Professional Documents

Culture Documents

3094 HW ECB

Uploaded by

radarskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3094 HW ECB

Uploaded by

radarskiCopyright:

Available Formats

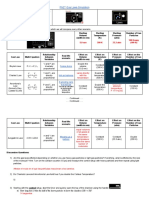

MSE2034 HW#EC B (Optional Extra Credit) Due Wednesday, March 2 at beginning of class 1 pt each, 8 pts extra credit maximum

1) An undeformed sample of some metal alloy with a recrystallization temperature of 400C is measured to have an average grain size of 0.050 mm. The required grain size to obtain sufficient strength in application is 0.020 mm. Explain how it would be possible to alter the sample to obtain this new structure, or explain why it is not possible to do so. 2) Refer to Fig 8.19. A cylindrical rod of brass with original diameter of 10.2 mm is to be cold-worked by a drawing process, maintaining the cylindrical cross-section during the process. Final properties required are a yield strength of at least 380 MPa and a ductility of at least 15%EL, with a final diameter of 7.6 mm. Describe a process that could achieve these properties, giving specific conditions for each required step. NOTE: Multiple sequential steps may be required to prevent failure during processing. 3) Consider a typical sample of window glass with elastic modulus of 69 GPa. If the most severe flaws in this sample are internal cracks with a total length of 0.2 mm and tip radius of curvature of 0.001 mm, would a 250 MPa tensile stress be sufficient to shatter the sample? HINT: Use elastic modulus to estimate the ideal strength of the material. 4) Consider a large thick plate (Y=1.1) of polycarbonate with yield strength of 62.1 MPa, plain-strain fracture toughness of 2.2 MPam, and surface cracks 0.05 mm in length (these are very small in comparison to the dimensions of the plate). The plate is stressed to a maximum of 20 MPa in tension. Determine what will occur (will it yield, fracture in ductile mode, or in brittle mode, or remain intact?). 5) See the data below for Charpy impact tests on a sample of low-carbon steel at various temperatures. Plot this data as impact energy vs. T, and estimate the ductile-to-brittle impact temperature by the following methods: (a) as the average of the impact energy levels at high and low T, (b) as the point of maximum change in impact energy with T (i.e., the inflection point of the curve), and (c) as the temperature where impact energy reaches 20 J. Briefly comment on the relative merits of these three estimation methods (which would be most useful in what situations, and why?).

Temperature [C] 50 40 30 20 10 0 -10 -20 -30 -40 -50 Impact Energy [J] 76 75 71 58 38 23 14 9 5 1.5 1.5

6) Given below are some data for fatigue in a typical steel. Use this data to generate an S-N plot for the steel and estimate the following: (a) the steel fatigue limit; (b) the fatigue lifetime at 400 MPa; and (c) the fatigue strength at 5x104 cycles. Also, (d) if the given data represent bending-rotating tests for an axle rotating at 600 RPM [revolutions per minute], how much actual use time would be allowable for this axle at a stress of 400 MPa? Stress Amplitude [MPa] 470 440 390 350 310 290 290 290 Cycles to Failure 104 3 x 104 105 3 x 105 106 3 x 106 107 108

7) Refer to Figures 9.37 and 9.38 showing creep information for a particular low carbonnickel alloy. Three samples of this alloy are subjected to a 60 MPa stress for an extended period, one at each of the given temperature levels [427C, 538C, and 649C]. If possible, estimate the expected rupture lifetime for each sample and the expected percent elongation due to steady-state creep in one year (Note that the data may not permit a reasonable estimate in certain cases). Comment on what you expect to happen qualitatively to each sample after one year under these conditions. 8) Refer to Figure 9.39, showing data for allowable stress vs. the Larson-Miller parameter for a S-590 iron alloy. A component made from this alloy must withstand steady stress at T=650C with a rupture lifetime of at least 10 years. Estimate the allowable stress level, employing a safety factor of 2 in stress to account for substandard samples. Note that the L-M parameter defined in Eqn 9.22 uses a common (base10) logarithm.

