Professional Documents

Culture Documents

Recycling of Plastics

Uploaded by

DIPAK VINAYAK SHIRBHATEOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recycling of Plastics

Uploaded by

DIPAK VINAYAK SHIRBHATECopyright:

Available Formats

Recycling of Plastics

INTRODUCTION

Recycling of plastics not only helps the conservation of raw materials

but also reduces the pollution of the environment. Different processes for

recycling of plastics are described in this topic. The method of recovery of plastics

from variety for wastes are also outlined in this topic.

Plastic in solid wastes are a great problem in the environment

for their indestructible nature. It is not surprising not learn that the overall growth of

solid wastes. Presently it is estimated that the generation of solid waste per capita

is around 1/2 kg which is likely to increase to I kg by the year 2000. Plastics as

wastes constitute around 4 wt %-5 wt % of solid waste. Almost 80 % of this

recyclable waste is collected by the rag pickers at source from the garbage

dumps. The balance 20 % goes to land filling.

In 1993, consumption of virgin plastics was 1.44 Mt (production

being 0.92 Mt and imports were 0.52 Mt) Besides 0.13 Mt plastics wastes was

reprocessed (amounted to 0.53 Mt) in India during 1993. This, the total

consumption of plastics in India during 1993 was around 2 Mt. It is predicted that by

the year 2000, consumption of virgin plastics will be 3.3 Mt and reprocessed plastics

will be 1.3 Mt (thus total consumption will be 4.6 Mt).

Govt. Poly. Washim. 1

Recycling of Plastics

Over a million rag pickers including plastics wastes collector are

involved and around 20000 units all over the country are engaged at present in

reprocessing around 0.4 Mt of plastic waste. It is predicted that I Mt of plastics

waste will be available by 2000. The polymer - wise share of plastics waste is

PVC - 45%, LDPE - 25%, HDPE-20%\ PP - 7.6% and others like PS-2.4%.

The two important environmental problems are how to reduce

pollution of air, water and land, and how to conserve raw materials. The planned

application of existing technologies would be sufficient to avoid any serious risks

of direct or transferred pollution by plastics wastes. Recycling of plastics is

currently believed to be the most acceptable route to solve the above problems in the

long run.

In addition to these, recycling of plastics will supplement the

requirement of plastics raw materials and reduce the import of plastic raw materials

in the country.

Govt. Poly. Washim. 2

Recycling of Plastics

SOURCES OF PLASTICS WASTE

Creation of waste occurs in three main areas :

a) During manufacture of the polymer;

b) During manufacture of the product; and

c) During the disposal of the product after use.

Figure 1 shows the flow of materials from the polymer producer until

it reaches the waste dump. This shows that primary as well as secondary raw

materials are absorbed, resulting from in-plant recycling and reclaiming. Plastics

reclaimers obtain their raw materials in the form of wastes from polymer producer,

plastic processor and industrial end users and converters.

Govt. Poly. Washim. 3

Recycling of Plastics

Primary Raw Material

Polymer Producer

Reprocessing

Commercial

Reclalmers Plastic Processors and Industrial

Waste

Reprocessing

Industrial End Users and

converters

Repeated Reuse

Private and Official Domestic

Households Waste

Flow of Material From Polymer Producer to the Waste Dump

Govt. Poly. Washim. 4

Recycling of Plastics

PROCESSES OF RECYCLING OF PLASTICS

Recycling describes the actual process for usefully employing the

recovered raw materials. There are three processes available for recycling of

plastics.

a) Direct recycling

This would be the use of recovered material for the manufacture of

identical or similar products;

b) Indirect recycling

This would imply the use of the recovered or salvaged material for the

manufacture or use of a product of less critical specification.

c) Thermal recycling

This implies that conversion of waste under conditions which generate

either energy or chemical products or both.

Direct Recycling of Plastics

This is mainly applicable to the wastes which arise during the

production processes within the plastics industry.

Govt. Poly. Washim. 5

Recycling of Plastics

For direct recycling, waste plastics must satisfy three requirements :

a) Satisfactory from (granules, pellets, powders etc.),

b) Homogeneity, because mixed grades of plastics will not possess the

required properties for most processes or products; and

c) Cleanliness, because contaminants such as dust, stray matter, oil etc. would

degrade the quality of the product.

