Professional Documents

Culture Documents

Material Handling Equipment: Navigation Search

Uploaded by

Edwin RajkumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Handling Equipment: Navigation Search

Uploaded by

Edwin RajkumarCopyright:

Available Formats

Material handling equipment

From Wikipedia

Jump to: navigation, search

Industrial mezzanine.

Selective pallet rack is an example of storage and handling equipment.

Forklifts are the most common type of industrial truck.

A Miniload AS/RS - an example of an engineered system

Industrial KUKA Robots for palletizing - an example of an engineered system Material handling equipment is all equipment that relates to the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption and disposal. Material handling equipment is the mechanical equipment involved in the complete system[1]. Material handling equipment is generally separated into four main categories: storage and handling equipment, engineered systems, industrial trucks, and bulk material handling.

Contents

[hide]

1 Ways in which material handling equipment can improve efficiency 2 Types of material handling equipment o 2.1 Storage and handling equipment o 2.2 Engineered systems o 2.3 Industrial trucks o 2.4 Bulk material handling 3 See also 4 References 5 External links

[edit] Ways in which material handling equipment can improve efficiency

Material handling equipment is used to increase throughput, control costs, and maximize productivity. There are several ways to determine if the material handling equipment is achieving peak efficiency. These include capturing all relevant data related to the warehouses operation (such as SKUs), measuring how many times an item is touched from the time it is ordered until it leaves the building, making sure you are using the proper picking technology, and keeping system downtime to a minimum.

[edit] Types of material handling equipment

[edit] Storage and handling equipment

Storage and handling equipment is a category within the material handling industry. The equipment that falls under this description is usually non-automated storage equipment. Products such as Pallet rack, shelving, carts, etc. belong to storage and handling. Many of these products are often referred to as "catalog" items because they generally have globally accepted standards and are often sold as stock materials out of Material handling catalogs.

[edit] Engineered systems

Engineered systems are typically custom engineered material handling systems. Conveyors, Handling Robots, AS/RS, AGV and most other automated material handling systems fall into this category. Engineered systems are often a combination of products integrated to one system. Many distribution centers will optimize storage and picking by utilizing engineered systems such as pick modules and sortation systems. Equipment and utensils used for processing or otherwise handling edible product or ingredients must be of such material and construction to facilitate thorough cleaning and to ensure that their use will not cause the adulteration of product during processing, handling, or storage. Equipment and utensils must be maintained in sanitary condition so as not to adulterate product.

[edit] Industrial trucks

Industrial trucks usually refer to operator driven motorized warehouse vehicles, powered manually, by gasoline, propane or electrically[2]. Industrial trucks assist the material handling system with versatility; they can go where engineered systems cannot. Forklift trucks are the most common example of industrial trucks but certainly aren't the extent of the category. Tow tractors and stock chasers are additional examples of industrial trucks.

[edit] Bulk material handling

Bulk material handling equipment is used to move and store bulk materials such as ore, liquids, and cereals. This equipment is often seen on farms, mines, shipyards and refineries. This category is also explained in Bulk material handling.

[edit] See also

You might also like

- Order ProcessingDocument5 pagesOrder ProcessingrsiyodiaNo ratings yet

- Material Handling EquipmentDocument3 pagesMaterial Handling EquipmentHari PrasadNo ratings yet

- Ergonomics AssignmentDocument13 pagesErgonomics AssignmentDame TolossaNo ratings yet

- Material Handling Equipment Is Equipment That Relate To The MovementDocument4 pagesMaterial Handling Equipment Is Equipment That Relate To The MovementResh MaNo ratings yet

- Packaging: Packaging Is The Science, Art and Technology ofDocument18 pagesPackaging: Packaging Is The Science, Art and Technology ofhsagarz1No ratings yet

- Topic IVDocument11 pagesTopic IVJasmine KariukiNo ratings yet

- Material Handling: Week 1Document37 pagesMaterial Handling: Week 1Norhidayah N ElyasNo ratings yet

- Etc Project FinalDocument11 pagesEtc Project FinalGroot AvengerNo ratings yet

- Chapter5 Detroit AutomationDocument33 pagesChapter5 Detroit AutomationGoogle UserNo ratings yet

- Emerging Trends of Material Management in Agricutural SectorDocument3 pagesEmerging Trends of Material Management in Agricutural SectorHarish ChowdaryNo ratings yet

- Material Handling Full Notes PDFDocument320 pagesMaterial Handling Full Notes PDFRamVijayVtmrNo ratings yet

- Materials HandlingDocument12 pagesMaterials HandlingdokrisztianNo ratings yet

- Material Handling by Dr.-Ing. Daniel KitawDocument225 pagesMaterial Handling by Dr.-Ing. Daniel Kitawahmed jemal100% (2)

