Professional Documents

Culture Documents

Flow Measurement With Orifices

Uploaded by

arnold1967Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Measurement With Orifices

Uploaded by

arnold1967Copyright:

Available Formats

lnt J Multiphase Flow Vol 18, No.

I, pp 149-155, 1992 Pnnted m Great Bntam All nghts reserved

0301-9322/92 $5.00+ 0.00 Copynght 1992 Pergamon Press plc

BRIEF COMMUNICATION

AN INVESTIGATION OF TWO-PHASE FLOW MEASUREMENT WITH ORIFICES FOR LOW-QUALITY MIXTURES H. J. ZnANG, S. J. LU and G. Z. Yu

Department of Chemical Engineering, Zhejiang Unwerstty, Hangzhou 310027, People's Republic of China

(Recemed I September 1990, in remsed form I August 1991)

1. I N T R O D U C T I O N

Measurement of gas-liquid two-phase flow rates is of interest in many fields of engineering, such as chemical, geothermal engineering, petroleum, power and nuclear energy. Although many methods, including ultrasonic waves, laser techniques, radiation etc., have been studied (Hewitt 1978; Reimann 1982), measurement of two-phase flow rates via orifices has received increasing attention in the last three decades. Numerous orifice equations for gas-liquid mixtures have been developed and some typical equations were proposed by Murdock (1962), James (1965), Chisholm (1967, 1974), Smith & Leang (1975) and Lin (1982). These equations can mostly be described by the following equation:

G= ~

CYAFa

KG~/2 APTppG,

[l]

where G is the mass flow rate of the gas-liquid mixture, C is the orifice discharge coefficient, Y is the compressibility coefficient of the fluid, A is the orifice flow area, Fa is the orifice thermal expansion factor, fl is the ratio of the orifice diameter to the internal pipe diameter, AP~, is the pressure drop across the orifice for the two-phase mixture, PG is the density of the gas phase and K6 is called the gas phase modified coefficient, which is dependent mainly on quality and the gas-liquid density ratio, and has several different forms (proposed by different authors). Murdock (1962) employed a separated flow model and derived the following two-phase correlation equation:

1

KG = X + 1.26( l - X) where CG and CL are the orifice discharge coefficients for gas and liquid, respectively, YG is the compressibility coefficient of the gas phase and Z is the quality. James (1965) used an effective mixture density to modify a homogeneous model, resulting in the expression /~ = ~5 I _ P G . +P_fG PL [31 CG YGP f ~ . ' [2]

Other authors proposed different modified two-phase correlation equations based on either the separated flow model or the homogeneous flow model. But in previous works, almost all orifice equations were derived from experiments with quality X > 1%. Some equations cannot be used particularly well and others become invalid at low quality--see Murdock's (1962) equation [2]. But low quality is widespread if the ratio of gas density to liquid density is small, even though the void fraction E is large. For this reason, our work is aimed at the measurement of two-phase flow with sharp-edged orifices for low quality. The experiments were made with an air-water flow system in the quality range 0.007-1%.

149

1.50

BRIEF COMMUNICATION

2. T H E O R Y For low-quality gas-liquid two-phase flow, the orifice equation for metering the mass flow rate has the following form (Zhang 1985):

G- ~/-1~~

CTp YTpA Fa

KLX/2AP~pL,

[4]

where YTP is the compressibility coefficient of the two-phase mixture and KL is the liquid modified coefficient. Note that in the above equation the liquid orifice discharge coefficient CL can be used to replace the two-phase mixture orifice discharge coefficient Cap if the Reynolds number for the liquid phase Ret is greater than the critical Reynolds number Re, (Matter et al. 1979). But the compressibility coefficient Yap will be different from the gas and liquid compressibility coefficients YG and YL for most cases. A simple theoretical equation for calculating Yap, proposed by Zhang (1985), is as follows: YTp YL(1 - E) + YGE, [5]

=

where E is the void fraction. Because YL = 1, [5] becomes YTp= 1 - E +EYG. [61

It is rather difficult to obtain a simple relationship for the modified coefficient KL from a theoretical analysis, so KL will be determined experimentally. It is thought that KL is a function of the density ratio PG/PLand of void fraction or quality, but for low quality it is better to use the void fraction as a parameter in the modified coefficient KL instead of normal quality, because in such a range of quality the void fraction will increase or decrease significantly with a small change in quality.

