Professional Documents

Culture Documents

CL-333 Manual MT 303: Batch Distillation

Uploaded by

yamini_krishnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CL-333 Manual MT 303: Batch Distillation

Uploaded by

yamini_krishnanCopyright:

Available Formats

CL-333 Manual MT 303: Batch Distillation

Batch Distillation Equipment

Operating Panel

Refrectometer

CL-333 Manual MT 303: Batch Distillation Objectives: To determine the height equivalent to number of theoretical stages and the number of transfer units for a packed column.

Theory: Distillation is the most widely used separation technique in the chemical and petroleum industry and is performed in either tray or packed columns. In a packed column, HETP (Height Equivalent to a Theoretical Pate) or HTU (Height of a Transfer Unit) are used to relate the column height with the number of theoretical stages obtained by standard design methods such as McCabe-Thiele or Ponchon-Savaritt. Distillation operated at total reflux yields maximum possible separation. The number of theoretical stages provided by the column is the minimum number of theoretical stages for the top and bottom composition. Minimum number of stages may be calculated using graphical methods or by Fenskes equation given by (1). x 1 xW log( D ) 1 xD xW NM +1 = log av

(1)

av = top X bottom

(2)

NM = number of theoretical stages at total reflux, and av = average relative volatility Experimental procedure: 1. Prepare a calibration chart of RI (Refractive Index) vs. mole fractions of components A and B. 2. Fill approximately 2/3rd volume of the reboiler kettle with a mixture of A and B. 3. Start water circulation through the condenser. 4. Close the bottom sample draw out valve to prevent the overflow of liquid through the sample line during the experiment. Switch on the heating mantle and allow the flask temperature to rise. 5. When the vapors rise to the top of the column, increase the heating rate if necessary. After about 30 min., note the temperatures along the length of the column. If some milky liquid appears in the reflux line, drain it in a small glass vessel and discard. This could be

due to the formation of emulsion of the organic liquid with moisture already present in the system. 6. When the temperature readings along the column length become steady (based on four successive readings taken at 10 min time interval) it indicates that the system has attained steady state and the samples may be withdrawn. 7. 2 to 4 ml of top sample is collected in a sample bottle after purging off some quantity. The bottle should be immediately closed to avoid losses. Determine the RI of the sample. 8. Step 7 should be repeated now for the bottom sample. 9. Count the number of actual plates in the column. HETP may be calculated by (3) once the number of theoretical stages (N M) provided by the column is known. HETP = Height of the column NM (3)

HTU can be calculated from (4) once NTU (Number of Transfer Units) for the column is known. NTU for a packed column is determined using (5). HTU = NTU = Height of the column NTU

yD

(4) (5)

yB

y * y

dy

# Please read standard text books (e.g. Treybal) on mass transfer operations to understand the difference between HTU and HETP. Observations Data from the literature 1. Molecular weights of A and B. 2. Boiling point of A and B. 3. Refractive indices of A and B at ambient temperature. 4. Densities of A and B at ambient temperature. 5. Height of Column.

Calibration data for mole fraction vs. RI S. No. Mole fraction of A RI

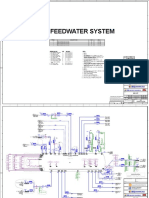

Figure 1: Set-up for Batch Distillation Observations 1. Number of actual stages in the column. 2. Top temperature. 3. Bottom temperature. 4. RI of top and bottom samples.

5. Mole fraction of top sample (xD). 6. Mole fraction of residue or bottom sample (xB). Calculations, Results and Discussion 1. Calculate the number of theoretical stages by McCabe Thiele method and calculate the HETP using equation (3). 2. Calculate the number of stages by Enthalpy-Composition (Ponchon-Savaritt) method and calculate the HETP using (3). 3. Find the number of stages by Fenskes equation (1) and compare the result with that obtained from Step 1 above. 4. Determine the NTU using (5). 5. Comment on the precaution and sources of error.

You might also like

- Lab ManualDocument58 pagesLab ManualAkhil KumarNo ratings yet

- Binary Distillation in A Sieve Plate ColumnDocument9 pagesBinary Distillation in A Sieve Plate ColumnSALONI BHOSALENo ratings yet

- Lab ManualDocument59 pagesLab ManualmarkNo ratings yet

- Packed Distillation Columns: 1. Determination of The Column HeightDocument7 pagesPacked Distillation Columns: 1. Determination of The Column Heightramsrivatsan1992No ratings yet

- 5 Distillation Final ReportDocument7 pages5 Distillation Final ReportElzubair EljaaliNo ratings yet

- Tray Distillation Column With RefluxDocument26 pagesTray Distillation Column With RefluxMelvin MoorNo ratings yet

- 132.3 Flash DistillationDocument26 pages132.3 Flash DistillationKeith SmithNo ratings yet

- ST2-5 Distillation PDFDocument20 pagesST2-5 Distillation PDFShaffaf ThajudheenNo ratings yet

- 8-Plant Design - Separation Units Part 4Document189 pages8-Plant Design - Separation Units Part 4MrHemFunNo ratings yet

- Unit-III Process Equipment Design CalculationsDocument51 pagesUnit-III Process Equipment Design CalculationsboiroyNo ratings yet

- Van DeemterDocument4 pagesVan DeemterSilloAntonioNo ratings yet

- CH 3520 Heat and Mass Transfer Laboratory: Title of The Experiment: Plate Column DistillationDocument7 pagesCH 3520 Heat and Mass Transfer Laboratory: Title of The Experiment: Plate Column DistillationVijay PrasadNo ratings yet

- Mi 123Document12 pagesMi 123Mehran IsgandarliNo ratings yet

- (Distillation) - Packed Distillation ColunmDocument12 pages(Distillation) - Packed Distillation Colunmandy175No ratings yet

- M6 Continuous DistillationDocument9 pagesM6 Continuous DistillationSzeQiLungNo ratings yet

- Melab HT Fall2015Document16 pagesMelab HT Fall2015SCNo ratings yet

- Module-4: by Pandurangan.K Assistant Professor Senior VIT VelloreDocument51 pagesModule-4: by Pandurangan.K Assistant Professor Senior VIT VelloreUrvaNo ratings yet

- McCabe-Thiele Distillation Column Design For A Methanol-Propanol SystemDocument12 pagesMcCabe-Thiele Distillation Column Design For A Methanol-Propanol SystemPeyton EllenNo ratings yet

- Mass LabDocument13 pagesMass Labhagt813No ratings yet

- Lecture 8Document23 pagesLecture 8tarhuniNo ratings yet

- Distillation ColumnDocument32 pagesDistillation ColumnTatiana RosarioNo ratings yet

- v01 I01 07Document7 pagesv01 I01 07SuperbankNo ratings yet

- Elison HR J Chem Educ 2005 82 1086Document3 pagesElison HR J Chem Educ 2005 82 1086Daniel ButlerNo ratings yet

- Fractional Distillation Experiment - ChEDocument6 pagesFractional Distillation Experiment - ChEmutencoNo ratings yet

- Theory:: ObjectivesDocument6 pagesTheory:: ObjectivesdjhgsuifsjhNo ratings yet

- Batch and Continuous Distillation - FINALDocument8 pagesBatch and Continuous Distillation - FINALPenny GildoNo ratings yet

- Study of A Sieved Tray Column For Methanol Water DistillationDocument19 pagesStudy of A Sieved Tray Column For Methanol Water DistillationTom Cullinan100% (1)

- Experiment No,-3 (A) : Mass Transfer Lab IIT KGPDocument3 pagesExperiment No,-3 (A) : Mass Transfer Lab IIT KGPSiddharth MohapatraNo ratings yet

- Theories of ChromatographyDocument13 pagesTheories of ChromatographyZarish Iftikhar100% (1)

- CH3802 Formal DistillationDocument33 pagesCH3802 Formal DistillationAldi StefanusNo ratings yet

- MET 387 Course PackDocument85 pagesMET 387 Course PackWilliam ShultsNo ratings yet

