Professional Documents

Culture Documents

2007 11 Cold Embrittlement and Thermal Stress

Uploaded by

Harshad SolankiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2007 11 Cold Embrittlement and Thermal Stress

Uploaded by

Harshad SolankiCopyright:

Available Formats

http://www.aiche.org/CCPS/Publications/Beacon/index.

aspx

Messages for Manufacturing Personnel

Sponsored by CCPS Supporters

November 2007

Cold Embrittlement and Thermal Stress

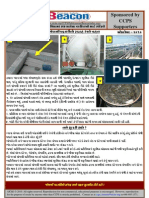

A pump which supplied hot oil to a heat exchanger in a gas processing plant stopped for several hours. With no flow of hot oil to the exchanger, the temperature in the heat exchanger, normally 100 degrees C (212 degrees F) or higher, dropped to 48 degrees below zero C (54 degrees below zero F). Ice was observed on the outside of the heat exchanger. The hot oil pump was re-started, and hot oil flow resumed to the heat exchanger. The low temperature had caused the steel heat exchanger to

become brittle, and the 150 C temperature differential from the sudden flow of hot oil caused additional stress. This resulted in a brittle fracture of the heat exchanger. A vapor cloud estimated to contain more than 10 tons of flammable gas was released, and subsequently ignited by a heater. The explosion and fires killed 2 workers, injured 8 others, and the fire burned for 2 days. The gas supply to a large part of Australia was disrupted for nearly 3 weeks, impacting the lives of an estimated 4 million people. Total economic loss was estimated at over 1 billion Australian dollars.

Do you know?

Some steels and other metals can become brittle when exposed to very low temperatures. Cold embrittlement can result in failure of process equipment such as vessels, heat exchangers, or piping. This failure can be rapid and catastrophic, resulting in release of a large amount material. Introduction of hot material into a cold pipe, vessel, or other process equipment causes stress because of the temperature gradient, and this stress may be sufficient to cause equipment damage, or even failure of the equipment.

PSID Members see "Free Search--Embrittlement"

What You Can Do

Know the design temperature range of the equipment in your plant both the high and the low temperature limits for safe operation. Know if you have any equipment in your plant which might be subject to cold embrittlement. Understand and follow all procedures which are required to ensure that equipment is not exposed to excessively high or low temperatures, or to excessive temperature gradients which might stress and damage the equipment. Learn more about this incident by searching the Internet for 1998 Esso Longford gas explosion.

Know the temperature capability of your plant both high and low!

AIChE 2007. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 212-591-7319 The Beacon is usually available in Chinese, Danish, Dutch, English, French, German, Gujarati, Hebrew, Hindi, Hungarian, English, Italian, Japanese, Korean, Malay, Persian, Portuguese, Russian, Spanish, Swedish, and Thai.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Beacon EnglishDocument1 pageBeacon EnglishselvajanarNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- 2009 03 Fatality Caused by Unloading The Wrong ChemicalDocument1 page2009 03 Fatality Caused by Unloading The Wrong ChemicalHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon HindiDocument1 pageBeacon HindiHarshad SolankiNo ratings yet

- Spill Containment BeaconDocument1 pageSpill Containment BeaconselvajanarNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishHarshad SolankiNo ratings yet

- 2009 01 Fire While Filling Portable ContainerDocument1 page2009 01 Fire While Filling Portable ContainerHarshad SolankiNo ratings yet

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDocument1 page2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiNo ratings yet

- 2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008Document1 page2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008liveconnectionz282No ratings yet

- 2009 05 Mechanical IntegrityDocument1 page2009 05 Mechanical IntegrityHarshad SolankiNo ratings yet

- 2009 04 Be PreparedDocument1 page2009 04 Be PreparedHarshad SolankiNo ratings yet

- 2008 10 Ice Ruptures Causes FireDocument1 page2008 10 Ice Ruptures Causes FireHarshad SolankiNo ratings yet

- 2008 11 Laboratory Refrigerator ExplosionsDocument1 page2008 11 Laboratory Refrigerator ExplosionsHarshad SolankiNo ratings yet

- Dust Explosion 2008 05 BeaconDocument1 pageDust Explosion 2008 05 BeaconHaresh PatelNo ratings yet

- 2008 07 What Is Process SafetyDocument1 page2008 07 What Is Process SafetyHarshad SolankiNo ratings yet

- 2008 08 Beacon Measuring Process Safety PerformanceDocument1 page2008 08 Beacon Measuring Process Safety PerformanceHarshad SolankiNo ratings yet

- Oil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersDocument1 pageOil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersNarasimmaraj NagarajanNo ratings yet

- 2008 03 Do Your Shutoff Systems Actually WorkDocument1 page2008 03 Do Your Shutoff Systems Actually WorkHarshad SolankiNo ratings yet

- 2008 06 Halon Cylinder Becomes RocketDocument1 page2008 06 Halon Cylinder Becomes RocketHarshad SolankiNo ratings yet

- 2008 09 Plant SecurityDocument1 page2008 09 Plant SecurityHarshad SolankiNo ratings yet

- 2008 02 How Can You Use The BeaconDocument1 page2008 02 How Can You Use The BeaconHarshad SolankiNo ratings yet

- 2007 10 We Have LiftoffDocument1 page2007 10 We Have LiftoffHarshad SolankiNo ratings yet

- 2007 09 Hot Work PermitsDocument1 page2007 09 Hot Work PermitsHarshad SolankiNo ratings yet

- 2007 08 Hazards of Temporary Confined SpacesDocument1 page2007 08 Hazards of Temporary Confined SpacesHarshad SolankiNo ratings yet

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDocument1 page2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MODBUS Interface: Communication PrinciplesDocument14 pagesMODBUS Interface: Communication PrinciplesMilson RodriguesNo ratings yet

- Cse111 PortfolioDocument8 pagesCse111 PortfolioPraneeth RayaluNo ratings yet

- KEYBOARD FUNCTIONS EXPLAINEDDocument2 pagesKEYBOARD FUNCTIONS EXPLAINEDRechell AnnNo ratings yet

- Gone in 30 SecondsDocument2 pagesGone in 30 Secondsqisz azizNo ratings yet

- Bourbaki - Elements of The History of Mathematics PDFDocument299 pagesBourbaki - Elements of The History of Mathematics PDFPol Asz Kid100% (6)

- Research Paper in Software Engineering PDFDocument7 pagesResearch Paper in Software Engineering PDFfxigfjrhf100% (1)

- Module 2: Signals in Frequency Domain Lecture 19: Periodic Convolution and Auto-CorrelationDocument4 pagesModule 2: Signals in Frequency Domain Lecture 19: Periodic Convolution and Auto-CorrelationAnonymous zzMfpoBxNo ratings yet

- PCMG's Oracle Engineering Systems Price ListDocument7 pagesPCMG's Oracle Engineering Systems Price ListssaeedsNo ratings yet

- Annas First DayDocument7 pagesAnnas First DaydoloresgenesisNo ratings yet

- Enable Liquidity PlanningDocument13 pagesEnable Liquidity PlanningUrandi MendesNo ratings yet

- Test 1 2ms4 22Document2 pagesTest 1 2ms4 22imane hopeNo ratings yet

- Result Gazette IX-2016Document94 pagesResult Gazette IX-2016WsxQazNo ratings yet

- Biography Writing PowerpointDocument7 pagesBiography Writing PowerpointSoniaNo ratings yet

- Advance Study in RCC-STEEL Building Design Using ETABS, STAAD, CSI SAFE and Manual ChecksDocument5 pagesAdvance Study in RCC-STEEL Building Design Using ETABS, STAAD, CSI SAFE and Manual ChecksmudasirqaqcNo ratings yet

- The Oral Approach and SituatioanalDocument5 pagesThe Oral Approach and SituatioanalKaka NurNo ratings yet

- Chapter-2 Analytic FunctionsDocument213 pagesChapter-2 Analytic FunctionsKriti TambareNo ratings yet

- Kami Export - Caylen Johnson - Geo - and - Culture - QuestionsDocument2 pagesKami Export - Caylen Johnson - Geo - and - Culture - QuestionsXxC JayxXNo ratings yet

- RIZALDocument47 pagesRIZALAngeloo AngelooNo ratings yet

- Mechanical (Production)Document13 pagesMechanical (Production)Lovejinder KaurNo ratings yet

- Final Module 2 TTL1Document8 pagesFinal Module 2 TTL1Arboleda, Mark Kenneth F.No ratings yet

- Circulating and Compiling The Litterae ADocument37 pagesCirculating and Compiling The Litterae AMartin M. MoralesNo ratings yet

- Introduction to BGC-8088 Microprocessor TrainerDocument42 pagesIntroduction to BGC-8088 Microprocessor TrainerJerico Renzo Taligatos VicedoNo ratings yet

- Vocabulary Words Kate L. MacabalosDocument18 pagesVocabulary Words Kate L. MacabalosTrisha Faye SagadalNo ratings yet

- Solution LARP Lab 01Document4 pagesSolution LARP Lab 01Abdul MateenNo ratings yet

- PERL BasicsDocument53 pagesPERL BasicsLalith KrishnanNo ratings yet

- Zachs Animals PDFDocument4 pagesZachs Animals PDFFares HaifNo ratings yet

- Unit 2 HumourDocument51 pagesUnit 2 Humourعبد الرحيم فاطمي100% (1)

- Pre-Quiz - Attempt ReviewDocument4 pagesPre-Quiz - Attempt ReviewVinesh DaraNo ratings yet

- Analysis of Critical Thinking and Problem SolvingDocument10 pagesAnalysis of Critical Thinking and Problem Solvingapi-353794467No ratings yet

- Final SY BSC PracticalsDocument40 pagesFinal SY BSC PracticalsPankaj AgreNo ratings yet