- Material Handling: Material Handling Involves Short-Distance Movement Within The Confines of A Building orDocument7 pagesMaterial Handling: Material Handling Involves Short-Distance Movement Within The Confines of A Building orNidhi EnterprisesNo ratings yet

- Material HandlingDocument28 pagesMaterial HandlingATAIYERO ADEKUNLENo ratings yet

- 1.1 Material Handling IndustryDocument18 pages1.1 Material Handling IndustryNeha PatilNo ratings yet

- Assignment 4Document8 pagesAssignment 4Miracle -No ratings yet

- Assignment 4Document8 pagesAssignment 4Miracle -No ratings yet

- Material Handling (Full Notes)Document320 pagesMaterial Handling (Full Notes)Kailas Sree Chandran90% (52)

- Material Handling Equipment (Meng-4251)Document19 pagesMaterial Handling Equipment (Meng-4251)broNo ratings yet

- Adv ManDocument1 pageAdv Mansupriya-nair-561No ratings yet

- Material Handling SystemsDocument56 pagesMaterial Handling SystemsSuresh KumarNo ratings yet

- 1 Material Handling and Identification TechnologiesDocument75 pages1 Material Handling and Identification TechnologiesPavan Teja100% (1)

- Material Handling EquipmentDocument7 pagesMaterial Handling EquipmentT ShanmugavelNo ratings yet

- Material HandlingDocument24 pagesMaterial HandlingMohammed AhmedNo ratings yet

- 137 Introduction To Materials Handling Sidphartha Ray Edisi 1 2008Document150 pages137 Introduction To Materials Handling Sidphartha Ray Edisi 1 2008JyNo ratings yet

- Introduction To Materials Handling PDFDocument8 pagesIntroduction To Materials Handling PDFhijzain75% (4)

- Logistic Question 1Document1 pageLogistic Question 1Smita SharmaNo ratings yet

- Types of Material Handling EquipmentDocument7 pagesTypes of Material Handling EquipmentWilly K. Ng'etichNo ratings yet

- Warehousing ElmerDocument107 pagesWarehousing ElmerJolina LuceroNo ratings yet

- Fuck UDocument3 pagesFuck UJoseph WongNo ratings yet

- Chapter 1. Material Handling EquipmentDocument45 pagesChapter 1. Material Handling EquipmentFedho CherinetNo ratings yet

- Research The Five Major Categories of Material Handling Equipments (Handoc R.)Document5 pagesResearch The Five Major Categories of Material Handling Equipments (Handoc R.)Rechelle Ann HandocNo ratings yet

- Materials Handling Chapter 1 and 2Document9 pagesMaterials Handling Chapter 1 and 2Edel Quinn Madali100% (1)

- Material HandlingDocument4 pagesMaterial HandlingSaravanan GNo ratings yet

- Cycle Time Calculation-Unit - 8 - Material - Transport - Systems PDFDocument22 pagesCycle Time Calculation-Unit - 8 - Material - Transport - Systems PDFzainikamal1975100% (1)

- Automation in Manufacturing 301Document57 pagesAutomation in Manufacturing 301MsNo ratings yet

- Report: Material Handling SystemDocument3 pagesReport: Material Handling SystemAmad ShaikhNo ratings yet

- Materials HandlingDocument6 pagesMaterials HandlingRose LopezNo ratings yet

- Chapter Two WarehouseDocument16 pagesChapter Two WarehouseToyeebNo ratings yet

- IIA - Module 3Document65 pagesIIA - Module 3Achsah K VijuNo ratings yet

- UNIT 1 - Introduction To Material Handling EquipmentsDocument20 pagesUNIT 1 - Introduction To Material Handling EquipmentsAdugna GosaNo ratings yet

- Abe 214 Lecture NoteDocument46 pagesAbe 214 Lecture Noteemmanueladah147No ratings yet

- III I Material Handling (OE)Document109 pagesIII I Material Handling (OE)RINKAL LOUNGANINo ratings yet

- Handling System PDFDocument7 pagesHandling System PDFIsihaka SuleimanNo ratings yet

- Material Handling SystemDocument2 pagesMaterial Handling SystemsureshNo ratings yet

- Unit 5 Design of CranesDocument51 pagesUnit 5 Design of CranesHarshad AherNo ratings yet

- Chapter 6Document36 pagesChapter 6Gaurav SinghNo ratings yet

- Material HandlingDocument24 pagesMaterial HandlingShivkarVishalNo ratings yet

- 1 - Basics of MHEsDocument48 pages1 - Basics of MHEsMengie ManNo ratings yet

- Material HandlingDocument26 pagesMaterial HandlingRohit AroraNo ratings yet

- WarehouseDocument6 pagesWarehouseHani AmirNo ratings yet

- Material Handling & PackagingDocument20 pagesMaterial Handling & PackagingHarshitha ReddyNo ratings yet

