Professional Documents

Culture Documents

Sp1 230 SPFL 00 DM RP 406 00 - Ifc Design Dossier

Uploaded by

api-26220184Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sp1 230 SPFL 00 DM RP 406 00 - Ifc Design Dossier

Uploaded by

api-26220184Copyright:

Available Formats

TABLE OF CONTENTS

1. GENERAL .....................................................................................................................................................3

2. COMPANY DOCUMENTS TO BE ENDORSED BY CONTRACTOR .........................................................4

3. DOCUMENTS NOT TO BE ENDORSED BY CONTRACTOR ....................................................................5

4. CONTRACTOR’S EXECUTIVE SUMMARY AND METHOD STATEMENT................................................6

R:\652027\Typing\Docs\NATIVES FILES\DOCUMENTS\SP1-230-SPFL-00-DM-xxx\SP1-230-SPFL-00-DM-RP-406-00_IFC- Design

dossier.doc Page 2 of 6

1. GENERAL

The DESIGN DOSSIER comprises the Documents listed in items 2 – 4 of this EXHIBIT E, and

contained in separate volumes.

R:\652027\Typing\Docs\NATIVES FILES\DOCUMENTS\SP1-230-SPFL-00-DM-xxx\SP1-230-SPFL-00-DM-RP-406-00_IFC- Design

dossier.doc Page 3 of 6

2. COMPANY DOCUMENTS TO BE ENDORSED BY CONTRACTOR

As provided in Article XX of the AGREEMENT, by his signature of the “Certificate of Endorsement

of the Design Dossier”, Annex XX of the AGREEMENT, CONTRACTOR is deemed to have

formally endorsed the following documents.

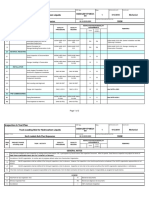

DOCUMENT

WP WU REFERENCE TITLE

ENDORSABLE DOCUMENTS

Work Package : Detailed Engineering - 18" Pipeline, Spool, Pieces & Risers

Work Unit : Design Documentation Review

2 2.1 SP1 230 SPFL 00 PL BR 201 Design Brief for 18" pipeline system

2 2.1 SP1 230 SPFL 00 PL DB 201 Design basis for 18" pipeline system

Work Package : Detailed Engineering - 18" Pipeline, Spool, Pieces & Risers

Work Unit : MTO's, Specs, Datasheets & Drawings for Pipeline and Risers

2 2.4 SP1 230 SPFL 00 PL AL 207 18" pipeline – Alignment sheets (4 sheets)

2 2.4 SP1 230 SPFL 00 PL DR 201 Drawing List

2 2.4 SP1 230 SPFL 00 PL DR 202 GENERAL NOTES

2 2.4 SP1 230 SPFL 00 PL DR 227 Pipeline typical anode details (+ attachment)

2 2.4 SP1 230 SPFL 00 PL DR 230 Riser Anchor Clamps - On SPP1 & SPD2 Jacket - Details

2 2.4 SP1 230 SPFL 00 PL DR 231 Riser Guide Clamps - On SPP1 & SPD2 Jacket - Details

2 2.4 SP1 230 SPFL 00 PL IS 215 Expansion spool piece at SPP1 - Isometric

2 2.4 SP1 230 SPFL 00 PL IS 218 Expansion spool piece at SPD2 - Isometric

2 2.4 SP1 230 SPFL 00 PL IS 221 Riser at SPP1 - Isometric

2 2.4 SP1 230 SPFL 00 PL IS 224 Riser at SPD2 - Isometric

2 2.4 SP1 230 SPFL 00 PL LY 205 18" In-field pipeline route

2 2.4 SP1 230 SPFL 00 PL LY 206 18" pipeline – Survey corridor

2 2.4 SP1 230 SPFL 00 PL LY 210 18" Infield - Spool Piece at SPP1 - General Arrangement

2 2.4 SP1 230 SPFL 00 PL LY 211 18" Infield - Spool Piece at SPD2 - General Arrangement

2 2.4 SP1 230 SPFL 00 PL LY 214 Expansion spool piece at SPP1 - Details

2 2.4 SP1 230 SPFL 00 PL LY 217 Expansion spool piece at SPD2 - Details

2 2.4 SP1 230 SPFL 00 PL LY 220 Riser at SPP1 (general layout + details)

2 2.4 SP1 230 SPFL 00 PL LY 223 Riser at SPD2 (general layout + details)

2 2.4 SP1 230 SPFL 00 PL LY 510 18'' Infield Pipeline system replacement- Pipeline only -spool piece at SPP1

2 2.4 SP1 230 SPFL 00 PL LY 511 18'' Infield pipeline system replacement-pipeline only - spool piece at SPD2

2 2.4 SP1 230 SPFL 00 PL MR 201 Requisition - Risers and Spool Piece - Line Pipe

2 2.4 SP1 230 SPFL 00 PL MR 202 Requisition - Risers and Spool Piece - Bend Pipe

2 2.4 SP1 230 SPFL 00 PL MR 203 Requisition - Flanges (including Gaskets, Bolts and Nuts)

2 2.4 SP1 230 SPFL 00 PL MR 204 Requisition - Pipeline Concrete Coating

2 2.4 SP1 230 SPFL 00 PL MR 205 Requisition - Sacrificial anodes

2 2.4 SP1 230 SPFL 00 PL MR 206 Requisition - Coal Tar Eramel

2 2.4 SP1 230 SPFL 00 PL MR 207 Requisition - Riser anti-corrosion coating

2 2.4 SP1 230 SPFL 00 PL SP 201 Specification - Risers and Spool Piece - Line Pipe

2 2.4 SP1 230 SPFL 00 PL SP 202 Specification - Risers and Spool Piece - Bend Pipe

2 2.4 SP1 230 SPFL 00 PL SP 203 Specification - Flanges (including Gaskets, Bolts and Nuts)

2 2.4 SP1 230 SPFL 00 PL SP 204 Specification - welding and NDT for Clad Line Pipe

2 2.4 SP1 230 SPFL 00 PL SP 205 Specification - Pipeline Concrete Coating

2 2.4 SP1 230 SPFL 00 PL SP 206 Specification - Pipeline Field Joint Coating

2 2.4 SP1 230 SPFL 00 PL SP 207 Specification - Sacrificial anodes

2 2.4 SP1 230 SPFL 00 PL SP 208 Specification - Coal Tar Eramel

2 2.4 SP1 230 SPFL 00 PL SP 209 Specification Riser anti-corrosion coating

Work Package : Construction and Installation Engineering

Work Unit : General documentation

4 4.1 SP1 230 SPFL 00 PL MR 306 Requisition for structural steel

4 4.1 SP1 230 SPFL 00 PL MR 307 Requisition for bolts, nuts, & miscellaneous items

4 4.1 SP1 230 SPFL 00 PL SP 305 Construction and Installation Specification - Pipeline

4 4.1 SP1 230 SPFL 00 PL SP 314 Anodes installation specification

4 4.1 SP1 230 SPFL 00 PL SP 315 Construction and Installation Specification- Risers & Spools

R:\652027\Typing\Docs\NATIVES FILES\DOCUMENTS\SP1-230-SPFL-00-DM-xxx\SP1-230-SPFL-00-DM-RP-406-00_IFC- Design

dossier.doc Page 4 of 6

3. DOCUMENTS NOT TO BE ENDORSED BY CONTRACTOR

As provided in Article XX of the AGREEMENT, the following documents are not required to be

formally endorsed by CONTRACTOR.

These docs are provided for information only.

DOCUMENT

WP WU REFERENCE TITLE

NON ENDORSABLE DOCUMENTS

4 4.1 SP1 230 SPFL 00 SA ST 302 Risk Assessment Analysis (installation w/o shut down)

Work Package : Construction and Installation Engineering

Work Unit : Installation of risers and spools

4 4.1 SP1 230 SPFL 00 PL DR 350 Installation drawing list

4 4.3 SP1 230 SPFL 00 PL DR 351 SPP1 - Riser Installation - Base Case Riser Connections by bolted flanges

4 4.3 SP1 230 SPFL 00 PL DR 352 SPP1 - Riser Installation - Alternative 1 - Riser connectoin by Welding

4 4.3 SP1 230 SPFL 00 PL DR 353 SPP1 Riser Installation - Alternative 2 Riser installed in one piece

4 4.3 SP1 230 SPFL 00 PL DR 354 SPP1 Riser Installation - Base case and alternative - Riser at Bottom of Jac

4 4.3 SP1 230 SPFL 00 PL DR 361 SPD2 Riser Installation - Base Case - Riser connections by bolted Flanges

4 4.3 SP1 230 SPFL 00 PL DR 362 SPD2 riser Installation - Alternative 1 - Riser Connections by welding

4 4.3 SP1 230 SPFL 00 PL DR 363 SPD2 Riser Installation - Alternative 2 - Riser installed in one piece

4 4.3 SP1 230 SPFL 00 PL DR 364 SPD2 Riser Installation - Base case and alternative 1 - Riser at Bottom of J

4 4.3 SP1 230 SPFL 00 PL DR 381 Spool removal sequences

4 4.3 SP1 230 SPFL 00 PL DR 382 Spool removal aids

4 4.3 SP1 230 SPFL 00 PL DR 383 Spool rigging arrangement & Details

4 4.3 SP1 230 SPFL 00 PL DR 384 Spool installation sequences

4 4.3 SP1 230 SPFL 00 PL DR 385 Spool installation aids

4 4.3 SP1 230 SPFL 00 PL DR 391 Riser removal sequences

4 4.3 SP1 230 SPFL 00 PL DR 392 Riser removal aids

4 4.3 SP1 230 SPFL 00 PL DR 393 Riser installation sequences

4 4.3 SP1 230 SPFL 00 PL DR 394 Risers installation aids

4 4.3 SP1 230 SPFL 00 PL PR 321 Outline spool fabrication procedure

4 4.3 SP1 230 SPFL 00 PL PR 322 Outline Riser fabrication procedure

4 4.3 SP1 230 SPFL 00 PL PR 323 Outline Riser & Spool removal & installation procedure

4 4.4 SP1 230 SPFL 00 PL PR 330 Pipeline system pre-comissionning Outline procedure

Work Package : Construction and Installation Engineering

Work Unit : Installation of pipeline

4 4.2 SP1 230 SPFL 00 PL DR 372 Typical deadman anchor GA drawing

4 4.2 SP1 230 SPFL 00 PL DR 373 Typical pulling head GA drawing

4 4.2 SP1 230 SPFL 00 PL DR 374 Pipeline rigging arrangement sketches

4 4.2 SP1 230 SPFL 00 PL DR 375 Pipeline installation sequences sketches

4 4.2 SP1 230 SPFL 00 PL PR 320 Outline pipeline installation procedure

4 4.2 SP1 230 SPFL 00 PL PR 324 Outline procedure for floading, Cleaning and gauging

R:\652027\Typing\Docs\NATIVES FILES\DOCUMENTS\SP1-230-SPFL-00-DM-xxx\SP1-230-SPFL-00-DM-RP-406-00_IFC- Design

dossier.doc Page 5 of 6

4. CONTRACTOR’S EXECUTIVE SUMMARY AND METHOD STATEMENT

CONTRACTOR’S Executive Summary and Method Statement, is a summarised description of his

technical proposal for the performance of the WORK as at EFFECTIVE DATE and prior to the

commencement of the detailed engineering phase of the WORK.

Should, as the result of the evolution in CONTRACTOR’S design during the performance of the

detailed engineering WORK, a change(s) take place in the methodology, means, design

assumptions and criteria, or any other aspect, compared with the proposal set out in the Executive

Summary and Method Statement, CONTRACTOR shall not be entitled to any adjustment of the

CONTRACT PRICE nor WORK TIME SCHEDULE in respect of such change(s).

{Whilst this section will be finalised prior to the EFFECTIVE DATE, CONTRACTOR is

requested to advise its draft wording for initial consideration by COMPANY}

R:\652027\Typing\Docs\NATIVES FILES\DOCUMENTS\SP1-230-SPFL-00-DM-xxx\SP1-230-SPFL-00-DM-RP-406-00_IFC- Design

dossier.doc Page 6 of 6

You might also like

- In-Service Storage Tank Inspection and Verification ChecklistDocument9 pagesIn-Service Storage Tank Inspection and Verification ChecklistAshif Khan100% (1)

- GB 150.4 Fabrication, Inspection and Testing, and Acceptance PDFDocument43 pagesGB 150.4 Fabrication, Inspection and Testing, and Acceptance PDFhuangjlNo ratings yet

- 2 Recommendation 02 Iss 11Document17 pages2 Recommendation 02 Iss 11g.noer8241No ratings yet

- OMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillDocument8 pagesOMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillLucas FladinirNo ratings yet

- Piping SpecificationDocument77 pagesPiping SpecificationVignesh Panchabakesan67% (3)

