Professional Documents

Culture Documents

DOE - Inner-Outer Arrays

Uploaded by

chit catOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DOE - Inner-Outer Arrays

Uploaded by

chit catCopyright:

Available Formats

STATGRAPHICS Rev.

7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 1

Design of Experiments Inner/Outer Arrays (Legacy Procedure)

Summary

The Inner and Outer Arrays selection on the Create Design menu creates experimental designs

in which two types of factors are varied:

- controllable factors that the experimenter can manipulate both during the experiment and

during production.

- noise factors that can be manipulated during the experiment but are normally

uncontrollable.

The goal of the designs is to find levels of the controllable factors where the response variables

are relatively insensitive to changes in the noise factors. Structurally, the experiment consists of

two designs: an inner array in which the controllable factors are varied, and an outer array in

which the noise factors are varied.

As pioneered by Genichi Taguchi, this emphasis on robustness in parameter design and

reduction in process variability is very important in developing a product which is capable of

meeting specifications on a daily basis.

Example

The example described in this documentation comes from Myers and Montgomery (2002). They

describe an experiment performed to help reduce the defect rate of a soldering process used in

the manufacture of printed circuit boards. The goal of the study was to find a combination of 5

controllable factors that would minimize the rate of solder defects. Those 5 factors are shown

below with the region over which they were to be studied:

Controllable Factor Low High Units

temperature 480 510 F

speed 7.2 10 ft/min

wave height 0.5 0.6 in

preheat temperature 150 200 F

flux density 0.9 1.0 degrees

As part of the study, 3 noise factors were also varied in order to judge the sensitivity of the defect

rate to uncontrollable fluctuations. Those factors and the range over which they were to be varied

is shown below:

Noise Factor Low High Units

solder -5 5 degrees

conveyor -0.2 0.2

assembly 1 2

In production situations, the noise factors would not be controlled.

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 2

Sample StatFolio: doe innerouter.sgp

Design Creation

The designs proposed by Taguchi are created by selecting Create Design from the design of

experiments menu and completing several dialog boxes.

Dialog #1 Design Type

The first dialog box displayed during design creation is shown below:

- Design Class: type of design to be created.

- No. of Response Variables: the number of response variables Y that will be measured during

each experimental run. This number may range from 1 to 16.

- No. of Control Factors: the number of experimental factors X that will be varied from run to

run in the inner array. These are factors which can normally be controlled and for which

optimal levels are desired. The number of controllable experimental factors may range from

2 to 8.

- No. of Noise Factors: the number of experimental factors X that will be varied from run to

run in the outer array. These are factors which cannot normally be controlled but tend to

introduce variability into the process. The number of noise factors may range from 0 to 11.

(Note that noise factors are not required. If none are provided, the design will consist of only

an inner array. In such cases, certain options will not be available.)

- Comment: a comment to appear on the output from the analysis procedures.

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 3

Dialog #2 Response Variables

The second dialog box requests information about each of the response variables:

Click on the numbers 1, 2, 3, , one at a time and enter the following information for each

response variable in the experiment:

- Name - a name for each response containing up to 32 characters.

- Units or comment - an optional label or comment of up to 64 characters to be included

on the experiment worksheet.

Dialog #3 Design Selection

The third dialog box is used to specify the types of designs to be used for the inner and outer

arrays:

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 4

Two designs must be specified:

1. Control Design (Inner Array) - a design in which the control factors are varied. In the

above dialog box, the design selected is an L8 design. This is an orthogonal array with 8

runs. The notation 2^7 indicates that it is capable of studying up to 7 factors or

interactions at 2 levels each. In fact, the design is equivalent to a 2-level fractional

factorial design in 8 runs.

2. Noise Design (Outer Array) - a design in which the noise factors are varied. The design

selected for the noise factors is run at each combination of the control factors. In this

case, a 4 run design (L4) has been selected. It is a 2^3 and thus capable of studying up to

3 main effects or interactions, each at 2 levels.

In general, the number after the L indicates the number of runs in the design. Notation such as

2^1x5^11 indicates that 1 factor may be studied at 2 levels and up to 11 factors may be studied at

5 levels each. Either or both of the designs may be run in random order.

