Professional Documents

Culture Documents

Sujith - Digital Light Processing

Uploaded by

api-3827000Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sujith - Digital Light Processing

Uploaded by

api-3827000Copyright:

Available Formats

Seminar Report ’03 Digital Light Processing

CONTENTS

1. Introduction

2. DMD Light Switch

3. Grayscale & Color Operation

4. DMD cell Architecture & Fabrication

5. Electronic Operation

6. DMD System Description & Operation

7. Projection Optics

8. Technology Advantages

9. Benefits

10. DMD Reliability

11. DLP brand Products

12. 12.Conclusion

13. 13.References

Dept. of ECE 0 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

INTRODUCTION

Large-screen, high-brightness electronic projection

displays serve four broad areas of application: (1) electronic

presentations (e.g., business, education, advertising), (2)

entertainment (e.g., home theater, sports bars, theme parks,

electronic cinema), (3) status and information (e.g., military,

utilities, transportation, public, sports) and (4) simulation (e.g.,

training, games). The electronic presentation market is being

driven by the pervasiveness of software that has put sophisticated

presentation techniques (including multimedia) into the hands of

the average PC user.

A survey of high-brightness (>1000 lumens) electronic

projection displays for comparing the already existing three types

of projection display technologies namely, Oil film, CRT-LCD,

and AM-LCD was conducted. Developed in the early 1940s at the

Swiss Federal Institute of Technology and later at Gretag AG, oil

film projectors (including the GE Talaria) have been the

workhorse for applications that require projection displays of the

highest brightness. But the oil film projector has a number of

limitations including size, weight, power, setup time, stability, and

maintenance. In response to these limitations, LCD-based

technologies have challenged the oil film projector. These LCD-

based projectors are of two general types: (1) CRT-addressed

LCD light valves and (2) active-matrix (AM) LCD panels. LCD-

Dept. of ECE 1 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

based projectors have not provided the perfect solution for the

entire range of high-brightness applications. CRT-addressed LCD

light valves have setup time and stability limitations. Most active-

matrix LCDs used for high-bright-ness applications are

transmissive and, because of this, heat generated by light

absorption cannot be dissipated with a heatsink attached to the

substrate. This limitation is mitigated by the use of large-area

LCD panels with forced-air cooling. However, it may still be

difficult to implement effective cooling at the highest brightness

levels.

In response to these and other limitations, as well as to

provide superior image quality under the most demanding

environmental conditions, high-brightness projection display

systems have been developed based on Digital Light Processing

technology. DLP is based on a micro electro mechanical system

(MEMS) device known as the Digital Micro mirror Device

(DMD). The DMD, invented in 1987 at Texas Instruments, is a

semiconductor-based array of fast, reflective digital light switches

that precisely control a light source using a binary pulse

modulation technique. It can be combined with image processing,

memory, a light source, and optics to form a DLP system

(Figure2) capable of projecting large, bright, seamless, high-

contrast color images.

Dept. of ECE 2 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

Figure 3 shows a DLP projector in an auditorium

environment. This photo was taken at the Texas Instruments

Digital Imaging Business Center in Dallas, Texas.

DLP-based projection displays are well-suited to high-

bright-ness and high-resolution applications: (a) the digital light

switch is reflective and has a high fill factor, resulting in high

optical efficiency at the pixel level and low pixelation effects in

the projected image; (b) as the resolution and size of the DMD

Dept. of ECE 3 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

increase, the overall system optical efficiency grows because of

higher lamp-coupling efficiency; (c) because the DMD operates

with conventional CMOS voltage levels (~5 volts), integrated row

and column drivers are readily employed to minimize the

complexity and cost impact of scaling to higher resolutions; (d)

because the DMD is a reflective technology, the DMD chip can be

effectively cooled through the chip substrate, thus facilitating the

use of high-power projection lamps without thermal degradation

of the DMD; and (e) finally, DLP-based systems are all-digital

(digital video in, digital light out), so reproduction of the original

video source material is accurate and the image quality is stable

with time.

The general movement of the display industry is in the

digital direction. Digital sources that are currently available

include digital video disk (DVD), digital satellite system (DSS),

and the Internet (World Wide Web). In the future, the recently

approved Advanced Television Standard (ATV) and the digital

distribution of movies (digital cinema) will be added to the list of

digital sources. Interfacing these digital sources to currently

available analog displays requires digital-to-analog conversion

and, in some instances, analog encoding (e.g., s-video or

composite), which result in degradation of the source image

quality. DLP-based displays, on the other hand, preserve the

digital integrity of the source image all the way to the eye. The

result is the best possible video quality.

Dept. of ECE 4 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

DMD LIGHT SWITCH

The mirror as a switch

The DMD light switch (Figure 4) is a member of a class of

devices known as microelectromechanical systems. Other MEMS

devices include pressure sensors, accelerometers, and

microactuators. The DMD is monolithically fabricated by CMOS-

like processes over a CMOS memory. Each light switch has an

aluminum mirror, 16 µm square that can reflect light in one of two

directions depending on the state of the underlying memory cell.

Rotation of the mirror is accomplished through electrostatic

attraction produced by voltage differences developed between the

mirror and the underlying memory cell. With the memory cell in

the on (1) state, the mirror rotates to +10 degrees. With the

memory cell in the off (0) state, the mirror rotates to −10 degrees.

A closeup of DMD mirrors operating in a scanning electron

microscope (SEM) is shown in Figure 5.

Dept. of ECE 5 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

By combining the DMD with a suitable light source and

projection optics (Figure 6), the mirror reflects incident light

either into or out of the pupil of the projection lens by a simple

beam-steering technique. Thus, the (1) state of the mirror ap-pears

bright and the (0) state of the mirror appears dark. Compared to

diffraction-based light switches, the beam-steering action of the

DMD light switch provides a superior tradeoff between contrast

ratio and the overall brightness efficiency of the system.

Dept. of ECE 6 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

By electrically addressing the memory cell below each

mirror with the binary bit plane signal, each mirror on the DMD

array is electrostatically tilted to the on or off positions. The

technique that determines how long each mirror tilts in either

direction is called pulse width modulation (PWM). The mirrors

are capable of switching on and off more than 1000 times a

second. This rapid speed allows digital gray scale and color

reproduction. At this point, DLP becomes a simple optical system.

After passing through condensing optics and a color filter system,

the light from the projection lamp is directed at the DMD. When

the mirrors are in the on position, they reflect light through the

projection lens and onto the screen to form a digital, square-pixel

projected image (figure shown in the next page).

Three mirrors efficiently reflect light to project a digital

image. Incoming light hits the three mirror pixels. The two outer

mirrors that are turned on reflect the light through the projection

lens and onto the screen. These two "on" mirrors produce square,

white pixel images. The central mirror is tilted to the "off"

position. This mirror reflects light away from the projection lens

to a light absorber so no light reaches the screen at that particular

pixel, producing a square, dark pixel image In the same way, the

remaining 508,797 mirror pixels reflect light to the screen or away

from it. By using a color filter system and by varying the amount

of time each of the 508,800 DMD mirror pixels is on, a full-color,

digital picture is projected onto the screen.

Dept. of ECE 7 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

Dept. of ECE 8 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

GRAYSCALE AND COLOR OPERATION

Grayscale is achieved by binary pulse width modulation of

the incident light. Color is achieved by using color filters, either

stationary or rotating, in combination with one, two, or three

DMD chips. The DMD light switch is able to turn light on and off

rapidly by the beam-steering action of the mirror. As the mirror

rotates, it either reflects light into or out of the pupil of the

projection lens, to create a burst of digital light pulses that the eye

interprets as an analog image. The optical switching time for the

DMD light switch is ~2 µs. The mechanical switching time,

including the time for the mirror to settle and latch, is ~15 µs [36].

The technique for producing the sensation of grayscale to the

observer’s eye is called binary pulse width modulation. The DMD

accepts electrical words representing gray levels of brightness at

its input and outputs optical words, which are interpreted by the

eye of the observer as analog brightness levels.

The details of the binary pulse width modulation (PWM)

technique are illustrated in Figure 7. For simplicity, the PWM

technique is illustrated for a 4-bit word (2 4 or 16 gray levels).

Dept. of ECE 9 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

Each bit in the word represents time duration for light to be

on or off (1 or 0). The time durations have relative values of 2 0, 2

1, 2 2, 2 3, or 1, 2, 4, 8. The shortest interval (1) is called the least

significant bit (LSB). The longest interval (8) is called the most

significant bit (MSB). The video field time is divided into four

time durations of 1/15, 2/15, 4/15, and 8/15 of the video field

time. The possible gray levels produced by all combinations of

bits in the 4-bit word are 2 4 or 16 equally spaced gray levels (0,

1/15, 2/15 . . . 15/15). Current DLP systems are either 24-bit color

(8 bits or 256 gray levels per primary color) or 30-bit color (10

bits or 1024 gray levels per primary color).

In the simple example shown in Figure 7, spatial and

temporal artifacts can be produced because of imperfect

integration of the pulsed light by the viewer’s eye. These artifacts

can be reduced to negligible levels by a “bit-splitting” technique.

In this technique, the longer duration bits are subdivided into

shorter durations, and these split bits are distributed through-out

the video field time. DLP displays combine pulse width

modulation and bit-splitting to produce a “true-analog” sensation,

but with greater accuracy and stability than can be achieved by

analog projection systems.

Dept. of ECE 10 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

DMD CELL ARCHITECTURE AND

FABRICATION

The DMD pixel is a monolithically integrated MEMS

super-structure cell fabricated over a CMOS SRAM cell (Figure

8). An organic sacrificial layer is removed by plasma etching to

produce air gaps between the metal layers of the superstructure.

The air gaps free the structure to rotate about two compliant

torsion hinges. The mirror is rigidly connected to an underlying

yoke. The yoke, in turn, is connected by two thin, mechanically

compliant torsion hinges to support posts that are attached to the

underlying substrate.

The address electrodes for the mirror and

yoke are connected to the complementary sides of the underlying

Dept. of ECE 11 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

SRAM cell. The yoke and mirror are connected to a bias bus

fabricated at the metal-3 layer. The bias bus interconnects the

yoke and mirrors of each pixel to a bond pad at the chip perimeter.

An off-chip driver supplies the bias waveform necessary for

proper digital operation. The DMD mirrors are 16 µm square and

made of aluminum for maximum reflectivity. They are arrayed on

17 µm centers to form a matrix having a high fill factor (~90%).

The high fill factor produces high efficiency for light use at the

pixel level and a seamless (pixelation-free) projected image.

Electrostatic fields are developed between the mirror and

its address electrode and the yoke and its address electrode,

creating an efficient electrostatic torque. This torque works

against the restoring torque of the hinges to produce mirror and

yoke rotation in the positive or negative direction. The mirror and

yoke rotate until the yoke comes to rest (or lands) against

mechanical stops that are at the same potential as the yoke.

Because geometry determines the rotation angle, as opposed to a

balance of electrostatic torques employed in earlier analog

devices, the rotation angle is precisely determined.

The fabrication of the DMD superstructure begins with a

completed CMOS memory circuit. A thick oxide is deposited over

metal-2 of the CMOS and then planarized using a chemical

mechanical polish (CMP) technique. The CMP step provides a

completely flat substrate for DMD superstructure fabrication,

ensuring that the projector’s brightness uniformity and contrast

ratio are not degraded.

Dept. of ECE 12 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

Through the use of six photomask layers, the superstructure is

formed with layers of aluminum for the address electrode (metal-

3), hinge, yoke and mirror layers and hardened photo-resist for the

sacrificial layers (spacer-1 and spacer-2) that form the two air

gaps. The aluminum is sputter-deposited and plasma-etched using

plasma-deposited SiO2 as the etch mask. Later in the packaging

flow, the sacrificial layers are plasma-ashed to form the air gaps.

The packaging flow begins with the wafers partially

sawed along the chip scribe lines to a depth that will allow the

chips to be easily broken apart later. The partially sawed and

cleaned wafers then proceed to a plasma etcher that is used to

selectively strip the organic sacrificial layers from under the DMD

mirror, yoke, and hinges. Following this process, a thin lubrication

layer is deposited to prevent the landing tips of the yoke from

adhering to the landing pads during operation. Before separating

the chips from one another, each chip is tested for full electrical

and optical functionality by a high-speed automated wafer tester.

Finally, the chips are separated from the wafer, plasma-cleaned,

relubricated, and hermetically sealed in a package.

Figure 9 shows a packaged DMD chip.

Dept. of ECE 13 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

An 848 x 600 Digital Micro mirror Device. The central,

reflective portion of the device consists of 508,800 tiny, tilt able

mirrors. A glass window seals and protects the mirrors.

Dept. of ECE 14 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

ELECTRONIC OPERATION

The DMD pixel is inherently digital because of the way

it is electronically driven. It is operated in an electro statically

bistable mode by the application of a bias voltage to the mirror to

minimize the address voltage requirements. Thus, large rotation

angles can be achieved with a conventional 5-volt CMOS address

circuit.

The pulse width modulation scheme for the DMD

requires that the video field time be divided into binary time

intervals or bit times. During each bit time, while the mirrors of

the array are modulating light, the underlying memory array is

refreshed or updated for the next bit time. Once the memory array

has been updated, all the mirrors in the array are released

simultaneously and allowed to move to their new address states.

This simultaneous update of all mirrors, when coupled

with the PWM bit-splitting algorithm produces an inherently low-

flicker display. Flicker is the visual artifact that can be produced

in CRTs as a result of brightness decay with time of the phosphor.

Because CRTs are refreshed in an interlaced scan-line format,

there is both a line-to-line temporal phase shift in brightness as

well as an overall decay in brightness. DLP-based displays have

inherently low flicker because all pixels are updated at the same

time (there is no line-to-line temporal phase shift) and because the

Dept. of ECE 15 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

PWM bit-splitting algorithm produces short-duration light pulses

that are uniformly distributed throughout the video field time (no

temporal decay in brightness).

Proper operation of the DMD is achieved by using the

bias and address sequence shown in Figure 11 and detailed in

Table 1.

Table 1. DMD address and reset sequence

1. Memory ready—All memory cells under the DMD have been

loaded with the new address states for the mirrors.

2. Reset—All mirrors are reset in parallel (voltage pulse applied

to bias bus).

3. Unlatch—The bias is turned off to unlatch mirrors and allow

them to release and begin to rotate to flat state.

4. Differentiate—Retarding fields are applied to the yoke and

mirrors in order to rotationally separate the mirrors that remain

in the same state from those that are to cross over to a new

state.

Dept. of ECE 16 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

5. Land and latch—The bias is turned on to capture the

rotationally separated mirrors and enable them to rotate to the

addressed states, then settle and latch.

6. Update memory array (one line at a time)—The bias remains

turned on to keep the mirrors latched so as to prevent them

from responding to changes in the memory, while the memory

is written with new video data.

7. Repeat sequence beginning at step 1.

The bias voltage has three functions. First, it produces a

bistable condition to minimize the address voltage requirement, as

previously mentioned. In this manner, large rotation angles can be

achieved with conventional 5-volt CMOS. Second, it

electromechanically latches the mirrors so that they cannot

respond to changes in the address voltage until the mirrors are

reset. The third function of the bias is to reset the pixels so that

they can reliably break free of surface adhesive forces and begin

to rotate to their new address states.

Although the metal surfaces of the superstructure are

coated with a passivation layer or lubrication layer, the remaining

Van der Waal or surface forces between molecules require more

than the hinge-restoring force to reliably reset the mirrors. A reset

voltage pulse applied to the mirror and yoke causes the spring tips

of the yoke (Figure 12) to flex.

Dept. of ECE 17 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

As the spring tips unflex, they produce a reaction force

that causes the yoke landing tips to accelerate away from the

landing pads, producing a reliable release from the surface.

Dept. of ECE 18 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

DLP SYSTEM DESCRIPTION AND

OPERATION

Figure 13 illustrates a generic three-chip DLP system

broken down into its functional components (video front-end,

digital processor, digital formatter, and digital display). The

generic video front-end accepts a variety of video sources (digital,

digital compressed, digital graphics, analog composite, analog s-

video, and analog graphics). The video front-end performs the

functions of decompression, decoding, and analog-to-digital

conversion, depending on the nature of the video source.

The first operation in the digital processor is

progressive-scan conversion. This conversion is required if the

original source material is interlaced. An interlaced format

provides even lines of video during one video field time and odd

Dept. of ECE 19 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

lines during the next field time. Progressive-scan conversion is the

process of creating (by an interpolation algorithm) new scan lines

between the odd or even lines of each video field.

Interlacing has been historically used in CRT-based

systems to reduce the video bandwidth requirements without

producing objectionable flicker effects created by the temporal

decay in phosphor brightness. For progressively scanned CRTs,

interlacing is unnecessary because additional bandwidth is

allocated so that every line of the CRT is refreshed during each

field time. Progressive scanning that incorporates motion-adaptive

algorithms helps to reduce interlace scanning artifacts such as

interline flicker, raster line visibility, and field flicker. These are

particularly noticeable in larger display formats.

The next operation in the digital processor is digital

resampling (or scaling). This operation resizes the video data to fit

the DMD’s pixel array, expands letterbox video sources, and

maintains a correct aspect ratio for the square pixel DMD format.

After the scaling operation, the video data is input to the color

space conversion block. If the video is not already in a red, green,

blue (R, G, B) format, it is converted from luminance and color

difference encoding (e.g., Y, CR, CB) into R, G, B. Next, a

degamma (inverse gamma) function is per-formed .CRT systems

have non-linear signal-to-light characteristics. Inorder to

compensate for this error, an error correction, called Gamma

correction is done on images. But as the DLP system has linear

signal-to-light characteristics, this correction is to be removed,

Dept. of ECE 20 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

which is done in the degamma section. The degamma operation

can produce low-light-level contouring effects, but these are

minimized by using an error diffusion technique.

Finally the R, G, B signal is input to the digital

formatter. First, the scan-line format data is converted into an R,

G, B bit-plane format. The bit planes are stored in a dual-

synchronous DRAM (SDRAM) frame buffer for fast access of the

bit-plane data. The bit-plane data is then output to the DMDs in a

PWM bit-splitting sequence. The DMD chip has multiple data

inputs that allow it to match the frequency capability of the on-

chip CMOS with the required video data rates. The bit-plane data

coming out of the frame buffer is multiplexed 16:1 and fed to the

multiple data inputs of each DMD. The bit-plane data is then

demultiplexed 1:16 and fed to the frame-memory underlying the

DMD pixel array.

Dept. of ECE 21 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

PROJECTION OPTICS

DLP optical systems have been designed in a variety of

con-figurations distinguished by the number of DMD chips (one,

two, or three) in the system. The one-chip and two-chip systems

rely on a rotating color disk to time-multiplex the colors. The one-

chip configuration is used for lower brightness applications and is

the most compact. Two-chip systems yield higher brightness

performance but are primarily intended to compensate for the

color deficiencies resulting from spectrally imbalanced lamps

(e.g., the red deficiency in many metal halide lamps). For the

highest brightness applications, three-chip systems are required.

A DLP optical system with three chips is shown in

Figure 14. Because the DMD is a simple array of reflective light

switches, no polarizers are required. Light from a metal halide or

xenon lamp is collected by a condenser lens. For proper operation

of the DMD light switch, this light must be directed at 20 degrees

Dept. of ECE 22 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

relative to the normal of the DMD chip (Figure 6). To accomplish

this in a method that eliminates mechanical interference between

the illuminating and projecting optics, a total internal reflection

(TIR) prism is interposed between the projection lens and the

DMD color-splitting/-combining prisms.

The color-splitting/-combining prisms use dichroic

interference filters deposited on their surfaces to split the light by

reflection and transmission into red, green, and blue components.

The red and blue prisms require an additional reflection from a

TIR surface of the prism in order to direct the light at the correct

angle to the red and blue DMDs. Light reflected from the on-state

mirrors of the three DMDs is directed back through the prisms and

the color components are recombined. The combined light then

passes through the TIR prism and into the projection lens because

its angle has been reduced below the critical angle for total

internal reflection in the prism air gap.

Dept. of ECE 23 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

A DLP three-chip prototype projection engine is shown

in Figure 15. It projects 1100 lumens with a 500-watt xenon

lamp. The size of the engine is 19.5 × 12.8 × 10 in. and it weighs

38 pounds. One of the DMD package assemblies with

thermoelectric cooler and fan is visible.

Dept. of ECE 24 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

TECHNOLOGICAL ADVANTAGES

1. The Digital Advantage

The audio world started the trend toward digital

technology well over a decade ago. Recently, an abundance of

new digital video technology has been introduced to the

entertainment and communications markets. The digital satellite

system (DSS) quickly became the fastest selling consumer

electronics product of all time, selling record numbers of units in

its first year of introduction. Sony, JVC, and Panasonic have all

recently introduced digital camcorders.

Epson, Kodak, and Apple are a few of the companies

that now have digital cameras on the market. The digital versatile

disc (DVD), a widely anticipated new storage medium, will

feature full-length films with better than laser disc video quality

by placing up to 17 gigabytes of information on a single disc.

Today we have the ability to capture, edit, broadcast, and receive

digital information, only to have it converted to an analog signal

just before it is displayed. DLP has the ability to complete the

final link to a digital video infrastructure as well as to provide a

platform on which to develop a digital visual communications

environment. Each time a signal is converted from digital to

analog (D/A) or analog to digital (A/D), signal noise enters the

data path. Fewer conversions translates to lower noise and leads to

Dept. of ECE 25 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

lower cost as the number of A/D and D/A converters decreases.

DLP offers a scalable projection solution for displaying a digital

signal, thus completing an all-digital infrastructure (figure shown

below).

The video infrastructure. DLP offers the final link to a

complete digital video infrastructure.

Another digital advantage is DLP’s accurate

reproduction of gray scale and color levels. And because each

video or graphics frame is generated by a digital, 8- to 10-bits-per-

color gray scale, the exact digital picture can be recreated time and

time again. For example, an 8-bits-per-color gray scale gives 256

different shades of each of the primary colors, which allows for

256³, or 16.7 million, different color combinations that can be

digitally created (Figure shown below).

Dept. of ECE 26 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

DLP can generate digital gray scale and color levels.

Assuming 8 bits per color, 16.7 million digitally created color

combinations are possible. Above are several combinations of

different gray scale levels for each of the primary colors and the

resultant digitally created pixel colors.

2. The Reflective Advantage

Because the DMD is a reflective device, it has a light

efficiency of greater than 60%, making DLP systems more

efficient than LCD projection displays. This efficiency is the

product of reflectivity, fill factor, diffraction efficiency, and actual

mirror "on" time.

LCDs are polarization-dependent, so one of the

polarized light components is not used. This means that 50% of

Dept. of ECE 27 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

the lamp light never even gets to the LCD because it is filtered out

by a polarizer. Other light is blocked by the transistors, gate, and

source lines in the LCD cell. In addition to these light losses, the

liquid crystal material itself absorbs a portion of the light. The

result is that only a small amount of the incident light is

transmitted through the LCD panel and onto the screen. Recently,

LCDs have experienced advances in apertures and light

transmission, but their performance is still limited because of their

dependence on polarized light.

3. Seamless Picture Advantage

The square mirrors on DMDs are 16 µm², separated by 1

µm gaps, giving a fill factor of up to 90%. In other words, 90% of

the pixel/mirror area can actively reflect light to create a projected

image. Pixel size and gap uniformity are maintained over the

entire array and are independent of resolution. LCDs have, at best,

a 70% fill factor. The higher DMD fill factor gives a higher

perceived resolution, and this, combined with the progressive

scanning, creates a projected image that is much more natural and

lifelike than conventional projection displays (Figure

18),(Figure19a), (Figure19b).

Fig.18

Dept. of ECE 28 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

Photograph used to demonstrate the DLP advantage.

This digitized photograph of a parrot was used to demonstrate the

seamless, filmlike DLP picture advantage detailed in Figures19a

and b. A leading video graphics adapter (VGA) LCD projector

was used to project the image of the parrot shown in Figure18. In

Figure19a, the pixelated, screen-door effect common to LCD

projectors can easily be seen.

The same image of the parrot was projected using a DLP

projector and is displayed in Figure 19b. Because of the high fill

factor of DLP, the screen-door effect is gone. What is seen is a

digitally projected image made up of square pixels of information.

With DLP, the human eye sees more visual information and

perceives higher resolution, although, as demonstrated, the actual

resolution shown in both projected images is the same. As the

photographs illustrate, DLP offers compellingly superior picture

quality.

Fig.19a Fig.19b

Figure19. Actual close-up photographs of both (a) an LCD-

projected image and (b) a DLP -projected image. A three-panel

polysilicon VGA resolution LCD projector (a) and a one-chip

VGA resolution DLP projector (b) both project the photograph of

Dept. of ECE 29 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

the parrot shown in Figure 18. Both the LCD and DLP photos

were taken under the same conditions, with each projector being

optimized for focus, brightness, and color. Note the high level of

pixelation in the LCD image in contrast to the seamless DLP

image. DLP offers superior picture quality because the DMD

mirror pixels are separated by only 1 µ thus eliminating

pixelation.

Dept. of ECE 30 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

BENEFITS

1. Clarity- As it is already explained, the DLP system provides

high clarity images due to its improved digital technology.

2. Better Resolution-As the mirrors are very closely packed to

give high fill factor of 90%. This high fill factor gives a higher

perceived resolution which results in much more natural and

lifelike projected image.

3. Maximum brightness-At high luminous flux densities

(lumens/cm2), optical absorption creates heating effects.

Excessive temperature can cause degradation of performance for

both LCDs and DMDs. In the case of LCDs, excessive heating

causes degradation of the polarizers. Furthermore, without

adequate cooling of the LCD panel, the temperature of the LCD

material can rise above its clearing temperature Tc. This renders

the LCD material useless for polarization rotation and the display

fails. For transmissive AM-LCD panels, a heatsink cannot be

attached to the substrate, so forced air cooling must be relied

upon. Larger transmissive panels mitigate this problem. Currently,

AM-LCD projectors having 3000-lumen outputs use

5.8 × 5.8 in. panels.

Excessive temperatures can also affect the long-term

reliability of the DMD by accelerating hinge deformation (metal

Dept. of ECE 31 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

creep) that can occur under high-duty-factor operation of the

mirror. Special hinge alloys have been developed to minimize this

deformation and guarantee reliable operation. High duty factors

occur when the mirror is operated in one direction for a much

greater part of the time, on average, than in the other direction.

For example, 95/5 duty factor operation means that a mirror is

95% of the time at one rotation angle (e.g., -10 degrees) and 5% of

the time at the other rotation angle (e.g., +10 degrees). This

situation would correspond to DMD operation with a video source

having a temporal average brightness of 5% (or 95%) of the peak

brightness. Although these extreme temporal averages are un-

likely to occur for extended periods of time, 95/5 duty factor is

chosen as a worst case reliability test condition for hinge

deformation. With current hinge metal alloys, long-term, reliable

DMD operation at the 95/5 duty factor is assured, provided the

operating temperature of the hinge is limited to <65°C.

For high-brightness applications, the mirrors can absorb

enough energy to raise the hinge temperature above 65°C unless

active cooling is applied to the package. Because the DMD is

reflective and built on a single-crystal silicon (X-silicon)

backplane, the absorbed heat can be efficiently extracted by

connecting a thermoelectric cooler (TEC) to the backside of the

DMD package. In Figure 15, one of the DMD package assemblies

with the thermoelectric cooler is visible. The DMD package

contains a “thermal via” to provide a low-thermal- impedance

path between the DMD chip and the TEC. A thermal model

predicts that for a three-chip SXGA projector producing 10,000

Dept. of ECE 32 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

screen lumens, the hinge temperature can be held to <65°C (with

TEC cooling and an internal ambient air temperature of 55°C) .

4. Brightness Uniformity-Brightness uniformity is also an

important part of image quality. Uniformity represents the

percentage of brightness carried throughout a projected image. A

higher uniformity percentage indicates that the projector delivers

brightness more evenly from center to the corners of the projected

image, eliminating hot spots and di8stortion.DLP system has got a

brightness uniformity of more than 85%.

5. Low flicker effect-Flicker is the visual articraft that can be

produced in CRTs as a result of brightness decay with time.

Usually in scatter scanning technique, the lines in the video

frames are scanned sequentially. So at a particular instant of a

time different points on the screen will have different brightness

levels. This will give rise to flicker. But in DLP, all the mirror

pixels are updated in parallel at the same time. This minimizes the

flicker.

6. Life like color -as already seen the digital technology will give

lifelike color and makes it possible to display 16.7 million

different color combinations on the screen at a time.

7. Contrast ratio-contrast ratio is the difference between the

lightest and the darkest portions of an image. The larger the

contrast ratio, the greater the ability of a projector to show subtle

color details and tolerate a room’s ambient light. The inherent

Dept. of ECE 33 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

contrast ratio of the DMD is determined by measuring the ratio of

the light flux with all pixels turned on versus the flux with all

pixels turned off. The system contrast ratio is determined by

measuring the light flux ratio between bright and dark portions of

a 4 × 4 checkerboard image according to ANSI specifications. The

checkerboard measurement takes into account light scatter and

reflections in the lens, which can degrade the inherent contrast

ratio of the DMD.

The full on/off contrast ratio determines the dark level

for scenes having a low average luminance level (e.g., outdoor

night scenes) as well as the video black level. The checker-board

contrast ratio is a measure of the contrast for objects in scenes

containing a full range of luminance levels.

The inherent contrast ratio of the DMD is limited by

light diffraction from the mirror edges, from the underlying

substrate, and from the mirror via (the metallized hole in the

middle of the mirror that acts as the mirror support post, as shown

in Figure 4). Recent architectural improvements to the DMD

pixels have led to improved contrast ratios.

8. Portability-Because of its very low size and weight, DLP

projector system is higly portable. A projector giving an output of

2000 lumens weigh only 6.6 pounds and that giving 1000 lumens,

which is called as the micro projector weighs only 2 pounds.

Dept. of ECE 34 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

9. Accuracy and Stability-Current high-brightness projection

displays for use in the audio/visual rental and staging business and

for private and corporate use have a number of limitations. These

include warm-up or stabilization time; setup time for convergence,

color balance, and gamma; and, finally, the stability of the image

quality once the system is operating. Maintaining stability over a

wide range of environmental conditions encountered in outdoor

applications is particularly difficult.

For video wall applications or other applications

requiring multiple side-by-side projectors, the setup time to make

the entire displays look identical is often unacceptable. Even when

great care has been taken in this procedure, lack of stability makes

periodic adjustments necessary.

DLP-based projection systems offer the potential of

short setup time and stable, adjustment-free images. Initial

stabilization time is minimal. The working is also very fast. This

is because of the fact that the optical switching time of the mirror

is only 2us and the mechanical switching time including the time

for the mirror to settle and latch is only 15 us. Convergence is

fixed by internal alignment of the three DMDs and is stable with

time and in-dependent of throw distance. Color balance,

uniformity, and gamma are digitally controlled by Pulse Width

Modulation and are not affected by temperature. Brightness roll

off is stable (fixed by a light integrator) and can be made small to

accommodate video wall applications.

Dept. of ECE 35 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

DMD Reliability

Steady improvements in DMD reliability have been

made. Some of these are listed below:

• An improved hinge material that reduces metal creep that can

occur under high-duty-factor and high-temperature operating

conditions. The hinge material is manufactured using ‘thin-film’

technology to get less stiff material.

• Improved packaging techniques that preserve the “lubricity” of

the landing surface over a wide range of environmental

conditions.

• A new architecture that incorporates spring tips at the landing tip

of the yoke. These springs store energy upon landing and push the

mirror away from the surface upon release. The result is greater

operating margins as the yoke releases (resets) from the

underlying surface. The picture of this spring structure is shown

below.

Dept. of ECE 36 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

• A particle reduction program that has dramatically reduced

particle contamination within the DMD package.

The DMD has passed a series of tests to simulate actual

DMD environmental operating conditions, including thermal

shock, temperature cycling, moisture resistance, mechanical

shock, vibration, and acceleration testing and has passed all of

these tests. In addition to these, other tests have been conducted to

determine the long-term result of repeated cycling of mirrors

between the on and off states. Mirror cycling tests look for hinge

fatigue (broken hinges) and failure of the mirrors to release

because of increased adhesion (reset failure). To date, in

accelerated tests, a lifetime of more than 765 billion cycles has

been demonstrated (equivalent lifetime >76,000 hours ie,

approximately 20 years of reliable operation) for a 10-bit/primary

color, three-chip projector configuration).

Dept. of ECE 37 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

DLP BRAND PRODUCTS

Texas Instruments is teamed with numerous projection

display manufacturers spanning

-Business (conference room),

-Consumer (home theater), and

-Professional (high-brightness)

markets. DLP brand products and prototypes serving all three

market segments have been demonstrated at numerous trade

shows including Cedia, Comdex, CES, Infocomm, EID, IFA, JES,

Photokina, Photonics West, SID, and Satis.

Currently, Digital Projection Ltd., Electrohome, and

Sony are developing high-brightness DLP brand products with

SVGA resolution and brightness levels ranging from 1100 lumens

to 3000 lumens.

Dept. of ECE 38 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

CONCLUSION

DLP brand projection displays are well-suited to high-

brightness and high-resolution applications. The digital light

switch is reflective and has a high fill factor that results in high

optical efficiency at the pixel level and low pixelation effects in

the projected image. The DMD family of chips uses a common

pixel design and a monolithic CMOS-like process. These factors,

taken together, mean that scaling to higher resolutions is

straightforward, without loss of pixel optical efficiency.

At higher resolutions, the DLP brand projector becomes

even more efficient in its use of light because of higher lamp-

coupling efficiency. Because the DMD is a reflective technology,

the DMD chip can be effectively cooled through the chip

substrate, thus facilitating the use of high-power projection lamps

without thermal degradation of the DMD. DLP brand systems are

all-digital (digital video in, digital light out) that give accurate,

stable reproduction of the original source material.

This single digital light display system is obviously

going to be the technology of future revolutionizing the field of

video display technology providing high clarity, high-resolution,

high-brightness seamless images.

Dept. of ECE 39 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

REFERENCES

1. www.ti.com/dlp

2. www.DLP.com/projector glossary

3. Digital Light Processing for High-Brightness,

High-Resolution Applications - L.J.Hornbeck,

Texas Instruments Ltd

4. Introduction to DLP Technology - Lars a. Yoder

Texas Instruments Ltd

5. Video Processing for DLP System - Vishal & Todd,

Digital Video Product

Texas Instruments Ltd

Dept. of ECE 40 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

ABSTRACT

Electronic projection display technologies for high

brightness applications, from the initial Gretag Eidophor, an oil

based projection, to solid state technology based LCD systems,

are all analog devices having many disadvantages. All the

products of this information age, digital cameras, digital

concoders, digital satellite system, DVDs, play source material of

unprecented image quality and so does the Internet-the seemingly

endless forum of digitized information. The whole exercise of

preserving digital video and graphic data would be pointless if it

has to be converted to analog before viewing.

Texas Instruments' Digital Light Processing technology-the

only available digital display technology is a revolutionary

alternative. At the heart of the DLP display is the Digital

Micromirror device (DMD), a semiconductor based array of fast,

reflective digital light switches. Digital electronics and optics

converge at DMD. Based on this DMD, DLP can form the final

link to digital visual communication. In the same way the compact

disc revolutionized the audio industry, DLP will revolutionize

video projection.

This seminar describes the design, operation, performance

and advantages of DLP based projection system for high

brightness, high resolution application.

Dept. of ECE 41 MESCE Kuttippuram

Seminar Report ’03 Digital Light Processing

Dept. of ECE 42 MESCE Kuttippuram

You might also like

- Real Time Operating System A Complete Guide - 2020 EditionFrom EverandReal Time Operating System A Complete Guide - 2020 EditionNo ratings yet

- Visual Programming Lab ManualDocument45 pagesVisual Programming Lab Manualthiruppathi3No ratings yet

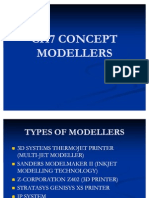

- Concept ModellersDocument39 pagesConcept ModellersParth Modi83% (6)

- Bresenham's Line AlgorithmDocument5 pagesBresenham's Line AlgorithmjayanthikrishnanNo ratings yet

- Presented By: B.Divya SD - Jasmeen MD - Hafeez External Guide: Dr.Y.Ragavender RaoDocument22 pagesPresented By: B.Divya SD - Jasmeen MD - Hafeez External Guide: Dr.Y.Ragavender RaoRaghavender MNo ratings yet

- Chapter 7-Callback Interfaces, DelegatesDocument36 pagesChapter 7-Callback Interfaces, DelegatesRudresh CMNo ratings yet

- CSE Digital Light ProcessingDocument15 pagesCSE Digital Light ProcessingKalyaniNo ratings yet

- Digital Image Processing - DR - B.chandra MohanDocument63 pagesDigital Image Processing - DR - B.chandra MohanPriyaNo ratings yet

- Virtual Base ClassDocument17 pagesVirtual Base ClassSrijana Shet YiascmNo ratings yet

- Project Report VlsiDocument33 pagesProject Report VlsiDhruv RastogiNo ratings yet

- Accenture Latest Syllabus & Pattern 2023-2024 - Talent BattleDocument7 pagesAccenture Latest Syllabus & Pattern 2023-2024 - Talent BattleNANXNo ratings yet

- Prototyping: Prototyping: Prototypes and Production - Open Source Versus Closed SourceDocument14 pagesPrototyping: Prototyping: Prototypes and Production - Open Source Versus Closed Sourcerajeswarikannan0% (1)

- Automatic Basket Ball Scoring Display Using FpgaDocument4 pagesAutomatic Basket Ball Scoring Display Using FpgagowrivelusNo ratings yet

- FDP BrochureDocument2 pagesFDP BrochureajbioinfoNo ratings yet

- MA JournalDocument35 pagesMA JournalRohit MiryalaNo ratings yet

- CG Unit 1 PPT NewDocument29 pagesCG Unit 1 PPT NewArjun K R100% (1)

- Contrast StretchingDocument9 pagesContrast StretchingKaustav MitraNo ratings yet

- Machine Vision SensorDocument18 pagesMachine Vision SensorSoumik DasNo ratings yet

- Project Report On "Efficient Solar Charging With Battery Protection"Document40 pagesProject Report On "Efficient Solar Charging With Battery Protection"PRAKASH CHOUDHARYNo ratings yet

- Seminar ReportDocument22 pagesSeminar ReportAbhinaw KumarNo ratings yet

- The Simplest Way To Examine The Advantages and Disadvantages of RISC Architecture Is by Contrasting It With ItDocument11 pagesThe Simplest Way To Examine The Advantages and Disadvantages of RISC Architecture Is by Contrasting It With ItsaadawarNo ratings yet

- Seminar Report On DTH by VidhuDocument27 pagesSeminar Report On DTH by Vidhupz29880% (1)

- How To Interface An LED With 8051 MicrocontrollerDocument7 pagesHow To Interface An LED With 8051 MicrocontrollerPramillaNo ratings yet

- Embedded System ManualDocument74 pagesEmbedded System ManualMuhammad Zeeshan SaeedNo ratings yet

- Report of Secure Data TransmissionDocument33 pagesReport of Secure Data TransmissionAsad Sarosh0% (1)

- Final Project Synopsis "Age and Gender Detection"Document17 pagesFinal Project Synopsis "Age and Gender Detection"Ankit KumarNo ratings yet

- Image Fusion PresentationDocument33 pagesImage Fusion PresentationManthan Bhatt100% (1)

- Hybrid Low Radix Encoding-Based Approximate Booth MultipliersDocument33 pagesHybrid Low Radix Encoding-Based Approximate Booth MultipliersAKASHDEEP MITRA100% (1)

- DSPAA Jan 2019 QP SolutionDocument34 pagesDSPAA Jan 2019 QP SolutionAbhishek SinghNo ratings yet

- 6.0 Introduction To Real-Time Operating Systems (Rtos)Document35 pages6.0 Introduction To Real-Time Operating Systems (Rtos)dhananjaypatilmeNo ratings yet

- The KLEIN Block CipherDocument18 pagesThe KLEIN Block Ciphertorchbearer one100% (1)

- 8K High Resolution Camera SystemDocument4 pages8K High Resolution Camera SystemTej NagNo ratings yet

- Imis Higher Diploma Syllabus 2Document52 pagesImis Higher Diploma Syllabus 2Tathokoza Mponda100% (2)

- Week 1 SolutionDocument13 pagesWeek 1 Solutionpba1 pba1No ratings yet

- School of Electrical, Electronic & Computer Engineering Course: Code: Practical No.: TitleDocument5 pagesSchool of Electrical, Electronic & Computer Engineering Course: Code: Practical No.: TitleNdumiso MtshaliNo ratings yet

- ECE-3502 IOT Domain Analyst - ELA Lab Task - 5 L15+L16Document8 pagesECE-3502 IOT Domain Analyst - ELA Lab Task - 5 L15+L16Kota Krishna DheerajNo ratings yet

- Practical Part 2Document143 pagesPractical Part 2HARSH SAVALIYANo ratings yet

- AL3452 Operating Systems Lecture Notes 1Document278 pagesAL3452 Operating Systems Lecture Notes 1rishashri004No ratings yet

- Case StudyDocument7 pagesCase StudyÀüsåf MûghãlNo ratings yet

- Get Access To C100DEV Exam Dumps Now: Pass MongoDB Certified Developer Associate Exam With Full Confidence - Valid IT Exam Dumps QuestionsDocument5 pagesGet Access To C100DEV Exam Dumps Now: Pass MongoDB Certified Developer Associate Exam With Full Confidence - Valid IT Exam Dumps QuestionsMai PhuongNo ratings yet

- Cloud Partitioning of Load Balancing Using Round Robin ModelDocument6 pagesCloud Partitioning of Load Balancing Using Round Robin ModelIJCERT PUBLICATIONSNo ratings yet

- Run Length Encoding and DecodingDocument3 pagesRun Length Encoding and DecodingDaniel SimanjuntakNo ratings yet

- Lab #4Document4 pagesLab #4Bryan Ricardo Boyer0% (1)

- Cse 202 Object Oriented ProgrammingDocument19 pagesCse 202 Object Oriented ProgrammingAnkur SinghNo ratings yet

- Simulation LaboratoryDocument102 pagesSimulation LaboratoryPUBG ASSASIN தமிழ் ASASSINNo ratings yet

- E-Content Available in VTU Elearning Website (E-Notes and Lecture Videos) SL No Sub. Code Course NameDocument6 pagesE-Content Available in VTU Elearning Website (E-Notes and Lecture Videos) SL No Sub. Code Course Nameysuresh_bngNo ratings yet

- Automatic ThresholdingDocument18 pagesAutomatic ThresholdingMuhammad Usman KhanNo ratings yet

- Solution Manual For Data Communications and Networking by Behrouz ForouzanDocument18 pagesSolution Manual For Data Communications and Networking by Behrouz ForouzanKoya Srinath100% (1)

- Histogram SpecificationDocument6 pagesHistogram SpecificationAbhishek ShaolinNo ratings yet

- 1-Introduction To NetworkingDocument18 pages1-Introduction To NetworkingmikeNo ratings yet

- Practical-2: 2IT702: Artificial Intelligence Practical-2Document5 pagesPractical-2: 2IT702: Artificial Intelligence Practical-2DEVANSHI PAREJIYANo ratings yet

- CST 64 Bit InstallationDocument6 pagesCST 64 Bit InstallationKrishna Yadav100% (2)

- Network Lab ManualDocument7 pagesNetwork Lab ManualANKIT67% (3)

- Practical 1 Dyna KitDocument5 pagesPractical 1 Dyna KitHet PatelNo ratings yet

- NTC PreparationDocument5 pagesNTC PreparationKaran Singh DhamiNo ratings yet

- Electronic Circuit Simulation SoftwareDocument4 pagesElectronic Circuit Simulation SoftwareIJRASETPublicationsNo ratings yet

- It342 Basic Video Compression StandardsDocument34 pagesIt342 Basic Video Compression StandardsSamNo ratings yet

- Assignment1 PDFDocument5 pagesAssignment1 PDFpristo sellerNo ratings yet

- DLP Seminar ReportDocument26 pagesDLP Seminar ReportManjunath CkmNo ratings yet

- Current Status and Future Applications For DMD - Based Projection DisplaysDocument4 pagesCurrent Status and Future Applications For DMD - Based Projection Displaysgangwar_neeteshNo ratings yet

- Subin S B (Virtual Keyboard)Document36 pagesSubin S B (Virtual Keyboard)yuben josephNo ratings yet

- SUBIN K M Freespace Laser CommunicationsDocument31 pagesSUBIN K M Freespace Laser Communicationsapi-3827000100% (3)

- Ushashi SMSDocument22 pagesUshashi SMSapi-3827000No ratings yet

- Sreerekha (FinFET)Document38 pagesSreerekha (FinFET)yuben josephNo ratings yet

- Sanjay - High Performance DSP ArchitecturesDocument38 pagesSanjay - High Performance DSP Architecturesapi-3827000No ratings yet

- Sreerekha (FinFET)Document38 pagesSreerekha (FinFET)yuben josephNo ratings yet

- Shyam Ac Performance of Nano ElectronicsDocument30 pagesShyam Ac Performance of Nano Electronicsapi-3827000100% (1)

- Prasanna (Code Division Duplex Ing)Document30 pagesPrasanna (Code Division Duplex Ing)yuben josephNo ratings yet

- Arun OFDMDocument42 pagesArun OFDMapi-3827000No ratings yet

- 64 Bit ComputingDocument18 pages64 Bit ComputingAshish MadaanNo ratings yet

- Anand 4G WirelessDocument31 pagesAnand 4G Wirelessapi-3827000100% (6)

- Girish TeleportationDocument26 pagesGirish Teleportationapi-3827000100% (3)

- Wireless FidelityDocument22 pagesWireless Fidelitymuraliraj_sNo ratings yet

- Wireless Local LoopDocument8 pagesWireless Local Loopapi-3827000100% (1)

- Surround SystemsDocument24 pagesSurround Systemsapi-3827000No ratings yet

- Tele ImmersionDocument20 pagesTele Immersionapi-3827000100% (8)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Voice MorphingDocument31 pagesVoice Morphingapi-382700092% (13)

- Polymer MemoryDocument27 pagesPolymer Memoryapi-3827000100% (4)

- Quadrics Interconnection NetworkDocument24 pagesQuadrics Interconnection Networkapi-3827000100% (1)

- Mage The Awakening Spell TranslationsDocument3 pagesMage The Awakening Spell TranslationsMathiasNo ratings yet

- Bulk Purchase Ridge Tiles: Trade Price List March 1 2019Document1 pageBulk Purchase Ridge Tiles: Trade Price List March 1 2019ekosuwantoNo ratings yet

- The List 662Document132 pagesThe List 662TheListLtdNo ratings yet

- Launchpad Training - Ebook (Vol. 2)Document141 pagesLaunchpad Training - Ebook (Vol. 2)Enrique Ignacio Germany MorrisonNo ratings yet

- Eng-Class IDocument29 pagesEng-Class ImmtrgriksdjNo ratings yet

- The African Art Centre: Focus On William ZuluDocument2 pagesThe African Art Centre: Focus On William ZuluSA BooksNo ratings yet

- Mysore Travel GuideDocument18 pagesMysore Travel GuideNipun SahniNo ratings yet

- Thematic Study of Fear in The Text 'Things Fall Apart'Document4 pagesThematic Study of Fear in The Text 'Things Fall Apart'Sankalp Pratap TrivediNo ratings yet

- NCERT Notes - Vedic Civilization - Important Events (Ancient Indian History Notes For UPSC)Document1 pageNCERT Notes - Vedic Civilization - Important Events (Ancient Indian History Notes For UPSC)rajat tanwarNo ratings yet

- ART Grade 1 Teaching GuideDocument3 pagesART Grade 1 Teaching GuideLary BagsNo ratings yet

- Bibliography of JazzDocument171 pagesBibliography of Jazzpendakigunung100% (1)

- Goju Ryu Bunkai GekisaiDocument3 pagesGoju Ryu Bunkai GekisaiMarloNo ratings yet

- A Teaching Pioneer: Star TrailsDocument2 pagesA Teaching Pioneer: Star TrailsDavor BatesNo ratings yet

- Evelyn Waugh Elena PDFDocument2 pagesEvelyn Waugh Elena PDFElizabeth0% (1)

- Pricecatalogue 130207 MiddleDocument93 pagesPricecatalogue 130207 MiddleDacian BalosinNo ratings yet

- Asme section-IIDocument25 pagesAsme section-IIAmit Singh100% (10)

- ARTnews Sold To Skate CapitalDocument2 pagesARTnews Sold To Skate CapitalLee Rosenbaum, CultureGrrlNo ratings yet

- Leisure Painter December 2017Document80 pagesLeisure Painter December 2017JuanRodriguez100% (2)

- Armory and Weapons GuideDocument9 pagesArmory and Weapons GuideVojvodakiza100% (1)

- The Old Man and The Little Cat Reading ComprehensionDocument2 pagesThe Old Man and The Little Cat Reading ComprehensionbettyNo ratings yet

- Character and Songs Requested With Links Provided: Mark La Vie BohemeDocument2 pagesCharacter and Songs Requested With Links Provided: Mark La Vie BohemejohnisaNo ratings yet

- Bill of Quantities (Boq)Document22 pagesBill of Quantities (Boq)DADADADGGGNo ratings yet

- Adverbial Clause: Your Date Here Your Footer HereDocument26 pagesAdverbial Clause: Your Date Here Your Footer HereIlona ViolaNo ratings yet

- Latin Medalist Syllabus - IdcDocument4 pagesLatin Medalist Syllabus - Idcapi-242835804No ratings yet

- Consumer List For P21062100068Document92 pagesConsumer List For P21062100068Samir BangarNo ratings yet

- Collaborations:: Fernando AmorsoloDocument3 pagesCollaborations:: Fernando AmorsoloCJ OngNo ratings yet

- The Max 1 200 Questions That Will Maximize You PDFDocument450 pagesThe Max 1 200 Questions That Will Maximize You PDFAnonymous XYzsI6YeXNo ratings yet

- Unit Key Points TipsDocument1 pageUnit Key Points TipsLeanne TehNo ratings yet

- KDC-MP242U/MP342U KDC-MP443U/MP5043U KDC-MP543U: Service ManualDocument46 pagesKDC-MP242U/MP342U KDC-MP443U/MP5043U KDC-MP543U: Service ManualCarol Eduardo Apitz DíazNo ratings yet

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsFrom EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNo ratings yet

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (10)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...From EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No ratings yet

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldFrom EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldRating: 4 out of 5 stars4/5 (87)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsFrom EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNo ratings yet