- Procedure For Crossings Construction and Free Span CorrectionDocument50 pagesProcedure For Crossings Construction and Free Span Correctionapi-3788654100% (1)

- DNV Guidelines 14 (1998)Document36 pagesDNV Guidelines 14 (1998)api-26220184100% (2)

- NATO STANAG 3609 5thed - Maint FuelDocument32 pagesNATO STANAG 3609 5thed - Maint FuelMiguel Gomez0% (1)

- ISA 75.19.01 Hydrostatic Testing of Control Valves PDFDocument34 pagesISA 75.19.01 Hydrostatic Testing of Control Valves PDFChristianGuerreroNo ratings yet

- Ml-18 Work Procedure For Crossing by HDD MethodDocument21 pagesMl-18 Work Procedure For Crossing by HDD MethodBrijesh Katariya VCS100% (1)

- Omae2017 61282Document13 pagesOmae2017 61282Thanh Trí TrươngNo ratings yet

- Stability Design of Articulated Concrete Mattress-Revision 5-Eil Approved in Code1Document87 pagesStability Design of Articulated Concrete Mattress-Revision 5-Eil Approved in Code1SAUGAT DUTTANo ratings yet

- Bab 13 Pipeline IntegrityDocument19 pagesBab 13 Pipeline IntegrityrWin doNo ratings yet

- Trenching, Backfilling & Compacting OPSS - Muni 401 Nov15Document10 pagesTrenching, Backfilling & Compacting OPSS - Muni 401 Nov15mmkamran1017No ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Anchor FlangeDocument8 pagesAnchor FlangeHanda Bin AdiNo ratings yet

- A Simplified 3D Model For Tunnel Constru PDFDocument8 pagesA Simplified 3D Model For Tunnel Constru PDFmightsrightNo ratings yet

- MEPG - Repurposing Existing Pipeline For CO2 TransportDocument33 pagesMEPG - Repurposing Existing Pipeline For CO2 TransportAmmarul NafikNo ratings yet

- Soil Axial Resistance of A PipelineDocument3 pagesSoil Axial Resistance of A PipelineFemi Richard FakoyaNo ratings yet

- Final ReportDocument19 pagesFinal ReportAbdul Azeez100% (1)

- Section 819 Microtunneling and PipeDocument22 pagesSection 819 Microtunneling and Pipeaz_zakiNo ratings yet

- Project Brief For OrcaflexDocument4 pagesProject Brief For OrcaflexyogacruiseNo ratings yet

- Ex Plan R2-SignedDocument74 pagesEx Plan R2-SignedZulhilmie BobNo ratings yet

- 2014 Guidelines Rockfall RemediationDocument9 pages2014 Guidelines Rockfall RemediationVashdevNo ratings yet

- Plf-jms-031 - r0 - Jms of Lifting, Shifting, Stringing, Lowering-In and Transportation Using Excavator - SignedDocument85 pagesPlf-jms-031 - r0 - Jms of Lifting, Shifting, Stringing, Lowering-In and Transportation Using Excavator - SignedHafiz YunusNo ratings yet

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesDocument21 pagesSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedNo ratings yet

- Annexure-1 Technical Specification For PipelinesDocument316 pagesAnnexure-1 Technical Specification For PipelinesUtkarsh ModhiaNo ratings yet

- 2009W ENGI 8673 L17 Ex 17 01 PDFDocument3 pages2009W ENGI 8673 L17 Ex 17 01 PDFThyago de LellysNo ratings yet

- 2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimDocument15 pages2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimYoungtae KimNo ratings yet

- MicrotunellingDocument10 pagesMicrotunellingleo.caguimbal6433No ratings yet

- Final As-Built Documentation FOR Muscat Sohar Products Pipeline (MSPP) ProjectDocument11 pagesFinal As-Built Documentation FOR Muscat Sohar Products Pipeline (MSPP) ProjectSiva baalan100% (1)

- Pipeline Routing StudiesDocument11 pagesPipeline Routing StudiesGodwinNo ratings yet

- Underwater Submarine Pipe LineDocument30 pagesUnderwater Submarine Pipe LinevillanuevamarkdNo ratings yet

- Thermal Buckling Comparative Analysis Using Different FE Tools 01Document4 pagesThermal Buckling Comparative Analysis Using Different FE Tools 01Waldek BanasiakNo ratings yet

- SEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev ADocument15 pagesSEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev APruthviraj JuniNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument8 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- TB 10Document10 pagesTB 10Ankur PandeyNo ratings yet

- 19 Pre Hydro TestingDocument5 pages19 Pre Hydro TestingManoranjan sharmaNo ratings yet

- TR2222 - Pipeline Flooding, Cleaning, Gauging and Pressure TestingDocument20 pagesTR2222 - Pipeline Flooding, Cleaning, Gauging and Pressure Testingmaximusala83No ratings yet

- Pre Trenching ProsedurDocument19 pagesPre Trenching Prosedurmaniacs14No ratings yet

- 4002 Rev.9 - FS For CP System For Submarine PipelineDocument13 pages4002 Rev.9 - FS For CP System For Submarine Pipelinesridar rNo ratings yet

- Free Span Design According To The DNV-RP-F105 For Free Spanning PipelinesDocument24 pagesFree Span Design According To The DNV-RP-F105 For Free Spanning PipelinesconanbhNo ratings yet

- PPSC - Product Data Sheet Concrete Weight CoatingsDocument1 pagePPSC - Product Data Sheet Concrete Weight CoatingsjulianpirahNo ratings yet

- AutoPIPE Quick ReferenceDocument1 pageAutoPIPE Quick Referenceskeggia85No ratings yet

- Numerical Modelling of Vortex Induced VibrationsDocument6 pagesNumerical Modelling of Vortex Induced VibrationscteranscribdNo ratings yet

- Technical Specification: 0 OriginalDocument22 pagesTechnical Specification: 0 OriginalGuilherme de BarrosNo ratings yet

- Basic Linear Static Finite Element AnalysisDocument19 pagesBasic Linear Static Finite Element AnalysisRuben Bartolome GarciaNo ratings yet

- Chapter 1: Subsea Production Systems: Definitions and AbbreviationsDocument14 pagesChapter 1: Subsea Production Systems: Definitions and AbbreviationsDan Joban RotaNo ratings yet

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document2 pagesDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- Equalizing Line Mbe 6 WTRDocument2 pagesEqualizing Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Pull in AnalysisDocument4 pagesPull in Analysisgvsha88No ratings yet

- Quality Requirements For Line Pipe: JanuaryDocument14 pagesQuality Requirements For Line Pipe: JanuaryJose Anisio Silva100% (1)

- IDBU-CW-LSPDS-000030 Rev D Upstream Process Piping Welding and InspectionDocument32 pagesIDBU-CW-LSPDS-000030 Rev D Upstream Process Piping Welding and Inspectionjoey garciaNo ratings yet

- Rock Dumping VesselsDocument2 pagesRock Dumping Vesselsalphading0% (1)

- Equipment List Including Long Lead ItemsDocument6 pagesEquipment List Including Long Lead Itemspapilolo2008No ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- UMF GN04 Issue 1 Free Span AnalysisDocument5 pagesUMF GN04 Issue 1 Free Span AnalysiszulikramNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IISikandar_30100% (1)

- API 5L 45-th Edition: Item No SawlDocument6 pagesAPI 5L 45-th Edition: Item No SawlRob WillestoneNo ratings yet

- Stress Analysis of Buried Pipeline Using Finite Element MethodDocument16 pagesStress Analysis of Buried Pipeline Using Finite Element MethodMaria TnsNo ratings yet

- Cobalch Aps - PTFE DetailDocument25 pagesCobalch Aps - PTFE DetailMorteza DianatfarNo ratings yet

- Vol-II of IV - Laying - HPCLDocument753 pagesVol-II of IV - Laying - HPCLupesddn20100% (1)

- HFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedDocument77 pagesHFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedVignesh Panchabakesan100% (1)

- Catalog Materiale de Adaos FileurDocument193 pagesCatalog Materiale de Adaos FileurRogo CatalinNo ratings yet

- References Are in Agreement With Umrl in Pipelines, Liquid Process PipingDocument110 pagesReferences Are in Agreement With Umrl in Pipelines, Liquid Process PipingrafieeNo ratings yet

- Narmada Hydrotest Procedure (Rigid) - Rev 1Document37 pagesNarmada Hydrotest Procedure (Rigid) - Rev 1api-2622018486% (7)

- Narmada Hydrotest Procedure (Rigid) - Rev 0Document95 pagesNarmada Hydrotest Procedure (Rigid) - Rev 0api-26220184100% (1)

