Professional Documents

Culture Documents

Pneumatic Lightweight Structures

Uploaded by

Atul GargOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pneumatic Lightweight Structures

Uploaded by

Atul GargCopyright:

Available Formats

Pneumatic lightweight structures

Documentation of development

Info

Manoeuvring with innovative lightweight structures

Basic pneumatic phenomenon (sketch)

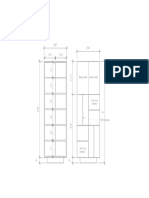

Displacement element/ modular system

30 degree offset radius

Free spatial movement

A technical focus of the Institute for Technology-Oriented Design Innovations (ITD) at the Offenbach Academy of Art and Design, headed by Prof. Dieter Mankau, is the creative and technological treatment of current bionic issues and already existing knowledge. The Institutes own research and development projects are concerned with adaptively responsive, locally elastic, pneumatic and kinematic structures and systems for lightweight elements. These findings form the basis of new product developments such as adaptively responsive lightweight load-bearing elements for textile construction in architecture, the design of modular care beds for long-term patients and the implementation locally elastic elements for office chairs. The development cooperation between the ITD and Festo AG & Co. KG is integrated into Festos Bionic Learning Network. The basis of this cooperation are the concepts developed by Professor Dieter Mankau for pneumatic lightweight structures, along with bionic robotic and automation systems. The focus here is on examining appropriate application-oriented implementation of the basic phenomena, along with elaboration and implementation options with a view to possible practical usage.

The project initially involved a general functional review of both familiar and newly developed principles. A solution for a displacement system with free spatial movement entails linking together pneumatic actuators into several linear functional strands, which are connected and selectively activated in combination with a carrier system to constitute a multi-axis displacement element. In addition to integration of the pneumatic components into a mechanical system, the possibility of implementation as an entirely non-mechanical, adaptive overall system was also considered from the outset. For this purpose, the pneumatic actuators were coated and embedded in highly flexible polyurethane cold foam to form a functional system without mechanical joints or bearings. The resulting structures constitute part of the new field of soft robotics. As non-static systems, these adaptive robots and gripper systems respond both passively and actively to their surroundings and can thus be used in the immediate environment of humans thereby eliminating the risk of injury. In view of the high complexity involved in realising the prototypes and the highly intricate openand closed-loop control for the various pressure applications and for generation of negative pressure, this concept has as yet only been implemented in rudimentary form. Following a general examination of the basic concepts, the focus was shifted to a principle in which displacement of a pneumatic actuator in combination with an overhead belt brings about a displacement of the entire system. This principle can be implemented in either two or three dimensions and, in addition to displacement defined by bearings or joints, yields non-static structures with a free spatial radius of operation. The functional principle of single-axis displacement elements was experimentally tested. This low-complexity pneumatic principle is well suited for simple, adaptive gripping and automation systems. Whereas the two-dimensional displacements are relatively easy to manage in technical terms, complexity increases in the case of a

Modular element with tyre and overhead belt, without cover

Displacement through pressure application in tyre

spatial and partly superimposed muscle configuration. The concept of generating multi-axis movement patterns by means of threedimensional pneumatic structures, with no association of mechanical cause-and-effect relationships, became the new objective. In a pneumatic, multi-axis movement system free of mechanical joints, the system is self-stabilising thanks to the differentiated pressure applications of the spatially antagonistic muscles; moreover, lightweight structures can be realised with an optimum weight/power ratio. In several prototypes, the effects of various arrangements of the pneumatic actuators were investigated along with their influence on the overall system and the movement patterns. Structures with 3 and 4 actuator strands were implemented in a rotationally symmetrical configuration around the centre of a carrier system. In addition, superimposed and offset arrangements of pneumatic actuators in these systems were examined. The piezo proportional control valves, with a maximum operating pressure of

one bar, were integrated into the carrier system. At this pressure, movement patterns can be generated without additional working load. For industrial applications, however, the system must be completely reworked. All components such as actuators, control elements etc. must be designed for a higher operating pressure in order to meet the requirements of possible use in automation. The experimental set-ups have shown that with the examined principles and structures, lightweight, adaptive and cost-efficient displacement and gripping systems can be generated, which by means of new production methods can be directly adapted to individual customer requirements in rapid manufacturing. The first design studies are currently being drawn up for the simple pneumatic principles, which have already been investigated and confirmed in their function, with the objective of a modular system that incorporates grippers and movement actuators as well as static connection elements etc.

Prototypes of pneumatic lightweight structures (left to right): Schematic representation of displacement movement, 4-chamber system with offset muscular strands, serial connection of linear displacement elements, 4-chamber system with sensors

Technical data Control: CPX-GE-EV controller/valve terminal from Festo Software: FST 4.1 from Festo Valves: 12 piezo proportional valves from Festo Operating pressure: 1 bar

Project partners Project initiator: Dr. Wilfried Stoll, Chairman of the Supervisory Board, Festo AG Project management: Prof. Dieter Mankau, Academy of Art and Design, Institute for Technology-Oriented Design Innovations, Offenbach, Germany Development team: Prof. Dieter Mankau, Dipl.-Des. Nico Sebastian Hopp, Academy of Art and Design, Institute for Technology-Oriented Design Innovations, Offenbach, Germany Visualisation: Dipl.-Des. Henrique Monnerat, Rio de Janeiro, Brazil Preliminary tests: Dipl.-Des. Lars Mayer, Marc Bischoff, Academy of Art and Design, Offenbach, Germany Project management Festo AG & Co. KG: Dipl.-Ing. (FH) Markus Fischer, Corporate Design Development team Festo AG & Co. KG: Dr. Rdiger Neumann, Mechatronic Systems Research Dr. Alexander Hildebrandt, Mechatronic Systems Research Control and regulation: Roland Grau, Exhibition Software, Festo AG & Co. KG 3D printing: Dipl.-Ing. Klaus Mller-Lohmeier, Helmut Mller, Manfred Morscheck, Advanced Prototyping Technology, Festo AG & Co. KG Plastics technology: Dr. Robert Mayr, Dipl.-Ing. Herbert Wittig, Polyvanced GmbH, Osnabrck, Germany

Prototypes Three-dimensional systems 4-chamber round system, length 20 cm, 12 pneumatic actuators 4-chamber system, length 130 cm, 26 pneumatic actuators 4-chamber system, length 110 cm, 20 pneumatic actuators 4-chamber system, length 35 cm, 8 pneumatic actuators 4-chamber system with offset actuators, length 80 cm, 22 pneumatic actuators 4-chamber system with offset actuators, length 115 cm, 20 pneumatic actuators 4-chamber modular system, 6 segments each with 4 pneumatic actuators, maximum length 150 cm 3-chamber system, length 125 cm, 21 large and 18 small pneumatic actuators 3-chamber system, length 40 cm, 6 large and 3 small actuators Linear system with offset elements, 5 elements each with 2 pneumatic actuators, length 75 cm Linear system with offset elements, 7 elements each with 2 pneumatic actuators, length 85 cm

Prototypes Two-dimensional systems Linear system, length 50 cm, 12 pneumatic actuators Linear system, length 80 cm, 10 pneumatic actuators Linear system, length 60 cm, 10 pneumatic main actuators, 8 reinforcement actuators Linear system, length 60 cm, 11 displaced pneumatic actuators In addition to the listed prototypes, a number of smaller experimental set-ups and tests were implemented.

Festo AG & Co. KG Corporate Design Ruiter Strasse 82 73734 Esslingen Germany www.festo.com/bionic Phone ++ 49 711 347- 38 80 Telefax ++ 49 711 347- 38 99 fish@ de.festo.com

50139 en 04/2010

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Award For New Design in Heritage ContextsDocument10 pagesThe Award For New Design in Heritage ContextsAtul GargNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Safety ProtectionDocument23 pagesSafety ProtectionKhurshed Alam IndiaNo ratings yet

- Emailing Projek PintarDocument9 pagesEmailing Projek PintarAtul GargNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AR2521 Software InstallationDocument12 pagesAR2521 Software InstallationAtul GargNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Research Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewDocument19 pagesResearch Frameworks, Methodologies, and Assessment Methods Concerning The Adaptive Reuse of Architectural Heritage - A ReviewAtul GargNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Meandering LightsDocument1 pageMeandering LightsAtul GargNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Sahil Seth Interiors (1) - Side Tablequilt and MirrorDocument1 pageSahil Seth Interiors (1) - Side Tablequilt and MirrorAtul GargNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Sahil Sethi Final SetDrawing1 - 1 - 25767 - 79-Livinf Room TV UnitDocument1 pageSahil Sethi Final SetDrawing1 - 1 - 25767 - 79-Livinf Room TV UnitAtul GargNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Heritage ValuesDocument1 pageHeritage ValuesAtul GargNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Sahil Sethi Final SetDrawing1 - 1 - 25767 - 79-Livinf Room TV unitEG PDFDocument1 pageSahil Sethi Final SetDrawing1 - 1 - 25767 - 79-Livinf Room TV unitEG PDFAtul GargNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Sahil Sethi Final SetDrawing1-MandirDocument1 pageSahil Sethi Final SetDrawing1-MandirAtul GargNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and MaterialsDocument6 pagesCode Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and MaterialsAtul GargNo ratings yet

- Artscience Museum at Marina Bay Sands 11 Apr 2021: Account Number: Name: 5875437 Atul GargDocument3 pagesArtscience Museum at Marina Bay Sands 11 Apr 2021: Account Number: Name: 5875437 Atul GargAtul GargNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Sahil Seth Interiors (1) - Master Bedroom AlmirahDocument1 pageSahil Seth Interiors (1) - Master Bedroom AlmirahAtul GargNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Public Toilet Design GuidelineDocument29 pagesPublic Toilet Design GuidelineAarthy ArasuNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Sahil Seth Interiors (1) - Parents Bedroom AlmirahDocument1 pageSahil Seth Interiors (1) - Parents Bedroom AlmirahAtul GargNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Sahil Seth Interiors (1) - Kitchen PDFDocument1 pageSahil Seth Interiors (1) - Kitchen PDFAtul GargNo ratings yet

- PORTAL DETAIL1-Model PDFDocument1 pagePORTAL DETAIL1-Model PDFAtul GargNo ratings yet

- Form BR-V A2Document2 pagesForm BR-V A2Atul GargNo ratings yet

- Between Looking and Making: Unravelling Dom Hans Van Der Laan's Plastic NumberDocument24 pagesBetween Looking and Making: Unravelling Dom Hans Van Der Laan's Plastic NumberAtul GargNo ratings yet

- Manish Interior-Full Section PDFDocument1 pageManish Interior-Full Section PDFAtul GargNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manish Interior-Details Modular PDFDocument1 pageManish Interior-Details Modular PDFAtul GargNo ratings yet

- AISC Design Guide 34-Steel Framed Stairway DesignDocument114 pagesAISC Design Guide 34-Steel Framed Stairway Designfzhou100% (9)

- Sahil Seth Interiors (1) - Guest and Parentsbedroom TV Panel PDFDocument1 pageSahil Seth Interiors (1) - Guest and Parentsbedroom TV Panel PDFAtul GargNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Indirapuram STP, Ghaziabad Co-Treatment Case Study: List of TablesDocument13 pagesIndirapuram STP, Ghaziabad Co-Treatment Case Study: List of TablesAtul GargNo ratings yet

- Price Support Scheme (PSS) : The Operational Guidelines Chapter - I ADocument13 pagesPrice Support Scheme (PSS) : The Operational Guidelines Chapter - I ACamila JaureguiNo ratings yet

- BuildrtDocument125 pagesBuildrtAtul GargNo ratings yet

- Advanced Strategies For Net-Zero Energy Building: Focused On The Early Phase and Usage Phase of A Building's Life CycleDocument52 pagesAdvanced Strategies For Net-Zero Energy Building: Focused On The Early Phase and Usage Phase of A Building's Life CycleHema VideosNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Kitchen Tall Unit - Revised PDFDocument1 pageKitchen Tall Unit - Revised PDFAtul GargNo ratings yet

- Sample Newsletter PDFDocument2 pagesSample Newsletter PDFAtul GargNo ratings yet

- Frt11 BetzDocument25 pagesFrt11 BetzArindam DasNo ratings yet

- The Love Affairs of Great Musicians, Volume 2 by Hughes, Rupert, 1872-1956Document123 pagesThe Love Affairs of Great Musicians, Volume 2 by Hughes, Rupert, 1872-1956Gutenberg.org100% (7)

- Theatrical Play Performance RubricDocument3 pagesTheatrical Play Performance Rubricjemilyn tungculNo ratings yet

- Content Beyond SyllabusDocument10 pagesContent Beyond Syllabussandhya_emeraldNo ratings yet

- Math Lesson Plan 10Document3 pagesMath Lesson Plan 10Mam NinzNo ratings yet

- Qualitative ResearchDocument28 pagesQualitative ResearchAastha VyasNo ratings yet

- Legal Ethics CasesDocument126 pagesLegal Ethics CasesKaye TolentinoNo ratings yet

- Till The Judge'S Verdict Do Them Part: The Prospect of Absolute Divorce in The PhilippinesDocument29 pagesTill The Judge'S Verdict Do Them Part: The Prospect of Absolute Divorce in The PhilippinesCheryl L. Daytec-YangotNo ratings yet

- REPORT CARD (New Format G1 & 2) SY 2018-2019Document2 pagesREPORT CARD (New Format G1 & 2) SY 2018-2019Goldine Barcelona EteNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pencak Silat Through My Eyes Indonesian Martial ArtsDocument16 pagesPencak Silat Through My Eyes Indonesian Martial ArtsxranarNo ratings yet

- Rubric Case Study 2 Group 2Document3 pagesRubric Case Study 2 Group 2Abang BulanNo ratings yet

- Training Development PNBDocument109 pagesTraining Development PNBPayal Sikka100% (1)

- Jose Prager - Name & SignDocument7 pagesJose Prager - Name & SignFreddie666100% (4)

- IFEM AppP PDFDocument7 pagesIFEM AppP PDFPippo MiriNo ratings yet

- Batch 2 Sept. 7 - 2020 SHS - 300 Virtual Classes - Aug. 24 - 2020 - 25 New Priority For SHSDocument73 pagesBatch 2 Sept. 7 - 2020 SHS - 300 Virtual Classes - Aug. 24 - 2020 - 25 New Priority For SHSBeatriz Caladiao Matitu50% (2)

- Thomas Deane Tucker, Stuart Kendall (Editors) - Terrence Malick Film and Philosophy - Continuum (2011)Document241 pagesThomas Deane Tucker, Stuart Kendall (Editors) - Terrence Malick Film and Philosophy - Continuum (2011)Laurentiu RaducanuNo ratings yet

- Five Year MA Integrated Regulations & Syllabus-030714Document100 pagesFive Year MA Integrated Regulations & Syllabus-030714anoopNo ratings yet

- Barbara H. Watters - Horary Astrology and The Judgement of Events PDFDocument226 pagesBarbara H. Watters - Horary Astrology and The Judgement of Events PDFyuorme88% (8)

- MMW 3Document24 pagesMMW 3Azril owayetNo ratings yet

- Guiquing, Lynet Claire - GEC 03 Module 9Document7 pagesGuiquing, Lynet Claire - GEC 03 Module 9justine bautistaNo ratings yet

- Tembisa Aborn Final EssayDocument14 pagesTembisa Aborn Final Essayapi-287299654No ratings yet

- Revision Unit 3 Marriage & Family Life - IGCSE Religious StudiesDocument27 pagesRevision Unit 3 Marriage & Family Life - IGCSE Religious Studiesaneeshj1No ratings yet

- Aesthetics of Sustainable ArchitectureDocument161 pagesAesthetics of Sustainable ArchitectureAdrian MoleavinNo ratings yet

- Circular Motion ExperimentDocument7 pagesCircular Motion ExperimentictStactsNo ratings yet

- Harrison Culture Diagnosis GenericDocument8 pagesHarrison Culture Diagnosis GenericSrivatsa GaneshNo ratings yet

- Competitive Bidding in The 21st CenturyDocument256 pagesCompetitive Bidding in The 21st CenturyOvidiu Manolescu100% (9)

- The Power of Neuro-PlasticityDocument31 pagesThe Power of Neuro-PlasticityNing JiaNo ratings yet

- IJMCTR021420Document3 pagesIJMCTR021420rtaneja008No ratings yet

- Reflection On LearningDocument6 pagesReflection On Learningapi-242022165No ratings yet

- Barangay Ambassador: Republic of The Philippines Province of Benguet Municipality of TublayDocument3 pagesBarangay Ambassador: Republic of The Philippines Province of Benguet Municipality of TublayKathlyn Ablaza100% (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)