- Gas Chromatography Principles and DeterminationDocument4 pagesGas Chromatography Principles and DeterminationJosé Esqueda LeyvaNo ratings yet

- Exp4 Batch DistillationDocument10 pagesExp4 Batch DistillationSaidNo ratings yet

- EME10406 Process Equipment Design: Fall Semester (2022-23) Lecture - 7 Distillation Column DesignDocument5 pagesEME10406 Process Equipment Design: Fall Semester (2022-23) Lecture - 7 Distillation Column DesignSara Al MandhariNo ratings yet

- Batch Distillation W 10Document6 pagesBatch Distillation W 10Junaid AhmadNo ratings yet

- 2018 End SemDocument2 pages2018 End SemAnand KumarNo ratings yet

- Vapor Liquid Equilibria: Experiment No: 1Document8 pagesVapor Liquid Equilibria: Experiment No: 1Harsh DuttaNo ratings yet

- Distillation Column Lab ReportDocument14 pagesDistillation Column Lab ReportWahida Shukori67% (3)

- Thermal BowingDocument8 pagesThermal BowingA. VenugopalNo ratings yet

- Lab Report Exp 4 G13Document25 pagesLab Report Exp 4 G13WanIntanNadiah50% (2)

- Heat of Solution - IDocument4 pagesHeat of Solution - IUgwu MmesomaNo ratings yet

- CHEN 3787L Signle Effect EvaporatorDocument5 pagesCHEN 3787L Signle Effect EvaporatorMARYAM shahNo ratings yet

- Formal Lab Report GuidelinesDocument7 pagesFormal Lab Report GuidelinesBryan Gabriel Dela LunaNo ratings yet

- The Effect of The Reflux Ratio: Olvar Andrés Pedraza, Juan Pablo González YundaDocument8 pagesThe Effect of The Reflux Ratio: Olvar Andrés Pedraza, Juan Pablo González YundaAndres PedrazaNo ratings yet

- Comparison of Actual and Theoretical Performance of Binary Batch Distillation in A Packed ColumnDocument20 pagesComparison of Actual and Theoretical Performance of Binary Batch Distillation in A Packed ColumnjayaprinaNo ratings yet

- Theoretical Plate: Unit OperationsDocument17 pagesTheoretical Plate: Unit OperationsMehari AsratNo ratings yet

- Lab 10-Batch ReactorDocument22 pagesLab 10-Batch Reactorniraj_bairagiNo ratings yet

- Chemical Engineering Laboratory CHEG 237 Bubble-Cap Distillation ColumnDocument14 pagesChemical Engineering Laboratory CHEG 237 Bubble-Cap Distillation ColumnWisnu WardanaNo ratings yet

- Heat of Adsorption: I TheoryDocument10 pagesHeat of Adsorption: I TheorymahmoudsabryNo ratings yet

- Lecture 3 (16-17) - Thermo Model, Hypo, SubflowsheetDocument15 pagesLecture 3 (16-17) - Thermo Model, Hypo, SubflowsheetAngela Paul PeterNo ratings yet

- Binary Distillation ManualDocument9 pagesBinary Distillation ManualMico AnonuevoNo ratings yet

- Lab Report Dist 1 Batch DistillationDocument20 pagesLab Report Dist 1 Batch Distillationcsgo accountNo ratings yet

- Heat Transfer Homework #4 Professor: Albio Gutiérrez - Office E33-2005 InstructionsDocument4 pagesHeat Transfer Homework #4 Professor: Albio Gutiérrez - Office E33-2005 InstructionsYELSI YAJAIRA QUICENO VILLANUEVANo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Heat and Moisture Transfer between Human Body and EnvironmentFrom EverandHeat and Moisture Transfer between Human Body and EnvironmentNo ratings yet

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsFrom EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNo ratings yet

- City Gas Handbook On Gas SupplyDocument54 pagesCity Gas Handbook On Gas SupplyjacleeNo ratings yet

- Compositional Analysis For Gas CondensateDocument2 pagesCompositional Analysis For Gas CondensateMaqsood IqbalNo ratings yet

- Le Chatelier's Principle PresentationDocument18 pagesLe Chatelier's Principle Presentationstevenbills120No ratings yet

- Air Products' Experience:: Leadership in Mid-Scale To Large LNG Plant ProjectsDocument2 pagesAir Products' Experience:: Leadership in Mid-Scale To Large LNG Plant ProjectsDineshNo ratings yet

- HaloalkanesDocument37 pagesHaloalkanesYuyeen FarhanahNo ratings yet

- The Reactions of AlkanesDocument3 pagesThe Reactions of AlkanesManP13No ratings yet

- 5.1. Exothermic and Endothermic ReactionsDocument1 page5.1. Exothermic and Endothermic ReactionsAkt PhyNo ratings yet

- Chemical Reactors Engineering Chapter 5 Homework SolutionsDocument22 pagesChemical Reactors Engineering Chapter 5 Homework SolutionsHo HumNo ratings yet

- Refrigerant Report 21Document46 pagesRefrigerant Report 21ramonluhrNo ratings yet

- Callidus Thermal Oxidizers For Waste Destruction BrochureDocument5 pagesCallidus Thermal Oxidizers For Waste Destruction BrochuretimNo ratings yet

- Types of WeldingDocument4 pagesTypes of WeldingMeesha RaheelNo ratings yet

- Linear Alkylbenzene (Lab) Manufacture: Andrea BozzanoDocument12 pagesLinear Alkylbenzene (Lab) Manufacture: Andrea BozzanoBharavi K SNo ratings yet

- PERP Program - Isoprene/Bioisoprene: Routes Via C5 StreamsDocument3 pagesPERP Program - Isoprene/Bioisoprene: Routes Via C5 StreamsHari PurwitoNo ratings yet

- Oil and Natural Gas Companies in CanadaDocument10 pagesOil and Natural Gas Companies in Canadabenki megeriNo ratings yet

- Design of Distillation Column PDFDocument25 pagesDesign of Distillation Column PDFRobert DsouzaNo ratings yet

- Pid of A Piping SystemDocument4 pagesPid of A Piping SystemBandaluppi VenkateshNo ratings yet

- GAHUMAN Dalton's LawDocument19 pagesGAHUMAN Dalton's LawTito V. Bautista Jr.No ratings yet

- Methane Oxidation To Acetic AcidDocument31 pagesMethane Oxidation To Acetic AcidАндрей КолесниковNo ratings yet

- 100 Problem SetsDocument30 pages100 Problem Setsapi-380015371% (7)

- Activity 8 Mass Transfer: B. Unsaturated Gas A. 1Document11 pagesActivity 8 Mass Transfer: B. Unsaturated Gas A. 1Jeanne Roselle Dulatre CortezNo ratings yet

- Bio (Enzymes)Document2 pagesBio (Enzymes)66rdsmh2mwNo ratings yet

- Student Industrial Training (Sit) Report JANUARY 2020 - AUGUST 2020Document51 pagesStudent Industrial Training (Sit) Report JANUARY 2020 - AUGUST 2020Aqilah HanimNo ratings yet

- Mixtures and Separations-Lecture#1Document15 pagesMixtures and Separations-Lecture#1victoria0% (1)

- Petroleum Refinery EngineeringDocument9 pagesPetroleum Refinery EngineeringMahtab SajnaniNo ratings yet

- Optimized Design and Operating Parameters For Minimizing Emissions During Thermal OxidationDocument8 pagesOptimized Design and Operating Parameters For Minimizing Emissions During Thermal Oxidationthlim19078656100% (1)

- Science 6 - Q1 - ST4Document2 pagesScience 6 - Q1 - ST4Jilliane DeligeroNo ratings yet

- Phy ChemDocument2 pagesPhy Chemanon_632542580No ratings yet

- INSTRUMENTOSDocument8 pagesINSTRUMENTOSRUDY CASTAÑEDANo ratings yet

- Tank Cleaning Guide BP 2004Document1 pageTank Cleaning Guide BP 2004mabrouk2013No ratings yet

- Anaerobic Digester Design and CalculationDocument42 pagesAnaerobic Digester Design and CalculationDavid Lambert60% (5)