- EPC3 Free Span Correction Procedure D1Document33 pagesEPC3 Free Span Correction Procedure D1api-26220184100% (3)

- DNV Rules For Submarine Pipeline Systems (1981)Document153 pagesDNV Rules For Submarine Pipeline Systems (1981)api-26220184100% (7)

- CV E MosaferDocument6 pagesCV E Mosaferapi-26220184No ratings yet

- F-3061 Jis 5K/Jis 10K: No Part Material CodeDocument1 pageF-3061 Jis 5K/Jis 10K: No Part Material CodeSergio Jesus SanjurjoNo ratings yet

- 52000427BD-Alliance-Airport Expansion (R-2) - EmailDocument3 pages52000427BD-Alliance-Airport Expansion (R-2) - EmailTanveer AzizNo ratings yet

- Denso Valve Flange Tape Wrapping SpecDocument3 pagesDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- Válvulas Newco Cast Teel PDFDocument64 pagesVálvulas Newco Cast Teel PDFAndres LopezNo ratings yet

- Pipe Flanges and Flanged Fittings ASME B16.5-2003Document1 pagePipe Flanges and Flanged Fittings ASME B16.5-2003Panchal ShaileshNo ratings yet

- ITP For Truck Loading Skid - Rev.01Document10 pagesITP For Truck Loading Skid - Rev.01KaramSobhyNo ratings yet

- TLV T8N Flow IndicatorDocument2 pagesTLV T8N Flow IndicatorDaniel ReyNo ratings yet

- Gate, Globe and Check Valves (Amendments/Supplements To Iso 15761)Document13 pagesGate, Globe and Check Valves (Amendments/Supplements To Iso 15761)rajeshNo ratings yet

- Carbon Steel Pipe and Fittings PDFDocument10 pagesCarbon Steel Pipe and Fittings PDFavazcNo ratings yet

- COMEM Porcelain Bushings-MANUALDocument36 pagesCOMEM Porcelain Bushings-MANUALVanaNo ratings yet

- Spare Part List HGX34e 315-4 S Up To DK 056Document4 pagesSpare Part List HGX34e 315-4 S Up To DK 056Mosleh AbdelkaderNo ratings yet

- Introduction To Square Flanges: SpecificationDocument2 pagesIntroduction To Square Flanges: SpecificationKunjal ShahNo ratings yet

- Data Sheet Gate Valves: FlangedDocument1 pageData Sheet Gate Valves: Flangedbmanojkumar16No ratings yet

- Design 1018S Control Valves With Type 3024S, 657, and 667 ActuatorsDocument22 pagesDesign 1018S Control Valves With Type 3024S, 657, and 667 ActuatorsRicardo Calderon ClarosNo ratings yet

- AG LCP Maintenance ManualDocument19 pagesAG LCP Maintenance Manualtxlucky800% (1)

- Accessories HydraulicsDocument47 pagesAccessories HydraulicsawfahaddadinNo ratings yet

- Gate Valve - Post IndicatorDocument20 pagesGate Valve - Post IndicatorLENINROMEROH4168No ratings yet

- Drum Replacement2Document20 pagesDrum Replacement2Alejandro RedondoNo ratings yet

- Parts Illustration - IT4 - C135063Document27 pagesParts Illustration - IT4 - C135063Franklin Gustavo Zagaceta Bautista0% (1)

- FH Series: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZDocument132 pagesFH Series: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZWilly RiosNo ratings yet

- Quotation: Dear Sir, Thank You For Your Inquiry, We Are Glad To Quote You Our Best Competitive Offer BelowDocument3 pagesQuotation: Dear Sir, Thank You For Your Inquiry, We Are Glad To Quote You Our Best Competitive Offer BelowgvasangNo ratings yet

- 31-SAMSS-010 - 25 Oct 2018Document9 pages31-SAMSS-010 - 25 Oct 2018Fayez Al-ahmadiNo ratings yet

- JIS KIS Flange Product Range CatalogueDocument8 pagesJIS KIS Flange Product Range CatalogueAsep DarojatNo ratings yet

- 3800 Series: Valve GroupDocument40 pages3800 Series: Valve GrouptechnicalNo ratings yet

- SAFE RING Flange GuardDocument11 pagesSAFE RING Flange Guardsushil kumar guptaNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet