Professional Documents

Culture Documents

Agile Product Data MGMT Process Ds 070039

Uploaded by

sau6181Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agile Product Data MGMT Process Ds 070039

Uploaded by

sau6181Copyright:

Available Formats

ORACLE DATA SHEET

AGILE PRODUCT DATA MANAGEMENT FOR PROCESS

KEY FEATURES Agile Product Data Management for Process is a Web-based application with a zero-client footprint that is accessible anytime, anywhere over a security-based Web browser. It provides prebuilt integrations with all bundles and modules within Oracles Agile product lifecycle management for process solution. Features of the four modules are listed below. Global Specification Management Module

Industry-specific and

Today, consumer goods companies often maintain islands of product information spread across different departments and business units, with no enterprisewide visibility, harmonization, or crossreferencing of specification information and product data. This inefficient method leads to high product costs, inconsistent quality, lost revenue opportunities, and reduced customer satisfaction. Oracles Agile Product Data Management for Process enables consumer goods enterprises to enhance global information visibility and traceability, reduce product costs, and accelerate product introductions with its Global Specification Management, Supply Chain Relationship Management, Content Syndication and Synchronization, and Reporting modules.

Global Specification Management The Global Specification Management module of Agile Product Data Management for Process enables you to create an enterprisewide single version of the truth of your entire product record, including finished products, manufacturing processes, bills of materials (BOMs), ingredients, and packaging materials. It provides you with collaborative business processes to create, review, and approve all specifications included in the product recordin all languages, cultures, units of measure, and currenciesthroughout the enterprise and across the supply chain. The entire product genealogy is connected, allowing you to ensure data traceability and attain an integrated view of the interrelationships among all specifications. Extend the Data Model as Needed The industry-specific data model embedded in Global Specification Management enables you to store data across the entire product genealogy, including finished products such as trade units and consumer units, manufacturing processes and intermediates, packaging materials, ingredients, and ingredient formulations. Not only can you nest all specifications to provide for infinite extensibility of the product genealogy, but you can also supplement the core attributes configured in Agile Product Data Management for Process with extended or user-defined attributes. Specify Workflows for Review and Approval Maintaining an enterprisewide data repository requires the ability to review and approve products at the global and local levels. Global Specification Management lets you define workflows based on attributes such as business unit, geography, and product taxonomy. The workflow engine allows for flexible transitions, permissions, and conditions that form the backbone for change control management.

extensible data model

Product data available in all

languages, cultures, units of measure, and currencies

Integrated workflow engine for

routing specifications

Integrated security model Configurable user interface

Supply Chain Relationship Management Module

Company/facility profiles Workflow-enabled sourcing

approvals

Supplier documentation and

contact management Content Synchronization and Syndication Module

Data synchronization to

internal systems and trading partners

On-demand and scheduled

syndication

Two-way messaging Flexible syndication methods GDSN-compliant solution

Reporting Module

Rich reporting capabilities on

specifications and suppliers

Flexible reporting layouts Integration with Excel

ORACLE DATA SHEET

Manage Formulations and Bills of Materials Global Specification Management lets you manage BOMs and processing instructions by dividing manufacturing processes into steps and intermediates. You can maintain specific parameters, such as floor summary, processing instructions, step-level BOM, component-level yield within each step, batch-level yield, water gain/loss factor, total solids, and density. Generate Factory Floor Documentation Global Specification Management can produce factory floor documentation, including step-by-step instructions, process maps, and factory floor worksheets. You can also syndicate the data to enterprise resource planning systems (ERP) and manufacturing execution systems. Manage Packaging and Labeling Data Global Specification Management integrates packaging and labeling data with product data, allowing you to trace the label contentsincluding ingredient statement, nutrition facts panel, and label claimsback to the supporting product data. This results in the streamlining and acceleration of the cross-functional packaging and labeling development and approval process. Maintain and Roll Up Compliance Data Global Specification Management provides the ability to maintain compliance data at each level of the specification genealogy. Compliance data includes compliance standards (such as kosher, vegan, and nongenetically modified), allergens, intolerances, additives, and analytical properties (such as chemical, physical, microbiological, and sensory). With Global Specification Management, you can roll up the compliance data from raw materials through the manufacturing processes to the finished products. Maintain and Roll Up Nutrient Data Global Specification Management enables you to maintain nutrient data at the ingredient level by leveraging the food composition library feature, which includes nutrient data loaded from the standard reference databases that you select. When implemented with the Design Workbench module of Oracles Agile Formulation and Compliance for Process, Global Specification Management also allows you to roll up nutrient data from raw materials through manufacturing processes to the finished products, taking into account the specific parameters tied to the componentlevel yield, batch-level yield, water gain/loss factor, and nutrient degradation. Manage Nutrition and Ingredient Labeling When implemented with the Design Workbench module, Global Specification Management allows you to create a nutrient profile that contains the finished products nutrition values. You can use the required rounding rules, such as the Nutrition Labeling and Education Act (NLEA) for the U.S., in order to generate the appropriate rounded values. You can then print the nutrition data based on nutrition panel formats, such as the ones included in the NLEA. In addition, Global Specification Management allows you to engineer the most-desirable ingredient statement for the finished products, based on a flexible user-defined set of options

