Professional Documents

Culture Documents

2003 10 Fill The Tank With Water

Uploaded by

Harshad SolankiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2003 10 Fill The Tank With Water

Uploaded by

Harshad SolankiCopyright:

Available Formats

CCP S

CENTER FOR CHEMICAL PROCESS SAFETY

Process Safety Beacon

http: //www.aiche.org/ccps/safetybeacon.htm

An AIChE Industry Technology Alliance

Messages for Manufacturing Personnel

Sponsored by CCPS

Supporters

October 2003

Dont pop your top

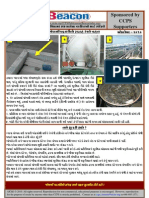

Heres What Happened: A very simple jobfill the tank with water. This is a common occurrence at a manufacturing plant and has minimal hazards. In this case, site personnel were being extra cautious. They started the water flow and confirmed that air was coming out of the vent on top of the tank. Everything seemed to be fineBUT the source of the water BUT, was the plant fire water system---and the flow was VERY high! The vent did not have enough capacity to relieve all of the displaced air, pressure built up in the tank, and BOOMthe top BOOM blew off when the roof seam failed. Transferring Liquids: What You Can Do to be Safe ! Watch out for Temporary operationsthis tank vent was probably sized for normal processing conditions, not for fire water addition. If uncertain---CHECK! TestingSafeOutCleaning: there are many times that a vessel must be filled with water. Each time it is, make sure that the fill rate is slow enough for the vent system to handle the displaced vapor. And just to be sure, monitor the pressure in the vent space to make sure it is less than the vessel's pressure rating. When unsure, add water at normal processing rates.

This topBelongs here!

How Did This Happen? Tank vents are usually sized to handle normal processing activities, such as pumping in to or out of the tank during product transfers. Venting and vacuum break capacities are determined using formulas, or engineering calculations. These calculations are often called the vent system design basis. Problems occur when the inflow or outflow of liquid is greater than the capacity of the vent system. For inflow, it leads to an increase of pressure inside the tank because the vapor cant get out fast enough. It doesnt take much pressure (in some cases just a few inches of water) to cause a lot of damage. Tanks usually have large surface areas, so when pounds per square inch is multiplied by a large number of square inches, the force can be huge! In this case, the roof seam was the weak point and failed first.

PSID Members look in Free SearchTank Overpressure

Liquid transfer can lead to major vessel damage. Transfer rate must not exceed vent capacity.

AIChE 2003. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 212-591-7319

This edition is also available in German. Contact CCPS at ccps_beacon@aiche.org for information.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Beacon EnglishDocument1 pageBeacon EnglishHarshad SolankiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 2008 09 Plant SecurityDocument1 page2008 09 Plant SecurityHarshad SolankiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 2009 05 Mechanical IntegrityDocument1 page2009 05 Mechanical IntegrityHarshad SolankiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 2007 05 Great Boston Molasses FloodDocument1 page2007 05 Great Boston Molasses FloodHarshad Solanki100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDocument1 page2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 2008 02 How Can You Use The BeaconDocument1 page2008 02 How Can You Use The BeaconHarshad SolankiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDocument1 page2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 2007 09 Hot Work PermitsDocument1 page2007 09 Hot Work PermitsHarshad SolankiNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2007 07 Hose Repaired With Duct TapeDocument1 page2007 07 Hose Repaired With Duct TapeHarshad SolankiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 2007 04 MR Potato Head Is DownDocument1 page2007 04 MR Potato Head Is DownHarshad SolankiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 2007 01 2006 Beacon ReviewDocument1 page2007 01 2006 Beacon ReviewHarshad SolankiNo ratings yet

- 2006 10 Store CylindersDocument1 page2006 10 Store CylindersHarshad SolankiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TDS For Rubber Lining 1056HTDocument2 pagesTDS For Rubber Lining 1056HTYao WangNo ratings yet

- Report TextDocument2 pagesReport Textsusila10No ratings yet

- Mechanical Properties OF Dental MaterialsDocument40 pagesMechanical Properties OF Dental MaterialsRamnarayan MeenaNo ratings yet

- 2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarDocument8 pages2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarCatherineNo ratings yet

- Convergence IndicatorDocument21 pagesConvergence Indicatorsikandar100% (1)

- Soil Science: Classification of PedologyDocument24 pagesSoil Science: Classification of Pedologyekush amar100% (1)

- Arta211 MidtermsDocument2 pagesArta211 MidtermsWallen LagradaNo ratings yet

- Role of Physics in Daily LifeDocument2 pagesRole of Physics in Daily LifeSadam MaharNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ReiewDocument19 pagesReiewcullen bohannonNo ratings yet

- CycloalkanesDocument60 pagesCycloalkanesmeri hardina zd100% (1)

- Stats 100A Hw1Document2 pagesStats 100A Hw1Billy BobNo ratings yet

- Various Types of Surfaces: Made By:-Nilesh Bhojani Guided By: - Prof. B.K. PatelDocument15 pagesVarious Types of Surfaces: Made By:-Nilesh Bhojani Guided By: - Prof. B.K. Patelnilesh bhojaniNo ratings yet

- Physics of SoundDocument33 pagesPhysics of SoundijahsmkutNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Document15 pagesTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueNo ratings yet

- Shear Strength of LateriteDocument10 pagesShear Strength of LateriteAndy UgohNo ratings yet

- MICROECONOMICS ch07ANNEXDocument6 pagesMICROECONOMICS ch07ANNEXSabrina GoNo ratings yet

- BroombastickDocument3 pagesBroombastickAllen SornitNo ratings yet

- Revista Domus 771Document10 pagesRevista Domus 771Claudia TecuceanuNo ratings yet

- Prediction and Visualization of Supersonic Nozzle Ows Using OpenfoamDocument22 pagesPrediction and Visualization of Supersonic Nozzle Ows Using OpenfoamSai Manohar RamachandranNo ratings yet

- For Online Practice Exam Visit Us atDocument12 pagesFor Online Practice Exam Visit Us atscribd scribdNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2nd Year Math Guess PaperDocument6 pages2nd Year Math Guess PaperArmaan MalikNo ratings yet

- Physical Sciences PDFDocument51 pagesPhysical Sciences PDFfarooqi111No ratings yet

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- T316Document5 pagesT316ANKIT SHARMA100% (1)

- Viado, Emmanuel Russell PDocument27 pagesViado, Emmanuel Russell PRussell ViadoNo ratings yet

- Quility Geo ScicenceDocument28 pagesQuility Geo ScicenceAsfandiyar SareerNo ratings yet

- Principles of Refrigeration: Standard Template Options and Samples - Mar 2016 - EMR:jmk 1Document17 pagesPrinciples of Refrigeration: Standard Template Options and Samples - Mar 2016 - EMR:jmk 1JhurremNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/42Document20 pagesCambridge IGCSE: MATHEMATICS 0580/42spotifysubs250No ratings yet

- WT Chapter 6 2Document21 pagesWT Chapter 6 2kanchanabalajiNo ratings yet

- Distance DisplacementDocument4 pagesDistance DisplacementRuchi Briam James LagitnayNo ratings yet