Details regarding orthogonal arrays may be found in books such as Logothetis and Wynn (1994).

The notation typically used for these designs is similar to the following for the L8 design:

Column

Run

1 2 3 4 5 6 7

1 1 1 1 1 1 1 1

2 1 1 1 2 2 2 2

3 1 2 2 1 1 2 2

4 1 2 2 2 2 1 1

5 2 1 2 1 2 1 2

6 2 1 2 2 1 2 1

7 2 2 1 1 2 2 1

8 2 2 1 2 1 1 2

In the above table, 1 indicates that a factor will be run at its first or low level, while 2 indicates

that the factor will be run at its second or high level. The design can accommodate up to 7

factors if no interactions are to be estimated. If less than 7 factors are to be varied (as in the

current case), then the unused columns may be assigned to interactions. Actually, since the

above design is resolution III, two-factor interactions are confounded with themselves and with

main effects. Taguchi typically relies on the experimenter being able to identify ahead of time

which interactions might be present, or else all interactions may be assumed to be nonexistent.

The outer array in the example is an L4, which can accommodate up to 3 factors at 2 levels each:

Column

Run

1 2 3

1 1 1 1

2 1 2 2

3 2 1 2

4 2 2 1

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 5

At each of the 8 settings in the inner array, 4 experiments will be done while varying the noise

factors according to the inner array. The total number of experiments to be performed is

consequently 8 x 4 = 32.

Dialog #3 Column Assignments

Once the orthogonal arrays have been created, a dialog box is displayed through which the

control and noise factors may be assigned to different columns of the orthogonal arrays:

Initially, STATGRAPHICS suggests column assignments that permit interactions amongst the

first several factors to be estimated if desired. For example, it suggests the following

assignments for the inner array:

Column 1 - factor A

Column 2 - factor B

Column 4 - factor C

Column 7 - factor D

Column 6 - factor E

This leaves columns 3 and 5 unassigned. However, the interactions are such that the last 2

columns may be used to estimate:

Column 3 - interaction AB

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 6

Column 5 - interaction AC

Actually, many other interactions could be estimated by columns 3 and 5 (and also the other

columns). For details on each of the available designs and which interactions are estimable by

which columns, refer to a book on Taguchi methods such as Logothetis and Wynn (1994).

Dialog #4 Experimental Factors

The fourth dialog box requests information about each of the experimental factors:

Click on the letters A, B, C, , one at a time and enter the following information for each

experimental factor in the design:

- Name - since factor names become column names in a standard STATGRAPHICS

datasheet, each name may have up to 32 characters and contain any character other than

symbols used in algebraic expressions.

- Units or comment - an optional label or comment of up to 64 characters to be included

on the experiment worksheet.

- Labels button labels are assigned to each level of the factors by pressing the Labels

button and entering information on the following dialog box:

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 7

If valid numeric values are entered in increasing order, the factor will be treated as

continuous. Otherwise, it will be treated as non-continuous. This affects the type of

analysis performed after the data is collected. If the Labels button is not pressed, the

numbers 1, 2, will be used to represent the levels and the factor will be assumed to be

continuous.

The following table shows the information for the current example:

Factor Low High Units

temperature 480 510 degrees F

speed 7.2 10 ft/min

wave height 0.5 0.6 inches

preheat temp 150 200 degrees F

flux density 0.9 1.0 degrees

solder -5 5 degrees

conveyor -0.2 0.2

assembly 1 2

The first 5 factors are the control factors. The last 3 are the noise factors.

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 8

Design Attributes

Once the dialog boxes have been completed, the Design Attributes window is displayed:

Inner/Outer Arrays Design Attributes

Design class: Inner/Outer Arrays

File name: <Untitled>

Comment: Myers and Montgomery soldering example

Base Design

Number of control factors: 5

Number of noise factors: 3

Number of responses: 1

Number of runs in inner array: 8

Number of runs in outer array: 4

Randomized: Outer array only

Factors Levels Units

temperature 2 degrees F

speed 2 ft/min

wave height 2 inches

preheat temperature 2 degrees F

flux density 2 degrees

solder 2 degrees

conveyor 2

assembly 2

Responses Units

defects DPM

It contains a summary of the input data.

