Professional Documents

Culture Documents

ALPOLIC-Fr Calc Example

Uploaded by

Arun RaveOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALPOLIC-Fr Calc Example

Uploaded by

Arun RaveCopyright:

Available Formats

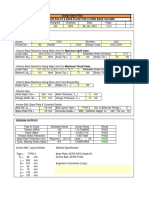

ALPOLIC/fr Panel Strength Calculation Project name:

1. Calculation basis - Panel thickness & type: - Panel size:

t 4 mm long side (a) short side (b)

- Supporting condition: - 0.2% proof stress of aluminium skin of ALPOLIC/fr (3105-H14) - Permissible stress of ALPOLIC/fr: - Wind load (Working load):

405 2000 mm 1000 mm < 4-side simply supported > 152 N/mm2

126 N/mm2 W= 1.5 kPa = 1500.0 * 10-6 N/mm2

2. Calculation of bending stress & deflection without stiffener (from White Binder P.7-13) [Bending stress] 2 2 - Formula of bending stress: AP = *W*b /t where, - a/b (long-short ratio): 2.00 - Coefficient : 0.613 - t2 (square of apparent thickness): - Bending stress: [Deflection] - Coefficient : - Eap* tap3: - Deflection: 9.25 2 2 AP = *W*b /t = 99 < 126 N/mm

2

OK

0.112 2546040 N.mm AP = *W*b4/(Eap* tap3) = 65.7 > 10 mm N.A.

3. Calculation with stiffener 3-1 Calculation basis - Stiffener size (by way of an example): - Material: - Permissible stress: - Number of stiffener(s) per panel: - Imposed load width per stiffener (B): - Span of stiffener (L)

Substructure

40 * 20 * t2 mm Aluminium extrusion (A6063, T5) 110 N/mm2 2 667 mm 1000 mm

20 667

ALPOLIC t=4 40 Stiffener 40 * 20 * t2 Stiffener 2000 667 667 1000

-1-

- Supporting condition of stiffener: - Elastic modulus: Stiffener (E1): ALPOLIC/fr (E2):

Simply supported 70000 N/mm2 39815 N/mm2

3-2 Moment of inertia and section modulus - Stiffener: - ALPOLIC:

I1 = Z1 = I2=B*(H h )/12= Z2=B*(H3h3)/6H=

where, B= H= h=

3 3

1.44 *104 mm4 1.44 *103 mm3 0.206 *104 mm4 1.028 *103 mm3

666.667 mm 4 mm 3 mm

- Stiffener+ALPOLIC: 3-3 Bending stress - Bending moment:

I = I1 + I2 =

1.646 *104 mm4

M = W*B*L2/8 = Stiffeners share: M1 = M*I1/(I1+I2)= ALPOLICs share: M2 = M*I2/(I1+I2)=

125000 Nmm 109386 Nmm 15614 Nmm

- Bending stress: Stiffener ALPOLIC 3-4 Deflection at stiffener center - Bending rigidity of stiffener: - Bending rigidity of ALPOLIC: - SEI: - Deflection (panel with stiffener) s1max = s2max = M1/Z1 = M2/Z2 = 76.0 15.2 < < 110 N/mm2 126 N/mm

2

OK OK

E1I1= E2I2= E1I1 + E2I2 = dmax = 5*W*B*L4/(384*SEI) =

100800 *104 Nmm2 8184 *104 Nmm2 108984 *104 Nmm2 11.9 mm

3-5 Calculation of flat area between stiffeners [Bending stress] - Panel size: a/b Coefficient : t2 (square of apparent thickness): Bending stress:

long side (a) short side (b)

1000 mm 666.67 mm 1.50 0.479 9.25 AP = *W*b2/t2 = 35 < 126 N/mm2 OK

[Deflection] - Coefficient : 3 - Eap* tap : - Deflection:

0.084 2546040 N.mm AP = *W*b4/(Eap* tap3) = 9.7 < 10 mm OK

-2-

You might also like

- Alpolic Design GuideDocument44 pagesAlpolic Design GuideGiri Dharan100% (1)

- Draft: European Standard Norme Européenne Pren 13474-3 Europäische NormDocument34 pagesDraft: European Standard Norme Européenne Pren 13474-3 Europäische NormViorel UngureanuNo ratings yet

- Ead 020002 00 0404 Balcony and Terrace Glazing System Without Vertical Frames 2016Document9 pagesEad 020002 00 0404 Balcony and Terrace Glazing System Without Vertical Frames 2016bmnNo ratings yet

- EC9-1,3 - Design of Aluminium Structures - Structures Susceptible To Fatigue PDFDocument100 pagesEC9-1,3 - Design of Aluminium Structures - Structures Susceptible To Fatigue PDFnebojsadj6411No ratings yet

- En 1999 1 5 2007 PDFDocument67 pagesEn 1999 1 5 2007 PDFNiko NeznanovicNo ratings yet

- SJ Mepla: Theory ManualDocument46 pagesSJ Mepla: Theory ManualSudhakar KrishnamurthyNo ratings yet

- SJ MEPLA Calculation Protocol: Analysis & Design of 12mm THK Monolithic Tempered GlassDocument11 pagesSJ MEPLA Calculation Protocol: Analysis & Design of 12mm THK Monolithic Tempered GlassThakshayani SellavelNo ratings yet

- Truss Framing PDFDocument2 pagesTruss Framing PDFJonald PoquizNo ratings yet

- Screws Details Pinnacle LGSDocument2 pagesScrews Details Pinnacle LGSPavan Poreyana BalakrishnaNo ratings yet

- Standards & RegulationsDocument12 pagesStandards & RegulationsdantranzNo ratings yet

- Regulations on Glass and SealantsDocument6 pagesRegulations on Glass and SealantsSiYing LaiNo ratings yet

- Eta-120114 Spax ScrewsDocument84 pagesEta-120114 Spax ScrewsSunnyWongNo ratings yet

- GB5237.2-2017 英文Document16 pagesGB5237.2-2017 英文TheAnh TranNo ratings yet

- Ul-Eu Certificate: Chris MilesDocument6 pagesUl-Eu Certificate: Chris Milescity chemNo ratings yet

- MBH Metals Catalogue 2018Document60 pagesMBH Metals Catalogue 2018Lorie Banka100% (1)

- Alpolic Cladding Panel PDFDocument5 pagesAlpolic Cladding Panel PDFdep_vinNo ratings yet

- Alucobond Processing enDocument46 pagesAlucobond Processing enOswaldo Diaz NievesNo ratings yet

- Branz Advisory Trower PartitionsDocument6 pagesBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- BS-EN1999-1-5 - E - 2007 - Shell Structures PDFDocument70 pagesBS-EN1999-1-5 - E - 2007 - Shell Structures PDFvozdricaNo ratings yet

- 1 Sean BalfeDocument25 pages1 Sean BalfeShrikant BudholiaNo ratings yet

- 16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01Document14 pages16 10 25 Epd 7 Reynaers Curtain Wall CW 50 r01supadiNo ratings yet

- Alubond Tech - Brochure PDFDocument8 pagesAlubond Tech - Brochure PDFLjubisa TopicNo ratings yet

- (1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsDocument88 pages(1-2) and 1111. (1-2) - 2015 - ISO Meteric Hexagon Bolts and ScrewsMark Carroll-ChiltsNo ratings yet

- Alumineum Rainscreen CladdingDocument10 pagesAlumineum Rainscreen CladdingAnonymous AJYdboNo ratings yet

- Kingspan Accessories Guide Provides Solutions for Roof Drainage and FlashingDocument20 pagesKingspan Accessories Guide Provides Solutions for Roof Drainage and FlashingCiprian VarlanNo ratings yet

- Clause H1 ComplianceDocument32 pagesClause H1 Compliancer1774287No ratings yet

- AD 431 - Column Web Panel Strengthening, June 2019Document1 pageAD 431 - Column Web Panel Strengthening, June 2019symon ellimacNo ratings yet

- 2046 - Decorative Synthetic Bonded Laminated SheetsDocument53 pages2046 - Decorative Synthetic Bonded Laminated SheetsKaushik SenguptaNo ratings yet

- BS5400 Part 4 Training Course - TE EpsomDocument19 pagesBS5400 Part 4 Training Course - TE EpsomjologscresenciaNo ratings yet

- Bruno Presezzi Casting LinesDocument23 pagesBruno Presezzi Casting LinesTKNo ratings yet

- Alpolic Manual ExcerptDocument17 pagesAlpolic Manual ExcerptWilliam David LeavittNo ratings yet

- SJ Mepla Manual Short Eng 50ee8Document14 pagesSJ Mepla Manual Short Eng 50ee8Aqil GhaffarNo ratings yet

- Handrail StandardsDocument4 pagesHandrail StandardsSachin SithikNo ratings yet

- AAMA 2605铝制品喷漆Document15 pagesAAMA 2605铝制品喷漆秦川No ratings yet

- Qseries BS5950Document11 pagesQseries BS5950jpkedahNo ratings yet

- Trimdek: Design and Installation GuideDocument6 pagesTrimdek: Design and Installation GuideHarold SanaresNo ratings yet

- Courses and Seminars CWCT (Centre For Window and Cladding Technology)Document7 pagesCourses and Seminars CWCT (Centre For Window and Cladding Technology)marlontosta5156No ratings yet

- Epoxy Undercoat Protects Steel and ConcreteDocument2 pagesEpoxy Undercoat Protects Steel and ConcreteMoin AltafNo ratings yet

- 50 CR Mo 4Document4 pages50 CR Mo 4Diogo NascimentoNo ratings yet

- I.s.en1634 1 2014+a1 2018Document83 pagesI.s.en1634 1 2014+a1 2018Geoff100% (1)

- 1202 Detail SheetsDocument61 pages1202 Detail SheetsUcok DedyNo ratings yet

- BsDocument33 pagesBsHussein BeqaiNo ratings yet

- EN Catalogo SchletterDocument68 pagesEN Catalogo SchletterMarcelo SilvaNo ratings yet

- Technical Info on Fine Thread Drywall ScrewsDocument2 pagesTechnical Info on Fine Thread Drywall ScrewsNajeeb AhmedNo ratings yet

- Iso 3506 1 2020Document46 pagesIso 3506 1 2020Anna BubblegumNo ratings yet

- Aluminium en AW 6082Document3 pagesAluminium en AW 6082doshi78No ratings yet

- Detecting Laminations in Thick Steel PlatesDocument4 pagesDetecting Laminations in Thick Steel PlatesirmakNo ratings yet

- Glossary of Terms For Hollow Metal Doors and Frames: SDI Technical Data Series Industry Alert 14Document28 pagesGlossary of Terms For Hollow Metal Doors and Frames: SDI Technical Data Series Industry Alert 14Г. БаянмөнхNo ratings yet

- Design Glass, Aluminum, Stainless SteelDocument36 pagesDesign Glass, Aluminum, Stainless Steely2kareinNo ratings yet

- Extruded Alloy 6063Document0 pagesExtruded Alloy 6063Lasantha DadallageNo ratings yet

- Types of Steel Profile and Its UsesDocument3 pagesTypes of Steel Profile and Its UsesednavilodNo ratings yet

- Gorter Brochure en PDFDocument20 pagesGorter Brochure en PDFBegoñaNo ratings yet

- Is 8147 1976Document173 pagesIs 8147 1976agrawalniteshNo ratings yet

- A1-10 Curtain WallsDocument58 pagesA1-10 Curtain WallsZYWNo ratings yet

- Catal Lindapter Facades+cladding en PDFDocument28 pagesCatal Lindapter Facades+cladding en PDFPaulNo ratings yet

- Panel Strength Calclation (4t APfr)Document2 pagesPanel Strength Calclation (4t APfr)Azahar Bin HashimNo ratings yet

- Example-Simply Supported Laterally Unrestrained BeamDocument9 pagesExample-Simply Supported Laterally Unrestrained BeamBejan Claudiu100% (2)

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- ALUM COMPOSITE PANELS SERIES C-3000 ACMDocument6 pagesALUM COMPOSITE PANELS SERIES C-3000 ACMArun RaveNo ratings yet

- RP 611Document9 pagesRP 611Arun RaveNo ratings yet

- 2205 Spec SheetDocument2 pages2205 Spec SheetDownloader99No ratings yet

- Mike OtletwebDocument78 pagesMike Otletwebqatarstructz30No ratings yet