ORACLE DATA SHEET

and rules, such as renaming, grouping, aliasing, and reconstituting. It also tracks all changes through an auditing feature. Determine Applicable Label Claims With Global Specification Management, you can determine which nutrient claims are applicable to the finished products based on nutrient data and specific product characteristics. Integrate with Internal Systems In conjunction with the Content Synchronization and Syndication module, Global Specification Management enables you to syndicate data from Global Specification Management to any internal systems, such as ERP, master data management, and procurement. It uses publication paths to describe the attributes, workflow, and messaging to be embedded into the syndication. This deep process integration makes product information available to downstream systems in real time, shortening the time to market for new products. Syndicate Data to Trading Partners In conjunction with the Content Synchronization and Syndication module, Global Specification Management allows you to syndicate specification data to any external data pools, such as 1SYNC and EANnet, using publication paths to describe the attributes, workflow, and messaging to be embedded into the syndication. Supply Chain Relationship Management The Supply Chain Relationship Management module of Agile Product Data Management for Process provides you with a collaborative business process for managing supply chain relationships with suppliers, distributors, and other supply chain participants. It enables you to create a single version of the truth of the entire supply network by building sourcing approvals across all supply chain entities, supporting as many supply chain tiers as needed. With Supply Chain Relationship Management, you can connect and integrate the entire supply network, with the interrelationships among all supply chain participants readily available to the usersall the way down to the individual specification level. Supply Chain Relationship Management allows you to create and maintain all supply chain entities and sourcing approvals as well as syndicate supplier data to other enterprise systems. Manage the Approved Supplier List Supply Chain Relationship Management lets you manage your approved supplier list (ASL). You can specify companies and facilities as far upstream in the supply network as needed and define sourcing approvals down to the specification level. This level of granularity in establishing the ASL across the entire supply network is a prerequisite for establishing traceability and accountability. With Supply Chain Relationship Management, you can store required documents at the company, facility, or specification-related sourcing approval level, thus monitoring product quality, food safety, and supplier conformance in multiple supply chain tiers.

ORACLE DATA SHEET

Improve Sourcing Strategies Supply Chain Relationship Management integrates all supply chain entities and sourcing approvals, giving you an in-depth understanding of the entire supply network down to the level of individual specifications. With this data, you will be able to enhance your local, regional, and global sourcing strategies at the category and supplier level, thereby simplifying supply chains and reducing product costs. Rationalize and Consolidate suppliers Supply Chain Relationship Management enables you to leverage the single version of the truth to understand how many suppliers are involved through the supply network for all raw material categories. You can then use this information to rationalize and consolidate suppliers, improve supply chain performance, and minimize overall costs. Improve Supplier Collaboration When implemented with the Supplier Portal module of Oracles Agile Product Supplier Collaboration for Process, Supply Chain Relationship Management allows you to share with your suppliers the specifications and documents stored in Global Specification Management, and the contact information stored in Supply Chain Relationship Management. Supply Chain Relationship Management provides suppliers with the visibility to review and verify the data stored within their customers systems, greatly enhancing the alignment and collaboration between value chain partners. Additionally, through the Supplier Portal module, suppliers can directly maintain their own contact data within Supply Chain Relationship Management, increasing data accuracy and timeliness while reducing the workload for those managing the many players within a supply chain. Content Synchronization and Syndication The Content Synchronization and Syndication module of Agile Product Data Management for Process provides a proven framework for secure, reliable content synchronization, supporting a variety of industry-standard XML-based syndication formats and distribution methods. It allows for the syndication of data from Oracles Agile product lifecycle management for process applications to distributed enterprise systems, trading partners, and industry exchangesimproving data integrity across the enterprise and with value chain partners, and facilitating global visibility and data harmonization. Content Synchronization and Syndication automates the task of distributing the product data that drives your business processeseither on demand or on a scheduled basis. The publication process and results are fully visible from within the related specifications, allowing for closed-loop monitoring. Automate Data Syndication With Content Synchronization and Syndication, the syndication of data to downstream systems is fully automated based on configurable publication paths. It uses flexible syndication methods that leverage XML Web services-based interoperability, Simple Object Access Protocol, legacy batch, electronic data