- Material Handling SystemsDocument30 pagesMaterial Handling SystemsSaadShees100% (1)

- Logistics Notes 2Document28 pagesLogistics Notes 2Radha Raman SharmaNo ratings yet

- DistmnDocument73 pagesDistmnJuvie Mangana Baguhin TadlipNo ratings yet

- DHMEDocument8 pagesDHMEDhrumil PatelNo ratings yet

- Automated Material Handling SystemDocument6 pagesAutomated Material Handling SystemSuraj Prakash100% (1)

- Packing ProcedureDocument24 pagesPacking ProcedureAditya NugrahaNo ratings yet

- Quality System ProcduresDocument534 pagesQuality System ProcduresJunaid Siddiqui50% (2)

- Teejan Equipment LLC PDFDocument48 pagesTeejan Equipment LLC PDFTeejan Equipment LLCNo ratings yet

- RA 08 For Installation of Steel Structure Platform For Air Coolers & AHU...Document4 pagesRA 08 For Installation of Steel Structure Platform For Air Coolers & AHU...venu gopalNo ratings yet

- About TVSDocument39 pagesAbout TVSVinodh Kumar LNo ratings yet

- NR040DA (A295) S/N A295N03604G Parts ManualDocument290 pagesNR040DA (A295) S/N A295N03604G Parts ManualCarlos Gomez86% (7)

- MMHE Lab 1Document9 pagesMMHE Lab 1Mohammad TooneerNo ratings yet

- Intrans MM WBRDocument65 pagesIntrans MM WBRskhNo ratings yet

- UNSPSC Punchout USDocument355 pagesUNSPSC Punchout USmanikdarshanNo ratings yet

- An Introduction To Material Handling Equipment SelectionDocument39 pagesAn Introduction To Material Handling Equipment Selectioncancer24No ratings yet

- Material Handling Check SheetDocument3 pagesMaterial Handling Check SheetJulius Mark CerrudoNo ratings yet

- EEC HiReach WebDocument16 pagesEEC HiReach WebcesarmroldanNo ratings yet

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocument2 pagesSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNo ratings yet

- Material Handling System and ASRS PDFDocument13 pagesMaterial Handling System and ASRS PDFHarsh PatelNo ratings yet

- KOCH Material HandlingDocument16 pagesKOCH Material HandlingHubert50% (2)

- FMS Environmental Rounds Checklist C Priorities, GenericDocument3 pagesFMS Environmental Rounds Checklist C Priorities, Generichany winihastutiNo ratings yet

- Warehouse Management Final Project ReportDocument23 pagesWarehouse Management Final Project ReportOlive100% (2)

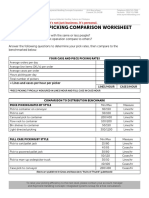

- Picking Comparison WorksheetDocument1 pagePicking Comparison WorksheetgaloNo ratings yet

- Lecture One: Basics of Materials Handling EquipmentDocument47 pagesLecture One: Basics of Materials Handling EquipmentPramod GowdaNo ratings yet

- Library Versapallet Robcad ComponentDocument27 pagesLibrary Versapallet Robcad ComponentJean RaminhoNo ratings yet

- Operationmanagementproblems 131216134550 Phpapp02Document86 pagesOperationmanagementproblems 131216134550 Phpapp02Mai LinhNo ratings yet

- QueimaDocument28 pagesQueimaALCIMAR ANGELO CONSALTER MENo ratings yet

- European University of Bangladesh - IPE 410 Lab ModuleDocument35 pagesEuropean University of Bangladesh - IPE 410 Lab ModuleIrfan KhanNo ratings yet

- Benchmarking ShipyardsDocument62 pagesBenchmarking ShipyardsJim GrayNo ratings yet

- Automated Material Handling and StorageDocument28 pagesAutomated Material Handling and StoragerobertharrisonNo ratings yet

- Brosur Overhead CraneDocument12 pagesBrosur Overhead CraneridwanmuharamNo ratings yet

- Material Handling PresentationDocument71 pagesMaterial Handling Presentationegy pure100% (1)

- A. Pendahuluan: Prosiding Teknik PertambanganDocument9 pagesA. Pendahuluan: Prosiding Teknik PertambanganarmadityaNo ratings yet

- Claudius Peters Stockyard Brochure en PDFDocument8 pagesClaudius Peters Stockyard Brochure en PDFgustavoNo ratings yet

- Automated Guided VehiclesDocument22 pagesAutomated Guided VehiclessurajNo ratings yet

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneFrom EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneRating: 4.5 out of 5 stars4.5/5 (5)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet