Professional Documents

Culture Documents

GEMS Use of Gems Information Management Mulabisna

Uploaded by

Gustavo CarvalhoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GEMS Use of Gems Information Management Mulabisna

Uploaded by

Gustavo CarvalhoCopyright:

Available Formats

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL Jeffrey Mulabisana De Beers Group, Venetia Mine

SYNOPSIS Venetia mine is an open pit diamond mine located in the Limpopo Province, close to borders of Zimbabwe and Botswana. The mine has about 15 kimberlite intrusions of which only two are currently mined. The mine has been using and implementing GEMS for the past few years in an effort to integrate data to be manipulated and utilized more efficiently. Commencing with a drilling strategy that will enable the Geologist and Geotechnical Engineers to achieve the most optimal results. GEMS is also used to provide an updated ore reserve model for end-users to plan and design the mining process more efficiently. Gems provided a platform for better information management. At present, the ore reserve model is used to plan new drill sites for optimal information retrieval, updating the model with the exploration data as well as blast hole information to create a new updated and accurate ore reserve model. Data is also manipulated in GEMS to determine the internal waste component of kimberlite that may contribute to mining dilution. Both the ore model and dilution model contributes considerably to the planning and mining processes of the mine. The systems and data that the Geotechnical Engineer uses, are integrated into GEMS to provide end users with information like rockmass ratings, fracture frequency and blastability indexes. The end result is block model being created and updated to view different features of the rockmass.

INTRODUCTION Venetia is located in the northern part of the Limpopo Province, 30 kilometers south of where the Botswana, Zimbabwe and South African borders meet. The mine is approximately 80 km west of the town Musina and 37 km north east of Alldays.

Venetia Mine has integrated most of its mining systems in the past few years. GEMS (Gemcom Enterprise Mining System) has been a key software in integrating Geological,

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL - MULABISANA

Geotechnical, Survey and other mining data. GEMS has provided the platform for better information management. Thousands of data points can now easily be plotted to produce a block model that becomes useful information for interpretation. This paper is aimed at giving the reader a preview of some of the uses of GEMS as an information management tool at Venetia Mine.

GEOLOGY Ore reserve drilling and delineation In the last few years Gems has been used extensively to design diamond drill holes at Venetia Mine. Polylines of the existing geological model are used to identify areas that need to be drilled in GEMS. Trial holes are then designed to intersect the required geological features at depth. Trial holes are displayed in both 3D and 2D views to see if they are intersecting the required geological features. Changes can be made to hole azimuth, dip, and hole position to design an optimal drillhole. The optimal hole position, azimuth and dip are recorded and used to position the drillhole in the field. Figure 1 below shows some of holes designed in GEMS.

Figure 1.

Section of Venetia Mine showing some drilled holes and planned holes for future drilling.

Once a hole is drilled and logged, the information is captured into a GEMS central database. The information captured from the drillhole is plotted in GEMS for interpretation. The ability to view the data in 2D and in 3D makes it easier to interpret the data. The attributes that one can link to the data are also quite handy for further interpretation of drillhole information. See Figure 2 below for an example of the information one can extract from a database using GEMS software.

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL - MULABISANA

Figure 2.

Drillhole with different rock units depicted in different colours to show the local stratigraphy.

The information deduced from the drillholes is used to delineate kimberlite contacts and other lithological units. Geological block models are created from the identified lithological units. These block models are also updated regularly using additional drillhole information. Ore Reserve Model Update The ore reserve model, i.e. kimberlite geological model, is updated on a monthly basis in GEMS. During the mining process, blast holes are logged in the field and updated in GEMS. Blast holes positions are merged into GEMS through the Survey System. The geologist update geological information for each blast hole in Gems. Figure 3 shows a blast pattern with geological information associated with each blast hole. The information from blast holes is used in GEMS to revise kimberlite contacts. Contacts are updated by revising polylines positions. Updated polylines are then used to create solids for the block model.

