Professional Documents

Culture Documents

Warehouse Assignment

Uploaded by

Cosmas TeoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warehouse Assignment

Uploaded by

Cosmas TeoCopyright:

Available Formats

WAREHOUSE MANAGEMENT

WAREHOUSE MANAGEMENT

By: Cosmas Teo

Warehouse Management

Page 1

WAREHOUSE MANAGEMENT

This page is intentionally left blank

Warehouse Management

Page 2

WAREHOUSE MANAGEMENT

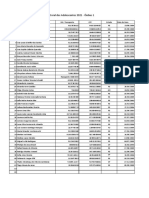

Table of Contents

Assignment Questions Introduction 1. Functions of Warehouse 1.1. Receiving 4 5 5 5 5 6 6 6 6 6 6 6 7 8 8 10 10 13 13

1.2. Storages 1.2.1. Pallet rack 1.2.2. Mezzanine 1.2.3. Cantilever rack 1.2.4. Shelving 1.2.5. Automated Storages & Retrieval System 1.3. Distribution 1.4. Other Packing & Repacking 2. Planning & SWOT Analysis to Set-up Warehouse 3. Warehouse Facilities Development 3.1. Size and Number 3.2. Location 3.3. Design & Layout 3.4. Transportation 4. Conclusions

Warehouse Management

Page 3

WAREHOUSE MANAGEMENT

Assignment Questions

The answers to the above two questions should be written in one assignment.

1. Describe briefly the main three functions of warehousing.

2. Discuss, with suitable illustrations, the factors that warehouse management should take into consideration in warehouse facility development. Your answer should include, among others, the following main elements in warehouse facility development: a. Size and number of warehouses, b. Location of warehouses and c. Design and layout of warehouses.

Warehouse Management

Page 4

WAREHOUSE MANAGEMENT

1. Introduction - In every industry neither in manufacturing, importer, exporter, wholesaler, transport business, or even customs, a warehouse is consider a must. Warehouse can be generally a large plain building located in industrial area, town, city, port, airport, etc, where good are temporally store before going for delivery or distribution. Warehouse usually has a loading and unloading bay to receiving and distribution of goods directly from seaports, airports or railways. In the warehouse normally equipped with forklift or crane for moving goods from one place to another. Goods usually placed on ISO standard pallet. Good stored in warehouse can be raw materials, components or finished goods for agriculture, manufacturing, or commerce. Function of warehouse can be neither internal nor external. It also serves as purpose or specialization for customer focus.

2. Among the functions of warehouse include; Receiving, Storage, Distribution, and other functions can be included packing & repacking, order accumulation and record keeping. 2.1.Receiving When goods arrive either at seaport, airport, train stations, goods will normally store temporally at warehouse before distribution to next locations. Or even in the factory or manufacturing goods, raw material where receive from outsider will store at warehouse before being used in producing final goods or product. Same for finish products/goods, it will also store at warehouse before being distribute to other locations. 2.2.Storage Warehouse can be also function as storage. Raw materials, components or finished goods / products can be store at warehouse before distribution. There are different storage systems for different type of goods / materials/ products being used for storage. The common storage systems can be either; 2.2.1. Pallet rack, - the goods or material are place on pallets or skid. Each pallet or skid is place on rack neither in horizontal row with multiple levels.

Warehouse Management

Page 5

WAREHOUSE MANAGEMENT

2.2.2. Mezzanine, - is an intermediate floor between main floors of a building, and therefore is not counted the overall floors of a building1. Normally mezzanine type is common if the warehouse buildings is tall, and have an extra space to build a certain level for storage. 2.2.3. Cantilever Rack, - is warehouse storage system consisting of the vertical column, the base, the arms, and the horizontal and/or cross bracing. These components are fabricated from both roll formed and structural steel. The horizontal and/or cross bracing are used to connect two or more columns together. They are commonly found in lumber yards, woodworking shops, and plumbing supply warehouses2. 2.2.4. Shelving, - a type of storage metal, steel, nor catwalk type. 2.2.5. Automated Storage and Retrieval System (ASRS) Most modern type of storage system in warehouse. It consist variety of computer system or latest technologies method of placing and retrieving loads from specific location in the warehouse. 2.3.Distribution All goods either raw materials or finish goods will surely not going to keep forever in the warehouse. Once the goods are ready, it will distribute out from the warehouse to destination where it will be utilized or use. The goods will distribute out will either use the method of FIFO (First in First out) or FILO (First in Last Out). 2.4. Other - Packing and Repacking Warehouse can also be a place for packing and repacking. Sometime goods are delivery to warehouse in big quantity and need to repacking into small or packages before delivery from warehouse. Finish goods sometime deliver in big amount or volume in order to save shipping cost, and it will delivery to warehouse first before distribute to final destination. And in the warehouse,

