Professional Documents

Culture Documents

DS1869 3V Dallastat Electronic Digital Rheostat: Features Pin Assignment

Uploaded by

ALZAleninOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS1869 3V Dallastat Electronic Digital Rheostat: Features Pin Assignment

Uploaded by

ALZAleninCopyright:

Available Formats

DS1869 3V Dallastat Electronic Digital Rheostat

TM

www.dalsemi.com

FEATURES

Replaces mechanical variable resistors Operates from 3V or 5V supplies Electronic interface provided for digital as well as manual control Internal pull-ups with debounce for easy interfacing to mechanical push buttons Wiper position is maintained in the absence of power Low cost alternative to mechanical controls Applications include volume, tone, contrast, brightness, and dimmer control 8-pin SOIC and 8-pin DIP packages are available Standard resistance values for Dallastat - DS1869-10 ~ 10 k - DS1869-50 ~ 50 k - DS1869-100 ~ 100 k Operating temperature range: - Industrial: -40C to +85C 3V to 8V differential supply operational range

PIN ASSIGNMENT

(RH) UC D (RL) 1 2 3 4 8 7 6 5 +V DC (RW ) V-

8-Pin DIP (300-mil) See Mech. Drawings Section

(RH) UC D (RL)

1 2 3 4

8 7 6 5

+V DC (RW ) V-

8-Pin SOIC (208-mil) See Mech. Drawings Section

PIN DESCRIPTION

RH RW RL -V, +V UC D DC - High Terminal of Potentiometer - Wiper Terminal of Potentiometer - Low Terminal of Potentiometer - Voltage Supply Inputs - Up Contact Input - Digital Input - Down Contact Input

DESCRIPTION

The DS1869 DallastatTM is a digital rheostat or potentiometer. This device provides 64 possible uniform tap points over the entire resistive range. The standard resistive ranges are 10 k, 50 k, and 100 k. The Dallastat can be controlled by either a switch contact closure input or a digital source input such as a CPU. The DS1869 operates from 3V or 5V supplies. Wiper position is maintained in the absence of power through the use of a EEPROM memory cell array. The EEPROM cell array will withstand more than 50,000 writes. The DS1869 is offered in two standard IC packages which include an 8-pin 300-mil DIP and an 8-pin 208-mil SOIC. The DS1869 can be configured to operate using a single pushbutton, dual pushbutton or digital source input by varying power-on conditions. This is illustrated in Figures 1 and 2. The DS1869 pinouts allow access to both ends of the potentiometer RL, RH, and the wiper, RW. Control inputs include the digital source input, D, the up contact input, UC, and the down contact input, DC. Other pins include the positive, +V, and negative, -V, supply inputs. The DS1869 is specified to operate from -40C to +85C. 1 of 8 112099