Figure 3.

Blast holes with their corresponding geological information.

Newly created solids are used by Surveyors to do their depletions. The integration of the Survey and Geology Systems has opened an opportunity for the mine to reconcile monthly

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL - MULABISANA

volume depletions more efficient. The accessibility of the latest geological model has a farreaching impact on the mine planning process. The integration of Survey and Geological Systems has not only opened the opportunity for the mine to reconcile monthly volume depletions more efficiently, but also provided the short-term planning process with valuable information. Both the Short-term Planner and Blasting Engineer need the most updated and accurate model to provide the miners with an achievable plan to conform to long-term budget targets. Selective blasting is one important and value adding process at the mine. To achieve this, the Blasting Engineer wants to avoid blasting waste and ore together in a single blast. The latest geological model is used to design the blast outlines considering kimberlite/waste contacts that will minimize mining dilutions and maximize grade. He also considers internal mining dilution and blastability indexes (next section) for optimal blast designs.

Pit Mapping GEMS is also used in pit mapping. Previous maps have been scanned and integrated into GEMS. This makes it easier for using this information together with other mining information etc. The latest mapping techniques in GEMS gives us the opportunity to use point data to digitize maps on the screen using polygons. Attributes of each polygon are entered into the system and basically describe the rock type and its structure. This system is still in its infant stage but it has shown a lot of potential for what we can call mapping information made easy.

Dilution Model The ability to integrate information into GEMS from different sources makes it easier to make better geological interpretations. Drillhole and blast hole information was used to create a dilution model for Venetia Mine K001 kimberlite. Figure 4 (a) shows waste rock embedded in the kimberlite. To pick up features of interest in drillholes, display profiles were created to pick up those features only (Fig. 4b). It was easier to pick areas with high concentrations of waste. Different profiles can be used to extract different information from the same set of drillholes. The dilution model was used successfully for better mine planning and geological ore quality control.

(a)

(b)

Figure 4.

(a) A block of country rock within kimberlite, (b) Core holes in GEMS discriminating kimberlite from waste.

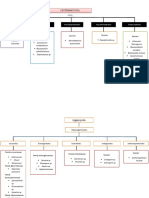

GEOTECHNICAL ENGINEERING There are a number of systems and other data sources for Geotechnical Engineering use. This data has been integrated into GEMS to produce useful information for Geotech purposes. Drill core, blast hole (Aquila System), Joint sampling, Bench Face Mapping are

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL - MULABISANA

main source of Geotechnical data. Figure 6 shows a schematic representation of Geotechnical Engineering data flow.

Information Management

Dril l core Logging Int erpret at ion and A nal ysis

Information Management

Face Mapping and J oint Sampl ing Rock Propert y Test s Sl ope Monit oring

GEMS Dril l ing W orkspace

Geot echnical Dat abase ( Access)

GEMS Dat abase ( SQL)

Fail ure Document at ion Fail ure Back- anal ysis Post - bl ast Face A nal ysis

Geot echnical Dat abase

Aut omat ed RMR cal cul at ions for Core Logging and Face Mapping

Model l ing and Design Processes

(a) Figure 5:

(b)

(a & b). Schematic representation of Geotechnical Information management system.

Drill core, face mapping and joint sampling information are entered into GEMS database drilling workspace. Face mapping and joint sampling data is interpreted before entered into the database. Whilst the information is in GEMS it is then used to create Geotechnical Block models. Block models are used for designing purposes. Rock Property Tests, Slope Monitoring, Failure Documentation, Failure Back-analysis, and Post-blast Face Analysis data is entered into a Geotechnical database, a Microsoft Access database. After the data is entered into the Geotechnical database, automated calculations are done and information like rockmass ratings (RMR) for core logging and face mapping are fed into GEMS database. Block models are also created from the data integrated into Gems Database. Block models are used for information interpretation. Block Models are created to view different features of the rockmass like blastibility, rock strength, Fracture frequency etc. (Fig. 6).

Figure 6:

Fracture frequency block model.

Block models created in GEMS are used to provide valuable information for risk management and mine design. GEMS has become a very useful information management tool that reduces all the unwanted small tasks of data management and provides required information at a ver short space of time.

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL - MULABISANA

CONCLUSION GEMS has been used creatively at Venetia Mine to integrate lots of data and to produce valuable information for both Geological and Geotechnical engineering and down the line end users (the mine planners). In the same time more information becomes available for the first end users like a short-term plan and blast outlines that helps communication between the different sections on the mine. While there is a lot of potential to do more with the system, it has at this stage been used to obtain very useful information. The importance of adding value to the overall mining process must never be underestimated.

THE USE OF GEMS AS AN INFORMATION MANAGEMENT TOOL - MULABISANA

You might also like

- Life-Of-Mine Process Simulation From Drill Holes To Net Present ValueDocument5 pagesLife-Of-Mine Process Simulation From Drill Holes To Net Present ValueworqueraNo ratings yet

- BetterDocument5 pagesBetterIfan AzizNo ratings yet

- A Topologically Based Framework For 3-D Basin Modeling: Ulisses T. MelloDocument15 pagesA Topologically Based Framework For 3-D Basin Modeling: Ulisses T. MelloThomas AyeniNo ratings yet

- Spe 193066 MsDocument14 pagesSpe 193066 MsFät MãNo ratings yet

- Computer Applications in Mining IndustryDocument54 pagesComputer Applications in Mining IndustryAudrey RobinsonNo ratings yet

- 80 Geological Geomechanical Modeling MarchesiDocument8 pages80 Geological Geomechanical Modeling MarchesiVinicius NavesNo ratings yet

- Sibiu 2013 U.P. Final EnglishDocument4 pagesSibiu 2013 U.P. Final EnglishlucianlupudNo ratings yet

- 097-116 Little PDFDocument20 pages097-116 Little PDFgia26No ratings yet

- Application of Geostatistics For Reservoir Characterization - Accomplishments and ChallengesDocument5 pagesApplication of Geostatistics For Reservoir Characterization - Accomplishments and ChallengesBirzhan AlimbekovNo ratings yet

- Major Synopsis Report 18MN002162Document14 pagesMajor Synopsis Report 18MN002162Tanish lasodNo ratings yet

- In The: Mineralized Zones in MinesightDocument3 pagesIn The: Mineralized Zones in MinesightKenny CasillaNo ratings yet

- SPE-163690-MS Synthetic, Geomechanical Logs For Marcellus ShaleDocument16 pagesSPE-163690-MS Synthetic, Geomechanical Logs For Marcellus ShalediditkusumaNo ratings yet

- A New Mine Planning Tool For Sub Level Caving Mines: White PaperDocument18 pagesA New Mine Planning Tool For Sub Level Caving Mines: White PaperacadNo ratings yet

- ISCSM 2018 KapageridisI - Etal.Document17 pagesISCSM 2018 KapageridisI - Etal.Sondang BerlianNo ratings yet

- Modelling Geological SubsurfacesDocument8 pagesModelling Geological SubsurfacesBenjamin Sanchez MaldonadoNo ratings yet

- Multidisciplinary and Integrated Methodology For Deepwater Thin Bed Reservoirs CharacterizationDocument16 pagesMultidisciplinary and Integrated Methodology For Deepwater Thin Bed Reservoirs CharacterizationDody Pratama GintingNo ratings yet

- GEMSDocument4 pagesGEMSCristian ArayaNo ratings yet

- 2019 Jan MiningDocument5 pages2019 Jan MiningmakksNo ratings yet

- SPE-56948 - Solving Sanding Problems Using A Sand Production Management System. Case HistoriesDocument11 pagesSPE-56948 - Solving Sanding Problems Using A Sand Production Management System. Case HistoriesAl FarrNo ratings yet

- 117-124 PoropatDocument8 pages117-124 PoropatDavid Fernando CalozumaNo ratings yet

- Mining Magazine - Design For LifeDocument8 pagesMining Magazine - Design For LifepaulogmelloNo ratings yet

- Gis in GeotechDocument4 pagesGis in GeotechmechenggsNo ratings yet

- Underground Mine Planning: Stope Layout Optimisation Under Grade Uncertainty Using Genetic AlgorithmsDocument19 pagesUnderground Mine Planning: Stope Layout Optimisation Under Grade Uncertainty Using Genetic AlgorithmsCecilia Obregón RiveraNo ratings yet

- Boisvert 2008Document12 pagesBoisvert 2008张程No ratings yet

- Drilling Grid Analysis For Defining Open-Pit and Underground Mineral Resource Classification Through Production DataDocument16 pagesDrilling Grid Analysis For Defining Open-Pit and Underground Mineral Resource Classification Through Production DatatikroumineNo ratings yet

- Access Layout Optimisation For Underground MinesDocument11 pagesAccess Layout Optimisation For Underground MinesWalter Cesar Loli MoralesNo ratings yet

- SGAGlasgow 2019 PDFDocument5 pagesSGAGlasgow 2019 PDFDaniel PachecoNo ratings yet

- Paper Basin LlanoDocument12 pagesPaper Basin LlanojimmymorelosNo ratings yet

- 10 1 1 113 3161simulation PDFDocument14 pages10 1 1 113 3161simulation PDFJesus SalamancaNo ratings yet

- Determination of Optimum Drawpoint Layout in Block Caving Using Sequential Gaussian SimulationDocument12 pagesDetermination of Optimum Drawpoint Layout in Block Caving Using Sequential Gaussian SimulationDiego Ignacio VelizNo ratings yet

- ISEE 201999 Cyprus SierritaDocument14 pagesISEE 201999 Cyprus SierritaGer Man Exe QuielNo ratings yet

- Minex Software: 1. Horizon - GeologyDocument11 pagesMinex Software: 1. Horizon - GeologyFerrySsnNo ratings yet

- MineSight For Geological ModelingDocument13 pagesMineSight For Geological ModelingToperAsullgrana50% (2)

- Paper IMCET2005 - Computer Aided Evaluation of A Magnesite Ore BodyDocument6 pagesPaper IMCET2005 - Computer Aided Evaluation of A Magnesite Ore BodyHank GreenNo ratings yet

- Preprint 10-037Document2 pagesPreprint 10-037Eduardo MenaNo ratings yet

- ISRM-Is-2000-013 - Rock Slopes in Civil and Mining EngineeringDocument16 pagesISRM-Is-2000-013 - Rock Slopes in Civil and Mining Engineeringcastille1956No ratings yet

- منهج الادارة المكمنيةDocument151 pagesمنهج الادارة المكمنيةjlkpoi77No ratings yet

- Balkanmine2011 OErdem TGuyagulerDocument12 pagesBalkanmine2011 OErdem TGuyagulerGbenga AdewumiNo ratings yet

- Preprint 04-19: SME Annual Meeting Feb. 23-25, Denver, ColoradoDocument7 pagesPreprint 04-19: SME Annual Meeting Feb. 23-25, Denver, ColoradoAlexis MaronNo ratings yet

- Integrated Seismic Multi-Attribute Analysis For Complex Fluvio-Deltaic Reservoir Properties Mapping, Minas Field, Central SumatraDocument23 pagesIntegrated Seismic Multi-Attribute Analysis For Complex Fluvio-Deltaic Reservoir Properties Mapping, Minas Field, Central Sumatrayudipurnama059806No ratings yet

- 3D Static ModelingDocument6 pages3D Static Modelingbidyut_iitkgpNo ratings yet

- MEASUREMENT WHILE DRILLING (MWD) AND IMAGE ANALYSIS SYSTEMS Today's Most Useful and Cost-Effective Tools For Mining IndustryDocument15 pagesMEASUREMENT WHILE DRILLING (MWD) AND IMAGE ANALYSIS SYSTEMS Today's Most Useful and Cost-Effective Tools For Mining Industrypartha das sharma100% (3)

- Gis Sols For MiningDocument8 pagesGis Sols For MiningRonaldo MutepaireNo ratings yet

- 16 BaylisDocument10 pages16 BaylisJoylie CarantoNo ratings yet

- Data Management For Improved BlastingDocument11 pagesData Management For Improved BlastingCarlos RojasNo ratings yet

- Data Management For Improved BlastingDocument11 pagesData Management For Improved BlastingCarlos RojasNo ratings yet

- Leapfrog GeothermalDocument7 pagesLeapfrog GeothermalREandoNo ratings yet

- Lever ImprovementsDocument4 pagesLever ImprovementsRifqi RizqullahNo ratings yet

- Geo-Spatial Data Foundation For Dam SiteDocument8 pagesGeo-Spatial Data Foundation For Dam SiteSanthi Swarup ManugulaNo ratings yet

- Slope Stability Considerations in Integrated Surface Mine DesignDocument16 pagesSlope Stability Considerations in Integrated Surface Mine DesignJuan PerezNo ratings yet

- IPTC 16715 Real-Time Modeling-While-Drilling For Optimized Geosteering and Enhanced Horizontal Well Placement in Thin and Complex ReservoirsDocument8 pagesIPTC 16715 Real-Time Modeling-While-Drilling For Optimized Geosteering and Enhanced Horizontal Well Placement in Thin and Complex ReservoirsarminNo ratings yet

- 91 DufourDocument20 pages91 DufourCristian AnderNo ratings yet

- Blasting Design Desired FragmentationDocument8 pagesBlasting Design Desired FragmentationJorge Eliecer Acevedo SilvaNo ratings yet

- Geostatistical Modeling of Mcmurray Oil Sands DepositsDocument10 pagesGeostatistical Modeling of Mcmurray Oil Sands Depositsemilia597No ratings yet

- Measurementof Size Distributionof Blasted Rock Using DIPDocument14 pagesMeasurementof Size Distributionof Blasted Rock Using DIPMr BenhaNo ratings yet

- Research On The Development of Three-Dimensional VDocument4 pagesResearch On The Development of Three-Dimensional VNtokozo NdalaNo ratings yet

- Optimization of Underground Mine AcDocument22 pagesOptimization of Underground Mine AcSuryajyoti NandaNo ratings yet

- Ipa07 G 135Document16 pagesIpa07 G 135Ryan PermanaNo ratings yet

- Quantifying Uncertainty in Subsurface SystemsFrom EverandQuantifying Uncertainty in Subsurface SystemsCéline ScheidtNo ratings yet

- Guide for Planning, Construction and Maintenance of Forest RoadsFrom EverandGuide for Planning, Construction and Maintenance of Forest RoadsNo ratings yet

- Tutorial SciencedirectDocument5 pagesTutorial SciencedirectSamo AtefNo ratings yet

- Appendix B - Equipment BrochureDocument24 pagesAppendix B - Equipment BrochureAllissa SuwondoNo ratings yet

- Groundwater For Sustainable DevelopmentDocument11 pagesGroundwater For Sustainable DevelopmentAsep IrawanNo ratings yet

- Radar Altimetry Tutorial 20090406Document342 pagesRadar Altimetry Tutorial 20090406Hyuk Park100% (1)

- IS 9120 - Guidelines For Planning Layout and Design of Cavities in Underground Hydroelectric Power Stations PDFDocument22 pagesIS 9120 - Guidelines For Planning Layout and Design of Cavities in Underground Hydroelectric Power Stations PDFthavisiNo ratings yet

- Bce 221 Sim SDL Manual Week 6-7Document35 pagesBce 221 Sim SDL Manual Week 6-7SHALOM EMMANUEL OHAONo ratings yet

- Primary Water Works 1st Flyer FINAL Rev3Document2 pagesPrimary Water Works 1st Flyer FINAL Rev3George Hamilton100% (1)

- File 13809Document8 pagesFile 13809Lâm LươngNo ratings yet

- Himley 2007Document9 pagesHimley 2007digitalpastNo ratings yet

- Is An Aquifer An Underground River?: Click HereDocument3 pagesIs An Aquifer An Underground River?: Click HereLasandu WanniarachchiNo ratings yet

- Barrettes Construction in Soft ClayDocument6 pagesBarrettes Construction in Soft ClayShahab KhaledNo ratings yet

- The Islamic University of GazaDocument54 pagesThe Islamic University of GazaAbed SolimanNo ratings yet

- 1 s2.0 S0267726199000123 MainDocument22 pages1 s2.0 S0267726199000123 MainBeta IwanNo ratings yet

- Draft Rain Water Harvesting ManualDocument77 pagesDraft Rain Water Harvesting ManualmaniNo ratings yet

- Lesson 5 MineralsDocument15 pagesLesson 5 MineralsMariel LolincoNo ratings yet

- Hoodoo You LoveDocument3 pagesHoodoo You LoveMeghan O'DellNo ratings yet

- Science10 - Q1 - Mod3 - Processes and Landforms Along Plate BoundariesDocument23 pagesScience10 - Q1 - Mod3 - Processes and Landforms Along Plate BoundariesMomshie Ella100% (10)

- Chytidiomycoya: Blastocladiales Neocallimasticales Monoblepbaridales Chytridiales SpizellomycetalesDocument7 pagesChytidiomycoya: Blastocladiales Neocallimasticales Monoblepbaridales Chytridiales Spizellomycetalesratih purwaningrum13No ratings yet

- 05 Pvk-5 - Geological InformationDocument9 pages05 Pvk-5 - Geological Informationsanjayvmishra5871No ratings yet

- Ressa Reslope and MsewDocument2 pagesRessa Reslope and Msewchehalis0% (1)

- Sub Surface GeologyDocument3 pagesSub Surface GeologyUmesh MishraNo ratings yet

- News Release: Ngex Reports Further Excellent Drill Results From Los Helados, ChileDocument7 pagesNews Release: Ngex Reports Further Excellent Drill Results From Los Helados, ChilealexpetNo ratings yet

- MagmaDocument22 pagesMagmaHannah Julia A. NgNo ratings yet

- D&D 3rd Ed.-A Magical Society-Ecology & Culture-PF PDFDocument160 pagesD&D 3rd Ed.-A Magical Society-Ecology & Culture-PF PDFfear31100% (1)

- Depth - Yt, M, PDocument1 pageDepth - Yt, M, PramesNo ratings yet

- 1991 Eruption of Mount PinatuboDocument6 pages1991 Eruption of Mount PinatuboMarilyn Estrada DullasNo ratings yet

- ELS Performance Task 3Document2 pagesELS Performance Task 3Kristine Claire LaureteNo ratings yet

- On Risk Control in The Well Plug and Abandonment Phase - The Case of The Norwegian Continental ShelfDocument9 pagesOn Risk Control in The Well Plug and Abandonment Phase - The Case of The Norwegian Continental ShelfFabian MontoyaNo ratings yet

- Grade 8 Q2 ST No. 1Document3 pagesGrade 8 Q2 ST No. 1Richelle Navarro-CheungcunNo ratings yet

- An Exploration of Durham Cave in 1893 (1897) - Henry Chapman MercerDocument40 pagesAn Exploration of Durham Cave in 1893 (1897) - Henry Chapman MercercaegeospNo ratings yet