1 2

http://en.wikipedia.org/wiki/Mezzanine_(architecture) http://en.wikipedia.org/wiki/Cantilever

Warehouse Management

Page 6

WAREHOUSE MANAGEMENT

it wills either packing or repacking accordingly. Order accumulation Warehouse also can function as temporally storage order accumulation before distribute out. Sometime, goods coming in will not meet up to the customer demand in quantity. So the goods will temporally store at the warehouse while waiting for the balance of the goods to arrive and meet the final demand before distribute out. Warehouse also can be function as record keeping like stock counting. 3. Any warehouse before set-up, it need a planning and SWOT Analysis to be study up. SWOT analysis is a strategic planning method used to evaluate the Strengths, Weakness, Opportunities and Threat involve before a warehouse being set-up. What is the purpose and objective of warehouse facilities being set up? Any natural of business neither in manufacturing, automobile, factories, or import & export, it required a warehouse. Before a warehouse needs to set up, management usually need a proper planning like where the warehouse will be built. Neither near the seaport if the goods are coming in thru seaport? Or near the factory, if the goods if direct coming thru the factory. It also needs to gather all relevant data such like shipment data or arrangement with end user or manufacturer. Such data can be crucial information. With the data gather, it can be use for analysis in setting up warehouse. That is why the SWOT Analysis is used for planning a warehouse in either internal or external factor, which is also will look into the warehouse facility development. What is the strength of the warehouse being set-up? Either in location, size, nor design etc. it must able to give advantages in internal or external. Such as if a warehouse being set-up near the seaport, will it able to give advantages. Then if the warehouse is set-up far away, will it give any weakness to the supplier or customers? Weakness is a characteristic that will bring disadvantages if the warehouse being set-up either in term of size, location, or design. Opportunities can be external changes to make in accommodate more than what a current warehouse is. It can be an opportunities for

Warehouse Management

Page 7

WAREHOUSE MANAGEMENT

other purpose of the current warehouse. Like to diversify to others functions of warehousing. There is a threat that can cause a problem or trouble when the warehouse is built. It can be either a threat in size, location, design or layout, transportation or software & IT. After the analysis is complete, it needs to put in paper or blue print. Whatever been planning, it needs to be put into model to see the effect of it and can be functioning according to what it been planning. And from there, it needs to be implemented. How to implement the plan is also important. It needs to set a target when to start the implementation of the plan. Only after the implementation, it needs to analysis it. It called the Post Implementation. By analysis it, we can know what when wrong or not according to what been plan early. By this way, we can try to minimize the mistake or to add the strength and opportunities. 4. Facilities development needs to include Internal and External factor. Internal factor is within the facilities its self. While the external factor, we look as overall of the whole facilities. Taken for example, in Oil and Gas industry, a management will not only consider just 1 warehouse to store all the cargoes or items, but will consider different sections of warehouse like Open storage Warehouse, Close storage warehouse, aircondition type warehouse or even chemical warehouse according to its needs and facilities. 4.1. Size and Number of warehouses is according to business or operation needs. Some type of business or operation may need just one warehouse, while other may need more than one warehouse to cater all the needs. Some business may need a small size warehouse while other may need larger size warehouse. Take for example in Labuan. Labuan is duty free island and main industry in oil and gas sector. In oil and gas industry most of the oil and gas companies required different sizes of warehouse for storages. Some need to be in open yard warehouse, some need to be in air-conditional

Warehouse Management

Page 8

WAREHOUSE MANAGEMENT

warehouse type, and close warehouse. Like all major oil & gas companies, Murphy Oil Corporation is also required warehouse for storage the items or cargo before ship out to offshore, or return from offshore, and coming in and out Labuan. Refer to the map 1 below. Map 1 Murphy Oil Corporation operates within the area of Asian Supply Base (ASB)

Labuan. ASB is a one-stop logistic support centre for oil and gas industry. ASB is also a port where general cargoes can be imported, exported and/or transhipped through and/or from its warehouse and open vast yards. Because of the nature of operation, it required different size and number of warehouses for its operation. In map 1 we can see inside the ASB, there are 4 warehouses with different sizes. Warehouse 1(Red colour outer line) is a closed warehouse type. It normally for storages of small items needs special or delicate care like drill bit, bolt and nut, electrical equipments, etc. Warehouse 2 & 3 (blue & yellow) is open yard storage. Open yard storage normally for putting a large or big size items or equipments, or something is not practically put inside the closed warehouse, example like casing pipe, riser, shipping container, etc. Warehouse 4 (Pink) is a chemical warehouse. Chemical

Warehouse Management

Page 9

WAREHOUSE MANAGEMENT

warehouse is for chemical products and it related product because it need special care and attention. This is also because of safety & health issue that chemical cannot store in normal warehouse or open yard warehouse. For the map, we can see the sizes of each warehouse according to its needs and number of warehouses required in this type of operations. 4.2. Location is also important for establishing warehouse. Warehouse management will look into the consideration to set up warehouse neither to focus on clients or supply. Warehouse must be located in the correct location to efficiently meet clients and customers delivery requirements. In focus of clients or supply requirements, warehouse maybe built near the client business premise or easy for access to supply to other locations. Location is important because 1) save cost, 2) transportation, 3) raw material, 4) import & export facilities example seaport or airport, 5) Labour catchment. One of the reason Murphy Oil set up warehouse within the ASB is because the location. It near to the jetty or port for vessel or supply boat to berth. Labuan is hub for oil and gas to offshore. At offshore, there are very limited storage for equipment and cargo. And the flow of the equipments and items is fast. And it need to constantly supply from the base where more items or cargo is being keep at the warehouse. In order to save time, transportation and easy access to jetty, it best way to have warehouse near the location. When the cargo being ship back to base, it will also easy to delivery to warehouse, especially big size or odd size cargo. 4.3. Design & layout of warehouse. An effective warehouse design must take into account a wide range of factors from all areas of the operation. The design of a warehouse can have an impact on your overall operations. In turn, this will affect inventory control, process flows and space utilisation. The scope of a warehouse design plan should encompass inventory levels, cycle and variance in inventory

Warehouse Management

Page 10

WAREHOUSE MANAGEMENT

throughout the business year, cost of space, warehouse operational management, cost of inventory transport and flexibility for future change adjustments in product or demand3. In Murphy Oil warehouse is consider an important to it operations in oil & gas sector. It functions as 1) Product storage, 2) Inbound operation, 3) Outbound Operation and 4) value-added processes. Most of the part, equipments are very crucial and important especially when need for replacement or changes in fast. If equipment or tool need urgency replacement, it cannot effort to wait for spare part to arrive in 1 or 2 weeks time especially order from overseas. Because any shut down, it will cost a million or thousand losses in operation. Because of this, warehouse is a place for product storage and advance order or replacement stored at warehouse, so that it can fast delivery to offshore. For some products, like chemical it will stored at Chemical warehouse, where specific handling for chemical and must follow the Safety and Health policy. In open yard warehouse, because of large hectares/yard normally it will required a special material handling equipment such like heavy lift crane, or 10 tons forklift or trailer to move any big or odd size items. In everyday, there will be an inward and outward of cargo to offshore and back from offshore. For example in warehouse 1 (Closed warehouse) the design of the warehouse is almost similar to the left photo. It is equipped with aisle on pallet on storage rack. One reason why it on pallet is because for easy movement and pick-up by 3 ton forklift, and stored on storage rack is to save on space and in order according to stock / items. The loading bay for loading and offloading is all at one place at the end of the warehouse. Refer to illustration 1. It because, all items coming in and out need to check and receiving by

http://www.supplychainlogistics-consulting.co.uk/warehouse.html

Warehouse Management

Page 11

WAREHOUSE MANAGEMENT

warehouse personnel for checking like need to be key in to inventory system, comply with company Health, Safety & Environment policy. All the cargo going for

outbound will also be labelling and re-labelling last destination of each cargo, and also MSDS for chemical. This value-added process is done in warehouse 1 to ensure all cargo is correctly label and accordingly. The layouts for warehouse is look simple and organize according to its sector. Each sector like Production, Drilling Sabah Water & Drilling Sarawak Water if place accordingly and not mix up. By doing it simple and more flexible, it can create a cost efficiency, flexibility, easy handling and more specific. The warehouse is also meet the specifications that can affect the storage and material handling like type of racks used, height of racks, lighting, equipment movement like forklift, loading and unloading bay etc..

RACK (Production) LOADING / UNLOADING BAY

RACK (Drilling - Sabah Water)

RACK (Drilling - Sabah Water)

OFFICE

RACK (Drilling Sarawak Water)

RACK (Drilling Sarawak Water)

Illustration 1

Warehouse Management

Page 12

WAREHOUSE MANAGEMENT

4.4 Transportation also plays an important role in goods movement. As the operation is mostly to offshore and require supply vessel for transportation, surely the warehouse needs to be set-up near the seaport. By setting up warehouse inside the ASB and near the ASB port / jetty it will provide easy 24 hours operation. ASB is operating 24 hours operation with its own facilities and infrastructure such like fuel & water bunker for vessel, security, material equipment handling, Temporary storage for discharging cargo, etc.

5. Conclusion Warehouse is important to its business needs either for clients or supply. Function of warehouse can be either for receiving, storages, distribution, or packing and repacking, and others that can contribute to its warehouse functions base on what the warehouse management need and want. Before to set-up a warehouse, it need proper planning and SWOT analysis to ensure it according to what the warehouse objective to be neither in business or operation. Among its planning, we need to look into warehouse facilities development like size and number of warehouses to be, location to set up, design & layout of warehouse based on its operation or business, and other like transportation facilities, that can contribute to proper warehouse planning and management.

Warehouse Management

Page 13

WAREHOUSE MANAGEMENT

BIBLIOGRAPHY 1. 2. 3. 4.

http://en.wikipedia.org/wiki/Mezzanine_(architecture) http://en.wikipedia.org/wiki/Cantilever http://www.supplychainlogistics-consulting.co.uk/warehouse.html http://en.wikipedia.org/wiki/Warehouse

Warehouse Management

Page 14

You might also like

- Coursera - Better Warehouse LayoutDocument1 pageCoursera - Better Warehouse Layoutabdulrahman70% (10)

- Build A Logistics NetworkDocument2 pagesBuild A Logistics NetworkDarshan Patel15% (13)

- 2-3 Assignments - Solution To Specified Problem IIDocument7 pages2-3 Assignments - Solution To Specified Problem IIINNOBUNo750% (2)

- Setting Up and Designing Your Warehouse LayoutDocument13 pagesSetting Up and Designing Your Warehouse LayoutSiew Ming SooNo ratings yet

- Warehousing Assignment: Step-By-Step Assignment Instructions Assignment TopicDocument2 pagesWarehousing Assignment: Step-By-Step Assignment Instructions Assignment TopicGumbat KPKNo ratings yet

- Supply Chain Logistics Coursera ReportDocument2 pagesSupply Chain Logistics Coursera ReportHân Nguyễn Đoàn NamNo ratings yet

- Logistic Case StudiesDocument28 pagesLogistic Case Studiessuhas_pr50% (2)

- Supply Chain Management - Chopra/MeindlDocument8 pagesSupply Chain Management - Chopra/Meindlchin_a40% (5)

- Peer Graded Assignment Transportation LogisticsDocument4 pagesPeer Graded Assignment Transportation LogisticsAbdiladif M Ismail DigriyeNo ratings yet

- Peer-Graded Assignment - Lay Out Your Own WarehouseDocument3 pagesPeer-Graded Assignment - Lay Out Your Own WarehouseKhalid Aris50% (6)

- Logistics Case StudyDocument8 pagesLogistics Case Studysmh9662No ratings yet

- This Study Resource Was: Peer-Graded Assignment: Build A Logistics NetworkDocument4 pagesThis Study Resource Was: Peer-Graded Assignment: Build A Logistics NetworkSulaiman NurNo ratings yet

- Supply Chain of Pepsi CoDocument19 pagesSupply Chain of Pepsi CoAnkit Sherawat60% (5)

- Warehouse An Overview ProjectDocument48 pagesWarehouse An Overview ProjectHuzaifa Jamnagarwala100% (7)

- Ba 4055 Warehouse ManagementDocument40 pagesBa 4055 Warehouse ManagementDEAN RESEARCH AND DEVELOPMENT100% (1)

- Storage Assignment in A Unit Load WarehouseDocument20 pagesStorage Assignment in A Unit Load WarehouseThong Yong JunNo ratings yet

- Supply Chain AssignmentDocument3 pagesSupply Chain Assignmenttaruntalwar632892% (13)

- Inventory ManagementDocument5 pagesInventory ManagementDr Sarbesh Mishra90% (10)

