Professional Documents

Culture Documents

4T40 Cuerpo Valvulas

Uploaded by

Jorge ArturoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4T40 Cuerpo Valvulas

Uploaded by

Jorge ArturoCopyright:

Available Formats

#07-07-30-025: Information on 4T40-E (MN4) and 4T45-E (MN5) Front Wheel Drive Automatic Transmission Valve Body Reconditioning

DTC P0741, P0742, P0751, P0752, P0756, P0757, P1811, Harsh Shift, Slip, No Drive/Reverse (Oct 1, 2007)

Information On 4T40-E (MN4) and 4T45-E (MN5) Front Wheel Drive Automatic Transmission Valve Body Reconditioning, DTC P0741, P0742, P0751, P0752, P0756, P0757, P1811, Harsh Shifts, Slips, No Drive, No Reverse Models: 1997-2005 Chevrolet Cavalier 1997-2007 Chevrolet Malibu 2005-2007 Chevrolet Cobalt 2006-2007 Chevrolet Malibu Maxx, HHR 1997-1998 Oldsmobile Cutlass 1999-2004 Oldsmobile Alero 1997-2005 Pontiac Sunfire 1999-2005 Pontiac Grand Am 2005-2006 Pontiac Pursuit (Canada Only) 2005-2007 Pontiac G6 2007 Pontiac G5 2000-2005 Saturn L-Series 2005-2007 Saturn ION, VUE 2007 Saturn Aura with Hydra-Matic 4T40-E (RPO MN4) and 4T45-E (RPO MN5) Automatic Transmission

The following new service information outlined in this bulletin will aid technicians in providing easy to follow valve body reconditioning instructions and new illustrations to simplify reassembly of the valve body. The service bulletin will also provide additional service information documents that are related to the 4L6x transmission family.

Related Service Documents

PIP 3253B - No Move Drive or Reverse 02-07-30-039F - Firm Transmission Shifts 02-07-30-050 - Engineering Change Valve Body

Important: If valve body cleaning is not required, Do Not disassembly bores unless it is necessary to verify movement of valves.

Inspection Procedure

1. Using the exploded views in this bulletin, inspect each bore for freedom of valve(s) movement and evidence of debris. Pay particular attention to those valves related to the customers concern. 2. Verify movement of the valves in their normal installed position. Valves may become restricted during removal or installation. This is normal due to small tolerances between the valves and bores. 3. If a valve is restricted and cannot be corrected by cleaning valve and bore, then replace valve body. Describe restricted valve on repair order.

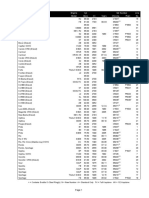

Valve Body Spring and Bore Plug Chart (Metric)

Valve Body Spring and Bore Plug Chart (Inch)

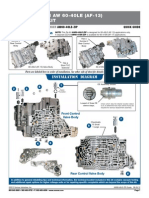

Left Side Control Valve Body Assembly

Call Out Number

301 302 304 305

Description

Spring, 1-2 Shift Valve Valve, 1-2 Shift Retainer Clip Solenoid with O-Ring, 1-2 Shift Solenoid with O-Ring, 2-3 Shift

306 307 308 309 312 314 315 316 317 318 319 321

Spring, 2-3 Shift Valve Valve, 2-3 Shift Spring, Torque Signal Regulator Valve, Torque Signal Regulator Solenoid, Pressure Control with Two O-Rings and Screen Filter, Actuator Oil Valve, Actuator Feed Limit Spring, Actuator Feed Limit Plug, Bore Spring, 3-4 Shift Valve Valve, 3-4 Shift Plug, Bore with O-Ring

Right Side Control Valve Body Assembly

Call Out Number

304 317 323 324 325 326 327 328 329 330 331 332 333 334 335 339 340 341

Description

Retainer Clip Plug, Bore Valve, Accumulator Bushing Valve, Pressure Regulator Boost Spring, Isolator Spring, Pressure Regulator Valve Valve, Pressure Regulator Spring, 2-3 Accumulator Valve Valve, 2-3 Accumulator Spring, TCC Feed Limit Valve, TCC Feed Limit Spring, TCC Control Valve Valve, TCC Control Solenoid, TCC with Two O-rings Valve, TCC Regulated Apply Spring, TCC Regulated Apply Valve Plug, Bore

Notice: Be sure all solenoids are installed with the electrical connectors facing the non-machined (cast) side of the valve body; otherwise, the solenoids will bind against the transmission case as the valve body bolts are tightened and damage may occur.