Clean process waste may be recycled by a relatively simple route as

shown in Fig. 2

Govt. Poly. Washim. 6

Recycling of Plastics

Virgin

Material

Processing Good

Machine Product Product

Processing

Cooling Waste Rejects

Regular

Granules Rechip

Extrude Recompound

Recycling Direct On Processing Machine

Govt. Poly. Washim. 7

Recycling of Plastics

Irregular shaped waste from production must be converted to a

consistent shape by a regranulation technique which involves a minimum of

temperature degradation. The introduction of irregular chips into a hopper

containing regular virgin granules causes preferential feeding of one component

in the hopper due to different flow-characteristic. The alternative to regranulation

lies in remixing or reextruding the rechipped material, so that it may then be cut

into regular granules like the virgin compounds.

The recycling of thermoplastic scrap from extrusion, injection

moulding, blow moulding, calendering, thermoforming and moulding operations has

always been a regular part of industrial practice and is one of the main reasons from

economical point of view for plastics with respect to other materials. In-plant

recycling is easy, the nature of the material is known an any defective products can

be internally recycled in the works provided that mixing of different wastes does not

occur.

Indirect Recycling of Plastic

Indirect recycling was defined earlier as the use of plastics

wastes for the manufacture of products having a less demanding specification than

that of the original product. In the case of plastics wastes the importance of

Govt. Poly. Washim. 8

Recycling of Plastics

downgrading the reuse may be the possibility of avoiding the requirements of

homogeneity and cleanliness which are fundamental to direct recycling.

In general, a process of indirect recycling would normally

commence with shredding and mixing of the thermoplastic wastes and

incorporation at this stage of compounding ingredients. This product would

then be compacted into granules and fed to a processing machine for the production

of the final product. The general sequence can be represented by flow diagram as

shown in fig. 3.

Govt. Poly. Washim. 9

Recycling of Plastics

Waste

Material

Granulator or

Shredders

Compounding

Ingredients Mixture

Extruder

Regular

Granules

Processing

Machine

Product

Flow Diagram of Indirect Recycling

Govt. Poly. Washim. 10

Recycling of Plastics

Thermal Recycling of Plastics

In thermal recycling, heat is generated and used (of course, once

only), so that the consumption of fossil fuels can be reduced.

The following three methods are used in thermal recycling of

plastics:

Incineration

The first method of thermal recycling of plastics waste is

incineration. Incineration is the term used for the combustion and

reduction to an inert residue of any combustible waste. Incineration can be used

as a means of plastic waste disposal and incinerators may be used to produce

steam for domestic heating and the generation of electricity.

In the incinerator the combustion takes place at high temperature

(around 7000 C) in the presence of the requisite amount of oxygen. Since the plastics

present in waste consist mainly of carbon and hydrogen, the product obtained after

combustion should consist mainly of carbon dioxide and water.

Incineration is not usually favored as a method of disposal because

of very high capital, maintenance and operating costs, unreliability and

adverse environmental impact. Problems are added when incineration is combined

with generation of steam and the output to be controlled to suit customer demand.

Govt. Poly. Washim. 11

Recycling of Plastics

PVC has received considerable criticism since HCI gas is evolved on

combustion for long term use, the incineration may be a favored and economical

method to dispose of all the plastics exclusive of PVC from the incinerator to

safeguard it from the problems associated with evolution of HCI, the other plastics

could be readily utilized as a high energy fuel, because they have considerably

high caloric value.

Pyrolysis

The second method of thermal recycling to plastics waste is heated

to a higher temperature in an inert atmosphere, possibly under pressure. This

process is sometimes called destructive destination where the decomposition

products formed may be used for producing fuels, energy and primary chemicals.

Plastics are considered as assets in pyrolysis. Pyrolysis is not yet entirely

satisfactory, because there is not yet, sufficient information about the reactions

which take place during pyrolysis. It has, therefore, not yet been possible to control

the processes accurately.

Hydrolysis

The third method of thermal recycling of plastics waste is

hydrolysis. The breaking down of plastics into their constituent raw materials

Govt. Poly. Washim. 12

Recycling of Plastics

by hydrolysis, is, of course, possible if the plastic contains that groups which can

be hydrolysed. Since hydrolysis is the reverse of condensation, it is clear that

plastics which can be hydrolysed are all those made by condensation. Whether

hydrolysis is practical or not, is solely a question for the reaction conditions.