- Supply Chain Academy: Advanced Warehouse ManagementDocument47 pagesSupply Chain Academy: Advanced Warehouse ManagementJesus Mata Facenda100% (1)

- Discussion QA 9to17Document56 pagesDiscussion QA 9to17April Reynolds100% (16)

- Lecture 7 - WAREHOUSING MANAGEMENTDocument51 pagesLecture 7 - WAREHOUSING MANAGEMENTsamwel100% (1)

- Logistics and Supply Chain Management AssignmentDocument13 pagesLogistics and Supply Chain Management AssignmentJon Kasimov80% (15)

- Case Study No.4Document1 pageCase Study No.4sasiganthNo ratings yet

- Assignment On Supply Chain ManagementDocument19 pagesAssignment On Supply Chain ManagementRayan Karim85% (27)

- Elements of Logistics Management NotesDocument45 pagesElements of Logistics Management NotesSujata Mansukhani93% (27)

- WarehousingDocument154 pagesWarehousingTapiwanashe Gwaze100% (4)

- Warehousing ProjectDocument12 pagesWarehousing Projectbombay10250% (6)

- 1.basics of Inventory Management PDFDocument38 pages1.basics of Inventory Management PDFEtoos EduNo ratings yet

- Warehousing AssignmentDocument10 pagesWarehousing AssignmentERICK MLINGWA0% (1)

- WarehouseDocument3 pagesWarehouseAmr M. AbdelhadyNo ratings yet

- Amazon Supply Chain Case StudyDocument2 pagesAmazon Supply Chain Case Studyknadmk100% (2)

- Global View of Supply Chain ManagementDocument7 pagesGlobal View of Supply Chain ManagementVinay IyerNo ratings yet

- A.B.C. Analysis (Always Better Control)Document3 pagesA.B.C. Analysis (Always Better Control)Navin Nadar100% (1)

- Supply Chain Management of Coca-ColaDocument20 pagesSupply Chain Management of Coca-ColaAditya Dethe85% (33)

- Supply Chain Management PepsiDocument25 pagesSupply Chain Management PepsiNaga NagendraNo ratings yet

- 3PLDocument42 pages3PLsanjeev kumar100% (1)

- Designing The Supply Chain NetworkDocument10 pagesDesigning The Supply Chain NetworkZahraShahid100% (1)

- SCM-CH 3 Supply Chain Drivers and MetricsDocument21 pagesSCM-CH 3 Supply Chain Drivers and MetricsSumit KumarNo ratings yet

- Warehouse Management SystemDocument31 pagesWarehouse Management SystemMaddy Rockzz100% (3)

- WarehousingDocument34 pagesWarehousingmapsara7988% (17)

- Practice Peer Six SigmaDocument1 pagePractice Peer Six Sigmahamzeh tatouNo ratings yet

- Logistics ManagementDocument16 pagesLogistics ManagementsmtbnmNo ratings yet

- Transport Peer Graded Assignment CourseraDocument5 pagesTransport Peer Graded Assignment CourseraAayush ThakurNo ratings yet

- Supply Chain ManagementDocument27 pagesSupply Chain ManagementParth Kapoor100% (1)

- Logistics and Supply Chain Management 1 PDFDocument11 pagesLogistics and Supply Chain Management 1 PDFDivya MittalNo ratings yet

- Warehouse Management SystemDocument38 pagesWarehouse Management SystemKeith Aranjuez75% (4)

- Logistic NotesDocument42 pagesLogistic NotesMansur Shaikh100% (1)

- Cross DockingDocument12 pagesCross DockingpisoyNo ratings yet

- Fedex E-Procurement CaseDocument13 pagesFedex E-Procurement CaseShubhanshu KatiyarNo ratings yet

- 3 Global Dimensions of Supply ChainDocument23 pages3 Global Dimensions of Supply ChainAnonymous skfyqk0diSNo ratings yet

- Element of Logistics and TransportationDocument5 pagesElement of Logistics and TransportationChong King Wei100% (3)

- INVENTORY MANAGEMENT TechniquesDocument24 pagesINVENTORY MANAGEMENT TechniquesWessal100% (1)

- Logistics and Supply Chain Management A Complete Guide - 2019 EditionFrom EverandLogistics and Supply Chain Management A Complete Guide - 2019 EditionRating: 3.5 out of 5 stars3.5/5 (3)

- Term PaperDocument4 pagesTerm PaperPraneeth Akula SonaNo ratings yet

- Stores and Inventory ManagementDocument18 pagesStores and Inventory ManagementUdit Sharma0% (1)

- Warehouse Layout and PlanningDocument12 pagesWarehouse Layout and PlanningJasmine KariukiNo ratings yet

- Understanding The Distribution Center LayoutDocument5 pagesUnderstanding The Distribution Center LayoutcortraboNo ratings yet

- Maharashtra Government Dilutes Gunthewari ActDocument2 pagesMaharashtra Government Dilutes Gunthewari ActUtkarsh SuranaNo ratings yet

- Grile EnglezaDocument3 pagesGrile Englezakis10No ratings yet

- Declarations On Higher Education and Sustainable DevelopmentDocument2 pagesDeclarations On Higher Education and Sustainable DevelopmentNidia CaetanoNo ratings yet

- Region 12Document75 pagesRegion 12Jezreel DucsaNo ratings yet

- Marketing Chapter001Document22 pagesMarketing Chapter001Reham MohamedNo ratings yet

- Lease FinancingDocument17 pagesLease FinancingPoonam Sharma100% (2)

- Information Security NotesDocument15 pagesInformation Security NotesSulaimanNo ratings yet

- Leadership and Followership in An Organizational Change Context (Sajjad Nawaz Khan, (Editor) ) (Z-Library)Document381 pagesLeadership and Followership in An Organizational Change Context (Sajjad Nawaz Khan, (Editor) ) (Z-Library)benjaminwong8029No ratings yet

- CEAT PresentationDocument41 pagesCEAT PresentationRAJNTU7aNo ratings yet

- A Study On Mobilization of Deposit and Investment of Nabil Bank LTDDocument68 pagesA Study On Mobilization of Deposit and Investment of Nabil Bank LTDPadamNo ratings yet

- Biology ProjectDocument7 pagesBiology ProjectChitwan GuptaNo ratings yet

- Use Case NarrativeDocument2 pagesUse Case NarrativePrajwol Sangat100% (1)

- Running Head: Problem Set # 2Document4 pagesRunning Head: Problem Set # 2aksNo ratings yet

- Coral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascDocument1 pageCoral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascGabriel Kuhs da RosaNo ratings yet

- Aims of The Big Three'Document10 pagesAims of The Big Three'SafaNo ratings yet

- Irony, Sexism and Magic in Paolo Sorrentino's FilmsDocument17 pagesIrony, Sexism and Magic in Paolo Sorrentino's FilmsLuisNo ratings yet

- Security Incidents and Event Management With Qradar (Foundation)Document4 pagesSecurity Incidents and Event Management With Qradar (Foundation)igrowrajeshNo ratings yet

- EA FRM HR 01 03 JobApplicationDocument6 pagesEA FRM HR 01 03 JobApplicationBatyNo ratings yet

- Rizal ParaniDocument201 pagesRizal ParaniMuhammadd YaqoobNo ratings yet

- HIMYM Episode 4 Season 1Document29 pagesHIMYM Episode 4 Season 1ZayNo ratings yet

- Total Gallium JB15939XXDocument18 pagesTotal Gallium JB15939XXAsim AliNo ratings yet

- DramaturgyDocument4 pagesDramaturgyThirumalaiappan MuthukumaraswamyNo ratings yet

- Abhiraj's Data Comm - I ProjectDocument15 pagesAbhiraj's Data Comm - I Projectabhirajsingh.bscllbNo ratings yet

- Chapter 11 Accounting PrinciplesDocument45 pagesChapter 11 Accounting PrinciplesElaine Dondoyano100% (1)

- GS Mains PYQ Compilation 2013-19Document159 pagesGS Mains PYQ Compilation 2013-19Xman ManNo ratings yet

- Ikea ReportDocument48 pagesIkea ReportPulkit Puri100% (3)

- Berkshire Hathaway Inc.: United States Securities and Exchange CommissionDocument48 pagesBerkshire Hathaway Inc.: United States Securities and Exchange CommissionTu Zhan LuoNo ratings yet

- Projections GuideDocument28 pagesProjections GuidemkmattaNo ratings yet

- Active Critical ReadingDocument22 pagesActive Critical ReadingYonn Me Me KyawNo ratings yet

- TS4F01-1 Unit 3 - Master DataDocument59 pagesTS4F01-1 Unit 3 - Master DataLuki1233332100% (1)