Disassembly/Reassembly

1. If a valve is restricted by a metal burr from machining that bore, remove valve and burr, then inspect movement in the valves normal position. If no other debris or restrictions are found, then reassemble valve body and install in the transmission. 2. If the valve body has been contaminated with debris from another transmission component failure, then disassemble all bores for complete cleaning of all valve body components. If possible keep individual bore parts

separated for ease of reassembly. Use the following illustrations in this bulletin for a positive identification and location of individual parts: Left Side Control Valve Body Assembly Right Side Control Valve Body Assembly Control Valve Body Assembly Chart, Valve Springs and Bore Plugs 5. Using GM Brake Clean, or equivalent, in a safe and clean environment (clean aluminum pan) clean the valve body and dry it with compressed air. Use appropriate eye protection. 6. Clean individual valve body components with GM Brake Clean, or equivalent. Coat each valve with clean ATF and reassemble in each bore. Check each valve for free movement during assembly of each bore.

You might also like

- 2005 Chevrolet ChevyDocument8 pages2005 Chevrolet ChevyDavidNo ratings yet

- TIMING DIAGRAMS - OutputDocument54 pagesTIMING DIAGRAMS - OutputDaniel100% (8)

- 5R55N Seminar InfoDocument18 pages5R55N Seminar InfocarlosNo ratings yet

- Operator's Manual: Massey Ferg NDocument78 pagesOperator's Manual: Massey Ferg Nmilan959100% (6)

- 5r55n How-To-Fix-ItDocument87 pages5r55n How-To-Fix-ItDavid Chalker100% (14)

- A4rab4rab46abdrabmxam4ras4raslxa20420speed PDFDocument2 pagesA4rab4rab46abdrabmxam4ras4raslxa20420speed PDFedger100% (1)

- Transmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesDocument5 pagesTransmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesFDONo ratings yet

- Overhaul A240eDocument140 pagesOverhaul A240eSamuel83% (6)

- GF4EATDocument112 pagesGF4EATVENDA DE PEÇAS CAMBIONo ratings yet

- Engine Valve Lash - Inspect/Adjust: Tela AnteriorDocument4 pagesEngine Valve Lash - Inspect/Adjust: Tela AnteriorSidartaTrovao BarbalhoNo ratings yet

- Carproof Used Car Buying GuideDocument29 pagesCarproof Used Car Buying GuideAbhinav BehlNo ratings yet

- Ford Edge 2008-2009 PDFDocument462 pagesFord Edge 2008-2009 PDFEnedine RamirezNo ratings yet

- Assembly U241E TransmissionDocument29 pagesAssembly U241E TransmissionFirman SuryaNo ratings yet

- 2004 Hyundai Sonata 2Document112 pages2004 Hyundai Sonata 2EJ EdgeNo ratings yet

- MIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of PowerDocument22 pagesMIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of Powerdamian berduscoNo ratings yet

- 6t40 Gen2 Zip inDocument10 pages6t40 Gen2 Zip inLuiz FernandoNo ratings yet

- Critical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55EDocument2 pagesCritical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55ECesar Isac PalominoNo ratings yet

- 4r44e 5r55e Zip BookletDocument8 pages4r44e 5r55e Zip BookletDaniel BernardNo ratings yet

- Aw60 40le Zip inDocument10 pagesAw60 40le Zip inMarko PavlovicNo ratings yet

- U760e Zip in PDFDocument11 pagesU760e Zip in PDFBilly100% (2)

- Aw60 40le Zip BookDocument8 pagesAw60 40le Zip BookMohamd Fadel Hassan80% (5)

- Toyota U140 / U240: FWD 4 SpeedDocument6 pagesToyota U140 / U240: FWD 4 Speedjuan carlos garcia100% (1)

- CD4EDocument7 pagesCD4EDaniel Gonzalez100% (1)

- 6F50 TipsDocument10 pages6F50 TipsNoah Istre100% (1)

- DP 0Document4 pagesDP 0zagardNo ratings yet

- BTR Automatic Transmission PDFDocument9 pagesBTR Automatic Transmission PDFJUAN CARLOS GLAUSERNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument16 pagesTechnical Service Information: Automatic Transmission Service GroupDenis Konovalov100% (2)

- A 131LDocument70 pagesA 131LGustavo Gamez100% (2)