You might also like

- Design of Penstock Pipe For A HydroelectDocument21 pagesDesign of Penstock Pipe For A Hydroelectjanardhana100% (1)

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadNo ratings yet

- Excersises For Essentials and Engineering of MaterialsDocument5 pagesExcersises For Essentials and Engineering of MaterialsBraulio BolañosNo ratings yet

- ME 303 Study Set PDFDocument44 pagesME 303 Study Set PDFFajar RumantoNo ratings yet

- Core Laminations SelectionDocument10 pagesCore Laminations SelectionJavo CoreNo ratings yet

- Gas-Liquid Flow Through Electric Submersible PumpsDocument8 pagesGas-Liquid Flow Through Electric Submersible PumpspicapicNo ratings yet

- AASHTO T315-12 Standard Method of Test For Determining The Rheological Properties of Asphalt Binder Using A Dynamic Shear Rheometer (DSR) - LightDocument33 pagesAASHTO T315-12 Standard Method of Test For Determining The Rheological Properties of Asphalt Binder Using A Dynamic Shear Rheometer (DSR) - LightDanny100% (1)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Problems 4012 PDFDocument8 pagesProblems 4012 PDFjonthemesNo ratings yet

- 307C Excavators Hydraulic System: Baj1-Up Bcm1-UpDocument2 pages307C Excavators Hydraulic System: Baj1-Up Bcm1-Upqwureyquwery67% (3)

- Exercises On Fracture MechanicsDocument33 pagesExercises On Fracture Mechanicsyaswanth199260% (5)

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- TSH5600G Welding SpotDocument6 pagesTSH5600G Welding SpotKrzysztof KołodziejczykNo ratings yet

- TUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignDocument8 pagesTUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignCharles OndiekiNo ratings yet

- CH 08Document8 pagesCH 08Ingi Abdel Aziz Srag0% (1)

- Solve Only For 25 PointsDocument6 pagesSolve Only For 25 PointsOscar HechtNo ratings yet

- Advanced Manufacturing ScienceDocument3 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- MCEN30017 Tutorial 5Document2 pagesMCEN30017 Tutorial 5vsanthanamNo ratings yet

- Fracture Analysis of a Square Steel Tube Using Finite Element MethodDocument9 pagesFracture Analysis of a Square Steel Tube Using Finite Element MethodAlbert AlmeidaNo ratings yet

- SampleqsDocument8 pagesSampleqstommtommNo ratings yet

- R7310305-Design of Machine Members-I2Document4 pagesR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- Tensile and Fracture Properties of X80 Steel Microstructures Relevant To The HazDocument9 pagesTensile and Fracture Properties of X80 Steel Microstructures Relevant To The HazMarcelo Varejão CasarinNo ratings yet

- 3 13Document8 pages3 13pitoulabeteNo ratings yet

- APSC 278 Midterm Feb 13 2013 SolutionsDocument9 pagesAPSC 278 Midterm Feb 13 2013 SolutionsykfungNo ratings yet

- Chemical Engineering Module Fundamentals of Materials Science and Engineering CLASS TEST Problems based QuestionsDocument4 pagesChemical Engineering Module Fundamentals of Materials Science and Engineering CLASS TEST Problems based Questionssherif115040 BueNo ratings yet

- Theoretical Background: 1. Process Under InvestigationDocument48 pagesTheoretical Background: 1. Process Under Investigationgalio28No ratings yet

- Sheet 2Document5 pagesSheet 2Abdalla Mohamed AbdallaNo ratings yet

- Soalan AssignmentDocument1 pageSoalan AssignmentTaha RahimiNo ratings yet

- Design of Machine Members - IDocument8 pagesDesign of Machine Members - IPradeepkumarKatgiNo ratings yet

- Mechanical properties of Ti-6Al-4V alloy with submicrocrystalline structureDocument6 pagesMechanical properties of Ti-6Al-4V alloy with submicrocrystalline structuremghgolNo ratings yet

- 7 4Document8 pages7 4Izwan HassanNo ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

- MET410 Fracture Mechanics Question PaperDocument1 pageMET410 Fracture Mechanics Question PaperAshish KumawatNo ratings yet

- Effect of triaxiality ratio on formability limit and ductile damage evolutionDocument4 pagesEffect of triaxiality ratio on formability limit and ductile damage evolutionEl Ehsan Abinya FatihNo ratings yet

- 1p2 2013 14 Materials Examples Paper 6Document5 pages1p2 2013 14 Materials Examples Paper 6davidsmith24026No ratings yet

- CivE 672 Assignment 1: Flexural design and analysisDocument3 pagesCivE 672 Assignment 1: Flexural design and analysisLennon BaronNo ratings yet

- Dmm1 Mar2007Document8 pagesDmm1 Mar2007prk74No ratings yet

- 9A03708 Modern Manufacturing MethodsDocument4 pages9A03708 Modern Manufacturing MethodssivabharathamurthyNo ratings yet

- Ilm College of Engineering & Technology: Model Exam - Novenber-2015Document2 pagesIlm College of Engineering & Technology: Model Exam - Novenber-2015Deepak V DasNo ratings yet

- Material Removal by Arc Ablation: Robert H SturgesDocument6 pagesMaterial Removal by Arc Ablation: Robert H SturgesinventionjournalsNo ratings yet

- Taller 3 - Propiedades MecánicasDocument2 pagesTaller 3 - Propiedades MecánicasJuan Pablo Rinc�n Ru�zNo ratings yet

- Exam QuestionsDocument2 pagesExam QuestionsFalak VatsNo ratings yet

- Metallurgical Characterization of Electrical Discharge Textured Roll SurfaceDocument8 pagesMetallurgical Characterization of Electrical Discharge Textured Roll Surfacevishalbhojak vishalbhojakNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- European Organization for Nuclear Research Studies Austenitic Steel StabilityDocument8 pagesEuropean Organization for Nuclear Research Studies Austenitic Steel StabilityKhairul MuzafarNo ratings yet

- MDoT Sample Exam PaperDocument22 pagesMDoT Sample Exam PapersamdelcalNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- B.Tech Exam Design of Machine Members QuestionsDocument8 pagesB.Tech Exam Design of Machine Members Questionsprk74No ratings yet

- DME-I Model Paper-3 2Document3 pagesDME-I Model Paper-3 2Srinivas KosuriNo ratings yet

- Explaining Metals Processing and Material PropertiesDocument6 pagesExplaining Metals Processing and Material PropertiesW GangenathNo ratings yet

- Performance Criteria For Dissipative Steel Plate Shear Walls StructuresDocument8 pagesPerformance Criteria For Dissipative Steel Plate Shear Walls StructuresgiorgosantzelidisNo ratings yet

- Effect of Tempering On The Microstructure and Mechanical Properties of Resistance of Spot Welded DP 980 SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Resistance of Spot Welded DP 980 SteelShameekaNo ratings yet

- Mats 3 Sol 3Document7 pagesMats 3 Sol 3Devansh GargNo ratings yet

- Mechanics of Solids exam questionsDocument10 pagesMechanics of Solids exam questionsgalehNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model PaperVinay Karanam100% (1)

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- 15M502Document3 pages15M502CRAZY PIANO PLAYERNo ratings yet

- Mechanics of Materials July 2013Document0 pagesMechanics of Materials July 2013Prasad C MNo ratings yet

- Unit 1 Principles of Electrical Machine DesignDocument8 pagesUnit 1 Principles of Electrical Machine Designbenh-aldj100% (1)

- Cardone 2019Document9 pagesCardone 2019Constanza CornejoNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Quiz 1Document13 pagesQuiz 1radarskiNo ratings yet

- 2011 Remote StartDocument159 pages2011 Remote Startradarski100% (1)

- MSE3094 Test 1 SOLNSDocument5 pagesMSE3094 Test 1 SOLNSradarskiNo ratings yet

- 3094 Solns ECBDocument5 pages3094 Solns ECBradarskiNo ratings yet

- HW #10 Solutions Problem #1)Document5 pagesHW #10 Solutions Problem #1)radarskiNo ratings yet

- MSE3094 Solns 1Document2 pagesMSE3094 Solns 1radarskiNo ratings yet

- 3094 Solns 9Document3 pages3094 Solns 9radarskiNo ratings yet

- MSE3094 HW#8 Solutions April 1, 2011 1) : A) The Data IsDocument5 pagesMSE3094 HW#8 Solutions April 1, 2011 1) : A) The Data IsradarskiNo ratings yet

- 3094 Solns ECADocument5 pages3094 Solns ECAradarskiNo ratings yet

- 3094 Solns 4Document2 pages3094 Solns 4radarskiNo ratings yet

- 3094solns5 1Document3 pages3094solns5 1radarskiNo ratings yet

- 3094 Solns 3Document5 pages3094 Solns 3radarskiNo ratings yet

- 3094 HW ECADocument1 page3094 HW ECAradarskiNo ratings yet

- 3094 Solns 2Document5 pages3094 Solns 2radarskiNo ratings yet

- Thin-Walled Structures: EXAM I: October 4 2010Document7 pagesThin-Walled Structures: EXAM I: October 4 2010radarskiNo ratings yet

- AST 441-Chapter 4-Rev 1Document80 pagesAST 441-Chapter 4-Rev 1samilkolsuz63No ratings yet

- UPVC Technical Data SheetDocument1 pageUPVC Technical Data SheetRND KencanaNo ratings yet

- Abel EM SeriesDocument6 pagesAbel EM SeriesPete PompesNo ratings yet

- Thermodynamical Fundamental ConceptsDocument25 pagesThermodynamical Fundamental ConceptsKshitij PanditNo ratings yet

- The Squeezing Potential of Rocks Around Tunnels Theory and PredictionDocument27 pagesThe Squeezing Potential of Rocks Around Tunnels Theory and PredictionprazNo ratings yet

- Modelling of Laser Welding of Aluminium Using COMSOL MultiphysicsDocument73 pagesModelling of Laser Welding of Aluminium Using COMSOL MultiphysicsAli NasserNo ratings yet

- PhET Gas Laws Simulation ExplainedDocument3 pagesPhET Gas Laws Simulation Explainedx0% (1)

- Counterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmentDocument2 pagesCounterbalance, Relief Compensated Poppet Type Differential Area, Counterclockwise AdjustmenttecnicomanelNo ratings yet

- 4.1 Laboratory Report Ideal Gas LawDocument5 pages4.1 Laboratory Report Ideal Gas Lawalejandro pederioNo ratings yet

- SP 721 V 201Document36 pagesSP 721 V 201Mandar KardekarNo ratings yet

- Viscosity Selection CriteriaDocument4 pagesViscosity Selection CriteriaBhushan VermaNo ratings yet

- Engineering Failure Analysis: Rui Yu, Jinxiang LiuDocument7 pagesEngineering Failure Analysis: Rui Yu, Jinxiang LiuPrasad GharatNo ratings yet

- Design of Purlin No:: 1.geometry Data 1.1 Material PropertiesDocument10 pagesDesign of Purlin No:: 1.geometry Data 1.1 Material PropertiesNieves GuardiianNo ratings yet

- E 21 - 92 R98 Tension Con TemepraturaDocument8 pagesE 21 - 92 R98 Tension Con TemepraturaCESAR GARCIA CASTILLONo ratings yet

- Renewable Energy Engineer Exam SyllabusDocument6 pagesRenewable Energy Engineer Exam SyllabusMishal LimbuNo ratings yet

- AlfaNova U - TurnDocument2 pagesAlfaNova U - Turnevrimk100% (1)

- Chem1101 - Acid, Bases, and Aqueous EquilibriumDocument19 pagesChem1101 - Acid, Bases, and Aqueous EquilibriumCharlotte HooperNo ratings yet

- Solution To Problem 133 Pressure Vessel - Strength of Materials Review at MATHalDocument7 pagesSolution To Problem 133 Pressure Vessel - Strength of Materials Review at MATHalMidas Troy VictorNo ratings yet

- Sample5 PVElite PDFDocument35 pagesSample5 PVElite PDFגרבר פליקסNo ratings yet

- Heat Transfer Assignments 02Document5 pagesHeat Transfer Assignments 02Konark SharmaNo ratings yet

- Disain Kolom-Segui PDFDocument4 pagesDisain Kolom-Segui PDFulalaNo ratings yet

- Chapter 11 - Refrigeration CyclesDocument25 pagesChapter 11 - Refrigeration CyclesPaul RodgersNo ratings yet

- 8 - PressurevalvesDocument68 pages8 - PressurevalvesMohamed ZahranNo ratings yet

- Psychrometric Chart - Us and Si UnitsDocument1 pagePsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914No ratings yet

- Simulation Investigation - Mechanical Equivalent of HeatDocument3 pagesSimulation Investigation - Mechanical Equivalent of Heatpixelhobo0% (1)

- Combined Gas LawDocument5 pagesCombined Gas LawJanelle Ghia RamosNo ratings yet

- Combustión: Análisis Termodinámico, Químico y Transferencia de MasaDocument365 pagesCombustión: Análisis Termodinámico, Químico y Transferencia de MasaPaulo Cæsar SlowNo ratings yet