ORACLE DATA SHEET

interchange, Secure File Transfer Protocol, ebXML Messaging Service, and Applicability Statement 2-compliant messaging engines. Content Synchronization and Syndication supports on-demand and scheduled syndication based on predefined business rules. It also provides workflow-enabled tracking and management of publication requests. Syndicate Data Externally with Global Data Synchronization NetworkCompliant Synchronization Together with the Global Specification Management module, Content Synchronization and Syndication forms the backbone of a Global Data Synchronization Network (GDSN)-compliant solution. Content Synchronization and Syndication is used on a daily basis to syndicate data into the GDSN in North America, Europe, Australia, and New Zealand. Syndicate Data to Internal Systems You can configure Content Synchronization and Syndication to support syndication to internal systems, such as ERP. Linking preconfigured publication requests to selected workflow states can automatically syndicate specifications. Content Synchronization and Syndication enables messages and responses from the target systems to be presented within the specifications, allowing you to know the status of the syndication at all times. Reporting The Reporting module of Agile Product Data Management for Process enables you to extract product and supplier data from the Global Specification Management and Supply Chain Relationship Management modules. You can generate your own reports based on user-defined layouts and reporting criteria. The Reporting module is Web based, with output formats that include XML, Microsoft Excel, and comma-separated values. In contrast to traditional enterprise reporting solutions, it operates against the object model rather than the database itself, fulfilling the majority of business users needs while respecting the security model established within Oracles Agile product lifecycle management for process applications. It is common for a company to integrate the Reporting module, which meets traditional business users reporting needs, with the companys enterprise reporting solution for global data warehousing and business intelligence needs. Generate User-Defined Layouts Reporting allows you to define any number of reporting layouts. You can select from a number of reporting criteria to display the required specification and supplier data stored in the Global Specification Management and Supply Chain Relationship Management modules. Generate Reports Reporting lets you generate reports asynchronously once you have defined the reporting layout and query. After the report is logged into a queue, you will receive an email as soon as the report is ready to be viewed. The email will contain a URL that will guide you directly back to the report queue, from which you can open the

ORACLE DATA SHEET

RELATED PRODUCTS

report. The Reporting module will open up directly in Excel, where you can further

Agile product lifecycle management for process is a fully integrated, comprehensive suite of software and services for collaborative product lifecycle management in the consumer goods industry. Agile product lifecycle management for process solutions provide visibility across product portfolios, projects, activities, and suppliers, allowing you to achieve optimal results from your innovation efforts.

review and analyze reports. Preserve Security Tied to Underlying Modules Reporting provides full integration with the security system of Agile product lifecycle management for process. The data presented to you in the reports fully respects your security profile within Global Specification Management and Supply Chain Relationship Management. The reports only include data that the user can access and view online. Contact Us For more information about how your organization can leverage the power of Oracles Agile Product Data Management for Process, please visit oracle.com or call +1.800.ORACLE1 to speak to an Oracle representative.

AGILE PRODUCT LIFECYCLE MANAGEMENT FOR PROCESS BUNDLES

Agile Product Data

Management for Process

Agile Formulation and

Compliance for Process

Agile Product Supplier

Collaboration for Process

Agile New Product

Development and Introduction for Process

Copyright 2007, Oracle Corporation and/or its affiliates. All rights reserved. This document is provided for information purposes only, and the contents hereof are subject to change without notice. This document is not warranted to be error-free, nor is it subject to any other warranties or conditions, whether expressed orally or implied in law, including implied warranties and conditions of merchantability or fitness for a particular purpose. We specifically disclaim any liability with respect to this document, and no contractual obligations are formed either directly or indirectly by this document. This document may not be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without our prior written permission. Oracle is a registered trademark of Oracle Corporation and/or its affiliates. Other names may be trademarks of their respective owners.