- RE5R05ADocument1 pageRE5R05APedroMecanicoNo ratings yet

- 6T45 ValvulebodyDocument2 pages6T45 Valvulebodyeduone65No ratings yet

- Control Solenoid Valve and Transmission Control Module Assembly Inspection (Gen 1 With 1.8L - LUW)Document2 pagesControl Solenoid Valve and Transmission Control Module Assembly Inspection (Gen 1 With 1.8L - LUW)fernando bastonNo ratings yet

- CVT Transmission Parts k313 Automatic Transmission Valve BodyDocument5 pagesCVT Transmission Parts k313 Automatic Transmission Valve BodyRepuestos Maceira0% (1)

- Rcrit 16V122 2231 PDFDocument319 pagesRcrit 16V122 2231 PDFarstjunkNo ratings yet

- Data-Tech 2007 Volkswagen Jetta 2.5L-Diagramas ElectricosDocument21 pagesData-Tech 2007 Volkswagen Jetta 2.5L-Diagramas ElectricosRuben100% (1)

- R4A51Document1 pageR4A51Vadim Urupa0% (1)

- Overhaul A240e PDFDocument140 pagesOverhaul A240e PDFMuslihnofal50% (2)

- 4 L 30 eDocument7 pages4 L 30 eLeonardo PaesNo ratings yet

- Qashqai j10 DLKDocument875 pagesQashqai j10 DLKa2s100% (6)

- Aw60 40le Zip in PDFDocument10 pagesAw60 40le Zip in PDFBrian Torres90% (10)

- in PDFDocument2 pagesin PDFenderson cruzNo ratings yet

- 7 Series Engine Powered Forklift 3.5-5.0 TonDocument8 pages7 Series Engine Powered Forklift 3.5-5.0 Tonwill wuNo ratings yet

- Just Another: Play BallDocument8 pagesJust Another: Play BallAnonymous eExWojLxNo ratings yet

- Forklift Fuel Consuption PDFDocument12 pagesForklift Fuel Consuption PDFVaisakh KrishnaNo ratings yet

- 2014 An125hkl4Document69 pages2014 An125hkl4El Turco ChalabeNo ratings yet

- Servodirectii EatonDocument14 pagesServodirectii Eatonwappii100% (1)

- 6T40 Gen2 Zip in PDFDocument10 pages6T40 Gen2 Zip in PDFnurdinzai100% (1)

- P2716Document4 pagesP2716David RosadoNo ratings yet

- Aw60 40leDocument2 pagesAw60 40leSnokeX100% (1)

- NPW MitsubishiDocument13 pagesNPW MitsubishiDJ90RADIONo ratings yet

- AW55-50SN, AW55-51SN, AF23/33, RE5F22A Zip Kit: Installation DiagramDocument10 pagesAW55-50SN, AW55-51SN, AF23/33, RE5F22A Zip Kit: Installation DiagramKalinin Pineda100% (1)

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- Ford 6R60E/6R75E (2006 - On) : 6 SPEED 2WD & 4WD (Full Electronic Control)Document4 pagesFord 6R60E/6R75E (2006 - On) : 6 SPEED 2WD & 4WD (Full Electronic Control)krzysiek1975No ratings yet

- 42rle 4 Speed: RemovalDocument43 pages42rle 4 Speed: RemovalKelvin Samuel Chirinos ChirinosNo ratings yet

- 6R60Document1 page6R60PedroMecanico50% (2)

- Ford Fnr5 TCC SlipDocument2 pagesFord Fnr5 TCC SlipAlex Maceira Graterol100% (2)

- Caja CVTDocument4 pagesCaja CVTEsteban CaceresNo ratings yet

- Magneti Marelli Selespeed CFC328 (DUALOGIC) - Italian Robot - The AKPPro MagazineDocument1 pageMagneti Marelli Selespeed CFC328 (DUALOGIC) - Italian Robot - The AKPPro MagazineGregNo ratings yet

- CHRYSLER A500 (40RH, 42RH, 40RE, 42RE, 44RE) : 4 SPEED RWD & 4WD (Hydraulic & Electronic Control)Document6 pagesCHRYSLER A500 (40RH, 42RH, 40RE, 42RE, 44RE) : 4 SPEED RWD & 4WD (Hydraulic & Electronic Control)Miguel GuzmanNo ratings yet

- A4 LDDocument1 pageA4 LDOmar Molina100% (1)

