS IN DESIGN 3 0 0 100 OBJECTIVE: To study the fundamentals of strength of materials, design of mechanical components, various geometric transformations, modeling techniques, visual realism methods and CAD software capabilities 1. INTRODUCTION 7

Tensile, Compressive and Shear stresses - Theory of bending, torsion and stresses Biaxial state of stress- Principal stresses and Principal planes 2. COMPUTER AIDED DESIGN OF MACHINE COMPONENTS 8

Design of mechanical components - Theories of failure Factor of Safety Fatigue strength - Solving design problems for Shafts, Gears, Springs and Belts using Auto-LISP /C 3. INTRODUCTION TO COMPUTER GRAPHICS 10

Output primitives (line, circle etc.) Algorithms 2D and 3D transformations Translation, Scaling, Rotation and Reflection etc.- Windowing Clipping. 4. MODELING AND VISUAL REALISM 10

Representation of the curves Continuity Requirements - Wire frame Surface Solid modeling Hidden line Surface Solid algorithms 5. ASSEMBLY AND CAPABILITIES OF CAD SOFTWARE 10

Mechanical assembly of parts Animation of mechanisms

- Data Exchange Mass property calculations

TOTAL : 45 TEXT BOOK 1. William .M. Newman and Robert .F. Sproull " Principle of Computer Graphics ", McGraw Hill Book Co. Singapore ,1989. 2. Donald Hearn and .M. Pauline Baker " Computer Graphics " Prentice Hall , Inc., 1992 REFERENCES: 1 Mikell .P. Groover and Emory .W. Zimmers Jr. " CAD/CAM Computer -- Aided Design and Manafacturing" Prentice Hall ,Inc., 1995. 2. Ibrahim Zeid " CAD/CAM -- Theory and Practice " - McGraw Hill , International Edititon , 1998.

PD1603 AIM

PRODUCT ENGINEERING TOOLS

3 0 0 100

To study about the tools required for various design activities, improvement methodologies and quality control charts and other standards. 1. TOOLS FOR CONCEPT DEVELOPMENT 9

Products division, Quality function Deployment, concept engineering Tools for Design Development: design failure mode and design analysis, Reliability prediction- Tools for Design Optimization: The Taguchi Loss Function, Optimizing Reliability- Tools for Design Verification: Reliability Testing, Measurement system Evaluation, Process Capability Evaluation. 2. TOOLS FOR PROCESS IMPROVEMENT 9

Process improvement methodologies, The Deming Cycle-FADE-Basic tools for process improvement: flow charts, run charts and control charts, check sheets, histograms, Pareto diagrams, Cause and Effect Diagrams-Scatter Diagrams-Other tools for process improvement: Kaizen Blitz, Poka-yoke (mistake proofing), process simulation-Engaging the work force in process improvement. 3. STATISTICAL PROCESS CONTROL 9

Quality control measurements-SPC Methodology- Control charts for variables dataSpecial Control charts for variables data- Control Charts for Attributes- Summary of control charts construction chart, np-charts,c & u charts Designing control charts:sampling,size,frequency-SPC,ISO 9000:2000, AND SIX SIGMA-Pre control.

4.

BENCHMARKING AND ESTABLISHING ENGINEERING SPECIFICATIONS

Benchmarking Approach Support tools for the benchmarking process: indented assembly cost analysis, form diagram, trend analysis- Setting product specifications: Basic, Advanced method. 5. PROJECT MANAGEMENT 9

Understanding and representing tasks: Tasks, charts- Baseline project planning Accelerating projects-project execution- Postmortem execution. TOTAL -45

TEXT BOOK: 1. Product Design & Development, KARL T. ULRICH, STEVEN D. EPPINGER, TATA McGRAW-HILL- 3rd Edition, 2003

REFERENCES: 1. Product Design Techniques in Reverse Engineering and New Product Development, KEVIN OTTO & KRISTIN WOOD, Pearson Education (LPE), 2001. The Management and control of Quality-6th edition-James R. Evens, William M Lindsay Pub:son south-western(www.swlearning.com)

2.

PD1604

METALS AND MANUFACTURING PROCESS

3 0 0 100

AIM

To study about various types of materials, manufacturing methods, tolerances in an industry and various case studies for optimization

1.

INTRODUCTION

Factors for mechanical, electrical and thermal properties Dimensional geometrical tolerances selection of materials 2. TYPES OF MATERIALS 10

Ferrous Ferrous Alloys, steel, stainless steel, etc. Non-ferrous, Aluminum, Copper, etc. Non ferrous alloys, Brass, Gun Metal, etc. Material Cost Cost usage ratio 3. MANUFACTURING METHODS 12

Metal extrusion, metal stamping, fine blanking, four slide metal parts, cold headed parts, extruded parts, tube and section bends, rolled formed parts, power metal parts forging electro forming parts specialized forming methods, turned parts, machined round holes, drilled parts, milled parts, planned shaped and slotted parts, screw threaded contoured and internal ground parts, centerless ground, electrical discharged, roller furnished parts, electro chemical and advanced machined parts. Sand cast, die cast, investment cast and other cast products. HERF Process Machined components conventional, nonconventional 4. ASSEMBLY OF COMPONENTS 10

Press fitting riveting screwing flanged connections - welded parts electric arc gas welding brazing soldering advanced techniques PCB 5. CASE STUDIES 6

Design for minimum cost, material, and process Total : 45 REFERENCES: 1. Mechanical Metallurgy, G.E. Dieter, McGraw Hill, 1987 2. Heat Treatment of Metals, B. Zakharove, Peace Publications., 1962

PD1605

DIGITAL PRODUCT DEVELOPMENT LAB-I

0 0 3 100

CAD Introduction. Sketcher Solid modeling Extrude, Revolve, Sweep, etc and Variational sweep, Loft ,etc Surface modeling Extrude, Sweep, Trim ..etc and Mesh of curves, Free form etc Feature manipulation Copy, Edit, Pattern, Suppress, History operations etc. Assembly-Constraints, Exploded Views, Interference check Drafting-Layouts, Standard & Sectional Views, Detailing & Plotting. Total-45 hr Equipments required CAD work stations 10 Nos CAD 3D Modelling software with assembly, Mechanism simulation and drafting modules : 10 Nos

DIGITAL PRODUCT DEVELOPMENT LAB-II

0 0 3 100

CNC Machines Features, Tooling CNC program simulation in FANUC/SINUMERIC systems. CAD/CAM connection & DNC link. Cutter path generation for Planar machining, Surface Machining, Cavity machining, Fixed & variable contour machining, Drilling,Turning, tool&die and mould machining Practical in Production CNC Machining & Turning Centres and Rapid Prototyping Machine Post processing & CNC code Generation for advanced machining.

Equipments required CAM Software for tool path generation for planer machining, contour machining, drilling, turning etc. & post processing modulus for different CNC controllers Medium production type CNC turning center with popular industrial type controller Medium production type CNC machining center with popular industrial type controller

10 Nos

You might also like

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Anna University, Chennai: Affiliated InstitutionsDocument36 pagesAnna University, Chennai: Affiliated InstitutionsAnonymous RCbfTbNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- M.E. Industrial Engineering SyllabusDocument46 pagesM.E. Industrial Engineering SyllabusJoswa CaxtonNo ratings yet

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsFrom EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNo ratings yet

- Engineering DesignDocument34 pagesEngineering DesignEmmanuel NicholasNo ratings yet

- PDD Syllabus Anna UniversityDocument41 pagesPDD Syllabus Anna UniversityVenkatakrishnan NatchiappanNo ratings yet

- Implementing the Stakeholder Based Goal-Question-Metric (Gqm) Measurement Model for Software ProjectsFrom EverandImplementing the Stakeholder Based Goal-Question-Metric (Gqm) Measurement Model for Software ProjectsNo ratings yet

- ME CAD SyllabusDocument50 pagesME CAD Syllabussubha_aeroNo ratings yet

- Product Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesNo ratings yet

- M.E. Computer Aided Design SyllabusDocument50 pagesM.E. Computer Aided Design SyllabusJoswa CaxtonNo ratings yet

- M.E. Mech (Prod Des & Devp)Document41 pagesM.E. Mech (Prod Des & Devp)Peter PushpanathanNo ratings yet

- From Project to Production: The Commonwealth and International Library: Social Administration, Training Economics, and Production DivisionFrom EverandFrom Project to Production: The Commonwealth and International Library: Social Administration, Training Economics, and Production DivisionNo ratings yet

- M.E. Quality Engineering and Management SyllabusDocument39 pagesM.E. Quality Engineering and Management SyllabusJoswa CaxtonNo ratings yet

- Six Sigma Green Belt Certification Project: Identification, Implementation and EvaluationFrom EverandSix Sigma Green Belt Certification Project: Identification, Implementation and EvaluationNo ratings yet

- M.E. Engineering DesignDocument47 pagesM.E. Engineering DesignSms RajaNo ratings yet

- Software Quality Assurance: In Large Scale and Complex Software-intensive SystemsFrom EverandSoftware Quality Assurance: In Large Scale and Complex Software-intensive SystemsRating: 5 out of 5 stars5/5 (1)

- Mtech Se July2011 PDFDocument50 pagesMtech Se July2011 PDFsavitrinaikNo ratings yet

- Sem 2Document11 pagesSem 2jtsrinivasdownNo ratings yet

- ME LM SyllabusDocument5 pagesME LM SyllabusSiddharth Narayanan ChidambareswaranNo ratings yet

- Anna University EDDocument48 pagesAnna University EDSivaji SivaNo ratings yet

- Ii To Iv Semesters (Full Time) Curriculum and SyllabusDocument22 pagesIi To Iv Semesters (Full Time) Curriculum and SyllabusKarthik Sp0% (1)

- Quality ConceptDocument2 pagesQuality ConceptSasiKumar PetchiappanNo ratings yet

- Product Design Engineering - II SyllabusDocument3 pagesProduct Design Engineering - II SyllabusSudeep UpadhyeNo ratings yet

- MTech PLM 2011Document15 pagesMTech PLM 2011Ubaid BahussainNo ratings yet

- Product Lifecycle ManagementDocument38 pagesProduct Lifecycle ManagementManjunatha0% (1)

- 3rd Sem SyllabusDocument3 pages3rd Sem SyllabusJai GaneshNo ratings yet

- PPC SYLLABUSDocument2 pagesPPC SYLLABUSddeepak123No ratings yet

- Ppce SyllabusDocument3 pagesPpce SyllabusVpr NaturalsNo ratings yet

- M.e.,cim SyllabusDocument44 pagesM.e.,cim SyllabusSiva PrakashNo ratings yet

- 7th SemDocument17 pages7th SemShankar MukalNo ratings yet

- Industrial Safety EngineeringDocument9 pagesIndustrial Safety EngineeringDurai KannanNo ratings yet

- CIM Course PlanDocument8 pagesCIM Course PlanKamal Vijay Ram R SNo ratings yet

- Mba611 Technology Management 3 0 0 3Document3 pagesMba611 Technology Management 3 0 0 3Selva Shri NathNo ratings yet

- Anna University of Technology, Coimbatore B.E - (Electronics and Communication Engineering) Semester V Code No-Course Title L T P M C TheoryDocument14 pagesAnna University of Technology, Coimbatore B.E - (Electronics and Communication Engineering) Semester V Code No-Course Title L T P M C TheoryragulsukumarNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial Engineeringnandan144No ratings yet

- 4th Year - II Sem - MechDocument10 pages4th Year - II Sem - MechaareachyuthNo ratings yet

- FALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusDocument3 pagesFALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusJawa freakNo ratings yet

- ME404 Industrial EngineeringDocument2 pagesME404 Industrial EngineeringRam RenNo ratings yet

- ME1001 Unconventional Machining Process 3 0 0 100: (Common To Mechanical and Production)Document22 pagesME1001 Unconventional Machining Process 3 0 0 100: (Common To Mechanical and Production)PatNo ratings yet

- Pom (Me403) 1Document6 pagesPom (Me403) 1Gajanan Shankarrao PatangeNo ratings yet

- Modified Scheme N Syllabus 6 SemDocument17 pagesModified Scheme N Syllabus 6 SemAmith ModiNo ratings yet

- Ie6605 Production Planning and Control L T P C 3 0 0 3Document1 pageIe6605 Production Planning and Control L T P C 3 0 0 3kumar km0% (1)

- Syllabus - Lean SixsigmaDocument2 pagesSyllabus - Lean SixsigmajvanandhNo ratings yet

- University Departments: Anna University Chennai:: Chennai 600 025Document42 pagesUniversity Departments: Anna University Chennai:: Chennai 600 025Jeyaram KumarNo ratings yet

- Pom IeDocument5 pagesPom IepmagrawalNo ratings yet

- Puter Integrated Manufacturing SyllabusDocument41 pagesPuter Integrated Manufacturing SyllabusJoswa CaxtonNo ratings yet

- PPC SyllabusqDocument1 pagePPC SyllabusqKannan MuthusamyNo ratings yet

- Mtech Iem 2013Document12 pagesMtech Iem 2013Jaykrishnan GopalakrishnanNo ratings yet

- IP SyllabusDocument2 pagesIP SyllabusSantosh SNo ratings yet

- Industrial Engineering and Management-PrintDocument55 pagesIndustrial Engineering and Management-PrintekstsalembaNo ratings yet

- Engineering Design SyllabusDocument49 pagesEngineering Design SyllabusanandandmeenaNo ratings yet

- Ie 6605 - PPC - SyllabusDocument2 pagesIe 6605 - PPC - SyllabusmuthusNo ratings yet

- Ie6605 Production Planning and Control L T P C 3 0 0 3Document2 pagesIe6605 Production Planning and Control L T P C 3 0 0 3Sathrudhan ChoudharyNo ratings yet

- Manufacturing Management L T P C 3 0 0 3Document2 pagesManufacturing Management L T P C 3 0 0 3IyappanNo ratings yet

- 111 SemDocument5 pages111 SempraveenaprabhuNo ratings yet

- Design of Hydraulic and Pneumatic SystemsDocument2 pagesDesign of Hydraulic and Pneumatic SystemsGokul raj SNo ratings yet

- Shri G. S. Institute of Technology and ScienceDocument32 pagesShri G. S. Institute of Technology and Scienceabhaymvyas1144No ratings yet

- Hydro Blasting StandardsDocument16 pagesHydro Blasting Standardsgorankajganic100% (1)

- The Manual For The Packaging MachineDocument14 pagesThe Manual For The Packaging MachineSunday Paul100% (2)

- Chapter 10 - Precast Elements: WJ Martin 10.1 ScopeDocument12 pagesChapter 10 - Precast Elements: WJ Martin 10.1 ScopeChinwendu Cno Onwukwe100% (2)

- Miranda PLDocument48 pagesMiranda PLGOYMA IMPEXNo ratings yet

- Chapter 9 - Part 1Document63 pagesChapter 9 - Part 1muhammad izzul100% (1)

- HTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Document4 pagesHTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Riddhi DasNo ratings yet

- Impact TestDocument7 pagesImpact TestChukkaNo ratings yet

- PP Pulprecycled Thickening Micrascreen e PDFDocument2 pagesPP Pulprecycled Thickening Micrascreen e PDFAkhmad ZaenudinNo ratings yet

- Electric Conductivity (EC) MeterDocument3 pagesElectric Conductivity (EC) MeterThanh NguyênNo ratings yet

- Residual Stress in Induction HardeningDocument2 pagesResidual Stress in Induction HardeningRajesh MalikNo ratings yet

- Hufcor 632 Paired F4149FDocument6 pagesHufcor 632 Paired F4149Fdoody.dpujaNo ratings yet

- Craftsman Tractor ManualDocument72 pagesCraftsman Tractor Manualbjhoxie106No ratings yet

- KT62 ManualDocument30 pagesKT62 ManualandyjwatsonNo ratings yet

- EL2 P SRelaysDocument75 pagesEL2 P SRelaysAnonymous vMzbUJNo ratings yet

- DEAERATORDocument26 pagesDEAERATORSai Swaroop100% (2)

- Dryers in Word FileDocument5 pagesDryers in Word FileHaroon RahimNo ratings yet

- Electrochemistry SimulationDocument8 pagesElectrochemistry Simulationfaridbaik89No ratings yet

- 4 Way Reversing Valve Series SHF L Data PDFDocument3 pages4 Way Reversing Valve Series SHF L Data PDFDharani PathyNo ratings yet

- Klüberlub NH1 11-222 EN enDocument2 pagesKlüberlub NH1 11-222 EN enKamila AriasNo ratings yet

- Bathtub: What Are They?Document5 pagesBathtub: What Are They?John Paul DenajibaNo ratings yet

- CH 02Document7 pagesCH 02hedayatullahNo ratings yet

- WEG Weg Automation Reference Codes Controls 50058173 Quick Guide EnglishDocument24 pagesWEG Weg Automation Reference Codes Controls 50058173 Quick Guide EnglishSergio Ricardo IbañezNo ratings yet

- Types of WireDocument2 pagesTypes of WireMICHAELNo ratings yet

- Sprinter 2.7 Liter Diesel Fuel Injection DiagnosisSprinterDocument150 pagesSprinter 2.7 Liter Diesel Fuel Injection DiagnosisSprinterMiguel Ángel Gil Pérez100% (13)

- Step 1: Making The LED Lights Dance To Your Music: HeadphoneDocument7 pagesStep 1: Making The LED Lights Dance To Your Music: HeadphoneNguyen LongNo ratings yet

- CG 2015193 01 B 1 SprinklersDocument2 pagesCG 2015193 01 B 1 SprinklersIskandar HasibuanNo ratings yet

- MS SDS SR Repo Ort: Name of S Model SampleDocument7 pagesMS SDS SR Repo Ort: Name of S Model SampleCamilo WispNo ratings yet

- GH 961Document1 pageGH 961ÄhmêdÄBdulhåqNo ratings yet

- MCM CatalogDocument71 pagesMCM Catalogjerji_jerjiNo ratings yet

- Modern Planter Box Plans, Copyright Crafted Workshop 2018Document11 pagesModern Planter Box Plans, Copyright Crafted Workshop 2018robins115350100% (2)