The polycondensation products which also include plastics

produced by polyaddition, encompass such as polyamides, polyesters,

polycarbonates, polyureas and polyurethanes. Hydrolysis involves the specific

reaction of the water molecule at the point of linkage with the starting materials (this

is the reverse of the reaction that produced the polymer originally), so that the

starting materials used originally are recovered directly. The groups of plastics

mentioned above as being hydrolysable are all resistant to hydrolysis under normal

conditions use. Hydrolysis must be induced under extreme conditions.

Govt. Poly. Washim. 13

Recycling of Plastics

PROCESSES OF RECOVERY OF PLASTICS

Recovery describes the process of collecting and/or segregating

homogeneous wastes for reuse, mainly in-plant or within the organization.

Depending on the types of plastics waste, the processes available for the

recovery are the following two :

Recovery of Plastics from Relatively Pure Waste

Relatively uncontaminated plastics waste is available from the

polymer producer as well as from the plastic processor. The waste is homogeneous

in nature unless it is allowed to mix with other types of plastics. Recovery at this

stage is rather simple. It is a traditional technique to recover the wastes produced

during polymer production or plastics processing and blend them with virgin

material. If these waste are allowed to become mixed and/or contaminated, they may

be of little value and find their way into industrial wastes. Where such wastes are

available in bulk quantities, it may be more economical to sort and grade them and

sell to reclaimers.

Recovery of Plastics from Mixed Plastics Wastes

Govt. Poly. Washim. 14

Recycling of Plastics

Mixed plastics waste, thermoplastics packaging waste mainly consist

of the five most important thermoplastics -LDPE, HDPE, PP, PS and PVC. A scheme

of separation for the five components has been shown based on the sink-float

method. This scheme relies on the use of fluids differing in composition and density.

A diagram of the scheme is shown in Fig. 4. the process requires chopping

/shredding or grinding of mixed plastics waste in a shredder or a grinder and also

washing throughly with running water to eliminate dust and external contamination.

Govt. Poly. Washim. 15

Recycling of Plastics

A Sink Float Method For Isolating the Thermoplastics in Four Liquids

Differing In Density d(g/ml)

CONCLUSION

Govt. Poly. Washim. 16

Recycling of Plastics

Recycling of plastics is possible when the recycled plastic is equal in

quality and not higher in cost than the virgin raw material. These two constraints

which effectively limit recycling at present, due to the cost of reclaiming or

salvaging followed by the further cost of sorting, grading and cleansing.

Thus, the waste occurred as a result of primary production is to

be recycled because recovery cost will be small and it is less likely to be

contaminated, while at the end of the user chain, the reverse will be true. At every

stage of production, distribution and consumption, there is a decline in quality of the

waste, for the purpose of recycling and a rise in the cost of reclaiming.

REFERENCES

1) Engineering Chemistry

Govt. Poly. Washim. 17

Recycling of Plastics

R. Gopalan

D. Venkappayya

S. Nagarajan

2) Organic Chemistry

Govt. Poly. Washim. 18

You might also like

- 2 Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Research Paper 4 8 August 2014Document8 pages2 Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Research Paper 4 8 August 2014DIPAK VINAYAK SHIRBHATENo ratings yet

- Aahan's BirthdayDocument22 pagesAahan's BirthdayDIPAK VINAYAK SHIRBHATENo ratings yet

- Educational Multimedia On Hydraulics and PneumaticsDocument89 pagesEducational Multimedia On Hydraulics and PneumaticsDIPAK VINAYAK SHIRBHATENo ratings yet

- New File ListDocument2 pagesNew File ListDIPAK VINAYAK SHIRBHATENo ratings yet

- Quality Circles For Vikramshila StudentsDocument22 pagesQuality Circles For Vikramshila StudentsDIPAK VINAYAK SHIRBHATENo ratings yet

- Quality Circle A Case Study: Prof. D.V. Shirbhate Principal, Vikramshila Polytechnic DarapurDocument34 pagesQuality Circle A Case Study: Prof. D.V. Shirbhate Principal, Vikramshila Polytechnic DarapurDIPAK VINAYAK SHIRBHATENo ratings yet

- Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Set PPRDocument6 pagesDipak Vinayak Shirbhate VSRDIJMCAPE 3631 Set PPRDIPAK VINAYAK SHIRBHATENo ratings yet

- Domestic Water Heater PDFDocument39 pagesDomestic Water Heater PDFDIPAK VINAYAK SHIRBHATENo ratings yet

- Prospectus Data 2013-14Document12 pagesProspectus Data 2013-14DIPAK VINAYAK SHIRBHATENo ratings yet

- Dipak Vinayak Shirbhate VSRDIJCSIT 3479 Research Communication June 2014Document4 pagesDipak Vinayak Shirbhate VSRDIJCSIT 3479 Research Communication June 2014DIPAK VINAYAK SHIRBHATENo ratings yet

- Girls Hostel FormDocument1 pageGirls Hostel FormDIPAK VINAYAK SHIRBHATENo ratings yet

- Kirti Polytechnic Prospectus Part ADocument5 pagesKirti Polytechnic Prospectus Part ADIPAK VINAYAK SHIRBHATENo ratings yet

- Kaizan Presentation 11092012Document12 pagesKaizan Presentation 11092012DIPAK VINAYAK SHIRBHATENo ratings yet

- Salary Slip - May 2014Document5 pagesSalary Slip - May 2014DIPAK VINAYAK SHIRBHATENo ratings yet

- Boys Hostel FormDocument1 pageBoys Hostel FormDIPAK VINAYAK SHIRBHATE100% (1)

- Prospectus For 14-15Document44 pagesProspectus For 14-15DIPAK VINAYAK SHIRBHATENo ratings yet

- Domestic Water Heater PDFDocument39 pagesDomestic Water Heater PDFDIPAK VINAYAK SHIRBHATENo ratings yet

- Ad Draft Approved by MsbteDocument1 pageAd Draft Approved by MsbteDIPAK VINAYAK SHIRBHATENo ratings yet

- Equivalence of Discipline Praposed Draft For Tech InstitutesDocument14 pagesEquivalence of Discipline Praposed Draft For Tech InstitutesDIPAK VINAYAK SHIRBHATENo ratings yet

- Performance ApprisalDocument12 pagesPerformance ApprisalDIPAK VINAYAK SHIRBHATENo ratings yet

- Prospectus For 13-14Document42 pagesProspectus For 13-14DIPAK VINAYAK SHIRBHATENo ratings yet

- Pramod Naik's Letter Director MsbteDocument1 pagePramod Naik's Letter Director MsbteDIPAK VINAYAK SHIRBHATENo ratings yet

- Vikramshila Polytechnic DarapurDocument1 pageVikramshila Polytechnic DarapurDIPAK VINAYAK SHIRBHATENo ratings yet

- Vikramshila Poly Prospectus MarathiDocument29 pagesVikramshila Poly Prospectus MarathiDIPAK VINAYAK SHIRBHATENo ratings yet

- Pragati Ahawal, 2010 11Document9 pagesPragati Ahawal, 2010 11DIPAK VINAYAK SHIRBHATENo ratings yet

- Creativity & The Business IdeaDocument12 pagesCreativity & The Business IdeaDIPAK VINAYAK SHIRBHATENo ratings yet

- Inplant TrainingDocument1 pageInplant TrainingDIPAK VINAYAK SHIRBHATENo ratings yet

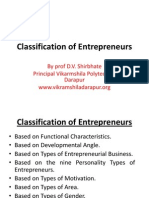

- Classification of EnterprenuersDocument12 pagesClassification of EnterprenuersDIPAK VINAYAK SHIRBHATE100% (2)

- Importance of Diploma Education For Rural StudentsnnDocument55 pagesImportance of Diploma Education For Rural Studentsnnvspd2010No ratings yet

- Mobile Number of StudentsDocument4 pagesMobile Number of Studentsvspd2010No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1 Adding Template For Faster NucleationDocument8 pages1 Adding Template For Faster Nucleationyyzalan8No ratings yet

- IQP Final Report 2Document81 pagesIQP Final Report 2Mohamed NasrNo ratings yet

- Cambridge IGCSE: 0500/11 FirstlanguageenglishDocument9 pagesCambridge IGCSE: 0500/11 FirstlanguageenglishKaashvi DewanNo ratings yet