- Catalog A760eDocument4 pagesCatalog A760eautomaticosbrasilNo ratings yet

- 4R44 55E p0741Document3 pages4R44 55E p0741Noah IstreNo ratings yet

- 01M Multiples CodigosDocument1 page01M Multiples Codigosflash_24014910No ratings yet

- Manual Caixa de Velocidades ZF 5HP19Document37 pagesManual Caixa de Velocidades ZF 5HP19Prósper Ponte100% (1)

- G4a El FallasDocument8 pagesG4a El FallasLogam Lopez100% (1)

- 1995 Ford Escort 1Document11 pages1995 Ford Escort 1Francisco SanchezNo ratings yet

- A/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Document6 pagesA/T - No Reverse/3rd or 5th Gear/MIL ON/DTC P0776Carlos CuellarNo ratings yet

- Series V100 Ball ValveDocument20 pagesSeries V100 Ball ValvejenniferNo ratings yet

- Evoque TransDocument16 pagesEvoque TransdanNo ratings yet

- Wheel Horse Hydraulic Lift Valve & Cylinder Repair ManualDocument12 pagesWheel Horse Hydraulic Lift Valve & Cylinder Repair ManualwordswainNo ratings yet

- CVS Type 1051 Rotary Actuator: Instruction ManualDocument12 pagesCVS Type 1051 Rotary Actuator: Instruction Manualsalmo83:18No ratings yet

- Machine Rating S450 Dimension: DI CE - Drève Richelle 167 - B-1410 Waterloo, BelgiumDocument4 pagesMachine Rating S450 Dimension: DI CE - Drève Richelle 167 - B-1410 Waterloo, BelgiumGeorgeNo ratings yet

- AP02AC9644Document1 pageAP02AC9644SWAMYNo ratings yet

- TGB Brochure 2010Document16 pagesTGB Brochure 2010JoergNo ratings yet

- Police Log March 2, 2016Document13 pagesPolice Log March 2, 2016MansfieldMAPoliceNo ratings yet

- Catalogo Buffalo Splinders, Bombas DH, Amortiguadores, Terminales 2016Document48 pagesCatalogo Buffalo Splinders, Bombas DH, Amortiguadores, Terminales 2016FRENOS CAMPANASNo ratings yet

- 3 Epic Classic 2015Document17 pages3 Epic Classic 2015WildWindTeamNo ratings yet

- Parts 3120789 ANSI English PDFDocument346 pagesParts 3120789 ANSI English PDFMexanik212No ratings yet

- Engine Cyl Set Number Line Application Model Bore CC Years Chrome Plain NoDocument3 pagesEngine Cyl Set Number Line Application Model Bore CC Years Chrome Plain Nomarran almarranyNo ratings yet

- VLX1T P150X 1970s No BatteryDocument1 pageVLX1T P150X 1970s No BatteryYudha AgungNo ratings yet

- Catalog 215: Spring IdentificationDocument5 pagesCatalog 215: Spring IdentificationZech FrostNo ratings yet

- GT 2015 TechbookDocument43 pagesGT 2015 TechbookValerian100% (1)

- Toll Free Order Line USA: 800 336 6500 - Canada: 888 922 3006 6Document30 pagesToll Free Order Line USA: 800 336 6500 - Canada: 888 922 3006 6Terry BradfordNo ratings yet

- TVS Motor Company Introduces 2 New, Exciting Colours For TVS WEGO (Company Update)Document5 pagesTVS Motor Company Introduces 2 New, Exciting Colours For TVS WEGO (Company Update)Shyam SunderNo ratings yet

- D3E8049715C-Wheels and Tyres GuideDocument496 pagesD3E8049715C-Wheels and Tyres Guidenikodem.kaczynskiNo ratings yet

- Catalogo FortecDocument21 pagesCatalogo FortecGenius EditorNo ratings yet

- Merlo TF33 7Document2 pagesMerlo TF33 7Pronto AccessNo ratings yet

- Consumer Durables MarketingDocument30 pagesConsumer Durables Marketingavsthi100% (1)

- Alfa Romeo Stelvio: History and Development Chassis, Mechanics and Suspensions ModelsDocument7 pagesAlfa Romeo Stelvio: History and Development Chassis, Mechanics and Suspensions ModelsrobertoNo ratings yet

- ZOOMLION Scissor Lifts DC SeriesDocument2 pagesZOOMLION Scissor Lifts DC SeriesFilex RobertNo ratings yet

- Datos Maquina TaylorDocument4 pagesDatos Maquina TaylorMarco Guachun50% (2)