Professional Documents

Culture Documents

Air Vee Bending

Uploaded by

anil chejaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Vee Bending

Uploaded by

anil chejaraCopyright:

Available Formats

AIR VEE BENDING

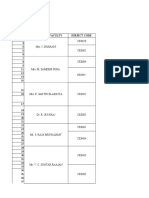

Name: Anil Chejara Roll no. : 9003022 Group no. : 5

BACKGROUND:

Bending is a process by which metal can be deformed by plastically deforming the material and changing its shape. The material is stressed beyond the yield strength but below the ultimate tensile strength. The surface area of the material does not change much. Bending usually refers to deformation about one axis. Bending is a flexible process by which many different shapes can be produced. Standard die sets are used to produce a wide variety of shapes. The material is placed on the die, and positioned in place with stops and/or gages. It is held in place with hold-downs. The upper part of the press, the ram with the appropriately shaped punch descends and forms the vshaped bend. Bending is done using Press Brakes.

Air Bending is done with the punch touching the work piece and the work piece, not bottoming in the lower cavity. This is called air bending. As the punch is released, the work piece ends up with less bend than that on the punch greater included angle. This is called spring-back. The amount of spring back depends on the material, thickness, grain and temper. The spring back usually ranges from 5 to 10 degrees. Usually the same angle is used in both the punch and the die to minimize setup time. The inner radius of the bend is the same as the radius on the punch.

THEORY BEHIND OPERATION: Spring back predictions are important to maintain the geometric tolerance of the finished part. Spring back refers to the elastic recovery of the non-uniformly distributed stresses in a deformed part after the forming load is removed. The unloading is always elastic.

AIM: To study the Air-Vee bending of sheet metal strip and calculate its spring back and its dependence on the process parameters.

PROCEDURE: The Air vee bending is done on fly press.

First load the sheet and press it by 5mm vertically. Take reading while the sheet is in a loaded condition. Unload the sheet and there will be a spring back. Trace its profile also. Now repeat the same experiment for 10mm and 15mm depth. Note down the angles measured on the sheet of paper for all the sheets. Repeat the experiments for anther material.

FORMULA USED:

OBSERVATION TABLE AND GRAPHICAL REPRESENTION:

RESULTS: As the depth of punch increases the spring back also increases. The spring back for steel is more than Aluminium.

SOURCE OF ERROR: Human error possible while taking reading. Load may not be applied uniformly. Process of finding bent radius will affect the results.

You might also like

- Bending ProcessDocument5 pagesBending ProcessMohamed Esmael ElsayedNo ratings yet

- BENDINGDocument10 pagesBENDINGBipin DashNo ratings yet

- Sheet Metal BendingDocument23 pagesSheet Metal BendingTuyenNo ratings yet

- Bending: Solid PartsDocument3 pagesBending: Solid Partsbellal_sustNo ratings yet

- Bending (Metalworking) : "Metal Bending" Redirects Here. For The Form of Stage Magic, SeeDocument10 pagesBending (Metalworking) : "Metal Bending" Redirects Here. For The Form of Stage Magic, SeeJordan MosesNo ratings yet

- Bending (Metalworking) : ProcessDocument9 pagesBending (Metalworking) : ProcessSubhransu Sekhar SahooNo ratings yet

- Bending (Metalworking)Document9 pagesBending (Metalworking)siswoutNo ratings yet

- Sheet Metal Forming PDFDocument9 pagesSheet Metal Forming PDFRakhesh Manchi100% (1)

- 3 Metal StampingDocument2 pages3 Metal StampingRavi Sharma M PNo ratings yet

- Bending (Metalworking) - Wikipedia, The Free EncyclopediaDocument8 pagesBending (Metalworking) - Wikipedia, The Free EncyclopediaSachin TechNo ratings yet

- Sheet Metal FormingDocument16 pagesSheet Metal FormingSabur Mythin Abdul AzeesNo ratings yet

- BendingDocument8 pagesBendingShal DxtNo ratings yet

- Bending (Metalworking)Document7 pagesBending (Metalworking)Odebiyi StephenNo ratings yet

- Bending (Metalworking) - Wikipedia, The Free EncyclopediaDocument8 pagesBending (Metalworking) - Wikipedia, The Free Encyclopediaavinashj18No ratings yet

- Bending (Metalworking)Document7 pagesBending (Metalworking)semizxxxNo ratings yet

- Die FormingDocument4 pagesDie FormingMohit KambojNo ratings yet

- Sheet Metal FabricationDocument70 pagesSheet Metal Fabricationnjsoffice33% (6)

- Sheet Metal FabricationDocument70 pagesSheet Metal Fabricationhsemarg100% (5)

- Chapter-2 BendingDocument16 pagesChapter-2 BendingNikhil PrasannaNo ratings yet

- Deep DrawingDocument4 pagesDeep DrawingSsk RogueNo ratings yet

- Bend Radius Bend Angle: Bending Is A Metal Forming Process in Which A Force Is Applied To A Piece of Sheet MetalDocument8 pagesBend Radius Bend Angle: Bending Is A Metal Forming Process in Which A Force Is Applied To A Piece of Sheet MetalSassyNo ratings yet

- Tool DesignDocument100 pagesTool DesignUDAYA KNo ratings yet

- RA BS 5 3 - Ch3Document17 pagesRA BS 5 3 - Ch3fraluleiNo ratings yet

- Bending ProcessDocument32 pagesBending ProcessdfdsNo ratings yet

- Press ToolsDocument31 pagesPress ToolsSunil MandoreNo ratings yet

- UntitledDocument39 pagesUntitledsasikumarNo ratings yet

- Advance Metal Forming ProcessDocument12 pagesAdvance Metal Forming ProcessRemo RamNo ratings yet

- Sheet Metal DesignDocument71 pagesSheet Metal DesignParag JaiswalNo ratings yet

- DieDocument6 pagesDieAditya GoelNo ratings yet

- Press & Press WorkDocument7 pagesPress & Press Workapi-19822628No ratings yet

- DiesDocument4 pagesDiesjohan pambudiNo ratings yet

- Air Vee BendingDocument4 pagesAir Vee BendingMohak Patel100% (1)

- The Material Is Stressed Beyond The Yield Strength But Below The Ultimate Tensile Strength of TheDocument10 pagesThe Material Is Stressed Beyond The Yield Strength But Below The Ultimate Tensile Strength of TheElaine JohnsonNo ratings yet

- Metal Forming TechniquesDocument49 pagesMetal Forming TechniquesSachinBhagiNo ratings yet

- Tool and DieDocument15 pagesTool and DieJohn Jhay CanlasNo ratings yet

- 2017im148, PTD Assignment 6 & 7Document8 pages2017im148, PTD Assignment 6 & 7rehmatali11121314No ratings yet

- Levelers: Internal Stress Coil Set Crossbow Edge Wave Center Buckle Flattening LevelingDocument4 pagesLevelers: Internal Stress Coil Set Crossbow Edge Wave Center Buckle Flattening LevelingangelokyoNo ratings yet

- 2017im148, PTD Assignment 6 & 7Document8 pages2017im148, PTD Assignment 6 & 7rehmatali11121314No ratings yet

- Sheet Metal Shearing and Bending: Training ObjectiveDocument6 pagesSheet Metal Shearing and Bending: Training ObjectiveLovely RainNo ratings yet

- Introduction To Tools and DiesDocument4 pagesIntroduction To Tools and DiesUmair KhattakNo ratings yet

- Press ToolsDocument6 pagesPress ToolsSamir BoseNo ratings yet

- Sheet Metal OperationsDocument27 pagesSheet Metal OperationsbmvinayNo ratings yet

- Metal Bending: Bending Is A Manufacturing Process That Produces A V-Shape, U-Shape, or ChannelDocument12 pagesMetal Bending: Bending Is A Manufacturing Process That Produces A V-Shape, U-Shape, or ChannelMizero AimeNo ratings yet

- Sunu 1Document16 pagesSunu 1Ayca Betul BingolNo ratings yet

- Design of Sheet Metal Working ToolsDocument38 pagesDesign of Sheet Metal Working ToolsAsef ShahriarNo ratings yet

- U BendingDocument31 pagesU BendingbabutyNo ratings yet

- Cold FormingDocument7 pagesCold FormingglaxionNo ratings yet

- K Factors + Bending InfoDocument9 pagesK Factors + Bending InfoashkansoheylNo ratings yet

- Sheet Metal-Bending Lab PresentationDocument30 pagesSheet Metal-Bending Lab PresentationHakan BilginNo ratings yet

- Shearing and Bending IntroductionDocument30 pagesShearing and Bending IntroductionmoriyasurjpNo ratings yet

- Sheetmetal IntroDocument48 pagesSheetmetal IntroBharat M GajeraNo ratings yet

- Sheetmetal FabricationDocument18 pagesSheetmetal FabricationSumeet Saini100% (1)

- Forging Operations: 1: DrawingDocument4 pagesForging Operations: 1: DrawingvijayakumarNo ratings yet

- My ForgingDocument20 pagesMy ForgingRam Janm SinghNo ratings yet

- Sheet Metal ProcessesDocument30 pagesSheet Metal ProcessesJagdish KolteNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Heat Transfer in Turbulent FlowDocument5 pagesHeat Transfer in Turbulent Flowanil chejaraNo ratings yet

- Finned Tube Heat ExchangerDocument6 pagesFinned Tube Heat Exchangeranil chejaraNo ratings yet

- Coordinate Measuring Machine (CMM)Document6 pagesCoordinate Measuring Machine (CMM)anil chejara86% (7)

- Natural ConvectionDocument6 pagesNatural Convectionanil chejaraNo ratings yet

- Heat Transfer in Laminar FlowDocument6 pagesHeat Transfer in Laminar Flowanil chejaraNo ratings yet

- RL Norton SolutionsDocument1,724 pagesRL Norton Solutionsanil chejara100% (1)

- Thermal Conductivity of Metal RodDocument6 pagesThermal Conductivity of Metal Rodanil chejara100% (6)

- Profile ProjecterDocument6 pagesProfile Projecteranil chejara100% (1)

- Calibration of Vernier CapilierDocument7 pagesCalibration of Vernier Capilieranil chejara100% (2)

- Metacentric HeightDocument4 pagesMetacentric Heightanil chejaraNo ratings yet

- Measurement of GearsDocument6 pagesMeasurement of Gearsanil chejaraNo ratings yet

- Imp Chip Diagrams 12Document7 pagesImp Chip Diagrams 12Chandani ShahNo ratings yet

- Circularity & CylindricityDocument8 pagesCircularity & Cylindricityanil chejaraNo ratings yet

- Forced VortexDocument4 pagesForced Vortexanil chejaraNo ratings yet

- Uniaxial Tension TestingDocument6 pagesUniaxial Tension Testinganil chejara100% (1)

- Free VortexDocument3 pagesFree Vortexanil chejaraNo ratings yet

- Calibration of Venturimeter and OrificemeterDocument6 pagesCalibration of Venturimeter and Orificemeteranil chejara83% (6)

- Governing Equation For Turbines and Classification of Pressure TanksDocument6 pagesGoverning Equation For Turbines and Classification of Pressure Tanksanil chejaraNo ratings yet

- Tensile TestDocument6 pagesTensile Testanil chejaraNo ratings yet

- Pitot Static TubeDocument4 pagesPitot Static Tubeanil chejara100% (1)

- Starin Gauge TestDocument6 pagesStarin Gauge Testanil chejaraNo ratings yet

- Materail Failure TheoriesDocument11 pagesMaterail Failure Theoriesanil chejaraNo ratings yet

- Hardness TestDocument10 pagesHardness Testanil chejara100% (1)

- Charpy Impact TestDocument6 pagesCharpy Impact Testanil chejara83% (6)

- NPCIL/RAPP Vocational Traniee ReportDocument37 pagesNPCIL/RAPP Vocational Traniee Reportanil chejaraNo ratings yet

- Numerical Analysis ProjectDocument12 pagesNumerical Analysis Projectanil chejaraNo ratings yet

- Uniaxial TestDocument6 pagesUniaxial Testanil chejaraNo ratings yet

- Impact TestDocument8 pagesImpact TestMustafa Ani100% (1)

- Lighting Bracket Manufracting PresentationDocument21 pagesLighting Bracket Manufracting Presentationanil chejaraNo ratings yet

- Mechdb Reviewer MidtermsDocument2 pagesMechdb Reviewer MidtermsBenjo SantosNo ratings yet

- FMC Elevator BucketsDocument11 pagesFMC Elevator BucketscesarNo ratings yet

- Structures Subjected To Repeated Loading-Stability and Strength - R Narayanan, 1990 PDFDocument259 pagesStructures Subjected To Repeated Loading-Stability and Strength - R Narayanan, 1990 PDFtmaNo ratings yet

- ArticleDocument4 pagesArticleNeil AgshikarNo ratings yet

- Alloy Materials and Their Allied Applications (2020)Document232 pagesAlloy Materials and Their Allied Applications (2020)Bunner FastNo ratings yet

- FK 2015 96irDocument43 pagesFK 2015 96irSang Ka KalaNo ratings yet

- Rebar Coupler Test StandartDocument6 pagesRebar Coupler Test StandartSaurav KumarNo ratings yet

- Structural Analysis EXAMPLEDocument8 pagesStructural Analysis EXAMPLEmodulor3dNo ratings yet

- Flexural Member DesignDocument50 pagesFlexural Member DesignremedanNo ratings yet

- In Situ Measurement of Masonry Mortar Joint Shear Strength IndexDocument7 pagesIn Situ Measurement of Masonry Mortar Joint Shear Strength Indexjuli_rad0% (1)

- Sandvik Slicklines: For The Oil & Gas IndustryDocument8 pagesSandvik Slicklines: For The Oil & Gas Industryhoss mosafaNo ratings yet

- Buckling Restrained Braces - BRBtips - 2Document78 pagesBuckling Restrained Braces - BRBtips - 2Rezky MuliaNo ratings yet

- HELICOIL Classic BAL EN PDFDocument28 pagesHELICOIL Classic BAL EN PDFPuvas NandakwangNo ratings yet

- Geological Condition Necessary For Construction of Dams, Tunnel & BuildingsDocument12 pagesGeological Condition Necessary For Construction of Dams, Tunnel & Buildingsberuniorolando0No ratings yet

- Behaviour of Laterally Loaded PilesDocument42 pagesBehaviour of Laterally Loaded PilesunbezonkingNo ratings yet

- Shear Transfer in Reinforced Concrete - Recent Research PDFDocument21 pagesShear Transfer in Reinforced Concrete - Recent Research PDFSumanthNo ratings yet

- Cive Group 8Document28 pagesCive Group 8Asif TasfiqNo ratings yet

- NBCC JE 8 May 2022 Paper With Key Civil JunctionDocument25 pagesNBCC JE 8 May 2022 Paper With Key Civil JunctionSudarshan bhadaneNo ratings yet

- Unit5 Design of KeysDocument32 pagesUnit5 Design of Keyssuswagat75% (4)

- Ra - Technical Design Guide Usa 06 2019Document88 pagesRa - Technical Design Guide Usa 06 2019Raul AntonieNo ratings yet

- Numerical-Experimental Study On Steel Plates Subjected To Blast LoadingDocument14 pagesNumerical-Experimental Study On Steel Plates Subjected To Blast LoadingGoutham BurraNo ratings yet

- Concrete Laboratory Procedure-OutlineDocument26 pagesConcrete Laboratory Procedure-OutlineKim Ciudadano100% (1)

- CHANCE Helical Piles For Structural Support - Guide SpecificationDocument28 pagesCHANCE Helical Piles For Structural Support - Guide SpecificationBruno RNo ratings yet

- Behaviour and Strengthening of RC T-Girders in Torsion and Shear (Deifalla PHD Thesis)Document276 pagesBehaviour and Strengthening of RC T-Girders in Torsion and Shear (Deifalla PHD Thesis)fefahimNo ratings yet

- Thamirabharani Engineering College: Sl. No Name of The Faculty Subject CodeDocument7 pagesThamirabharani Engineering College: Sl. No Name of The Faculty Subject CodeMuthu GaneshNo ratings yet

- Chapter 3Document12 pagesChapter 3Markos MikoNo ratings yet

- Theory of Plasticity For Steel StructuresDocument257 pagesTheory of Plasticity For Steel StructuresMahdi100% (2)

- Assistant Engineer in KamcoDocument16 pagesAssistant Engineer in KamcoLearn Mechanical EngineeringNo ratings yet

- Design and Modeling of High Mast Solar Light PDFDocument5 pagesDesign and Modeling of High Mast Solar Light PDFGeEs AnggaNo ratings yet