Professional Documents

Culture Documents

Artificial Heart Valves in Encyclopedia of Bio Medical 1510

Uploaded by

mdicksonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artificial Heart Valves in Encyclopedia of Bio Medical 1510

Uploaded by

mdicksonCopyright:

Available Formats

ARTIFICIAL HEART VALVES

DAN T. SIMIONESCU

Clemson University Clemson, South Carolina

1. INTRODUCTION The cardiovascular system is a closed circulatory system that ensures blood ow through the human body. Blood circulates through two systems; the rst is responsible for pushing blood from the heart to the lungs to capture oxygen, and the second is responsible for distributing oxygenated blood to body organs. This system is composed of a double pump with branched tubes that leads blood from the heart to the organs (arteries) and returns it to the heart (veins). The heart is essentially a muscular pump with four rooms, two for receiving incoming blood (atria) and two for pushing blood toward the organs (ventricles). In order to maintain unidirectional ow of blood, 3-D open-close gateways (valves) are optimally located between atria and ventricles, and between the ventricles and the emerging arteries. The workload of heart valves is nothing short of extraordinary. The valves open and close once per second totaling more than 3 billion times in a lifetime. These movements take place under constant pressure and in owing blood, a very viscous uid rich in minerals, proteins, lipids, and cells. Valves may progressively become defective and critically inuence the performance of the heart. These defects are collectively named valve diseases. As the properties of normal and diseased valves are not sufciently understood, no drugs are available to treat and cure valve diseases. The only curative solution is to perform open-heart surgery to replace diseased valves with articially engineered devices. These valve substitutes are nonliving materials fashioned in the form of valves that reestablish initial mechanical functions and restore the functionality of the heart. However, these devices may eventually fail because of imperfections in design, composition, or bio-

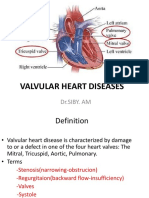

compatibility. Once a device shows signs of failure, the patient requires a second open-heart surgery for replacement of the defective device. Reoperations are generally risky and pose additional problems for children who naturally outgrow their implants. Thus, the long-term goal of biomedical engineering is to nd better methods for treating valvular diseases and thus impact lives of millions of patients worldwide. This daunting effort brings together a multidisciplinary team of specialists in medicine, biology, engineering, and mechanics. This chapter describes the structure, function, biology, and pathology of heart valves; information on current replacement devices; and the necessary prerequisites for constructing an ideal replacement valve. Ongoing research is aimed at improving existing devices by enhancing biocompatibility, as well as pioneering work on novel tissue-engineering approaches, which would facilitate complete regeneration of valve tissues. 2. NATURAL HEART VALVES ARE SPECIALIZED CARDIOVASCULAR TISSUES The mechanical action of the human heart is similar to that of the two-cylinder engine. Four natural heart valves maintain the direction of blood ow within the circulatory system (Fig. 1). The tricuspid and mitral valves (collectively called the atrioventricular valves) open to allow blood to ll the ventricular cavities. These two admission (inow) valves are connected to the subjacent heart muscle via brous extensions (chordae tendinae). When the inow valves are closed, blood is forced to ow through the aortic and pulmonary valves (collectively called the semilunar valves). These two ejection (outow) valves open in response to blood ow and immediately close after ejection. Although not initially apparent, a structural and functional correlation between the heart muscle and the valves exists (Fig. 1). A 3-D network of extra cellular matrix (mainly collagen bers), formally known as the cardiac skeleton, maintains the spatial structure and function of the heart muscle. This cardiac skeleton includes large structures (macro-skeleton), such as the

P Tri

Ao

Mi Macroskeleton Fibrous ring Matrix

Figure 1. Functional anatomy of the heart valves. Longitudinal section diagram depicting venous blood (dark blue arrows) collecting in the right ventricle via the tricuspid valve (Tri) and sent through the pulmonary valve (P) to the lungs. Oxygenated blood (red arrows) returns to the left ventricle via the mitral valve (Mi) and is directed to the organs via the aortic valve (Ao). Insert at left shows a cross section through the heart at the level of the four heart valves.

P Ao Tri

Tri P Ao

Tricuspid Pulmonary Aortic Mitral

Mi

Mi

Microskeleton

1

Wiley Encyclopedia of Biomedical Engineering, Copyright & 2006 John Wiley & Sons, Inc.

ARTIFICIAL HEART VALVES

heart valves, the chordae tendinae, and the septum, and a brous micro-skeleton of connective tissue, which comprises the entire collagenous network that encloses heart muscle bers. Besides providing structural support for the cells, the cardiac skeleton allows a mechanical coupling function [i.e., the concomitant contraction of all muscle bers during ventricular contraction (systole)] (1). The heart valves are structurally composed of thin sheets of tissue (cusps or leaflets), which represent anatomical extensions of the cardiac endocardium (Fig. 2). These cusps are strengthened with a hydrophobic, collagenous, load-bearing tissue layer (brosa) that maintains continuity with the brous ring into which it is inserted (2). Elastic bers that provide resilience and recoil are predominantly present in the inow layers of the heart (e.g., the ventricularis of the semilunar valves) (3). Between these two layers is a loose connective tissue comprised predominantly of hydrophilic, shock-absorbing glycosaminoglycans (spongiosa) (4). This gel-like matrix acts as a space-ller and a lubricant to permit continuous bending, rearranging, straightening, and rotating of structural bers with minimal friction (5). In addition to these explicit biochemical and 3D constructs, specic cells exhibiting metabolic and contractile

Atrial endocardium Auricularis Spongiosa Ann Fibr Ventricularis Chordae Ventricular endocardium Aortic media Aortic intima Aorta Arterialis Fibrosa Ann Fibr Ventricularis Ventricular endocardium

Figure 2. General structure of the heart valves. Representative schematic depicting a simplied cross section through an atrioventricular valve (top) and a semilunar valve (bottom); direction of blood ow is shown by thick arrow. Note the central supporting structure (brosa) inserted in the brous ring (Ann. Fibr.) and the presence of shock-absorbing layers (spongiosa), which are structural extensions of the cardiac endocardium.

properties are also found in each heart valve, which include matrix-producing cells known as broblasts, active valvular interstitial cells known as myobroblasts, and endothelium and resident macrophages (Fig. 3). Valvular cells exhibit high metabolic activities related to matrix homeostasis (synthesis and degradation of collagen and proteoglycans) as well as reactivity toward vasoactive compounds such as epinephrine and angiotensins. Therefore, this multivariate cell design clearly indicates that specic cellular activities characterize the form and function of each valve, which permits continuous adaptation to subtle hemodynamic modications (6). In conclusion, heart valves are unique, specialized components of the cardiac connective tissue network that rely on delicately balanced homeostatic activities for their mechanical and biological functions.

3. HEART VALVE DISEASES ARE CURED BY SURGICAL REPLACEMENT Valvular pathology is an important aspect of cardiovascular diseases. Mechanically speaking, valve dysfunction can be expressed as either imperfect closure (insufciency) or incomplete opening (stenosis). In the majority of pathological cases, valvular tissue appears either excessively deformed (oppy) or very thick and rigid, characterized by leaflet calcication (Fig. 4). The importance of the structural/functional connection of the heart muscle and the valves is clearly demonstrated by known pathologic situations. For example, in aortic stenosis, the heart muscle attempts to compensate for deciencies in blood ow by growing in mass (hypertrophy). Consequently, regression of myocardial mass after valve replacement is one of the major clinical indicators of effective treatment of valvular pathology (7). Valvular diseases associate with cell activation and alterations in metabolism of collagen and proteoglycans. These structural changes induce functional modications that eventually lead to malfunction. The causes of valvular diseases are typically associated with congenital defects, atherosclerosis, infections, or postrheumatic episodes (6). However, the mechanisms of onset and progression of valvular diseases are largely unknown, specifically because of the lack of adequate experimental models. Heart valve diseases progress rapidly and may become fatal. As the majority of heart valve disease is irreversible, its progression cannot be prevented by pharmacological treatments. Moreover, damaged heart valves lack the ability to spontaneously regenerate (8). The only treatment option presently available is open-heart surgery, in which the diseased valve is removed and replaced with an articial device. Although effective, this procedure is quite traumatic for the patient. For a fortunate few, however, small areas of the valve can be reconstructed or repaired using biomaterials, obviating the need for major surgery to install new articial heart valves. Pathological heart valves exhibit significantly altered mechanical and biological properties that eventually require surgical replacement with articial devices. For an excellent update on

Atrium Fibrosa

Ventricle

Spongiosa Ventricle

ARTIFICIAL HEART VALVES

Atrium Legend Myocytes Ventricle Smooth muscle cells Endothelium Valvular int. cells Aorta Fibroblasts Macrophages Ventricle

Figure 3. Cell types and distribution in heart valves. Representative schematic depicting a simplied cross section through an atrioventricular valve (top) and a semilunar valve (bottom); direction of blood ow is shown by arrow. Myocytes and smooth muscle cells populate the base of the valve indicating a transition area from a muscular structure to a specialized brous connective tissue. Fibroblasts and interstitial cells mainly populate the load-bearing valve structures; valves are fully covered by a continuous layer of endothelial cells.

(a)

(b)

Figure 4. Pathology of human mitral valves (viewed from the atrial side). Photo depicting (a) an apparently normal valve, with some signs of leaflet thickening (o); (b) stenotic valve with signs of thickening (o); and extensive calcium deposits (m) in both (c) and (d) with signs of chordae thickening.

(c)

(d)

heart valve pathology, please refer to the work of F. J. Schoen (6).

4. ARTIFICIAL HEART VALVES ARE EXCELLENT MECHANOMIMETIC DEVICES Heart valve replacement, pioneered in the early 1970s, is now a routine surgical procedure that employs devices made of nonliving, nonresorbable biomaterials for substi-

tution of the valvular mechanical functions (9). Replacement of heart valves offers an excellent improvement in the quality of life for thousands of patients and can be considered one of the major accomplishments of biomedical engineering. It is estimated that more than 275,000 replacement heart valves are implanted annually worldwide; thus the social and economic impact of heart valves research and development is considerable (10).

ARTIFICIAL HEART VALVES

Engineered devices, or mechanical valves, are used to replace diseased human heart valves in approximately 50% of the cases. Valves made of processed biological tissues are used in an additional 45% of cases. Pulmonary autograft valves (whereby the patients own pulmonary valve is transplanted into the aortic position) and human cryopreserved allograft valves represent the remainder of implanted valves. Autografts and allografts exhibit excellent durability after implantation, but are not readily available for all patients (11). Mechanical heart valves are constructed from rigid supporting materials and mobile components whose designs range from that of a caged ball device to designs encompassing free-moving tilting discs or aps with restricted movement (Fig. 5). The components ensuring proper opening and closing of valvular orices are made of inert, biocompatible materials such as pyrolitic carbon, polyester (Dacron)-covered polymers, or metals (12). Blood pressure differences within the chambers of the heart enable these mechanical valves to properly function. For example, for a caged ball valve inserted in the aortic

position, contraction of the left ventricle will create sufcient blood pressure to thrust the ball toward the opposite end of the cage, thus allowing blood to ow around the ball. Immediately after systole (ventricular contraction), the ventricular pressure decreases and the ball is pushed toward the circular valve base, closing the orice completely. However, imperfect blood ow through some of these devices can create nonphysiological patterns that may induce the formation of blood clots. Furthermore, the surfaces exposed directly to blood ow are not entirely antithrombogenic. For these reasons, in order to avoid complications caused by thrombus formation, patients with mechanical heart valves are required to take anticoagulation medications for the rest of their lives (13). As such, because patients may have possible episodic internal bleeding, mechanical valves are of limited use for pregnant women or women considering pregnancy and patients with coagulation diseases. Biological heart valves (bioprostheses) are made of porcine aortic valves or bovine pericardial sheets that are mounted on adequate supports (stents) to mimic the

(c) (a) (b)

(d)

(e)

(f)

Figure 5. Articial heart valves. Photo showing mechanical valves including devices that employ a caged ball (a) or two hinged leaflets (b) for functioning. Tissue valves are either made from bovine pericardium (c), porcine heart valves mounted on stents (d), or left unmounted (e and f). Valves in (a), (c)(e) are shown in closed position, and valve (b) in a partially open position. Images (a), (c), and (f) were provided courtesy of Edwards Lifesciences, Inc. Models depicted are: Starr-Edwardss Ball Valves (a), Carpentier-Edwardss PERIMOUNT Magnas Pericardial Bioprosthesis (c), and Edwards Prima Pluss Stentless Bioprosthesis (f). Copyright Edwards Lifesciences, Inc. 2005. All rights reserved. Images (b), (d), and (e) were provided courtesy of St. Jude Medical, Inc. Models depicted are: St Jude Medicals Regent Valve (b), Biocor Aortic (d), and Toronto SPV (e). Copyright St. Jude Medical, Inc. 2005. All rights reserved.

ARTIFICIAL HEART VALVES

valvular architecture, or they are left unmounted (stentless) (Fig. 5) (14). To understand how these devices are created, a typical procedure for creating a pericardiumderived heart valve is shown in Fig. 6. Bovine pericardium (the external brous sac that encloses the heart) is collected at the slaughterhouse, chemically stabilized, cut into three leaflets, and mounted on a three-legged (stented) ring using surgical sutures. The nal product is adapted with a circular ring at the base that allows the surgeon to secure the device to the human brous ring. Similar to natural valves, the function of bioprostheses is pressure-driven. When the blood pressure below the valve is greater than the pressure above, the leaflets are forced toward the outside, thus reversing curvature and causing the valve to open. When the blood pressure above the valve is greater than the pressure below, the valve closes by pushing the leaflets toward the center. As the total surface of the leaflets exceeds that of the orice, the leaflets overlap in the center (coaptation) and allow for complete closure of the orice, without backow (regurgitation). Cross-species implantation of animal tissues is clearly prone to severe immune rejection and rapid tissue degeneration. For this reason, bovine or porcine tissues are treated with glutaraldehyde, a water-soluble cross-linker, which almost completely reduces tissue antigenicity (15). In addition, glutaraldehyde devitalizes tissues and kills all resident cells, prevents degradation by host enzymes,

and sterilizes the tissue for implantation. Interestingly, the use of glutaraldehyde was inspired from its use in microscopy (as a xative) and as a hospital sterilant (in the form of Cidex, a commonly used bactericidal liquid sterilization medium for heat-sensitive materials) (16). Tissuederived heart valves are less thrombogenic than their mechanical counterparts and do not require long-term anticoagulation. For an excellent overview of different models and properties of heart valves, please refer to the work of J. Butany et al. (14). Overall, mechanical and tissue-derived heart valves perform exceptionally well as devices intended to open and close valvular orices, and thus could be considered as admirable mechano-mimetic replacements.

5. ARTIFICIAL HEART VALVES HAVE A LIMITED BIOLOGICAL DURABILITY Articial heart valves function quite effectively for many years after implantation, but their long-term durability is quite limited. Clinical follow-ups indicate that more than 50% of patients with articial valve implants develop complications within 10 years (6). This disturbing trend suggests that the majority of implanted valves would have to be explanted after 20 years. From the perspective of the valvular patients, a second open-heart surgery to retrieve and replace the defective device is prone to high clinical risks, and therefore undesirable. The lack of long-term

(a)

(b)

(c)

(d)

Figure 6. Articial heart valve from bovine pericardium. Diagram showing the steps involved in creating a heart valve device. Bovine pericardium is collected (a) then crosslinked in glutaraldehyde (b), fashioned into three leaflets (c), mounted on a stent (d), and tted with a sewing ring. While opening, blood ow (arrow) pushes leaflets toward the outside (e) and creates an almost circular orice (insert). Upon closure, leaflets are pushed toward the center of the valve (f) and complete closure is ensured by central coaptation of leaflets (insert).

(e)

(f)

ARTIFICIAL HEART VALVES

valve durability is especially important in the case of pediatric patients, where supplemental surgical procedures are required to accommodate the natural growth of the patients. The choice between bioprosthetic and mechanical valves depends on specic patient characteristics. Mechanical valves are more durable but require life-long anticoagulant therapy, whereas bioprostheses tend to deteriorate more rapidly because of degenerative processes but do not require anticoagulation therapy. In general, tissue valves are implanted in elderly patients (6065 years or older), which have a lower tendency to calcify tissue implants and a mean life expectancy of 10 to 15 years (17). Conversely, more mechanical valves are implanted in younger patients and children. Analysis of explanted valves revealed that the principal causes of device failure are thrombosis, degeneration, and lack of full integration into host tissue, perivalvular leaks, host tissue overgrowth, and susceptibility to infections. Complications related to thrombogenicity are the major problems of mechanical valves, whereas tissue-derived valves are mainly affected by the degeneration and calcication of the tissue components (18). For example, explanted pericardial valves reveal tissue abrasion and erosion, tearing and perforations, deformations and loss of bending stiffness, along with deposition of calcium minerals (Fig. 7). Tissue degeneration in articial heart valves occurs as a result of the interplay between host-related factors and implant-related factors. As a response to the implant, the host selects one or more defense mechanisms that correspond to the degree of activation induced by the implant. Implantation of tissue heart valves induces a chronic foreign-body response, a low degree of immune reaction, activation of the coagulation cascade, and inammatory response. These reactions are translated into deposition of brin immunoglobulins and complement inltration of activated macrophages and lymphocytes and growth of host brous tissue over nonmoving parts of the implant (18). The main pathways of bioprosthetic heart valve failure are structural damage and calcication of the tissue component. Analysis of explanted (failed) bioprosthetic heart valves typically reveals the coexistence of structural damage and calcication. Structural damage may be pure (noncalcic), stress-induced disruption of ber architecture (19), or mediated by enzymatic degradation (20). Me5

Figure 7. Pathology of tissue heart valves. Diagram showing typical aspects observed in explanted devices, including (1) tissue ruptures, (2) abrasions, (3) thickening of the tissue, (4) calcication, and (5) host tissue overgrowth.

chanical deformation was shown to accelerate calcication and, conversely, calcic deposits significantly alter mechanical properties (21). These processes may be synergistic, but convincing evidence also exists that each may occur independently. Many improvements in design and geometry of the leaflets have reduced, but not fully eliminated, the incidence of mechanical damage. For an excellent overview of heart valve design issues, please refer to the work of I. Vesely (22). Calcium deposition in tissue-derived articial heart valves is one of the major causes of their clinical failure. For this reason, noteworthy efforts have been made to elucidate the mechanisms of valve calcication and to implement treatments that would prevent this unwarranted side effect (23). Calcication typically appears as granular, brillar, or lamellar deposits, which greatly reduce tissue mechanical properties and can effectively contribute to erosion, abrasions, tearing, and perforations. The major factors involved in calcication are young age, hypercholesterolemia, and exural stress, implant composition, and chemical pretreatments of the biological tissues. Calcication may occur through passive mechanisms (direct deposition of calcium and phosphate) but host cells, via remodeling mechanisms involving proteasemediated degeneration of matrix components and deposition of bone proteins, can mediate it (24). Mechanisms underlying calcication of tissue-derived articial heart valves in patients are still not fully understood, although tissue composition and the use of glutaraldehyde appear to be two essential factors. In most cases analyzed thus far, the mineral phase is composed of bone-like hydroxyapatite associated with collagen, elastin, and chemically devitalized cells. Ongoing research focuses on prevention of calcication in tissue-derived articial heart valves by attempts to remove or extract cells, by structural modication of collagen and elastin, and by stabilization or addition of natural calcication inhibitors (25,26). Glutaraldehyde induces adequate preservation of collagenous structures, but also triggers severe cell alterations, which result in the formation of cell debris that resemble matrix vesicles formed by bone cells. For this reason, treatments are under study to extract all cellular components before implantation (23). Residual loosely bound or unreacted aldehyde groups may also be involved in tissue calcication. Neutralization of free aldehyde groups with compounds that possess reactive amines such as glutamine, glycine, homocysteic acid, and lysine has been shown to reduce calcication in animal models. In addition to simple aldehyde neutralization, amino-oleic acid, a treatment recently implemented in clinical use, may also hinder calcication by mechanisms related to reduction of calcium diffusion through tissues (27). Additionally, amino-biphosphonates (28) may also act as crystal growth inhibitors to hinder calcication. A different approach involving the use of stabilization chemistries, which do not employ glutaraldehyde, is also under investigation. These chemistries include carbodiimides, dyemediated photo xation, and epoxy-based crosslinkers (29). Tissues cross-linked with nonglutaraldehyde agents do not calcify in experimental models to the same extent as glutaraldehyde-xed tissues, thus directly linking the

ARTIFICIAL HEART VALVES

presence of glutaraldehyde as one direct cause of tissue calcication. Extensive research on alternative cross-linking methods is currently being pursued, but none have yet reached clinical use. These results indicate that mechanical and biological factors contribute significantly to failure of articial heart valves. Although they perform well mechanically, articial heart valves do not possess sufcient biological assets to fulll the requirements of true biomimetic devices. Their lack of biologic properties may account for their limited durability after implantation. As articial heart valves lack live cells, they are decient in their ability to maintain and adapt the valvular matrix composition or to maintain an adequate calcium homeostasis. In the absence of live cells, degenerative processes induced by mechanical fatigue, proteolytic enzymes, and calcium deposition slowly erode the structural components and lead to progressive valve deterioration. In addition, the lack of an intact layer of endothelial cells may allow free inux of blood components and could also contribute to device-related thrombogenicity. Finally, the majority of current articial heart valves, except newer stentless valves, do not maintain their cardiac skeleton-valve continuity and thus may progressively impair heart function. In conclusion, pathological articial valves exhibit altered mechanical properties, similar to human pathological valves. However, exciting research is currently ongoing to improve these devices and increase their biological durability. It is expected that efforts targeted toward understanding the pathology of articial heart valves will facilitate greater insights into human valvular pathology. 6. THE IDEAL ARTIFICIAL HEART VALVE One of the greatest biomedical engineering challenges today is to develop an implantable device that resists the natural conditions to which heart valves are subjected, without eliciting host reactions that would impair their function. This research eld is very exciting and poses abundant questions whose answers will positively impact the lives millions of patients. Specifically, these natural conditions affecting the lifespan of an articial heart valve include their durability to 40 million beats per year for about 80 years (summing up to about 3.2 billion cycles in a lifetime) under a cyclical pressure of about 200 g/cm2 in a very aggressive, corrosive uid of high viscosity. Other research endeavors include testing valves within elevated concentrations of calcium and phosphate, proteins, lipids, enzymes, and cells, in the presence of potentially destructive defense mechanisms such as the immune system, coagulation cascade, inammation, encapsulation, and calcication (30). This ongoing research has initially concluded that the ideal articial heart valve should fulll the following specic clinical, mechanical, and biological prerequisites. These prerequisites include, but are not limited to: 1. Full valve closure and release, and an internal orice area close to the natural valve;

2. Limited resistance to blood ow while moving, and laminar ow through valve; 3. Mechanically durable, resistant to wear, maintain properties throughout lifetime; 4. Perfect integration into host tissue with minimal healing responses; 5. Chemically stable, nonleachable, noncytotoxic components; 6. Nonhemolytic, nonthrombogenic, substrate not supportive of infections; 7. Nonimmunogenic, noninammatory, noncalcifying; 8. Long-term shelf life without changes in properties and sterility; 9. Continuity with the cardiac skeleton; 10. Ease of implantation, preferably using minimally invasive surgery; 11. Available in all sizes and reasonably priced. To assess these properties, articial heart valves are rigorously tested in vitro and in vivo, before being approved for human use. In vitro testing includes analysis of ow patterns by computer modeling and evaluation of hydrodynamic functions using ventricle simulators (31). In addition, valve components are routinely tested for mechanical properties such as elasticity, tensile strength, and wear resistance. For long-term durability evaluation, valves are subjected to fatigue testing at accelerated rates (up to 20 times faster that normal heart rate) (32). In vivo tests include subdermal implantation of tissue valve components for calcication studies (33) and valve replacement in sheep (34). Currently, no articial heart valve device, either mechanical or tissue-derived, fullls all those previously described prerequisites. No material produced by the human imagination or through cutting-edge technology available can fully reproduce the complexity of the natural heart valve. However, the possibilities for creating such a naturally complex construct are endless if biomaterials or approaches can be developed that, instead of waging war with biology, will promote perfect integration within local and systemic physiologic systems. One such promising avenue is the regenerative medicine/tissue engineering approach.

7. REGENERATIVE MEDICINE APPROACHES TO HEART VALVE REPLACEMENT The eld of regenerative medicine is based on the innovative and visionary principle of using the patients own cells and extracellular matrix components to restore or replace tissues and organs that have failed. This regenerative approach is a derivative of reconstructive surgery, where surgeons use the patients tissues to rebuild injured or aging body parts. Modern approaches to heart valve regenerative medicine include several research methodologies, collectively known as tissue engineering. The most intensely researched approaches are (1) the use of decellularized tissues as scaffolds for in situ regeneration, (2)

ARTIFICIAL HEART VALVES

construction of tissue equivalents in the laboratory before implantation, and (3) use of scaffolds preseeded with stem cells. A widespread approach is to use native (uncrosslinked) decellularized valves obtained from processed human or animal tissues. Once implanted, decellularized tissues are expected to provide proper environment and sufcient stimuli for host cells to inltrate, remodel, and eventually regenerate the valvular tissue. As antigenic determinants are mainly concentrated on the surface of cells, removal of the original cells (decellularization) is necessary for avoiding complications related to immune rejection, which can be satisfactorily attained using combinations of detergents and enzymes, leaving behind 3-D scaffolds comprising apparently intact matrix molecules. Experimental data obtained with decellularized porcine valves yielded spectacular results (35). In vitro hydrodynamic performance was excellent, and valves performed well after implantation in sheep for 5 months as replacement of pulmonary valves. Explanted valves showed good repopulation of porcine scaffolds with broblast-like cells as well as an almost complete re-endothelialization of valve surfaces. These encouraging studies prompted several smallscale studies in humans using a commercially available decellularized porcine heart valve. However, despite the initial enthusiasm, the results of a small study in children were catastrophic. In a breakthrough and intrepid study, a group of cardiac surgeons from Austria reported that three out of four children implanted with decellularized porcine heart valves had died within 1 year after implantation because of tissue rupture, degeneration, and calcication of the implant (36). Analysis of explanted decellularized porcine heart valves revealed lack of cell repopulation or endothelialization. The collagen matrix induced a severe inammatory response and encapsulation of the graft and also served as a substrate for development of numerous calcication sites. The same group of researchers also recently identied the presence of the porcine cell-specic disaccharide galactose-alpha-1-3-galactose (alpha-Gal epitope) in decellularized porcine heart valves as the possible source of immunogenicity (37). Similarly, decellularized blood vessels also elicited inammatory responses (38) and failed to maintain patency (39). Evidently, more basic studies are required for further development of these products as well as to reevaluate the relevance of animal models. Several academic groups, as well as a group of medical device companies, continue to pursue research and development of decellularized cardiovascular tissues (4042). A second approach involves construction of tissue equivalents in the laboratory prior to implantation, with the expectation that assembling the tissue-engineered valvular constructs from appropriate cells, and synthetic or natural matrix components, would create mechanically competent, nonthrombogenic, living tissues capable of adaptation and growth. Compared with decellularized tissues, this approach provides better control of the device properties before implantation. However, because of the enormity of this task, and because of possible early clinical failures of decellularized tissues, researchers in the eld of

heart valve tissue regeneration have taken a cautious, stepwise approach. The in vitro assembly of heart valve tissue from its individual components was pioneered by I. Vesely et al. (43,44). In this ingenious approach, a chemically crosslinked nonbiodegradable glycosaminoglycan gel was seeded with vascular cells and cultured in vitro, which resulted in the formation of a thin sheet of elastin at the interface between cells and the glycosaminoglycan gel. The collagen structural component was created by broblast-mediated compaction of soluble collagen, with the expectation that in vitro assembly of these building blocks would, at some point, create a valve-like structure. For more details, please refer to the chapter on Tissue Engineering of Heart Valves in this Encyclopedia. In an exemplary collaborative effort, clinicians, basic scientists, polymer chemists, and biomedical engineers focused on creating functional tissue-engineered heart valves in vitro using biodegradable scaffolds (45). These efforts included scaffold design and characterization, optimization of cell sources, nding adequate mechanisms for cell delivery, and optimizing in vitro culture of the seeded scaffolds, culminating with the surgical replacement of heart valves in sheep. A wide variety of scaffolding models created from biodegradable polymers have been tested for heart valve tissue engineering, including polyglycolic acid, polylactic acid, polycaprolactone, and biodegradable elastomers, which are manufactured into nonwoven textiles in shapes and conformations that mimic the natural architecture of the heart valve. These scaffolds are then seeded with cells that can be obtained from (1) fully differentiated cells such as myobroblasts and endothelial cells derived from systemic arteries, or (2) pluripotent stem cells derived from adipose tissue, bone marrow, or peripheral blood (46). As mature cells have a limited lifespan, an attractive cell source was stem cells for heart valve tissue engineering. Recently, in a landmark experiment, mesenchymal stem cells obtained from ovine bone marrow were seeded onto biodegradable scaffolds and the constructs were cultured in vitro before implantation as a valve in the pulmonary position of sheep (47) for up to 8 months. Tissue-engineered valves performed well hemodynamically, with signs of slow degradation of the scaffolds, and concomitant deposition of new extracellular matrix. Moreover, cell types resembled those present in natural heart valves. Overall, these exciting results hold great promise for truly effective regenerative approaches to treatment of heart valve disease.

8. FUTURE AND PERSPECTIVES By virtue of its clinical applications, biomedical engineering has matured into an interdisciplinary medical specialty, which necessitates intertwining expertise from numerous elds, including surgery, pathology, cell and molecular biology, matrix biochemistry, engineering, and mechanics. In anticipation of major scientic breakthroughs in this eld, surgeons will continue to treat these diseases by rst reestablishing the mechanical functions of the heart using articial valves. The yellow brick

ARTIFICIAL HEART VALVES

road leading to effective treatments of valvular disease continues to present multiple challenges. Three extremely exciting lines of investigation are:

BIBLIOGRAPHY

1. J. M. Icardo and E. Colvee, Atrioventricular valves of the mouse: III. Collagenous skeleton and myotendinous junction. Anat. Rec. 1995; 243(3):367375. 2. I. Vesely and R. Noseworthy, Micromechanics of the brosa and the ventricularis in aortic valve leaflets. J. Biomech. 1992; 25(1):101113. 3. I. Vesely, The role of elastin in aortic valve mechanics. J. Biomech. 1998; 31(2):115123. 4. J. Lovekamp and N. Vyavahare, Periodate-mediated glycosaminoglycan stabilization in bioprosthetic heart valves. J. Biomed. Mater. Res. 2001; 56(4):478486. 5. J. J. Lovekamp, D. T. Simionescu, J. J. Mercuri, B. Zubiate, M. S. Sacks, and N. R. Vyavahare, Stability and function of glycosaminoglycans in porcine bioprosthetic heart valves. Biomaterials, in press. 6. F. J. Schoen, Cardiac valves and valvular pathology: update on function, disease, repair, and replacement. Cardiovasc. Pathol. 2005; 14(4):189194. 7. X. Y. Jin and J. R. Pepper, Do stentless valves make a difference? Eur. J. Cardiothorac. Surg. 2002; 22(1):95100. 8. E. Rabkin-Aikawa, J. E. Mayer, Jr., and F. J. Schoen, Heart valve regeneration. Adv. Biochem. Eng. Biotechnol. 2005; 94:141179. 9. M. I. Ionescu, B. C. Pakrashi, D. A. Mary, I. T. Bartek, and G. H. Wooler, Replacement of heart valves with frame-mounted tissue grafts. Thorax 1974; 29(1):5667. 10. Y. S. Morsi, I. E. Birchall, and F. L. Rosenfeldt, Articial aortic valves: an overview. Int. J. Artif. Organs 2004; 27(6):445 451. 11. F. J. Schoen and R. J. Levy, Founders Award, 25th Annual Meeting of the Society for Biomaterials, perspectives. Providence, RI, April 28May 2, 1999. Tissue heart valves: current challenges and future research perspectives. J. Biomed. Mater. Res. 1999; 47(4):439465. 12. J. Butany, M. S. Ahluwalia, C. Munroe, C. Fayet, C. Ahn, P. Blit, C. Kepron, R. J. Cusimano, and R. L. Leask, Mechanical heart valve prostheses: identication and evaluation. Cardiovasc. Pathol. 2003; 12(6):322344. 13. D. Horstkotte, Prosthetic valves or tissue valvesa vote for mechanical prostheses. Z. Kardiol. 1985; 74 (Suppl 6):1937. 14. J. Butany, C. Fayet, M. S. Ahluwalia, P. Blit, C. Ahn, C. Munroe, N. Israel, R. J. Cusimano, and R. L. Leask, Biological replacement heart valves. Identication and evaluation. Cardiovasc. Pathol. 2003; 12(3):119139. 15. M. Dahm, M. Husmann, M. Eckhard, D. Prufer, E. Groh, and H. Oelert, Relevance of immunologic reactions for tissue failure of bioprosthetic heart valves. Ann. Thorac. Surg. 1995; 60(2 Suppl):S348S352. 16. D. T. Cheung, N. Perelman, E. C. Ko, and M. E. Nimni, Mechanism of crosslinking of proteins by glutaraldehyde III. Reaction with collagen in tissues. Connect. Tissue Res. 1985; 13(2):109115. 17. A. M. Borkon, L. M. Soule, K. L. Baughman, W. A. Baumgartner, T. J. Gardner, L. Watkins, V. L. Gott, K. A. Hall, and B. A. Reitz, Aortic valve selection in the elderly patient. Ann. Thorac. Surg. 1988; 46(3):270277. 18. F. J. Schoen and C. E. Hobson, Anatomic analysis of removed prosthetic heart valves: causes of failure of 33 mechanical valves and 58 bioprostheses, 1980 to 1983. Hum. Pathol. 1985; 16(6):549559.

A. Finding causes and developing nonsurgical therapy approaches for valvular disease. To achieve this goal, more detailed molecular, biochemical, and cellular studies are needed on normal and diseased human valves as well as development of more clinically relevant animal models for valve diseases. B. Improvement of current articial devices. Regarding mechanical valves, it would be a milestone of success to drastically reduce the incidence of thrombogenicity caused by valve replacement with mechanical devices. For tissue valves, more effective stabilization and anticalcication treatments are required to reduce the incidence of tissue degeneration and extend device durability. More studies on implant-host tissue interactions are needed to develop innovative materials that elicit minimal healing responses that are caused by surgically invasive and inherently traumatic valve replacement techniques. Finally, a need to develop minimally invasive implantation approaches that would reduce the need for open-heart surgery for valve replacement exists. C. Regenerative medicine approaches. Heart valve tissue engineering is only in the nascent stage of research. Therefore, to succeed, it is imperative that we fully understand the structural-functional properties of normal heart valves and to determine how the valvular cells remodel the tissue. As stem cell research offers a marvelous potential for effective regeneration of heart valve tissue by differentiation into the proper cells, insights into embryological development are also essential (8).

9. CONCLUSIONS Heart valves are connective tissues that maintain their remarkable mechanical and biological functions under austere biomechanical and biochemical conditions within the human body. As heart valve injuries lead to diseases that cause progressive valve degeneration, open-heart surgery to replace diseased tissue with an engineered device is, at present, the only curative method for correcting these altered mechanical and biological properties. Mechanical and tissue-derived articial heart valves successfully reestablish mechanical functions but do not replenish the biological requisites for long-term durability and eventually fail. Remarkable research efforts are underway to develop better devices as well as to open new and exciting avenues for tissue engineering approaches, which could potentially facilitate a complete regeneration of valve tissues.

10

ARTIFICIAL HEART VALVES 35. S. Goldstein, D. R. Clarke, S. P. Walsh, K. S. Black, and M. F. OBrien, Transpecies heart valve transplant: advanced studies of a bioengineered xeno-autograft. Ann. Thorac. Surg. 2000; 70(6):19621969. 36. P. Simon, M. T. Kasimir, G. Seebacher, G. Weigel, R. Ullrich, U. Salzer-Muhar, E. Rieder, and E. Wolner, Early failure of the tissue engineered porcine heart valve SYNERGRAFT in pediatric patients. Eur. J. Cardiothorac. Surg. 2003; 23(6):10021006; discussion 1006. 37. M. T. Kasimir, E. Rieder, G. Seebacher, E. Wolner, G. Weigel, and P. Simon, Presence and elimination of the xenoantigen gal (alpha1, 3) gal in tissue-engineered heart valves. Tissue Eng. 2005; 11(78):12741280. 38. F. Sayk, I. Bos, U. Schubert, T. Wedel, and H. H. Sievers, Histopathologic ndings in a novel decellularized pulmonary homograft: an autopsy study. Ann. Thorac. Surg. 2005; 79(5):17551758. 39. M. A. Sharp, D. Phillips, I. Roberts, and L. Hands, A cautionary case: the SynerGraft vascular prosthesis. Eur. J. Vasc. Endovasc. Surg. 2004; 27(1):4244. 40. H. E. Wilcox, S. A. Korossis, C. Booth, K. G. Watterson, J. N. Kearney, J. Fisher, and E. Ingham, Biocompatibility and recellularization potential of an acellular porcine heart valve matrix. J. Heart Valve Dis. 2005; 14(2):228236; discussion 236237. 41. E. Rieder, G. Seebacher, M. T. Kasimir, E. Eichmair, B. Winter, B. Dekan, E. Wolner, P. Simon, and G. Weigel, Tissue engineering of heart valves: decellularized porcine and human valve scaffolds differ importantly in residual potential to attract monocytic cells. Circulation 2005; 111(21):27922797. 42. D. T. Simionescu, Q. Lu, Y. Song, J. Lee, T. N. Rosenbalm, C. Kelley, and N. R. Vyavahare, Biocompatibility and remodeling potential of pure arterial elastin and collagen scaffolds. Biomaterials 2006; 27(5):702713. 43. A. Ramamurthi and I. Vesely, Evaluation of the matrix-synthesis potential of crosslinked hyaluronan gels for tissue engineering of aortic heart valves. Biomaterials 2005; 26(9):9991010. 44. Y. Shi, A. Ramamurthi, and I. Vesely, Towards tissue engineering of a composite aortic valve. Biomed. Sci. Instrum. 2002; 38:3540. 45. S. P. Hoerstrup, R. Sodian, S. Daebritz, J. Wang, E. A. Bacha, D. P. Martin, A. M. Moran, K. J. Guleserian, J. S. Sperling, S. Kaushal, J. P. Vacanti, F. J. Schoen, and J. E. Mayer, Jr., Functional living trileaflet heart valves grown in vitro. Circulation 2000; 102(19 Suppl 3):III44III49. 46. F. W. Sutherland and J. E. Mayer, Jr., Tissue engineering for cardiac surgery. In: L. H. Cohn and L. H. Edmunds, Jr., eds., Cardiac Surgery in the Adult. New York: McGraw-Hill, 2003, pp. 15271536. 47. F. W. Sutherland, T. E. Perry, Y. Yu, M. C. Sherwood, E. Rabkin, Y. Masuda, G. A. Garcia, D. L. McLellan, G. C. Engelmayr, Jr., M. S. Sacks, F. J. Schoen, and J. E. Mayer, Jr., From stem cells to viable autologous semilunar heart valve. Circulation 2005; 111(21):27832791.

19. M. S. Sacks and F. J. Schoen, Collagen ber disruption occurs independent of calcication in clinically explanted bioprosthetic heart valves. J. Biomed. Mater. Res. 2002; 62(3):359 371. 20. D. T. Simionescu, J. J. Lovekamp, and N. R. Vyavahare, Extracellular matrix degrading enzymes are active in porcine stentless aortic bioprosthetic heart valves. J. Biomed. Mater. Res. A 2003; 66(4):755763. 21. I. Vesely, J. E. Barber, and N. B. Ratliff, Tissue damage and calcication may be independent mechanisms of bioprosthetic heart valve failure. J. Heart Valve Dis. 2001; 10(4):471477. 22. I. Vesely, The evolution of bioprosthetic heart valve design and its impact on durability. Cardiovasc. Pathol. 2003; 12(5):277286. 23. D. T. Simionescu, Prevention of calcication in bioprosthetic heart valves: challenges and perspectives. Expert Opin. Biol. Ther. 2004; 4(12):19711985. 24. A. Simionescu, D. Simionescu, and R. Deac, Biochemical pathways of tissue degeneration in bioprosthetic cardiac valves. The role of matrix metalloproteinases. Asaio. J. 1996; 42(5):M561M567. 25. N. Vyavahare, M. Ogle, F. J. Schoen, and R. J. Levy, Elastin calcication and its prevention with aluminum chloride pretreatment. Am. J. Pathol. 1999; 155(3):973982. 26. C. M. Giachelli, Ectopic calcication: gathering hard facts about soft tissue mineralization. Am. J. Pathol. 1999; 154(3):671675. 27. J. P. Gott, C. Pan, L. M. Dorsey, J. L. Jay, G. K. Jett, F. J. Schoen, J. M. Girardot, and R. A. Guyton, Calcication of porcine valves: a successful new method of antimineralization. Ann. Thorac. Surg. 1992; 53(2):207215; discussion 216. 28. R. J. Levy, G. Golomb, J. Wolfrum, S. A. Lund, F. J. Schoen, and R. Langer, Local controlled-release of diphosphonates from ethylenevinylacetate matrices prevents bioprosthetic heart valve calcication. Trans. Am. Soc. Artif. Intern. Organs 1985; 31:459463. 29. M. A. Moore, PhotoFix: unraveling the mystery. J. Long Term Eff. Med. Implants 2001; 11(34):185197. 30. T. Gudbjartsson, S. Aranki, and L. H. Cohn, Mechanical/bioprosthetic mitral valve replacement. In: L. H. Cohn and L. H. Edmunds, Jr., eds., Cardiac Surgery in the Adult. New York: McGraw-Hill, 2003, pp. 951986. 31. A. P. Yoganathan, Z. He, and S. Casey Jones, Fluid mechanics of heart valves. Annu. Rev. Biomed. Eng. 2004; 6:331362. 32. K. Iwasaki, M. Umezu, K. Iijima, and K. Imachi, Implications for the establishment of accelerated fatigue test protocols for prosthetic heart valves. Artif. Organs 2002; 26(5):420429. 33. F. J. Schoen, G. Golomb, and R. J. Levy, Calcication of bioprosthetic heart valves: a perspective on models. J. Heart Valve Dis. 1992; 1(1):110114. 34. M. F. Ogle, S. J. Kelly, R. W. Bianco, and R. J. Levy, Calcication resistance with aluminum-ethanol treated porcine aortic valve bioprostheses in juvenile sheep. Ann. Thorac. Surg. 2003; 75(4):12671273.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Algorithms To Guide Your Diagnosis and TreatmentDocument245 pagesAlgorithms To Guide Your Diagnosis and TreatmentVirgo PotensNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ECG Workout - Excercises in Arrhythmia InterpretationDocument415 pagesECG Workout - Excercises in Arrhythmia InterpretationAna-Maria Astănoaei100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Auscultation - Cardiac - Learning Cardiac Auscultation From Essentials To Expert Clinical Interpretation 1st Ed2015Document428 pagesAuscultation - Cardiac - Learning Cardiac Auscultation From Essentials To Expert Clinical Interpretation 1st Ed2015programgrabberNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Valvular Heart DiseaseDocument42 pagesValvular Heart DiseaseareeparambilNo ratings yet