Worksheet

The experimental runs are entered into the datasheet automatically. They may also be displayed

in the Worksheet, a portion of which is shown below:

Worksheet for solder.sfx - Myers and Montgomery soldering example

run block temperature speed wave height preheat temperature flux density solder conveyor assembly defects

(degrees F) (ft/min) (inches) (degrees F) (degrees) (degrees) (DPM)

1 1 480.0 7.2 0.5 150.0 0.9 -5.0 0.2 2.0

2 1 480.0 7.2 0.5 150.0 0.9 5.0 -0.2 2.0

3 1 480.0 7.2 0.5 150.0 0.9 5.0 0.2 1.0

4 1 480.0 7.2 0.5 150.0 0.9 -5.0 -0.2 1.0

5 2 480.0 7.2 0.6 200.0 1.0 -5.0 0.2 2.0

6 2 480.0 7.2 0.6 200.0 1.0 5.0 -0.2 2.0

7 2 480.0 7.2 0.6 200.0 1.0 -5.0 -0.2 1.0

8 2 480.0 7.2 0.6 200.0 1.0 5.0 0.2 1.0

9 3 480.0 10.0 0.5 200.0 1.0 -5.0 0.2 2.0

10 3 480.0 10.0 0.5 200.0 1.0 5.0 0.2 1.0

11 3 480.0 10.0 0.5 200.0 1.0 5.0 -0.2 2.0

12 3 480.0 10.0 0.5 200.0 1.0 -5.0 -0.2 1.0

Each run in the inner array is shown with a different block number. Within each block are the 4

runs in the outer array, where the noise factors are changed.

The sample data has been saved in a file called solder.sfx, together with the response data.

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 9

Analyzing the Data

After the results of the experimental runs have been entered, Analyze Data can be selected from

the DOE menu. A dialog box will be displayed requesting the column containing the response to

be analyzed and the performance measure to be modeled:

The performance measure specifies the type of statistic that will be calculated for each run in the

inner array. Various measures are available, including:

- Mean - calculates the mean value Y for each run in the inner array. In the current

example, 8 means would be calculated, one for each block of four runs. The analysis

would then show the effect of each of the control factors on the mean defect rate.

- Log Variance - calculates ln(s

2

) for each run in the outer array. This gives a direct

measurement of the variability at each set of conditions and shows the effect of each

control factor on the variance. The log transformation is needed to stabilize the

variability of the measure, since the standard error of a variance estimate grows as its

mean value grows.

- Signal-to-Noise Ratio - Taguchi suggested calculating

) log( 10

2

1

s SNR

T

= (1)

for situations where the goal of the experiment is to hit a particular target value, and

when the mean and variance of the process can be altered independently. This is

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 10

equivalent to the measure discussed immediately above, except that it differs in sign.

Some analysts prefer this measure since large values are preferable to small ones, in line

with normal interpretations of a signal-to-noise ratio.

- Signal-to-Noise Ratio (Target Value) - For situations where the goal is to hit a target

value but the standard deviation of the response is related to its mean, Taguchi proposed

|

|

.

|

\

|

=

2

2

log 10

2

s

Y

SNR

T

(2)

This is related to the common coefficient of variation Y s / , except it is again defined so

that larger values are preferable. In both this case and the case immediately above, the

goal is to find a tuning factor that affects the mean (so that the target value may be hit)

but has little effect on the SNR.

- Signal-to-Noise Ratio (Larger the Better) - For situations in which the response is to be

maximized, Taguchi proposed

=

|

|

.

|

\

|

=

n

i

i

L

ny

SNR

1

2

1

log 10 (3)

- Signal-to-Noise Ratio (Smaller the Better) - For situations in which the response is to

be minimized, Taguchi proposed

=

|

|

.

|

\

|

=

n

i

i

S

n

y

SNR

1

2

log 10 (4)

- Noise Factors - When selected, an analysis is performed on the noise factors only. Each

run of the inner array is treated as one replicate of the outer design, with blocking factors

allowing the means of each block to vary.

- Crossed Array - When selected, the individual measurements are analyzed as a standard

response surface design involving all of the control and noise factors.

It should be noted that for all of the signal to noise ratios, larger values correspond to preferable

conditions. Although much has been said about the utility of the ratios that Taguchi proposes,

they do provide a simple way of incorporating the mean and variance into a single performance

measure. An excellent critique of the various signal-to-noise ratios is given by Myers and

Montgomery (2002), together with a general discussion of variance minimization experiments.

Analysis Summary

When the Analyze Design dialog box is completed, STATGRAPHICS invokes one of three

procedures, depending on how the control factors were defined and what type of design was

selected:

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 11

1. If all of the control factors are continuous and there are only 2 levels of all of the factors,

the standard analysis for Screening Designs is invoked.

2. If all of the control factors are continuous but there are 3 or more levels for at least one of

the factors, the standard analysis for Response Surface Designs is invoked.

3. If any of the control factors are not continuous, the Multifactor ANOVA procedure is

invoked.

This gives the analyst the most appropriate plots and analyses for each situation.

Since the goal of the current experiment is to reduce the rate of defects, the SNR for Smaller the

Better is a natural choice. From the standardized Pareto chart, it will be noted that all but one of

the factors appears to be statistically significant:

Standardized Pareto Chart for defects (SN: smaller)

0 4 8 12 16 20 24

Standardized effect

B:speed

D:preheat temperature

C:wave height

A:temperature

E:flux density +

-

Flux density appears to have the largest effect on the defect rate. To illustrate the effects, the

Main Effects Plot is particularly effective:

Main Effects Plot for defects (SN: smaller)

-49

-47

-45

-43

-41

d

e

f

e

c

t

s

(

S

N

:

s

m

a

l

l

e

r

)

temperature

speed

wave height

preheat temperature

flux density

Low flux density and high temperature appear to yield a high SNR.

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 12

The Optimization pane will determine the optimal settings for each factor:

Optimize Response

Goal: maximize defects (SN: smaller)

Optimum value = -39.6893

Factor Low High Optimum

temperature 480.0 510.0 510.0

Speed 7.2 10.0 7.2

wave height 0.5 0.6 0.5

Preheat temperature 150.0 200.0 200.0

flux density 0.9 1.0 0.9

The rightmost column displays the best settings of the controllable factors over the experimental

region. At the indicated settings, the value of

=

|

|

.

|

\

|

=

n

i

i

S

n

y

SNR

1

2

log 10 is estimated to equal

39.7.

Interactions

By default, STATGRAPHICS chose to estimate a first-order model with only main effects. If

desired, second-order interactions can be included by selecting Analysis Options and setting

Maximum Order Effect to 2:

The Pareto chart then takes the following form:

STATGRAPHICS Rev. 7/24/2009

2009 by StatPoint Technologies, Inc. DOE Inner/Outer Arrays - 13

Pareto Chart for defects (SN: smaller)

Effect

+

-

0 1 2 3 4 5 6

AC+BD

AB+CD

B:speed-CE

D:preheat temperature-AE

C:wave height-BE

A:temperature-DE

E:flux density-AD-BC

Each main effect is shown together with the confounding interactions. In addition, two additional

effects have been estimated, each consisting of the sum of 2 interactions. As indicated when the

design was constructed, neither AB nor AC is confounded with any main effect. Had the user

expected ahead of time that two interactions were likely to exist, it would have been beneficial to

assign labels to the factors so that they corresponded if possible to AB and AC.

You might also like

- Ejemplos DOEDocument63 pagesEjemplos DOEFrancisco HernandezNo ratings yet

- Frequency of Simulation Results File WritingDocument4 pagesFrequency of Simulation Results File WritingpotriNo ratings yet

- DOE Wizard - Multilevel Factorial DesignsDocument11 pagesDOE Wizard - Multilevel Factorial DesignsAnonymous FZNn6rBNo ratings yet

- System Model H (T) Inlet E (T) Outlet E H (T) System Model H (T) Inlet E (T) Outlet E H (T)Document19 pagesSystem Model H (T) Inlet E (T) Outlet E H (T) System Model H (T) Inlet E (T) Outlet E H (T)WillykateKairuNo ratings yet

- What Is A Taguchi Design (Also Called An Orthogonal Array) ?Document11 pagesWhat Is A Taguchi Design (Also Called An Orthogonal Array) ?Nyssa SanNo ratings yet

- Utomatic Ynamic Ncremental Onlinear Nalysis: ADINA System 8.7 Release NotesDocument25 pagesUtomatic Ynamic Ncremental Onlinear Nalysis: ADINA System 8.7 Release NotesCarlos Gustavo MéndezNo ratings yet

- Soil Nail ManualDocument63 pagesSoil Nail ManualGnabBangNo ratings yet

- Battery PDFDocument17 pagesBattery PDFTania IbarraNo ratings yet

- Control Engineering LAb 7Document17 pagesControl Engineering LAb 7johnyrock05No ratings yet

- dx10 02 3 Gen2factor PDFDocument18 pagesdx10 02 3 Gen2factor PDFELFER OBISPO GAVINONo ratings yet

- Robust Design Taguchi Module 808Document17 pagesRobust Design Taguchi Module 808moragorNo ratings yet

- Displaying The Alias Structure For A Taguchi DesignDocument6 pagesDisplaying The Alias Structure For A Taguchi DesignaliNo ratings yet

- 20 Guided-3D Knuckle Pin JointDocument19 pages20 Guided-3D Knuckle Pin Jointashoku2No ratings yet

- Ansys - MEMS Lab IntroductionDocument9 pagesAnsys - MEMS Lab IntroductionJag JagNo ratings yet

- MOde Frontier TutorialDocument35 pagesMOde Frontier Tutorialgurpinder.rajgarh1331No ratings yet

- ECE238L - FALL 2015 Lab 0: Design and Simulate GatesDocument37 pagesECE238L - FALL 2015 Lab 0: Design and Simulate GatesazonegrpzNo ratings yet

- TH Quick Start GuideDocument11 pagesTH Quick Start GuideostogradskiNo ratings yet

- Example 1. Analysis of 2D Frame: DescriptionDocument27 pagesExample 1. Analysis of 2D Frame: DescriptionAngel CiarbonettiNo ratings yet

- Its413 Assignment TemplateDocument2 pagesIts413 Assignment Templateابتهاج عبدالسلامNo ratings yet

- Introduction To Taguchi Method PDFDocument6 pagesIntroduction To Taguchi Method PDFShikhar KumarNo ratings yet

- Ecen 248 Lab 11 ReportDocument4 pagesEcen 248 Lab 11 Reportapi-241454978No ratings yet

- Ee201 TestbenchDocument19 pagesEe201 TestbenchSamNo ratings yet

- A Differential Evolution Based Nonlinear Least Squares Fortran 77 ProgramDocument13 pagesA Differential Evolution Based Nonlinear Least Squares Fortran 77 ProgramSudhanshu K Mishra100% (5)

- Lab Manual 6EE7 CsDocument55 pagesLab Manual 6EE7 Cs9351399193inNo ratings yet

- Tutorial 29 Application of Joint NetworksDocument17 pagesTutorial 29 Application of Joint Networksrongow titoNo ratings yet

- 8 NFT Application GuideDocument57 pages8 NFT Application GuideSuleman JahangirNo ratings yet

- SAGParam OpenDocument129 pagesSAGParam OpenCristian Riquelme ContrerasNo ratings yet

- Communicatin System 1 Lab Manual 2011Document63 pagesCommunicatin System 1 Lab Manual 2011Sreeraheem SkNo ratings yet

- Taguchi QeDocument36 pagesTaguchi QeEmad KhanNo ratings yet

- FEAP - A Finite Element Analysis Program: Version 8.3 Example ManualDocument58 pagesFEAP - A Finite Element Analysis Program: Version 8.3 Example ManualBrandon BuchnaNo ratings yet

- MPI Lab ManualDocument68 pagesMPI Lab Manualsansure100% (1)

- GNU Radio TutorialsDocument91 pagesGNU Radio TutorialsHassaan AhmadNo ratings yet

- OPNET Modeler - Introduction LTE SimulationDocument16 pagesOPNET Modeler - Introduction LTE SimulationAnonymous TTVlXoNo ratings yet

- Design of Experiments Via Taguchi Methods Orthogonal ArraysDocument21 pagesDesign of Experiments Via Taguchi Methods Orthogonal ArraysRohan ViswanathNo ratings yet

- PR3 PDFDocument4 pagesPR3 PDFTanmay SapkalNo ratings yet

- UnitTesting TechniquesDocument53 pagesUnitTesting TechniquesBurlacu LucianNo ratings yet

- Network Slab RecordDocument50 pagesNetwork Slab RecordSandeep V GowdaNo ratings yet

- Nonmem Users Guide Introduction To Nonmem 7 Robert J. Bauer ICON Development Solutions Ellicott City, Maryland February 26, 2010Document61 pagesNonmem Users Guide Introduction To Nonmem 7 Robert J. Bauer ICON Development Solutions Ellicott City, Maryland February 26, 2010gshgssgNo ratings yet

- 7209 English IranArzeDocument33 pages7209 English IranArzeTatiek AndajaniNo ratings yet

- Experimental Design Process: 1) Define Problem(s) 5) Conduct Experiment & Collect DataDocument15 pagesExperimental Design Process: 1) Define Problem(s) 5) Conduct Experiment & Collect DataMark ShusterNo ratings yet

- Ansys Lab Manual 2020-2Document36 pagesAnsys Lab Manual 2020-2Getresponsespatil 1No ratings yet

- Taguchi's Design of Experiments and Selection of Orthogonal ArrayDocument22 pagesTaguchi's Design of Experiments and Selection of Orthogonal ArrayBhavin DesaiNo ratings yet

- RES3DMOD Ver. 2.14: For Windows 95/98/Me/2000/NTDocument9 pagesRES3DMOD Ver. 2.14: For Windows 95/98/Me/2000/NTlutte88No ratings yet

- Ansys Basic Analysis GuideDocument237 pagesAnsys Basic Analysis GuideUmesh Vishwakarma100% (1)

- Documents - Ecet380 Ilab1 Key v1.1Document15 pagesDocuments - Ecet380 Ilab1 Key v1.1Arnab NiloyNo ratings yet

- Ijcet: International Journal of Computer Engineering & Technology (Ijcet)Document8 pagesIjcet: International Journal of Computer Engineering & Technology (Ijcet)IAEME PublicationNo ratings yet

- Tensile Test ME 272 Experiment #1: ObjectiveDocument7 pagesTensile Test ME 272 Experiment #1: ObjectiveBia MughalNo ratings yet

- Res 1 DDocument7 pagesRes 1 DDeokumar Lachhman100% (1)

- CST Patch AntennaDocument15 pagesCST Patch AntennaJahedul IslamNo ratings yet

- General Factorial Tutorial (Part 1 - Categoric Treatment) : Introduction - A Case Study On Battery LifeDocument11 pagesGeneral Factorial Tutorial (Part 1 - Categoric Treatment) : Introduction - A Case Study On Battery LifeIvan CaNo ratings yet

- Design of Experiments Via Taguchi Methods - Orthogonal Arrays - ControlsWikiDocument11 pagesDesign of Experiments Via Taguchi Methods - Orthogonal Arrays - ControlsWikiRachel HillNo ratings yet

- Black Box Testing ExamplesDocument9 pagesBlack Box Testing ExamplesMasud RannaNo ratings yet

- Application of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing OperationDocument7 pagesApplication of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing Operationwww.irjes.comNo ratings yet

- Simulated Annealing For The Optimisation of A Constrained Simulation Model in ExcellDocument19 pagesSimulated Annealing For The Optimisation of A Constrained Simulation Model in Excelllcm3766lNo ratings yet