DS1869

OPERATION

The DS1869 can be configured to operate from a single contact closure, dual contact closure, or a digital source input. Figures 1 and 2 illustrate both contact closure configurations. Contact closure is defined as a transition from a high level to a low level on the up contact (UC) or down contact (DC) inputs. All three control inputs are active when in a low state and are inactive when in a high state. The DS1869 interprets input pulse widths as the means of controlling wiper movement. A single pulse input on the UC, DC, or D input terminals will cause the wiper position to move 1/64th of the total resistance. A transition from a high to low on these inputs is considered the beginning of pulse activity or contact closure. A single pulse must be greater than 1 ms but lasting no longer than 1 second. Pulse timings are shown in Figure 5. Repetitive pulsed inputs can be used to step through each resistive position of the device in a relatively fast manner (see Figure 5b). The requirement for repetitive pulsed inputs is that pulses must be separated by a minimum time of 1 ms. If the input is not allowed to be inactive (high) for at least 1 ms, the DS1869 will interpret repetitive pulses as a single pulse. Pulse inputs lasting longer than 1 second will cause the wiper to move one position every 100 ms following the initial 1-second hold time. The total time to transcend the entire potentiometer using a continuous input pulse is given by the formula below: 1 second + 63 X 100 ms = 7.3 (seconds) Single contact closure operation allows the user to control wiper movement in either direction from a single pushbutton input. Figure 1 presents a typical single pushbutton configuration. The UC input is used to increment and decrement wiper position for single pushbutton mode of operation. The DC input provides no functionality in this mode but must be connected to the positive supply voltage (VCC). The digital source input (D) can be allowed to float. On device power-up, the configuration shown in Figure 1 must exist in order to enter the single contact closure mode of operationespecially and specifically, the (DC) inputs direct connection to the positive supply voltage (VCC). The initial direction of wiper movement in single pushbutton operation is determined by prior activity. The initial direction of wiper movement will be opposite to that of the previous activity. Changing the direction of wiper movement in single pushbutton mode is accomplished by allowing a period of inactivity on the UC input of (greater than) 1 second, or by moving the wiper to the end of the potentiometer range. This will occur regardless of whether the input is a continuous pulse, a sequence of repetitive pulses or a single pulse. The digital source input, D, was designed for microprocessor or controlled applications. This control input manipulates the device in the same manner as the single pushbutton configuration, controlling movement of the wiper position in both upward and downward directions. One added feature over the single pushbutton configuration is the ability to increment or decrement wiper position at a faster rate. Digital source input control is available regardless of the type of pushbutton configuration. Dual pushbutton mode of operation is entered when the DC input is floated on power-up. If interfacing contact closure control inputs to digital logic, the DC input must be interfaced to an open drain drive which is high impedance during power-up; see Figure 2B. This will prevent the device from entering a single pushbutton mode of operation. 2 of 8

DS1869

In dual pushbutton mode, each direction is controlled by the up contact (UC) and down contact (DC) inputs, respectively. No wait states are required to change wiper direction in dual pushbutton mode. In dual pushbutton mode, as the wiper position reaches the end of the potentiometer, the direction of wiper movement will not change. Wiper position will remain at the potentiometers end until an opposite direction input is given. All contact closure control inputs, UC, DC, and D, are internally pulled-up by a 100 k=resistance. The UC and DC inputs are internally debounced and require no external components for input signal conditioning.

DS1869 SINGLE PUSHBUTTON CONFIGURATION (TYPICAL EXAMPLE) Figure 1

DS1869 DUAL PUSHBUTTON CONFIGURATION (TYPICAL EXAMPLE) Figure 2A

3 of 8

DS1869

DS1869 DUAL PORT CONFIGURATION (TYPICAL EXAMPLE) Figure 2B

The DS1869 is provided with two supply inputs -V and +V. The maximum voltage difference between the two supply inputs is +8.0 volts. The minimum voltage difference is +2.7 volts. All input levels are referenced to the negative supply input, -V. The voltage applied to any Dallastat terminal must not exceed the negative supply voltage (-V ) by -0.5 or the positive supply voltage (+V) by +0.5 volts. The minimum logic high level must be +2.4 volts with reference to the -V supply voltage input for +V=5V. A logic low level with reference to the -V supply voltage has a maximum value of +0.8 volts. Dallastats exhibit a typical wiper resistance of 400 ohms with a maximum wiper resistance of 1000 ohms. The maximum wiper current allowed through the Dallastat is specified at 1 milliamps (see DC Electrical Characteristics).

NONVOLATILE WIPER SETTINGS

Dallastats maintain the position of the wiper in the absence of power. This feature is provided through the use of EEPROM type memory cell arrays. During normal operation the position of the wiper is determined by the input multiplexer. Periodically, the multiplexer will update the EEPROM memory cells. The manner in which an update occurs has been optimized for reliability, durability, and performance. Additionally, the update operation is totally transparent to the user. When power is applied to the Dallastat, the wiper setting will be the last recorded in the EEPROM memory cells. If the Dallastat setting is changed after power is applied, the new value will be stored after a delay of 2 seconds. The initial storage of a new value after power-up occurs when the first change is made, regardless of when this change is made. After the initial change on power-up all subsequent changes of the wiper position will be recorded only if the 4th LSB (out of a 6-bit total for 64 positions) is being changed. Thus any change greater than 12.5% of the total resistance range will trigger one EEPROM write cycle. Changes or storage to the EEPROM memory cells must allow for a 2-second delay to guarantee that updates will occur. The EEPROM memory cells are specified to accept greater that 50,000 writes before a wear-out condition. If the EEPROM memory cells do reach a wear-out condition, the Dallastat will still function properly while power is applied. However, on power-up the devices wiper position will be that of the position last recorded before memory cell wear-out. 4 of 8

DS1869

FLOWCHART: ONE-BUTTON OPERATION AND ELECTRICAL CONTROL Figure 3

CONTACT OPEN AND CONTACT CLOSURE TIMING IS 1 SECOND 15%

5 of 8

DS1869

FLOWCHART: TWO-BUTTON OPERATION Figure 4

CONTACT OPEN AND CONTACT CLOSURE TIMING IS 1 SECOND 15%

6 of 8

DS1869

ABSOLUTE MAXIMUM RATINGS*

Voltage on Any Pin Relative to -V Operating Temperature Storage Temperature Soldering Temperature * -V -0.5V +8.0V -40C to +85C -55C to +125C 260C for 10 seconds

This is a stress rating only and functional operation of the device at these or any other conditions above those indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods of time may affect reliability.

RECOMMENDED DC OPERATING CONDITIONS

PARAMETER + Supply Voltage - Supply Voltage Resistor Inputs Logic Input 1 Logic Input 0 Wiper Current SYMBOL +V -V RH,RW,RL VIH VIL IW MIN -V + 2.7 +V - 8.0 -V - 0.5 +2.4 +0.8 1 TYP MAX -V + 8.0 +V - 2.7 +V + 0.5

(-40C to +85C)

UNITS V V V V V mA 1, 2, 10 1, 2, 10 5 NOTES

DC ELECTRICAL CHARACTERISTICS (-40C to +85C; -V to +V = 2.7V to 8.0V)

PARAMETER End to End Resistor Tolerance +, - Supply Current Supply Current, Idle State At 3.3V At 8.0V Wiper Resistance Temperature Coefficient SYMBOL ICC1 ICC2 2 10 RW 400 750 1000 A ppm/C 9 MIN -20 TYP 1 MAX 20 2 UNITS % mA NOTES 11 3

AC ELECTRICAL CHARACTERISTICS (-40C to +85C; -V to +V = 2.7V to 8.0V)

PARAMETER Input Pulse Width (D-input) Contact Pulse Width (UC, DC inputs) Capacitance Repetitive Input Pulse High Time Continuous Input Pulse SYMBOL tPW tCPW CIN tHPW tCCP 1 1 MIN 1 1 5 TYP MAX DC DC 10 DC DC UNITS s ms pF ms s NOTES 1, 7, 8 1, 7, 8 6 1, 7, 8 1, 7, 8

7 of 8

DS1869

TIMING DIAGRAMS Figure 5

tCPW

NOTES:

All inputs; UC, DC, and D are internally pulled up with a typical resistance of 100 k. Input logic levels are referenced to -V. ICC is the internal current that flows between -V and +V. Input leakage applies to contact inputs UC and DC and the digital input (D). Wiper current is the maximum current which can flow through the wipers. Capacitance values apply at 25C. Input pulse width is the minimum time required for an input to cause an increment or decrement. If the UC, DC, or D input is held active for longer than 1 second, subsequent increments or decrements will occur on 100 ms intervals until the inputs UC, DC, and/or D is released to VIH. 8. Repetitive pulsed inputs on UC, DC, or D will be recognized as long as the pulse repetition occurs within 1 second of each other. Pulses occurring faster than 1 ms apart may not be recognized as individual inputs but can be interpreted a constant input. Tolerance for pulse timing is 15% on minimum inputs. 9. Idle state supply current is measured with no pushbutton pressed and with the wiper RW tied to a CMOS load. 10. For +V referenced to -V = 5V. 11. Valid at 25C only. 1. 2. 3. 4. 5. 6. 7.

8 of 8

You might also like

- DS1669Document11 pagesDS1669Ghost9231No ratings yet

- Digital Rheostat DS1669 Technical OverviewDocument10 pagesDigital Rheostat DS1669 Technical Overviewpedro santosNo ratings yet

- DS1809 010 64-Position Linear Taper Two Nonvolatile Wiper Storage Options 10K OHMSDocument9 pagesDS1809 010 64-Position Linear Taper Two Nonvolatile Wiper Storage Options 10K OHMSJuan Gil RocaNo ratings yet

- DS1804Document10 pagesDS1804Brzata PticaNo ratings yet

- DS1804Document6 pagesDS1804jnax101No ratings yet

- DS1802Document17 pagesDS1802roNo ratings yet

- DM74123 Dual Retriggerable One-Shot With Clear and Complementary OutputsDocument5 pagesDM74123 Dual Retriggerable One-Shot With Clear and Complementary OutputsDiego HenriqueNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- DS1804 PDFDocument10 pagesDS1804 PDFhelveciotfNo ratings yet

- X9313 Terminal Voltage 5V, 32 Taps: AvailableDocument10 pagesX9313 Terminal Voltage 5V, 32 Taps: Availableblackwolf511No ratings yet

- Xr1 e Rotor Earth Fault RelayDocument12 pagesXr1 e Rotor Earth Fault RelayKrisada ThongkamsaiNo ratings yet

- Power Designs 5020 Precision Power Source Manual Newer EditionDocument20 pagesPower Designs 5020 Precision Power Source Manual Newer EditionVivi LazuliNo ratings yet

- DS1801 Dual Audio Taper Potentiometer: Features Pin AssignmentDocument10 pagesDS1801 Dual Audio Taper Potentiometer: Features Pin AssignmentnicolaunmNo ratings yet

- Earth Leakage Relays ELRV30-2-A RMS PDFDocument2 pagesEarth Leakage Relays ELRV30-2-A RMS PDFDEADMANNo ratings yet

- Touch Screen Controller TipsDocument9 pagesTouch Screen Controller TipsArchana N AmbarishNo ratings yet

- Proy. Electrónico DC Power MeterDocument20 pagesProy. Electrónico DC Power Metervpol25No ratings yet

- UC3842 current mode controller application noteDocument7 pagesUC3842 current mode controller application noteCui BapNo ratings yet

- Hardware Description: TheoryDocument21 pagesHardware Description: TheoryRamawatar VaishnavNo ratings yet

- GE2011 IbDocument152 pagesGE2011 IbEsteban SosaNo ratings yet

- Dual Digital Potentiometer Chip with Ultra-Low Power and Temperature CompensationDocument12 pagesDual Digital Potentiometer Chip with Ultra-Low Power and Temperature CompensationManuel NolascoNo ratings yet

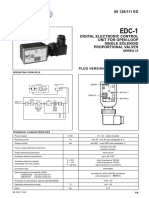

- Amplifier Card EDC-1 Plug in VersionDocument4 pagesAmplifier Card EDC-1 Plug in VersionLibinNo ratings yet

- Handbook UPS PDFDocument52 pagesHandbook UPS PDFJoni EfwanNo ratings yet

- LTC3780 Description: Quick Start Guide For Demonstration Circuit Dc686Document6 pagesLTC3780 Description: Quick Start Guide For Demonstration Circuit Dc686Yung SangNo ratings yet

- Dual Slope AdcDocument5 pagesDual Slope AdcvishvinnyNo ratings yet

- Prekidačka NapajanjaDocument48 pagesPrekidačka NapajanjaDamir PranjkovicNo ratings yet

- Switch Mode Power Supply (SMPS) Topologies (Part I) - MicrochipDocument48 pagesSwitch Mode Power Supply (SMPS) Topologies (Part I) - MicrochipGhulam AbbasNo ratings yet

- AN1114 - Switch Mode Power Supply (SMPS) Topologies (Part I) - MicrochipDocument48 pagesAN1114 - Switch Mode Power Supply (SMPS) Topologies (Part I) - MicrochipbmmostefaNo ratings yet

- Dkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportDocument43 pagesDkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportLuis Fernando CuaspudNo ratings yet

- M XxuywDocument13 pagesM XxuywRenganathan KrishnanNo ratings yet

- PTS HIPOT INSTRUMENTS OPERATOR MANUALDocument34 pagesPTS HIPOT INSTRUMENTS OPERATOR MANUALOmar Marquez BonillaNo ratings yet

- New EhtcDocument4 pagesNew EhtcRamakrishnan NatarajanNo ratings yet

- Docs Books M-2001B-IB PDFDocument130 pagesDocs Books M-2001B-IB PDFDomingo CordovaNo ratings yet

- Very Wide Input Voltage Range-Flyback (90V To 600V AC)Document12 pagesVery Wide Input Voltage Range-Flyback (90V To 600V AC)senkum812002No ratings yet

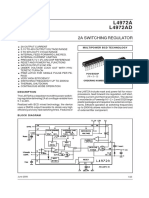

- L4972ADocument23 pagesL4972ARICHIHOTS2No ratings yet

- DS1666Document7 pagesDS1666jnax101No ratings yet

- PSU TSP3222 4pDocument4 pagesPSU TSP3222 4psajedaliNo ratings yet

- UC3879Document9 pagesUC3879Christina Tio TrisnasariNo ratings yet

- CD 00003131Document24 pagesCD 000031314131etasNo ratings yet

- UC2842 Philips AN1272 PDFDocument7 pagesUC2842 Philips AN1272 PDFupali01No ratings yet

- Closed Loop Control System (CSL - 04) : Technical Manual FORDocument19 pagesClosed Loop Control System (CSL - 04) : Technical Manual FORAAYUSH KUMARNo ratings yet

- 78S40Document0 pages78S40Pravin MevadaNo ratings yet

- 60W Wide-Range Power Supply For LCD Monitor or TV, Using The L5991Document17 pages60W Wide-Range Power Supply For LCD Monitor or TV, Using The L5991Grzegorz WegnerNo ratings yet

- Dual Full-Bridge Driver: DescriptionDocument13 pagesDual Full-Bridge Driver: DescriptionBaher Bassem MorkosNo ratings yet

- Cat5113 DDocument13 pagesCat5113 DVolkan YılmazNo ratings yet

- Imprimir Datasheet 1Document14 pagesImprimir Datasheet 1Randy Siancas VelezNo ratings yet

- Actaris Transmitters SpecDocument4 pagesActaris Transmitters SpecDaniel GarciaNo ratings yet

- Uploads Product Rishmaster EM3490 1PH Manual PDFDocument2 pagesUploads Product Rishmaster EM3490 1PH Manual PDFKo PaukNo ratings yet

- DC/DC Converter Operation GuideDocument6 pagesDC/DC Converter Operation GuidesaeidraminaNo ratings yet

- 90W Smps For Monitors With Constant Power Limiting Function: AN1133 Application NoteDocument11 pages90W Smps For Monitors With Constant Power Limiting Function: AN1133 Application NoteMadein ChinaNo ratings yet

- On-Load Tap Changer Operating ManualDocument16 pagesOn-Load Tap Changer Operating ManualculwavesNo ratings yet

- Alstom L3-KBCH-BR-04-05-0910-GBDocument8 pagesAlstom L3-KBCH-BR-04-05-0910-GBsteve_osullivanNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- 10 ExtSpringsDocument27 pages10 ExtSpringsresh27No ratings yet

- Project Planning HandbookDocument21 pagesProject Planning HandbookPhilip JonesNo ratings yet

- Adiabatic Production of Acetic AnhydrideDocument7 pagesAdiabatic Production of Acetic AnhydrideSunilParjapatiNo ratings yet

- Drainage PDFDocument1 pageDrainage PDFSwapnil JainNo ratings yet

- Enabling Keycloak Metrics - KeycloakDocument3 pagesEnabling Keycloak Metrics - Keycloakhisyam darwisNo ratings yet

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDocument7 pagesPlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteNo ratings yet

- Mitigating arc ash hazards design constraintsDocument6 pagesMitigating arc ash hazards design constraintswaqas_a_shaikh4348No ratings yet

- PLC SCADA ASSIGNMENT SsDocument10 pagesPLC SCADA ASSIGNMENT SsShadab AhmadNo ratings yet

- Exoskeleton Power Requirements Based on Human BiomechanicsDocument54 pagesExoskeleton Power Requirements Based on Human Biomechanicsja2ja1No ratings yet

- Strategic Investment Plan ForDocument78 pagesStrategic Investment Plan Forapi-3833112No ratings yet

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDocument17 pagesMDS Report Substances of Assemblies and Materials: 1. Company and Product Namejavier ortizNo ratings yet

- 13 Nilufer-CaliskanDocument7 pages13 Nilufer-Caliskanab theproNo ratings yet

- DVOR Principle 코이카 양식Document71 pagesDVOR Principle 코이카 양식Undral Batbayar100% (1)

- Halo Outdoor slmt1000 - slmt1000wDocument1 pageHalo Outdoor slmt1000 - slmt1000wFrank MoyaNo ratings yet

- Topic 3Document28 pagesTopic 3Ashraf YusofNo ratings yet

- World MultipleDocument271 pagesWorld MultipleatrkpoleNo ratings yet

- Ayurveda Signs of LifeDocument15 pagesAyurveda Signs of LifeSanjeethNo ratings yet

- Instruction Manual Series 854 XTG Level GaugeDocument60 pagesInstruction Manual Series 854 XTG Level GaugeJandri JacobNo ratings yet

- Influence of Social Studies Education On Ethnic and Religious Tolerance Among National Certificate of Education Students in Kaduna State.Document104 pagesInfluence of Social Studies Education On Ethnic and Religious Tolerance Among National Certificate of Education Students in Kaduna State.Tsauri Sule SalehNo ratings yet

- Verb-Particle Constructions in Romance. A Lexical-Syntactic AccountDocument29 pagesVerb-Particle Constructions in Romance. A Lexical-Syntactic AccountWagaJabalNo ratings yet

- Tiger AnddragonDocument61 pagesTiger AnddragonAdil SiddiquiNo ratings yet

- Formal Analysis of Timeliness in Electronic Commerce ProtocolsDocument5 pagesFormal Analysis of Timeliness in Electronic Commerce Protocolsjuan david arteagaNo ratings yet

- God in The Quran A Metaphysical StudyDocument133 pagesGod in The Quran A Metaphysical StudyFaisal Ali Haider LahotiNo ratings yet

- BOQ Sample of Electrical DesignDocument2 pagesBOQ Sample of Electrical DesignAshik Rahman RifatNo ratings yet

- MD SHAFIUL ISLAM 沙菲 ID;20183290290Document23 pagesMD SHAFIUL ISLAM 沙菲 ID;20183290290SHAFIUL SETUNo ratings yet

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- LTE Interview QuestionsDocument10 pagesLTE Interview QuestionsMahesh Pratap100% (1)

- Listening Script 11Document11 pagesListening Script 11harshkumarbhallaNo ratings yet

- Wavemakers For Physical Models: EquipmentDocument10 pagesWavemakers For Physical Models: Equipmentesmaeil013No ratings yet

- Effective-Plant-Course Brochure NovDocument8 pagesEffective-Plant-Course Brochure NovAzri HafiziNo ratings yet