Professional Documents

Culture Documents

Epoxy coating for immersed areas and hull repair

Uploaded by

napster386Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epoxy coating for immersed areas and hull repair

Uploaded by

napster386Copyright:

Available Formats

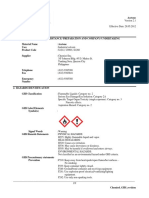

Product Data

HEMPADUR MASTIC 45880/ HEMPADUR MASTIC 45881

High temperatures: 45881: BASE 45889 with CURING AGENT 95881 Low to medium temperatures: 45880: BASE 45889 with CURING AGENT 95880 Description: HEMPADUR MASTIC 45880/45881 is a two-component polyamide adduct cured, high solids, high build epoxy paint. It forms a hard and tough coating, has good wetting properties and low temperature curing. As a selfprimed, surface tolerant paint system or as an intermediate or finishing coat in heavy duty paint systems where low VOC and high film build are required. Multipurpose coating as per specification for maintenance and minor repairs in immersed areas including ballast tanks and underwater hull specifically in those cases where a need for few products outweighs more specialised coatings. Can be specified where extended recoating properties for polyurethane topcoats are requested (typically travel coating). May be used directly on cured zinc silicate (GALVOSIL products) or spray-metallized surfaces to minimize popping. As a topcoat where the usual outdoor cosmetic appearance of epoxy paints is acceptable. Maximum, dry exposure only: 120C/248F Tested for non-contamination of grain cargo at the Newcastle Occupational Health, Great Britain. Complies with Section 175.300 of the Code of Federal Regulations in respect of carriage of dry foodstuffs (FDA) in spaces with an internal surface area larger than 1000 m/10,750 sq.ft. HEMPADUR MASTIC 45881 is in accordance with Aramcos specification APCS 1, APCS 12, APCS 26 and 26T. Classified as class 1 material according to BS 476: Part 7: 1997 (fire testing). HEMPADUR MASTIC 45880 is approved as a low flame spread material by Danish, French, Spanish, Singaporean, Malaysian and Indonesian authorities according to IMO resolution MSC 61 (67). Has a French, Spanish, Danish, Singaporean, Malaysian and Indonesian EC-type Examination Certificate. Complies with EU Directive 2004/42/EC, subcategory j. Please see REMARKS overleaf. Part of Group Assortment. Local availability subject to confirmation. 45880 45881 Grey/12170* Grey/12170* Semi--gloss Semi--gloss 80 1 80 1 4 m/litre - 200 micron 4 m/litre - 200 micron 160 sq.ft./US gallon - 8 mils 160 sq.ft./US gallon - 8 mils 39C/102F 39C/102F 1.5 kg/litre - 12.5 lbs/US gallon 1.5 kg/litre - 12.5 lbs/US gallon 4 (approx) hours at 20C/68F 3 (approx) hours at 30C/86F 7 days at 20C/68F 5 days at 30C/86F 220 g/litre - 1.8 lbs/US gallon 220 g/litre - 1.8 lbs/US gallon *Wide range of colours available via Hempel's MULTI-TINT system.

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

Recommended use:

Service temperatures: Certificates/Approvals:

Availability: PHYSICAL CONSTANTS: Version, mixed product: Colours/Shade nos: Finish: Volume solids, %: Theoretical spreading rate: Flash point: Specific gravity: Dry to touch: Fully cured: V.O.C.:

APPLICATION DETAILS: Version: Mixing ratio: Application method: Thinner (max. vol.): Pot life: Nozzle orifice: Nozzle pressure: Cleaning of tools: Indicated film thickness, dry: Indicated film thickness, wet: Recoat interval, min/max:

Safety:

45880 45881 Base 45889 : Curing agent 95880 Base 45889 : Curing agent 95881 3 : 1 by volume 3 : 1 by volume Airless spray Brush (touch up) Airless spray Brush (touch up) Depending on purpose usually less than 5% THINNER 08450 (See REMARKS overleaf) 1 hour (20C/68F) (Airless spray) 1 hour (30C/86F) (Airless spray) 2 hours (20C/68F) (Brush) 2 hours (30C/86F) (Brush) .017"-.023" (See separate APPLICATION INSTRUCTIONS) 250 bar/3600 psi (Airless spray data are indicative and subject to adjustment) HEMPELS TOOL CLEANER 99610 or HEMPEL'S THINNER 08450 200 micron/8 mils (see REMARKS overleaf) 250 micron/10 mils According to separate APPLICATION INSTRUCTIONS

Handle with care. Before and during use, observe all safety labels on packaging and paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do not swallow. Take precautions against possible risks of fire or explosions as well as protection of the environment. Apply only in well ventilated areas

Issued: March 2011

Page 1 of 3

HEMPEL Product Data Sheet

HEMPADUR MASTIC 45880/45881

SURFACE PREPARATION:

New steel: When used as an intermediate or finishing coat please refer to the data sheet for the preceding GALVOSIL or HEMPADUR primer. When used as a primer please refer to the specification. Zinc silicate painted or spray-metallized surfaces: Remove oil and grease, etc. with suitable detergent. Remove salt and other contaminants by (high pressure) fresh water cleaning. Zinc salts (white rust) must be removed by high pressure hosing combined with rubbing with a stiff nylon brush if necessary. It is recommended to recoat spray-metallized surfaces as soon as possible to avoid possible contamination. Concrete: Remove slip agent and other possible contaminants by emulsion washing followed by high pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and uniform surface, preferably by abrasive blasting, possibly by other mechanical treatment or acid etching. Seal surface with suitable sealer, as per relevant painting specification. Repair and maintenance: Remove oil and grease, etc. with suitable detergent. Remove salt and other contaminants by (high pressure) fresh water cleaning. Clean damaged areas thoroughly by power tool cleaning to minimum St 2 (spot-repairs) or by abrasive blasting to min. Sa 2, preferably to Sa 2. Improved surface preparation will improve the performance of HEMPADUR MASTIC 45880/45881. As an alternative to dry cleaning, water jetting to min. Wa 2 (ISO 85014:2006)(or according to specification), may be used. A flash-rust degree of maximum M (ISO 85014:2006) is acceptable before application. Feather edges to sound and intact paint. Dust off residues. On pit-corroded surfaces, excessive amounts of salt residues may call for water jetting, wet abrasive blasting, alternatively dry abrasive blasting, high pressure fresh water hosing, drying, and finally, dry abrasive blasting again. Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation. Use only when application and curing can proceed at temperatures above -5C/23F (recommended lowest temperature is 0C/32F) for HEMPADUR MASTIC 45880 and above approx 15C/59F for HEMPADUR MASTIC 45881. The temperature of the paint itself should be 15C/59F or above, but advantageously below approximately 30C/86F to secure proper application properties. Optimal spraying properties are obtained at a paint temperature of 1822C/64-72F. In warmer climates, the paint should be stored in a cool place and the paint temperature should preferably be kept below 30C/86F. In confined spaces provide adequate ventilation during application and drying. In cases where faster drying at very low temperatures is required, HEMPADUR MASTIC 45880 may advantageously be replaced by HEMPADUR 45143. Please also see separate APPLICATION INSTRUCTIONS.

APPLICATION CONDITIONS:

PRECEDING and SUBSEQUENT COAT: None or according to specification.

45880 5 vol. % thinning Limit phase II, 2010 VOC in g/l 250 500 45881 As supplied 5 vol. % thinning Limit phase II, 2010 VOC in g/l 220 250 500 VOC: For VOC of other shades, please refer to Safety Data Sheet. Certificates have been issued under the former quality number 4588. Colours/ColourCertain lead-free red and yellow colours may discolour when exposed to chlorine- containing stability: atmosphere. Leaded colours may become discoloured when exposed to sulphide-containing atmosphere. Like other epoxy coatings in white/whitish colour a yellowing may take place in cases of application under unfavourable weather conditions, especially sudden drops in temperature during drying and initial cure and/or lack of ventilation. Weathering/service The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more temperatures: sensitive to mechanical damage and chemical exposure at elevated temperatures is also reflected in this product. Film thicknesses/ May be specified in another film thickness than indicated depending on purpose and area of use. thinning: This will alter spreading rate and may influence drying time and recoating interval. Normal range dry is 125-200 micron/5-8 mils. May be specified in lower film thickness for which purpose additional thinning is required, please see separate APPLICATION INSTRUCTIONS. Avoid application of excessive film thicknesses. As supplied 220

REMARKS: VOC - EU directive 2004/42/EC:

Shades:

The product is also available in a Micaceous Iron Oxide (MIO) pigmented shade (Shade no. 12430 reddish grey ) and in aluminium pigmented shades (Shade nos. 19870 - dark alu and 19000 light alu).

Issued: March 2011

Page 2 of 3

Product Data Sheet

HEMPADUR MASTIC 45880/45881

Application onto zinc silicate or spraymetallized surfaces (thinning): Curing agents: Note: ISSUED BY:

It is recommended to apply HEMPADUR MASTIC 45880/45881 by using a "mist-coat" procedure Provided the paint temperature is approximately above 20C/68F: A thin, diluted coat is applied (the mist coat) and after a few minutes, a second coat is applied in the full specified film thickness. If the paint temperature is below 20C/68F, thinning (max 15%) may be required. Curing agents 95880 and 95881 are hazy. This is intended and has no negative influence on the performance. HEMPADUR MASTIC 45880/45881 is for professional use only. HEMPEL A/S - 4588012170CO015/4588112170CO013

This Product Data Sheet supersedes those previously issued. For explanations, definitions and scope, see Explanatory Notes in the HEMPEL Book. Data, specifications, directions and recommendations given in this data sheet represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions of any intended use of the Products herein must be determined exclusively by the Buyer and/or User. The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise. Product data are subject to change without notice and become void five years from the date of issue.

Issued: March 2011

Page 3 of 3

Product Data Sheet

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 45881Document3 pages45881amachmouchiNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- Hempadur Mastic 45880 & 45881Document2 pagesHempadur Mastic 45880 & 45881Syarif Irwanto100% (1)

- Pds Hempadur Mastic 45880Document3 pagesPds Hempadur Mastic 45880sibi_s_rajNo ratings yet

- HEMPADUR MASTIC 45881 Product Data SheetDocument3 pagesHEMPADUR MASTIC 45881 Product Data Sheetshujad77No ratings yet

- High Build Epoxy Coating for Hulls and Ballast TanksDocument3 pagesHigh Build Epoxy Coating for Hulls and Ballast Tankskasosei0% (1)

- Product Data Sheet Hempadur 45880Document2 pagesProduct Data Sheet Hempadur 45880Julius HendraNo ratings yet

- Hempadur Mastic 45880: Page 1 of 2 Issued: January 2010Document2 pagesHempadur Mastic 45880: Page 1 of 2 Issued: January 2010daimaheshNo ratings yet

- HEMPADUR MASTIC 4588W Product Data SheetDocument2 pagesHEMPADUR MASTIC 4588W Product Data SheetNassim Ben AbdeddayemNo ratings yet

- Hempadur Mastic 45880 Product Data SheetDocument3 pagesHempadur Mastic 45880 Product Data SheetDeepak YadavNo ratings yet

- Hempadur Mastic 45881-12170Document3 pagesHempadur Mastic 45881-12170Bang OchimNo ratings yet

- APCS-26T HempelDocument5 pagesAPCS-26T HempelarjunmohananNo ratings yet

- HEMPADUR MASTIC 45880 Product DataDocument3 pagesHEMPADUR MASTIC 45880 Product DataQA QCNo ratings yet

- Pds Hempadur Multi-Strength GF 35870 En-GbDocument3 pagesPds Hempadur Multi-Strength GF 35870 En-GbThines KumarNo ratings yet

- Hempadur Pro Zinc 17380 Zinc-Rich Epoxy Primer Product Data SheetDocument2 pagesHempadur Pro Zinc 17380 Zinc-Rich Epoxy Primer Product Data Sheetprabha221No ratings yet

- Hempedur 85671Document2 pagesHempedur 85671Shanoor ASNo ratings yet

- HEMPADUR 47140: DescriptionDocument2 pagesHEMPADUR 47140: DescriptionMashudi FikriNo ratings yet

- PDS Hempadur 45883Document2 pagesPDS Hempadur 45883Fredy Xavier DomínguezNo ratings yet

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanNo ratings yet

- Hempadur Quattro InglesDocument3 pagesHempadur Quattro InglesElizabeth Maria Bazán MoralesNo ratings yet

- PDS en-GB 1736g19840Document2 pagesPDS en-GB 1736g19840nihad_mNo ratings yet

- Pds Hempadur 15570 En-GbDocument3 pagesPds Hempadur 15570 En-GbdcsamaraweeraNo ratings yet

- 15550Document2 pages15550khalid764No ratings yet

- Hempadur 15570 15570 En-GbDocument2 pagesHempadur 15570 15570 En-GbgabyorNo ratings yet

- Application Instructions for HEMPADUR MASTIC 45880/45881Document6 pagesApplication Instructions for HEMPADUR MASTIC 45880/45881Mohamed NouzerNo ratings yet

- Intergard 269 DatasheetDocument4 pagesIntergard 269 DatasheetBalasubramanian AnanthNo ratings yet

- Pds Hempadur Zinc 17360 En-GbDocument2 pagesPds Hempadur Zinc 17360 En-GbTukur AngeleyeNo ratings yet

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 pagesPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- Product Data for HEMPATHANE HS 55610 Protective CoatingDocument3 pagesProduct Data for HEMPATHANE HS 55610 Protective CoatingAnonymous HPlNDhM6ejNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Krishna Vacha100% (1)

- 15780Document7 pages15780khalid764No ratings yet

- Paint Specification HamadourDocument2 pagesPaint Specification HamadourAbdul Majid LodhiNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Internationa Paint MSDSDocument4 pagesInternationa Paint MSDStsoheil100% (1)

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBalouisNo ratings yet

- Hempel - Hempadur Multi-Strength 45753 (Cold Climate)Document3 pagesHempel - Hempadur Multi-Strength 45753 (Cold Climate)CallumWoodwardNo ratings yet

- Interbond 808Document4 pagesInterbond 808shameelNo ratings yet

- Hempadur Primer 15300Document2 pagesHempadur Primer 15300anto081287No ratings yet

- Aplicación Epoxi Poliamida 45150 00Document4 pagesAplicación Epoxi Poliamida 45150 00kdt3No ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- Hempadur 15570Document2 pagesHempadur 15570Edwin HarrisNo ratings yet

- Tikkurila Temacoat RM 40Document3 pagesTikkurila Temacoat RM 40miagheorghe25No ratings yet

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNo ratings yet

- Hempaprime Multi 500 Summer 45950Document3 pagesHempaprime Multi 500 Summer 45950omar alkarabliehNo ratings yet

- Pds Hempadur 85671 En-GbDocument3 pagesPds Hempadur 85671 En-GbMario KoričanNo ratings yet

- International Interswift 6800HS Antifouling Product Data SheetDocument4 pagesInternational Interswift 6800HS Antifouling Product Data Sheetadul sungkatinNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interswift 6800HS Eng A4 20160419Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interswift 6800HS Eng A4 20160419shunanlatheefNo ratings yet

- Pds Hempel's Coal Tar Epoxy Mastic 35670 En-GbDocument2 pagesPds Hempel's Coal Tar Epoxy Mastic 35670 En-GbShanoor AS100% (1)

- Pds Hempadur Spray-Guard 35490 En-GbDocument2 pagesPds Hempadur Spray-Guard 35490 En-GbVijayaraghavan SrinivasamurthiNo ratings yet

- Zinc Silicate Coating TDSDocument5 pagesZinc Silicate Coating TDSadeoye_okunoyeNo ratings yet

- HempadurDocument2 pagesHempadurLuciano SalituriNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- The French Polisher's Manual - A Description of French Polishing Methods and TechniqueFrom EverandThe French Polisher's Manual - A Description of French Polishing Methods and TechniqueNo ratings yet

- MCC Vicinity MapDocument1 pageMCC Vicinity Mapnapster386No ratings yet

- Lehe0439 01Document6 pagesLehe0439 01ddzoningcomNo ratings yet

- Y-Type and Basket Strainer: Valve GroupDocument3 pagesY-Type and Basket Strainer: Valve Groupxaaabbb_550464353No ratings yet

- Msds AcetoneDocument9 pagesMsds Acetonenapster386No ratings yet

- Process Piping Equations Set 1Document2 pagesProcess Piping Equations Set 1napster386No ratings yet

- Dynapocket: Pocket-Size Hardness Tester Standardized To ASTM A 956Document4 pagesDynapocket: Pocket-Size Hardness Tester Standardized To ASTM A 956napster386No ratings yet

- Why Use Washers PDFDocument2 pagesWhy Use Washers PDFnapster386No ratings yet

- Y-Type and Basket Strainer: Valve GroupDocument3 pagesY-Type and Basket Strainer: Valve Groupxaaabbb_550464353No ratings yet

- PAUT Advantages Set1Document1 pagePAUT Advantages Set1napster386No ratings yet

- AutomatedListProfits PLR License PDFDocument3 pagesAutomatedListProfits PLR License PDFCarlos HenryNo ratings yet

- Ultimate Scoring WorkoutDocument2 pagesUltimate Scoring WorkoutrcdpreludeNo ratings yet

- Angping AddressDocument1 pageAngping Addressnapster386No ratings yet

- A516 NormalizedDocument3 pagesA516 Normalizediran1362No ratings yet

- Gary Valenciano Lead Me Lord ChordsDocument2 pagesGary Valenciano Lead Me Lord Chordsnapster386No ratings yet

- Angping AddressDocument1 pageAngping Addressnapster386No ratings yet

- Application OpenAccount Form 4 PDFAgreementDocument8 pagesApplication OpenAccount Form 4 PDFAgreementnapster386No ratings yet

- My Maid Invests in The Stock Market by Bo SanchezDocument29 pagesMy Maid Invests in The Stock Market by Bo SanchezGerald Magno100% (1)

- Engineering Design Guideline Pump Rev3Document14 pagesEngineering Design Guideline Pump Rev3hclsvw67% (3)

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Document17 pagesStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Total Dynamic HeadDocument2 pagesTotal Dynamic Headrajbhar_sNo ratings yet

- Activity 3Document26 pagesActivity 3napster386No ratings yet

- Total Dynamic HeadDocument2 pagesTotal Dynamic Headrajbhar_sNo ratings yet

- Material Safety Data Sheet: CAUSTIC SODA SOLUTION: Chemicals and Vinyls, LLCDocument9 pagesMaterial Safety Data Sheet: CAUSTIC SODA SOLUTION: Chemicals and Vinyls, LLCganukaniNo ratings yet

- Viscosity and vapor pressure of fuelsDocument2 pagesViscosity and vapor pressure of fuelsnapster386No ratings yet

- Velocity and Pressure Drop in PipesDocument5 pagesVelocity and Pressure Drop in Pipeskiran9285No ratings yet

- Chlor TestDocument1 pageChlor Testnapster386No ratings yet

- MSDS: Ammonia Safety Hazards and First AidDocument3 pagesMSDS: Ammonia Safety Hazards and First Aidnapster386No ratings yet

- Product Data Sheet: Conservation VentDocument8 pagesProduct Data Sheet: Conservation Ventnapster386No ratings yet

- Paint DefectsDocument129 pagesPaint Defectsmohammad100% (6)

- How To Connect Your Laptop To The TVDocument8 pagesHow To Connect Your Laptop To The TVnapster386No ratings yet

- T SP CM 1 2004Document11 pagesT SP CM 1 2004Andrew HillNo ratings yet

- Mixtec Rulership Colonial TimesDocument32 pagesMixtec Rulership Colonial TimesEmiliano GarciaNo ratings yet

- Module On Art History and Art Movements (Part 1)Document8 pagesModule On Art History and Art Movements (Part 1)Paul macaraegNo ratings yet

- Glenn Adamson Thinking Through CraftDocument118 pagesGlenn Adamson Thinking Through CraftНаталья Панкина100% (4)

- Architectural Building MaterialsDocument239 pagesArchitectural Building MaterialsLaurence CalpoturaNo ratings yet

- CRETAzDocument53 pagesCRETAzFelipe Santiago Vega Fermin100% (1)

- Quarter 3-Arts Lesson 1-4Document52 pagesQuarter 3-Arts Lesson 1-4Sarah Grace ManuelNo ratings yet

- Landscape Photography (From Snapshots To Great Shots)Document50 pagesLandscape Photography (From Snapshots To Great Shots)António Alves ChavesNo ratings yet

- Puducherry Artwork.Document14 pagesPuducherry Artwork.Yukta SainiNo ratings yet

- Löfgren M - Proletär SkissDocument130 pagesLöfgren M - Proletär SkissBeata AgrellNo ratings yet

- A Week in AlicanteDocument1 pageA Week in AlicanteAlexandruOpreanNo ratings yet

- Title: Bedsheet TensionerDocument6 pagesTitle: Bedsheet TensionerRA Mikael Master MindNo ratings yet

- Woodwork: Scheme of ExaminationDocument10 pagesWoodwork: Scheme of ExaminationKunbi Santos-ArinzeNo ratings yet

- Dave Spence MansionDocument3 pagesDave Spence MansionDarin Reboot CongressNo ratings yet

- Fictional Reality 9Document82 pagesFictional Reality 9alaling1100% (1)

- Assessment Task Photographic and Digital Media STG 5Document1 pageAssessment Task Photographic and Digital Media STG 5api-225564671No ratings yet

- Baselitz - Exhibition CatalogueDocument5 pagesBaselitz - Exhibition CatalogueArtdataNo ratings yet

- Top 20 Tourist Spots in Ilocos RegionDocument6 pagesTop 20 Tourist Spots in Ilocos RegionJenica Joyce BautistaNo ratings yet

- Clay Wireframe Renders With Mental Ray & 3ds MaxDocument11 pagesClay Wireframe Renders With Mental Ray & 3ds Maxnam_paphNo ratings yet

- 10 MuchaDocument37 pages10 MuchaMickel Ng100% (5)

- Artaud 2Document177 pagesArtaud 2Veronica DellacroceNo ratings yet

- Level B2 Word ListDocument1,231 pagesLevel B2 Word ListIvanDarioMontealegreVela100% (2)

- Trading PointDocument4 pagesTrading PointTibi M.No ratings yet

- Masonic Lodge Symbols EducationDocument10 pagesMasonic Lodge Symbols Educationedpoli5205100% (2)

- History of Urban Planning in 40 CharactersDocument1 pageHistory of Urban Planning in 40 CharactersKarla AmarNo ratings yet

- Art History Lecture Guided NotesDocument2 pagesArt History Lecture Guided Notesapi-577132896No ratings yet

- g30 Brochure Dec04Document12 pagesg30 Brochure Dec04Igor SimunovicNo ratings yet

- Alvar AaltoDocument27 pagesAlvar AaltoPragya Singh100% (2)

- 2940361193Document16 pages2940361193Karla Díaz TurchanNo ratings yet

- Makeup Transformation BookDocument25 pagesMakeup Transformation Bookmeryxarly100% (9)