You might also like

- PIM - Data HubDocument3 pagesPIM - Data Hubmdfaraz55No ratings yet

- Microsoft Dynamics 365 For Finance & OperationsDocument9 pagesMicrosoft Dynamics 365 For Finance & OperationsABT SuppNo ratings yet

- Food & Beverage IndustryDocument8 pagesFood & Beverage IndustryMadhur AnandNo ratings yet

- Websphere Product Center: OverviewDocument51 pagesWebsphere Product Center: OverviewNithya MarimuthuNo ratings yet

- PDS Syncade RADocument6 pagesPDS Syncade RAKeith userNo ratings yet

- MetaphaseDocument4 pagesMetaphasesmartfox99No ratings yet

- PDF Enovia Matrixone 02Document2 pagesPDF Enovia Matrixone 02khiladi2No ratings yet

- Brochure Invensys FoodBeverage 02-12Document8 pagesBrochure Invensys FoodBeverage 02-12Sriharsha ReddyNo ratings yet

- Oracle ModulesDocument3 pagesOracle ModulesdanangwwNo ratings yet

- MI0029 - Enterprise Resource PlanningDocument23 pagesMI0029 - Enterprise Resource PlanninghemangiraneNo ratings yet

- Doors AssignmentDocument29 pagesDoors AssignmentSama TaleeNo ratings yet

- Erp AssignmentDocument7 pagesErp AssignmentNikita JadhavNo ratings yet

- EdiTRACK Lighthouse Software Product Description V1Document16 pagesEdiTRACK Lighthouse Software Product Description V1nalaka.sampathNo ratings yet

- Oracle Process Manufacturing - Statement of DirectionDocument13 pagesOracle Process Manufacturing - Statement of DirectionMaulik DixitNo ratings yet

- MetTeam Management SoftwareDocument8 pagesMetTeam Management SoftwareMorosanu Andreea-DianaNo ratings yet

- BakeryDocument12 pagesBakeryBabatunde YusufNo ratings yet

- Supplier Hub & Supplier Lifecycle ManagementDocument9 pagesSupplier Hub & Supplier Lifecycle ManagementRanganath Havaldar100% (1)

- SIA Lab Act #2 - Delos Santos, Mary Roan C.Document5 pagesSIA Lab Act #2 - Delos Santos, Mary Roan C.Anne DSNo ratings yet

- Hyperion Data Relationship Management DatasheetDocument5 pagesHyperion Data Relationship Management DatasheetTony KiratsousNo ratings yet

- FSD Lims Sap Part4Document2 pagesFSD Lims Sap Part4HTENo ratings yet

- Oracle - Data Sheet - Demantra Demand Management (057040)Document4 pagesOracle - Data Sheet - Demantra Demand Management (057040)Victor MillanNo ratings yet

- Product Lifecycle ManagementDocument15 pagesProduct Lifecycle Managementshashanksir100% (2)

- Supply Chain Order MGMT Analytics DatasheetDocument5 pagesSupply Chain Order MGMT Analytics Datasheetsumanth_0678No ratings yet

- Architecting High Performing, Scalable and Available Enterprise Web ApplicationsFrom EverandArchitecting High Performing, Scalable and Available Enterprise Web ApplicationsRating: 4.5 out of 5 stars4.5/5 (2)

- Six Ways To Optimize Your Quality Management System and Ensure Fda and Iso ComplianceDocument6 pagesSix Ways To Optimize Your Quality Management System and Ensure Fda and Iso ComplianceDavid GeorgeNo ratings yet

- Unit 4Document7 pagesUnit 4Aniket PathakNo ratings yet

- Retail Industry Trend: Improved StateDocument10 pagesRetail Industry Trend: Improved StatemildratNo ratings yet

- SAP Manufacturing ExecutionDocument14 pagesSAP Manufacturing Executionrizqi_83100% (2)

- Brochure AVEVA YieldAccounting 02-19Document5 pagesBrochure AVEVA YieldAccounting 02-19Karin RodriguezNo ratings yet

- ENOVIA V6 Product PortfolioDocument24 pagesENOVIA V6 Product Portfoliosrvsd3sNo ratings yet

- Oracle Supply Chain Analytics: Key BenefitsDocument4 pagesOracle Supply Chain Analytics: Key BenefitsDumbrava Caius FlorinNo ratings yet

- Info Sphere Information Analyzer - Methodology and Best PracticesDocument127 pagesInfo Sphere Information Analyzer - Methodology and Best PracticesRoshava KratunaNo ratings yet

- Oracle Database Lifecycle Management PackDocument4 pagesOracle Database Lifecycle Management PackmdalaminNo ratings yet

- Oracle Daily Business IntelligenceDocument5 pagesOracle Daily Business Intelligenceziaulhaq31No ratings yet

- Oracle Supply Chain Management Cloud: Spotlight OnDocument9 pagesOracle Supply Chain Management Cloud: Spotlight OnMag MarinaNo ratings yet

- FactoryTalk® Batch Software SuiteDocument8 pagesFactoryTalk® Batch Software SuiteVÕ QUỐC HIỆUNo ratings yet

- Synopsis of Inventory Management SystemDocument29 pagesSynopsis of Inventory Management SystemSANDIP DHARNo ratings yet

- Oracle Manufacturing Operations Center: Key FeaturesDocument4 pagesOracle Manufacturing Operations Center: Key FeaturesmpdallesNo ratings yet

- FactoryTalk Pharma SuiteDocument2 pagesFactoryTalk Pharma Suiterabt1No ratings yet

- Ds Apps MGMT Suite PSFT 166219Document4 pagesDs Apps MGMT Suite PSFT 166219Jhonoswaldo_delgadoriveraNo ratings yet

- Agile PLMDocument0 pagesAgile PLMSriram KalidossNo ratings yet

- Oracle Business Intelligence Enterprise Edition 11G: Product Facts & FeaturesDocument3 pagesOracle Business Intelligence Enterprise Edition 11G: Product Facts & FeaturesNatasha LoboNo ratings yet

- Oracle Enterprise Manager 10 System Monitoring Plug-In For Microsoft Biztalk ServerDocument4 pagesOracle Enterprise Manager 10 System Monitoring Plug-In For Microsoft Biztalk Servervenu_dbaNo ratings yet

- Voyager Manufacturing PlanningDocument2 pagesVoyager Manufacturing PlanningGaby SalgueiroNo ratings yet

- Ds Apps MGMT Suite Ebs 166218Document6 pagesDs Apps MGMT Suite Ebs 166218Al DeNo ratings yet

- A Case Study in Integrated Quality Assurance For PDocument11 pagesA Case Study in Integrated Quality Assurance For PMuhammad FadhilNo ratings yet

- Oracle Information Integration, Migration, and ConsolidationFrom EverandOracle Information Integration, Migration, and ConsolidationNo ratings yet

- Chapter 03 - ER SystemsDocument23 pagesChapter 03 - ER Systemssammarmughal77No ratings yet

- DWH DraftDocument2 pagesDWH DraftLrv RamanaNo ratings yet

- Data Sheet 11i10 Inventory Optimization DsDocument7 pagesData Sheet 11i10 Inventory Optimization DsRamkumar_PuthukodeNo ratings yet

- Binary Decision Diagrams and Extensions for System Reliability AnalysisFrom EverandBinary Decision Diagrams and Extensions for System Reliability AnalysisNo ratings yet

- Prophet Professional 8.2 2013Document4 pagesProphet Professional 8.2 2013vamshidsNo ratings yet

- Finacle WatchWizDocument4 pagesFinacle WatchWizrajsalgyanNo ratings yet

- MasterControl Change Control™Document2 pagesMasterControl Change Control™mastercontroldotcomNo ratings yet

- Proces wp001 - en P PDFDocument16 pagesProces wp001 - en P PDFReinaldo GomezNo ratings yet

- Manufacturing Intelligence Provides The Right Mix For Dairy ProcessorDocument3 pagesManufacturing Intelligence Provides The Right Mix For Dairy ProcessorsayedmhNo ratings yet

- Msv58 - Material Cost and Analysis SystemDocument20 pagesMsv58 - Material Cost and Analysis SystemUniq ManjuNo ratings yet

- SNP - Network PlanningDocument17 pagesSNP - Network PlanningDebasis NandaNo ratings yet

- Factorytalk® Batch: Effi Cient, Consistent and Predictable Batch Control For More Comprehensive OperationsDocument4 pagesFactorytalk® Batch: Effi Cient, Consistent and Predictable Batch Control For More Comprehensive OperationsNelsonNo ratings yet