3. E X P E R I M E N T A L APPARATUS AND RESULTS

Experiments were carried out in a two-phase flow measurement apparatus, as shown in figure 1. Air and water were used as the gas and liquid phases, respectively. Before they were mixed, air and water flow rates were measured individually. The test gas mass velocity ranged from 0.9 to 9.1 kg/m ~. s with the liquid mass velocity from 840 to 1648 kg/m ~. s, while the quality ranged from 0.007 to 1%. The sharp-edged orifices used for the tests were mounted on a horizontal pipe with i.d. = 50.8 mm. The diameters of the orifices were 25.36 and 21.42 mm, with a diameter ratio of = 0.499 and fl = 0.422, respectively. The pressure taps on each orifice were standard corner taps with carrier rings. Before the tests the orifices were carefully calibrated with single-phase water. During the tests the total mass flow rates and quality were obtained from the readings of the gas and liquid flowmeters. Void fraction was measured by two quick-closing valves which were installed

3 2 1

Figure 1. Schematic dmgram of the experimental apparatus: 1, compressor; 2, filter; 3, gas flowmeter; 4, pump; 5, hqmd flowmeter, 6, qmck-closmg valves; 7, onfice

BRIEF COMMUNICATION

151

1.0 0.g 0.8 0.7 0.6 0.5 0

1.0

Av v A v A V~AdlT,L . ClamOr -- V m t . o - 1 5 7 8 k g l m 2 " s ~ "~ mL0 = 1507kglrn2.s A

mLO = 1 6 4 8 k g l m 2 . s Q mL0-1296kg/m2.1 mL0-1112kg/rn2.s A rnt.0.943kg/m2-s 0.0-0.8--

v , va, ~

o a ,., v * o v []

KL

KL

0.70.6--

v []

ml.o - 1 6 2 0 k g l m 2 " s mL0"1436kg/m2"m mL0-123kg/mg.s

I

0.2

I

0.4 Void

I

0.6 fraction

I

0.8

I

1.0

os

0

I

0.2

I

0.4 Void

I

0.6 fraction

I

0.8

I

1.0

Ftgure 2 Experimental values of K L vs void fracUon for fl = 0 499

Figure 3. Experimental values of KL vs void fraction for fl = 0.422.

,.o

.,,,

,

1.o

0.9

0.9 rnLo-1578kg/m2"s ml.o 11507kg I m 2 " l mLol1298kglm2"t mLo -1112kg/rn2 .s mLo 1943kg/m 2 .s I I II 10 - 4 Quality I I I ,I I o-s , , K L 0.8 -A 0.7 -0.6-, ,I 10 - 2 05 10 - I , , ,I 10 -4 Quality I , , ,I 10 -3 v mLO'1820kglm2"l mL0-1438kglm2.1 Cl m L o - 1 2 5 S k g l m 2 . e

~~,

Q

K L 0.8 0.7

--

0.6 -0.5 10 - 5 I

v O

i il 10 -2

Figure 4 Experimental values o f K L vs quahty for fl = 0 499

Figure 5 Experimental values o f K L vs quahty for fl = 0.422.

on the two sides of the sharp-edged orifice. A pressure gauge was installed before the orifice to indicate the pressure of the two-phase flow. If APav is measured by a differential pressure transmitter connected to the orifice, KL can be calculated from [4]. Since the tests were performed at normal temperature, the orifice thermal expansion factor Fa is unity and the water density is about 998 kg/m 3. All the experimental data are summarized in table 1. Figures 2 and 3 show the experimental values of KL vs void fraction, and figures 4 and 5 are the experimental values of KL vs quality. In figures 2-5, mL0 is the liquid mass flow rate per unit area when the gas flow rate is zero; with an increase in the gas flow rate the liquid flow rate will decrease, because the position of the valve for controlling the liquid phase flow rate has not changed. 4. C O M P A R I S O N W I T H R E S U L T S FROM PREVIOUS W O R K Because Murdock's (1962) correlation equation for two-phase flow does not apply at low quality, comparisons can only be made with the homogeneous flow model and the James model here. For the homogeneous flow model, the theoretical equation for the liquid phase modified coefficient KL is as follows:

KL= . PL'

1+1 where n = 1. Substituting experimental data for X, Pc and PL into [7], the theoretical KL can be obtained. The errors between the actual KL and the KL value calculated from [7] are shown in figure 6(a). Figure 6(a) shows that the actual values are greater than the calculated values and the errors increase with increasing quality. For the James (1965) model, the equation for KL is the same as [7], but n = 1.5. The deviation of actual KL values from those given by [7] is shown in figure 6(b). It is seen from the figure that most data are negative, which means that the actual KL is less than the calculated KL. It is also found that the absolute errors are less than those for the homogeneous model.

1~

BRIEF COMMUNICATION

BRIEF COMMUNICATION

153

o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o o

"

~ .

. . . . .

~ ~ ~

~~

0 ~ 0 ~ 0 0 0 ~ 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 ~ 0 0 0 0 0 0 0 0 0 0 0 0 ~ 0 0 0 0 ~ 0

~o~

'

~0

154

BRIEF COMMUNICATION

40% 20%

0%

e~ I

(a)

I , ,I

l, IW ~ *

, , , II , , , ,I

-~ -20% f "o o o E

~ m

Homogeneousflow

model

20% 0%

-20%

os

F

(b)

400

I I I I [

..

O0

I i

leO01

J a m e s ' s model

c 4)

E

a,. 4) o. x

0%

e~e

ee

-20% 0 .m > 4) a

I I ]

I I ]

I I ]

(C) Authors' m o d e l

modified

with q u a l i t y

20%

0%

-20%

I , ,

","

O*o

, 1

o

, , ,

Qp.%

~ a , 5 , o g] 5 o .

, , , , I

10 .5

(d)

10 -4 Authors' model modified Quality

10 .3 with void fraction

10

.2

Figure 6 Deviation of experimental K L values from those from different models,

5.

NEW

EQUATIONS

Because most errors between actual and calculated K, values are greater than zero for the homogeneous flow model, but less than zero for the James (1965) model, it is thought that [7] may be appropriate for two-phase flow with n being from 1 to 1.5. Using the experimental data shown in table 1, n is found to be n = 1.25 + 0.25 . IS]

When g approaches unity, n = 1.5, i.e. it becomes the same as the James model. If [8] is used to calculate KL, we find it is quite close to the experimental KL shown in figure 6(c). If the void fraction is employed as a parameter in the modified coefficient KL then, from the homogeneous flow model, the theoretical equation is

,9]

where n, -- 1. But this equation has significant errors compared with the experimental data. To fit the data, the method of least squares was used and we obtained n, = 4. Figure 6(d) shows the differences between the actual KL values and those calculated from [9].

BRIEF COMMUNICATION

155

6. DISCUSSION AND CONCLUSIONS For a gas-liquid mixture of low quality, the two-phase flow rate can be measured with sharp-edged orifices. If the quality is used to modify the orifice equation, then the total mass flow rate of the two-phase mixture can be calculated using the following equation:

G.

CL YavAFa [

. . . . .

2 APavpL

.

[101

where n = 1.25 + 0.25 x}/-~. The orifice equation for the single-phase flow rate may be modified using the void fraction when the quality of the mixture is low, because under these conditions the void fraction will change more sharply than the quality and have greater values. Introducing void fraction, the modified orifice equation becomes

G =CLYveAFa /2APTpPLFE4(P~--I)+ 11.

~ I -- f14 V L \PL

[11]

Although the deviation of experimental KL values from those calculated by [9] is not sufficiently small [see figure 6(d)], [9] is very useful for low quality. If the void fraction is estimated, the liquid modified coefficient may be evaluated quickly. Moreover, for E ~<0.5, then from [9] we get KL ~<0.96, which means that there is no significant difference between the modified orifice equation for the two-phase flow rate and the common orifice equation for the single-phase liquid flow rate. Furthermore, if the compressibility coefficient YTP is considered, we can expect that the maximum error in the mass flow rate will be within 10% if the orifice equation of single-phase liquid flow is used to measure the two-phase mass flow rate, because for most cases the compressibility coefficient is <0.95. The above conclusions are derived from experiments with an air-water two-phase flow system. To contain their general validity additional experiments with different two-phase mixtures, pipe diameters and density ratios are required. However, the present work may be instructive in the further study of the measurement of gas-liquid mixture at low quality.

REFERENCES

CHISHOLM,D. 1967 Pressure gradients during the flow of an incompressible two-phase mixture through pipes, venturis and orifice plates. Br. Chem. Engng 12, 454-457. CHISHOLM, D. 1974 Pressure drop during steam/water flows through orifices. J. Mech. Engng Sci.

16, 353-355. HEWITT, G. F. 1978 Measurements of Two-phase Parameters. Academic Press, London. JAMES, R. 1965 Metering of steam-water two-phase flow by sharp-edged orifices. Proc. lnst Mech. Engrs 180, 549-566. LIN, Z. H. 1982 Two-phase flow measurements with sharp-edged orifices. Int. J. Multiphase Flow 8, 683-693. MATTER, L., NICHOLSOY,M., AzIz, K. & GREGORY,G. A. 1979 Orifice metering of two-phase flow. J. Petrol. Technol. 31, 955-961. MURDOCK, J. W. 1962 Two-phase flow measurements with orifices. J. Bas. Engng 84, 419-433. REIMANN,J. 1982 Developments in two-phase mass flow rate instrumentation. In Advances in Two-

phase Flow and Heat Mass Transfer; Proceedings of the NA TO Advanced Research Workshop on the Advances in Two-phase Flow and Heat Transfer, pp. 339-402.