- Assessment of Cardiovascular SystemDocument41 pagesAssessment of Cardiovascular Systembicariato100% (7)

- 515Document972 pages515solecitodelmarazul100% (6)

- Physical AssessmentDocument12 pagesPhysical Assessmentteslimolakunleraji100% (1)

- Lab Activity (Dissection of Pigs Heart)Document3 pagesLab Activity (Dissection of Pigs Heart)Emily Dueñas SingbencoNo ratings yet

- Aortic StenosisDocument11 pagesAortic StenosisIra Anuddin100% (1)

- Voluson E8 Expert DatasheetDocument15 pagesVoluson E8 Expert Datasheetnkurmis100% (2)

- Genesis Machines Computing Code of Life AmosDocument5 pagesGenesis Machines Computing Code of Life AmosmdicksonNo ratings yet

- Cruz Suicide PaperDocument21 pagesCruz Suicide PapermdicksonNo ratings yet

- How Jesus Interpreted His BibleDocument11 pagesHow Jesus Interpreted His Biblejos44prietoNo ratings yet

- Lookup Article New Scientist by Michael Brooks 2008Document1 pageLookup Article New Scientist by Michael Brooks 2008mdicksonNo ratings yet

- Imago Dei and Sexual Difference SoskiceDocument11 pagesImago Dei and Sexual Difference SoskicemdicksonNo ratings yet

- The Many Facets of Natural ComputingDocument10 pagesThe Many Facets of Natural ComputingmdicksonNo ratings yet

- Mjpjay Pmjay Package CostsDocument31 pagesMjpjay Pmjay Package Coststanuj9117No ratings yet

- NCLEX CardiovascularDocument93 pagesNCLEX CardiovascularYaoling WenNo ratings yet

- 8 TraDocument10 pages8 Traغلا العسكريNo ratings yet

- (03241750 - Acta Medica Bulgarica) Multiple Congenital Heart AbnormalitiesDocument4 pages(03241750 - Acta Medica Bulgarica) Multiple Congenital Heart AbnormalitiesTeodorNo ratings yet

- MD8 ManualDocument23 pagesMD8 ManualCESAR AUGUSTO ARIAS MOLANONo ratings yet

- Structure and Function of The Cardiovascular System PDFDocument9 pagesStructure and Function of The Cardiovascular System PDFteuuuuNo ratings yet

- "Pregnancy and Labor With Extragenital Diseases": TH NDDocument29 pages"Pregnancy and Labor With Extragenital Diseases": TH NDirfan fadilah100% (1)

- Cambridge International AS & A Level: Biology 9700/12Document20 pagesCambridge International AS & A Level: Biology 9700/12Pranav Ramesh BadrinathNo ratings yet

- Cardiovascular Physical ExaminationDocument29 pagesCardiovascular Physical ExaminationannisNo ratings yet

- Pharm D (PB) 2 YEAR 2020-2021: Under The Guidance of GuideDocument41 pagesPharm D (PB) 2 YEAR 2020-2021: Under The Guidance of Guidesufiya fatimaNo ratings yet

- Anatomy & PhysiologyDocument11 pagesAnatomy & PhysiologyArah Lyn ApiagNo ratings yet

- Jugular Venous Pressure: Syed Farrukh UmairDocument30 pagesJugular Venous Pressure: Syed Farrukh UmairsfumairNo ratings yet

- 1Document24 pages1Noey TabangcuraNo ratings yet

- On To DiagramDocument27 pagesOn To DiagramharriselNo ratings yet

- 12 Transport of O2 & Co2Document169 pages12 Transport of O2 & Co2Bakhtiar Effendi YahyaNo ratings yet

- Infective Endocarditis HumanoDocument13 pagesInfective Endocarditis HumanoAna AldazNo ratings yet

- Medical ElectronicsDocument167 pagesMedical ElectronicsVASANTHKUMAR M SNo ratings yet

- HAP Chapterwise MCQ For 2nd Sessional PDFDocument6 pagesHAP Chapterwise MCQ For 2nd Sessional PDFsaurav prasadNo ratings yet

- Mitral ValveDocument48 pagesMitral Valvestoicea_katalinNo ratings yet

- PMR Science Form 3 TipsDocument41 pagesPMR Science Form 3 TipsSuntharan MuniandyNo ratings yet