- Harmonized Quality Management Drives Business BenefitsDocument6 pagesHarmonized Quality Management Drives Business BenefitsAndraNo ratings yet

- Linkedin ProfileDocument2 pagesLinkedin ProfilePrinceKirankumar KirruNo ratings yet

- Computer Basic TrainingDocument71 pagesComputer Basic TrainingSalman FarsiNo ratings yet

- Real-Time Data Exchange (RTDE) GuideDocument16 pagesReal-Time Data Exchange (RTDE) Guide徐海东No ratings yet

- Unit IDocument25 pagesUnit IRamarao BNo ratings yet

- Analysis On Business Buying Behavior of Laptop (HCL)Document103 pagesAnalysis On Business Buying Behavior of Laptop (HCL)lokesh_045No ratings yet

- III Year April, 2019Document3 pagesIII Year April, 2019J chandramohanNo ratings yet

- User's Manual For DM320100Document34 pagesUser's Manual For DM320100Yatish KhareNo ratings yet

- Pardot SpecialistDocument7 pagesPardot SpecialistrajNo ratings yet

- Enterprise Resource and Planning - ERPDocument20 pagesEnterprise Resource and Planning - ERPyogendra reddyNo ratings yet

- Minitab GuideDocument21 pagesMinitab GuideBlazieNo ratings yet

- Inspiron 5590: Setup and SpecificationsDocument21 pagesInspiron 5590: Setup and SpecificationsAsuna KiRigayaNo ratings yet

- Mobile Ip & Wap NotesDocument17 pagesMobile Ip & Wap NotesMelissa HobbsNo ratings yet

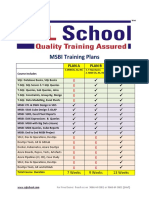

- MSBI Training Plans: Plan A Plan B Plan CDocument14 pagesMSBI Training Plans: Plan A Plan B Plan CVeerendra ReddyNo ratings yet

- cdf3 FaqDocument7 pagescdf3 FaqMaps 3No ratings yet

- Cable HDMI 10 MetrosDocument3 pagesCable HDMI 10 Metroschristian eduardoNo ratings yet

- Cyber AttakDocument2 pagesCyber AttakAnkit KumaarNo ratings yet

- Network CablesDocument16 pagesNetwork CablesQueen It isNo ratings yet

- Computer-Fundamentals Solved MCQs (Set-28)Document8 pagesComputer-Fundamentals Solved MCQs (Set-28)krishna chaithanyaNo ratings yet

- Robotic ArmDocument11 pagesRobotic ArmDanial DarNo ratings yet

- SJ-20131203170829-006-ZXSDR UniRAN FDD-LTE Base Station (V3.20.30) Radio Parameters Reference - 558739Document341 pagesSJ-20131203170829-006-ZXSDR UniRAN FDD-LTE Base Station (V3.20.30) Radio Parameters Reference - 558739moslem100% (1)

- QIROX® Software: Management For ProfessionalsDocument16 pagesQIROX® Software: Management For ProfessionalsNaufal JuveNo ratings yet

- Cyber Safety - FinalDocument16 pagesCyber Safety - Finalkushagra khatriNo ratings yet

- Date Field FunctionsDocument21 pagesDate Field FunctionsChavala SatishNo ratings yet

- Market Basket Analysis Using Improved FP-treeDocument4 pagesMarket Basket Analysis Using Improved FP-treeIIR indiaNo ratings yet

- Semester 2 Final Exam - Oracle AcademyDocument23 pagesSemester 2 Final Exam - Oracle AcademyAri Yanto100% (1)

- Advertising: Google On Ad-Tech London, 2010Document10 pagesAdvertising: Google On Ad-Tech London, 2010ankush birlaNo ratings yet

- Preethi.K: Senior Software EngineerDocument5 pagesPreethi.K: Senior Software Engineersubash pradhanNo ratings yet

- CEA Full ChapterDocument58 pagesCEA Full ChapterNguyen Trong Phuc (FUG CT)No ratings yet

- Exemple de Dissertation Sur Le CapitalismeDocument8 pagesExemple de Dissertation Sur Le CapitalismeCollegePaperHelpFargo100% (1)

- SSIS Best PracticesDocument14 pagesSSIS Best PracticesmailtopvvkNo ratings yet