SMITH, R. V. & LEANG, J. T. 1975 Evaluations of correlations for two-phase flowmeters three current-one new. ASME Ser. A 97, 589-593. ZnA~G, H. J. 1985 Measurement of gas-liquid two-phase flow with the differential pressure method. M.Sc. Thesis, Zhejiang Univ., Hangzhou, P.R.C.

You might also like

- Solution MunkersDocument6 pagesSolution Munkersarnold1967No ratings yet

- EnergyDocument3 pagesEnergyarnold1967No ratings yet

- Solution MunkersDocument6 pagesSolution Munkersarnold1967No ratings yet

- Seawater EnergyDocument3 pagesSeawater Energyarnold1967No ratings yet

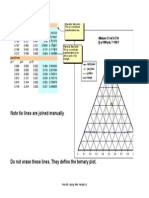

- Ternary PlotDocument1 pageTernary Plotarnold1967No ratings yet

- Note Tie Lines Are Joined Manually: xc1 xc4 xc10 X yDocument1 pageNote Tie Lines Are Joined Manually: xc1 xc4 xc10 X yarnold1967No ratings yet

- Pictures of Mount EverestDocument1 pagePictures of Mount Everestarnold1967No ratings yet

- Ferdinand MagellanDocument4 pagesFerdinand Magellanarnold1967No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- New Centum VP Dcs With Network Io WhitepaperDocument4 pagesNew Centum VP Dcs With Network Io WhitepaperFarrukh MajeedNo ratings yet

- Rotork: Product TrainingDocument4 pagesRotork: Product TraininghieuNo ratings yet

- Marantz Product Catalogue 2010 2011Document31 pagesMarantz Product Catalogue 2010 2011O M Gee100% (1)

- Top Links October 2018Document122 pagesTop Links October 2018Andrew Richard ThompsonNo ratings yet

- Proposal Tripurainfo Job PortalDocument10 pagesProposal Tripurainfo Job PortalEkta DevNo ratings yet

- 09-SAMSS-089 Shop Applied FBE Coating Jan 2018Document28 pages09-SAMSS-089 Shop Applied FBE Coating Jan 2018Ahmed & Rehana MoinuddinNo ratings yet

- Spam DetectionDocument142 pagesSpam DetectionRahul GantaNo ratings yet

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Document12 pagesOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldNo ratings yet

- TemplateDocument17 pagesTemplatedaveNo ratings yet

- 2SK2188Document2 pages2SK2188Abigail HoobsNo ratings yet

- JUNOS Cheat SheetDocument2 pagesJUNOS Cheat SheetJaeson VelascoNo ratings yet

- Arc Welding ProcessesDocument153 pagesArc Welding Processespratap biswasNo ratings yet

- What Is NoSQLDocument4 pagesWhat Is NoSQLDulari Bosamiya BhattNo ratings yet

- REVIEWDocument12 pagesREVIEWGoka Agbesi GokaNo ratings yet

- Pedoman Planologi PDFDocument187 pagesPedoman Planologi PDFRetno Kartika SariNo ratings yet

- Fuses & Circuit Breakers PDFDocument13 pagesFuses & Circuit Breakers PDFCarlos Luis Santos SomcarNo ratings yet

- Operations Management: William J. StevensonDocument36 pagesOperations Management: William J. StevensonRubel Barua100% (4)

- Datasheet Si-113 EN Ball Segment ValveDocument8 pagesDatasheet Si-113 EN Ball Segment ValveAnonymous ItzBhUGoiNo ratings yet

- RSC 406 (English)Document11 pagesRSC 406 (English)Tuấn DũngNo ratings yet

- 1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)Document84 pages1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)khanh phanNo ratings yet

- Presentation DIP5000 enDocument31 pagesPresentation DIP5000 enNeelakandan MasilamaniNo ratings yet

- Lab 11 12 ECA HIGH AND LOW PASSDocument32 pagesLab 11 12 ECA HIGH AND LOW PASSAmna EjazNo ratings yet

- 50rhe PDDocument40 pages50rhe PDm_moreira1974No ratings yet

- BDM DriverDocument16 pagesBDM DrivervolvodiagNo ratings yet

- Incredible IndiaDocument13 pagesIncredible IndiaShradha DiwanNo ratings yet

- Acord and IAADocument4 pagesAcord and IAABHASKARA_20080% (1)

- Plastiment BV 40: Water-Reducing Plasticiser For High Mechanical StrengthDocument3 pagesPlastiment BV 40: Water-Reducing Plasticiser For High Mechanical StrengthacarisimovicNo ratings yet

- Informatics in Logistics ManagementDocument26 pagesInformatics in Logistics ManagementNazareth0% (1)

- BK3251 BekenDocument13 pagesBK3251 BekenDanny DurhamNo ratings yet

- Culminating Activity: (A Proposal)Document3 pagesCulminating Activity: (A Proposal)Landice Myoui100% (1)