- Me006 PDFDocument5 pagesMe006 PDFabdullahNo ratings yet

- Tugas Makalah DR Iman (Translated)Document8 pagesTugas Makalah DR Iman (Translated)RizerFNo ratings yet

- DLL - English 6 - Q3 - W1Document5 pagesDLL - English 6 - Q3 - W1Sheryl Alas SantosNo ratings yet

- 1 Plastics Give A Helpful HandDocument10 pages1 Plastics Give A Helpful HandNIranjanaNo ratings yet

- Clean Baras (Final Pa Sa Final)Document9 pagesClean Baras (Final Pa Sa Final)xylynn myka cabanatanNo ratings yet

- The Next 50 Years - The Price of Garbage: 1 CommentDocument14 pagesThe Next 50 Years - The Price of Garbage: 1 CommentApplebottomreaderNo ratings yet

- Golf Ball Cleanup 1Document2 pagesGolf Ball Cleanup 1Haris ZaheerNo ratings yet

- Project ProposalDocument6 pagesProject ProposalaileenmaesomidoNo ratings yet

- Eng DebateDocument12 pagesEng Debatechloemonique76No ratings yet

- Communication Plan: Nifty Sustainability ProjectDocument18 pagesCommunication Plan: Nifty Sustainability ProjectSovetskaiah ImperialNo ratings yet

- Amfori Effective Sustainability Communication Guide 2019 0 1Document53 pagesAmfori Effective Sustainability Communication Guide 2019 0 1Yessica HerradaNo ratings yet

- Sample/Pre-Board Paper 20 Class X Term 1 Exam Nov - Dec 2021 English Language and Literature (Code 184)Document5 pagesSample/Pre-Board Paper 20 Class X Term 1 Exam Nov - Dec 2021 English Language and Literature (Code 184)Tamil FutureNo ratings yet

- Threat of Plastic Pollution To Seabirds Is Global, Pervasive, and IncreasingDocument6 pagesThreat of Plastic Pollution To Seabirds Is Global, Pervasive, and IncreasingNatalia Reyes EscobarNo ratings yet

- Microplasticsreview Coleetal 2011Document11 pagesMicroplasticsreview Coleetal 2011Natnael GosaNo ratings yet

- Cause and Effect EssayDocument4 pagesCause and Effect EssayaNo ratings yet

- A Plastic OceanDocument2 pagesA Plastic OceanSilvia LunguNo ratings yet

- EAT GlobeScan Grains of Truth Report September 2021Document30 pagesEAT GlobeScan Grains of Truth Report September 2021ComunicarSe-ArchivoNo ratings yet

- Isolation and Screening of Polyethylene Degrading Bacterial StrainDocument11 pagesIsolation and Screening of Polyethylene Degrading Bacterial Straindeepa gujjarNo ratings yet

- Tactical TargetingDocument14 pagesTactical TargetingMarcos, Jayven B.No ratings yet

- (Đề thi có 4 trang) Thời gian làm bài: 50 phút (không kể thời gian phát đề)Document5 pages(Đề thi có 4 trang) Thời gian làm bài: 50 phút (không kể thời gian phát đề)khanhhoi.clcNo ratings yet

- Research ManusriptDocument42 pagesResearch ManusriptJeffer BontesNo ratings yet

- Coursework Writing EssayDocument3 pagesCoursework Writing EssayAhmed NasrNo ratings yet

- Sri Lanka Youth Statement To COP28Document9 pagesSri Lanka Youth Statement To COP28Bodh MaathuraNo ratings yet

- Polymers: Production of Fuel From Plastic Waste: A Feasible BusinessDocument9 pagesPolymers: Production of Fuel From Plastic Waste: A Feasible BusinessBipin KumarNo ratings yet

- 6min PlasticDocument5 pages6min PlasticBila TranNo ratings yet

- Pi ECO Vietnam Project Abstract & Summary 7 March 2019Document11 pagesPi ECO Vietnam Project Abstract & Summary 7 March 2019ICT Bảo HànhNo ratings yet

- The Institution Environment - The Marine Ecosystem 1Document13 pagesThe Institution Environment - The Marine Ecosystem 1api-527107294No ratings yet