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- Practical Design of Experiments: DoE Made EasyFrom EverandPractical Design of Experiments: DoE Made EasyRating: 4.5 out of 5 stars4.5/5 (7)

- BSI Singapore Training Schedule 2017 With Booking LinksDocument3 pagesBSI Singapore Training Schedule 2017 With Booking Linkschit catNo ratings yet

- Risk Management For Medical Devices Webinar SlidesDocument35 pagesRisk Management For Medical Devices Webinar Slideschit cat100% (1)

- ISO 13485 2016 - Vs - FDA 21 CRF Part 820Document3 pagesISO 13485 2016 - Vs - FDA 21 CRF Part 820chit catNo ratings yet

- It Security For Medical DevicesDocument3 pagesIt Security For Medical Deviceschit catNo ratings yet

- Iso 13485 and FDA CGMPDocument3 pagesIso 13485 and FDA CGMPchit catNo ratings yet

- Agathon Shaft TolerancesDocument1 pageAgathon Shaft Toleranceschit catNo ratings yet

- Quality Control in Measurements: Tom Colella CLAS Goldwater Environmental LabDocument20 pagesQuality Control in Measurements: Tom Colella CLAS Goldwater Environmental Labchit catNo ratings yet

- Comparison of ISO9001:2008 To AS91000 / AS9110 / AS9120Document5 pagesComparison of ISO9001:2008 To AS91000 / AS9110 / AS9120chit catNo ratings yet

- BS Iso594-1 1986Document25 pagesBS Iso594-1 1986chit catNo ratings yet

- Excel GD&T SymbolsDocument2 pagesExcel GD&T Symbolschit cat100% (1)

- AS9100D Clause by ClauseDocument37 pagesAS9100D Clause by Clausechit cat100% (5)

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- eDocument255 pagesechit catNo ratings yet

- Pareto AnalysisDocument6 pagesPareto Analysischit catNo ratings yet

- One Way AnovaDocument23 pagesOne Way Anovachit cat100% (1)

- 11 1 GohDocument11 pages11 1 Gohchit catNo ratings yet

- Analysis Procedures: Data Input Dialog BoxesDocument12 pagesAnalysis Procedures: Data Input Dialog Boxeschit catNo ratings yet

- Market Research Final Revision Semester B 2013Document32 pagesMarket Research Final Revision Semester B 2013Chip choiNo ratings yet

- BRL R. 1344Document77 pagesBRL R. 1344Aleem Ullah CheemaNo ratings yet

- A Critical Review of Stephen Hawking's Godless Universe by Junaid HasanDocument146 pagesA Critical Review of Stephen Hawking's Godless Universe by Junaid HasanZaky MuzaffarNo ratings yet

- 1997 El Rol de Los Sesgos en Las Negociaciones PDFDocument46 pages1997 El Rol de Los Sesgos en Las Negociaciones PDFSergio OrdóñezNo ratings yet

- 27.09.2013 RM QBDocument64 pages27.09.2013 RM QBRahul Ghosale0% (1)

- Econometric CausalityDocument55 pagesEconometric CausalityKarim Ait ChabaneNo ratings yet

- Kinds of Research Across Fields: Grade 9Document11 pagesKinds of Research Across Fields: Grade 9Rosalyn RayosNo ratings yet

- Weerakkody Research GlossaryDocument12 pagesWeerakkody Research GlossarysamarNo ratings yet

- Research HirayaDocument16 pagesResearch HirayaMich Rose JovNo ratings yet

- Teacher Notes Cycles (STD)Document46 pagesTeacher Notes Cycles (STD)Bernard ChanNo ratings yet

- Historical Background of Educational PsychologyDocument18 pagesHistorical Background of Educational Psychologyburhan AhmedNo ratings yet

- MODULE 1 - Introduction To Research - Research Jargons (Lesson Plan)Document6 pagesMODULE 1 - Introduction To Research - Research Jargons (Lesson Plan)Bienne JaldoNo ratings yet

- Greenhalgh (2009) Evidence Based PolicymakingDocument16 pagesGreenhalgh (2009) