Professional Documents

Culture Documents

Application of Micro Turbine

Uploaded by

pankaj_pawar89Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Micro Turbine

Uploaded by

pankaj_pawar89Copyright:

Available Formats

Microturbine

Page 1 of 3

Home Solution Company Non Solar Apps

Heat Exchanger Microturbine

Wilson Microturbine

Wilson Solarpower is developing a revolutionary 300 kWe microturbine that uses ceramic components and a unique three-stage turbine to achieve a breakthrough level of electrical efficiency.

Ultra-efficient and clean power generation creates new cost-saving opportunities for many commercial and industrial applications. When considering the many benefits of installing a microturbine energy system, most potential users must achieve an acceptable value proposition based on fuel costs and how efficiently the microturbine converts that fuel to useful energy. Existing microturbines operate at 20% to 35% electrical efficiency and must use waste-heat recovery systems to justify economic feasibility. Only those facilities and process operations that have a need for continuous onsite thermal energy (hot water or hot air) are currently acceptable candidates for existing microturbines. Because the efficiency of a Wilson Microturbine is estimated by experts to be 50%, it does not require heat recovery to provide an attractive economic return. In many regions, the microturbine will be able to generate electric-only power at a cost less than local utility rates. And in some high-rate locations, the microturbine has the potential to generate an annual IRR up to 200%. Using the heat recovered from the microturbine engine to meet onsite hot water and heating/drying needs can create a total system efficiency up to 80% to deliver even greater economic value.

Press Room Contact

The Wilson Microturbine 300 kWE

The Wilson Microturbine will dramatically improve the energy economics of many municipalities, commercial businesses, and industrial processes while also meeting current and planned regulations for harmful emissions. For some installations, the Wilson Microturbine has a sufficiently high electrical efficiency to be a profit center. Other planned applications that could significantly benefit include commercial vehicles and marine engines.

Breakthrough Technologies

The ultra-efficient Wilson Heat Exchanger and the ingenious design of the Wilson Microturbine combine to enable exceptionally high efficiency. The synergy of these technologies is expected to offer least-cost and lowest-emissions electricity for distributedpower installations as well as other industrial and commercial applications with high energy consumption.

ELEVEN-INCH, HIGH-TEMPERATURE, LOW-SPEED CERAMIC ROTORS

Ceramic blades used in a proprietary low-speed turbine permit higher turbine inlet temperatures that significantly increase performance and efficiency. The low-speed and lowpressure design (compared to competing microturbines) reduces stresses in the rotor and

http://www.wilsonturbopower.com/index.php/nonsolarapps/microturbine.html

10/3/2011

Microturbine

Page 2 of 3

extends system life.

UP TO 98% EFFECTIVE, LONG-LIFE, CERAMIC-CORE REGENERATOR

The high heat-transfer efficiency of the Wilson Heat Exchanger results in a lower optimumcycle pressure ratio to permit a lower blade speed of the ceramic rotors. And because the ceramic core of the heat exchanger transfers more heat and permits a much higher operating temperature than conventional metal-core systems, it contributes more thermal energy to preheating the inlet air.

THREE-STAGE TURBINE DESIGN

Rather than using a typical single-stage turbine design, the Wilson Microturbine uses three stages to improve performance and raise the overall microturbine efficiency to 50% well above the performance of any previous microturbine.

The Basis for the Prediction of High Thermal Efficiency in Wilson TurboPower Gas-Turbine Engines

Operation

High turbine-inlet temperature produces high efficiency

The high efficiency of our multistage ceramic-bladed turbine design can produce an attractive

Broad Applications

The Wilson Microturbine will offer new and beneficial energy-management opportunities for many types of businesses and applications requiring economical, dependable, and lowemissions onsite power, either independent or connected to the grid. Some of these applications will include:

http://www.wilsonturbopower.com/index.php/nonsolarapps/microturbine.html

10/3/2011

Microturbine

Page 3 of 3

economic return even in the absence of CHP.

Dr. David Gordon Wilson Professor Emeritus, MIT Chief Scientist, Wilson TurboPower, Inc.

Distributed power generation Onsite generation at point of use Military power systems Transportation propulsion systems High energy-consumption sites High energy-cost markets Facility base-load power Peak shaving Sites isolated from grid power Utility substation generation Combined heat and power (CHP) Environmental and energy service company (EESCO) installations

Copyright 2010 Wilson Solarpower Corporation, All Rights Reserved. | Phone 781.368.1000| Email WSC Login

http://www.wilsonturbopower.com/index.php/nonsolarapps/microturbine.html

10/3/2011

You might also like

- Micro Turbine Generating SystemDocument12 pagesMicro Turbine Generating SystemRajesh CharyNo ratings yet

- Micro TurbineDocument24 pagesMicro Turbinesabale_007No ratings yet

- Microturbines: Within This PageDocument12 pagesMicroturbines: Within This PagekarpakkiNo ratings yet

- What Is A MicroturbineDocument1 pageWhat Is A Microturbinecharanbagh6402No ratings yet

- Micro TurbineDocument22 pagesMicro Turbineravikiranzz12345100% (1)

- Types of Distributed Energy ResourcesDocument13 pagesTypes of Distributed Energy ResourceschaitanyadathNo ratings yet

- Microsteam Power System Distributed Power Generation Microsteam Power System ConfigurationDocument3 pagesMicrosteam Power System Distributed Power Generation Microsteam Power System ConfigurationAlejandro RiveraNo ratings yet

- Micro Grid ConDocument43 pagesMicro Grid ConɌobeɌt CristianoNo ratings yet

- Microturbines Generate Power from WWTP BiogasDocument2 pagesMicroturbines Generate Power from WWTP BiogasKwang Je LeeNo ratings yet

- Reliable Systems and Combined Heat and Power: BstractDocument6 pagesReliable Systems and Combined Heat and Power: BstractLuis Felipe ZuñigaNo ratings yet

- Compact Heat Exchangers For Microturbines: R.K. ShahDocument18 pagesCompact Heat Exchangers For Microturbines: R.K. Shah조기현No ratings yet

- Micro Turbine Power Market Study PDFDocument20 pagesMicro Turbine Power Market Study PDFMal KukuraNo ratings yet

- Fuel Cell Facts: Where Are Fuel Cells Used?Document1 pageFuel Cell Facts: Where Are Fuel Cells Used?Radu Victor TapuNo ratings yet

- Micro Turbine GeneratorDocument21 pagesMicro Turbine GeneratorChandana BJNo ratings yet

- Microgrids Distributed Power GenerationDocument4 pagesMicrogrids Distributed Power GenerationBasilNo ratings yet

- 1.3.4. Energy StorgeDocument3 pages1.3.4. Energy StorgeDr. Narendra AgnihotriNo ratings yet

- Kawasaki v12 300 Por 380Document85 pagesKawasaki v12 300 Por 380wellington freitasNo ratings yet

- Microgrid: A Conceptual Solution: Lasseter@engr - Wisc.eduDocument6 pagesMicrogrid: A Conceptual Solution: Lasseter@engr - Wisc.eduArijit Das AvroNo ratings yet

- Chronological History of Wind Turbine Technology DevelopmentDocument2 pagesChronological History of Wind Turbine Technology DevelopmentDeepak AshokanNo ratings yet

- Electrical UsesDocument5 pagesElectrical UsesPravin KumarNo ratings yet

- Combined Cycle Power PlantDocument29 pagesCombined Cycle Power Plantrajib0403050cuetNo ratings yet

- ABSTRACT-distributed Generation, Defined As Generation Located at or Near The Load Centres, Is BeingDocument11 pagesABSTRACT-distributed Generation, Defined As Generation Located at or Near The Load Centres, Is BeingscrsanNo ratings yet

- Power Generation: Schematic Diagram of Diesel Power StationDocument7 pagesPower Generation: Schematic Diagram of Diesel Power StationsoyabkhanNo ratings yet

- Energy Recovery Technology - 2011Document5 pagesEnergy Recovery Technology - 2011Saibal RoyNo ratings yet

- Elliott Turbine-Generator ConfigurationsDocument8 pagesElliott Turbine-Generator Configurationskishwar999100% (1)

- Microgrid: A Conceptual Solution: Lasseter@engr - Wisc.eduDocument6 pagesMicrogrid: A Conceptual Solution: Lasseter@engr - Wisc.eduShiva KiranNo ratings yet

- Micro Turbine Generator SystemDocument28 pagesMicro Turbine Generator Systembapu26No ratings yet

- Micro-Turbine Generator System: Submitted by Manas Kumar Padhi Electrical & Electronics Engg 0501209277Document28 pagesMicro-Turbine Generator System: Submitted by Manas Kumar Padhi Electrical & Electronics Engg 0501209277Sai PrasadNo ratings yet

- Welcome To The Seminar On MICROTURBINESDocument13 pagesWelcome To The Seminar On MICROTURBINESAnonymous vxNf3n3yMNo ratings yet

- Microturbine Generators: Fig 1.block Diagram of A Microturbine Generator SystemDocument21 pagesMicroturbine Generators: Fig 1.block Diagram of A Microturbine Generator SystemanoopijtNo ratings yet

- Heat Pumps Up To 2000 KWDocument42 pagesHeat Pumps Up To 2000 KWanon_411130333No ratings yet

- CHP PrezentareDocument5 pagesCHP PrezentarelevlarsanNo ratings yet

- Diesel Electric Power PlantsDocument16 pagesDiesel Electric Power PlantsCharlo AngelesNo ratings yet

- 2008 Product CatalogueDocument255 pages2008 Product Cataloguexlongg7No ratings yet

- Hybrid Power SystemDocument31 pagesHybrid Power SystemAnil Kumar67% (9)

- Distributed Generation NotesDocument21 pagesDistributed Generation Notessvuce201175% (4)

- Performance Analysis of Microturbine SystemDocument5 pagesPerformance Analysis of Microturbine SystemNikhil MhatukadeNo ratings yet

- Technical Description Steam EnginesDocument6 pagesTechnical Description Steam Enginescarzante100% (1)

- Power GenerationDocument6 pagesPower Generationveenau 1No ratings yet

- AAYE KONSA SUBJECT PASAND HAI - BaiganDocument13 pagesAAYE KONSA SUBJECT PASAND HAI - Baigankrishna patilNo ratings yet

- Conclusion and Future ScopeDocument4 pagesConclusion and Future Scopeapi-249277319100% (1)

- Distr GenDocument22 pagesDistr GenHari PrasadNo ratings yet

- Lava Final ReportDocument69 pagesLava Final ReportUma MaheshNo ratings yet

- SURYALAKSHMI COTTON MILLS LIMITED 25 MW COAL POWER PLANT DPRDocument122 pagesSURYALAKSHMI COTTON MILLS LIMITED 25 MW COAL POWER PLANT DPRAbhinav TewariNo ratings yet

- PE Assignment RazaDocument6 pagesPE Assignment RazaMuhammad RazatirmaziNo ratings yet

- UNIBLOCK UBTD Diesel Rotary UPS from 400kVA-50MVA maximum power supplyDocument12 pagesUNIBLOCK UBTD Diesel Rotary UPS from 400kVA-50MVA maximum power supplyEnrique RiberoNo ratings yet

- Eco WhisperDocument2 pagesEco WhisperDuvel AragoNo ratings yet

- Eco WhisperDocument2 pagesEco WhisperDuvel AragoNo ratings yet

- Ess CHP UnitsDocument20 pagesEss CHP UnitsanonimppNo ratings yet

- Distributed Generation in Developing CountriesDocument12 pagesDistributed Generation in Developing CountriesZara.FNo ratings yet

- Project Aerolon: "Smooth Sailing To The Future, With Wind"Document18 pagesProject Aerolon: "Smooth Sailing To The Future, With Wind"John E M RaynerNo ratings yet

- Proposal XtiDocument10 pagesProposal XtiTentinay HizkielNo ratings yet

- Wind Powered Turbine Generator.Document2 pagesWind Powered Turbine Generator.Gary Kenp MarasiganNo ratings yet

- COGENERATION: Technology and Economics: Electricity Out Fuel in Heat or Cooling OutDocument4 pagesCOGENERATION: Technology and Economics: Electricity Out Fuel in Heat or Cooling OutShrikant KajaleNo ratings yet

- TECHNOLOGIES FOR BIOMASS CHPDocument13 pagesTECHNOLOGIES FOR BIOMASS CHPRk SkNo ratings yet

- DOE New CapstoneDocument2 pagesDOE New Capstonescribd-dudeNo ratings yet

- Gas Turbine ApplicationDocument15 pagesGas Turbine ApplicationsecahegazyNo ratings yet

- KSB Booklet Relief ValveDocument12 pagesKSB Booklet Relief Valvepankaj_pawar89No ratings yet

- Flowserve Pompe PDFDocument76 pagesFlowserve Pompe PDFrossifrancescoNo ratings yet

- Flowserve Pompe PDFDocument76 pagesFlowserve Pompe PDFrossifrancescoNo ratings yet

- John Crane CouplingDocument8 pagesJohn Crane Couplingel harsal hichamNo ratings yet

- 27 Psychological Reasons Why Good People Do BadDocument57 pages27 Psychological Reasons Why Good People Do Badpankaj_pawar89No ratings yet

- How To Use This Manual: Types G20/G32/G52 Sizes 1080-1300 & 2080-2300 (Page 1 of 10)Document10 pagesHow To Use This Manual: Types G20/G32/G52 Sizes 1080-1300 & 2080-2300 (Page 1 of 10)pankaj_pawar89No ratings yet

- Tyre-Flex Coupling DeatilsDocument19 pagesTyre-Flex Coupling DeatilsDnyanesh BhaleraoNo ratings yet

- Catr 2001 eDocument126 pagesCatr 2001 eSaeedAkbarzadehNo ratings yet

- Catr 2001 eDocument126 pagesCatr 2001 eSaeedAkbarzadehNo ratings yet

- Catr 2001 eDocument126 pagesCatr 2001 eSaeedAkbarzadehNo ratings yet

- Pss 10 5.3 e - 0 PDFDocument2 pagesPss 10 5.3 e - 0 PDFpankaj_pawar89No ratings yet

- 1-Pump Selection Guide by Goulds - Rev - PSG PDFDocument24 pages1-Pump Selection Guide by Goulds - Rev - PSG PDFMelvin MagbanuaNo ratings yet

- Seal WorkingDocument1 pageSeal Workingpankaj_pawar89No ratings yet

- Elastomers - A Beginner's Guide - FlowGeeksDocument4 pagesElastomers - A Beginner's Guide - FlowGeekspankaj_pawar89No ratings yet

- Balance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1Document11 pagesBalance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1FabbroxNo ratings yet

- Diaphragm Compressors: Hermetically Sealed Design for Lubricant-Free CompressionDocument20 pagesDiaphragm Compressors: Hermetically Sealed Design for Lubricant-Free Compressionnelsonsa88100% (1)

- Materials - Viton, Nitrile, Silicone, Polyurethane, EPDM, Fluorosilicone, Teflon, PTFE Filled, PEEK, Nylon, AcetalDocument14 pagesMaterials - Viton, Nitrile, Silicone, Polyurethane, EPDM, Fluorosilicone, Teflon, PTFE Filled, PEEK, Nylon, Acetalpankaj_pawar89No ratings yet

- Elastomers - A Beginner's Guide - FlowGeeksDocument4 pagesElastomers - A Beginner's Guide - FlowGeekspankaj_pawar89No ratings yet

- Williams Fire Foam SYSTEMSDocument46 pagesWilliams Fire Foam SYSTEMSstormer_bw0% (1)

- Alloys: Stainless SteelsDocument2 pagesAlloys: Stainless Steelspankaj_pawar89No ratings yet

- Petrogas Absorption1Document6 pagesPetrogas Absorption1pankaj_pawar89No ratings yet

- A Quick Look at Pneumatic Conveying System BasicsDocument3 pagesA Quick Look at Pneumatic Conveying System BasicsParmasamy Subramani100% (1)

- Material GradesDocument2 pagesMaterial Gradespankaj_pawar89No ratings yet

- Fgcs DescriptionDocument4 pagesFgcs Descriptionpankaj_pawar89No ratings yet

- Platinum 36 PCL Tara FFFDocument2 pagesPlatinum 36 PCL Tara FFFpankaj_pawar89No ratings yet

- Micro PumpDocument16 pagesMicro Pumppankaj_pawar89No ratings yet

- Intercom List January 2012Document6 pagesIntercom List January 2012pankaj_pawar89No ratings yet

- A Mathematical Model and Experimental Investigation On Increasing Starting Altitude of Turbine EngineDocument7 pagesA Mathematical Model and Experimental Investigation On Increasing Starting Altitude of Turbine Enginepankaj_pawar89No ratings yet

- Power GenerationDocument61 pagesPower GenerationKrishanNo ratings yet

- Sheet 16 U-820 Sulfur Recovery Unit: Technical ServicesDocument1 pageSheet 16 U-820 Sulfur Recovery Unit: Technical ServicesAsad PatelNo ratings yet

- Energy Crisis in PakistanDocument7 pagesEnergy Crisis in PakistanAkashKhanSwatiNo ratings yet

- VVER-1500 Nuclear Reactor Safety and CompetitivenessDocument9 pagesVVER-1500 Nuclear Reactor Safety and Competitivenessadhikosh002No ratings yet

- For Pakistan & Gulf EconomistDocument3 pagesFor Pakistan & Gulf EconomistShobyjafriNo ratings yet

- Marinduque State College: School of EngineeringDocument4 pagesMarinduque State College: School of EngineeringLEONEL SOTTONo ratings yet

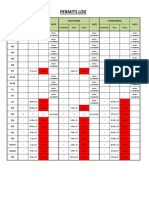

- Mawaqif Sector Permit LogDocument9 pagesMawaqif Sector Permit LogburereyNo ratings yet

- IEC TR Nanotechnology LRDocument106 pagesIEC TR Nanotechnology LRMario Daniel ConejoNo ratings yet

- Mec257 61 20160062Document20 pagesMec257 61 20160062Ahmed HazemNo ratings yet

- Lech Valdez - Research On Tidal EnergyDocument27 pagesLech Valdez - Research On Tidal EnergyStephany PolinarNo ratings yet

- PPTDocument17 pagesPPTOmkarNo ratings yet

- Renewable Energy in Hawai I: A Comparative Analysis of Wind, Solar, and Geothermal Energy ResourcesDocument19 pagesRenewable Energy in Hawai I: A Comparative Analysis of Wind, Solar, and Geothermal Energy ResourcesHPR News100% (1)

- Excel Furnace (Recovered)Document25 pagesExcel Furnace (Recovered)Bunga Rajhana Ragil GayatriNo ratings yet

- Dual Fuel EngineDocument14 pagesDual Fuel Enginesrinivasareddy59223950% (4)

- 2018-2027 Luelco PSPP PDFDocument21 pages2018-2027 Luelco PSPP PDFEveinegerrssNo ratings yet

- SCK Cai548756Document152 pagesSCK Cai548756Adis Sarac0% (1)

- Natural Gas Processing Over ViewDocument5 pagesNatural Gas Processing Over ViewsatishchemengNo ratings yet

- Cogeneration Application Considerations: GE Power GenerationDocument24 pagesCogeneration Application Considerations: GE Power GenerationaustintanNo ratings yet

- Cooling of Turbo AlternatorsDocument15 pagesCooling of Turbo AlternatorsRam Balaji0% (1)

- Certificate Ts Iec 62804-1 Pid-Free Rec TP Pe NP Aa CombinedDocument2 pagesCertificate Ts Iec 62804-1 Pid-Free Rec TP Pe NP Aa CombinedWharren GuerreroNo ratings yet

- Introduction To Geothermal Comfort Systems Dave Buss GAOI Northern Meeting 10 30 13Document83 pagesIntroduction To Geothermal Comfort Systems Dave Buss GAOI Northern Meeting 10 30 13Md Shane KarimiNo ratings yet

- Heat Rate Test / Performance Test of Power PlantsDocument6 pagesHeat Rate Test / Performance Test of Power PlantsSumaira KhanNo ratings yet

- Bu 2 Prelim LessonDocument78 pagesBu 2 Prelim LessonJanryLibrandoNo ratings yet

- Rooftop Solar Photovoltaic For CSIR-NPL at New Delhi: A Case StudyDocument6 pagesRooftop Solar Photovoltaic For CSIR-NPL at New Delhi: A Case StudyRahul SharmaNo ratings yet

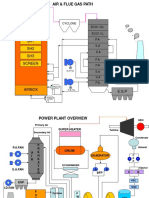

- Air & Flue Gas Path CFBCDocument2 pagesAir & Flue Gas Path CFBCJAY PARIKHNo ratings yet

- SGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHDocument3 pagesSGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHjeromejoeNo ratings yet

- NCEF Brief - Post - BE - 2017-18Document6 pagesNCEF Brief - Post - BE - 2017-18aakashNo ratings yet

- Consumer AwarenessDocument11 pagesConsumer AwarenessJuhil Susan'naNo ratings yet

- Non-Conventional Energy Resources: MultidisciplinaryDocument1 pageNon-Conventional Energy Resources: MultidisciplinaryvvNo ratings yet

- Refresher Course Material - 1.0 PDFDocument268 pagesRefresher Course Material - 1.0 PDFajithkrak100% (1)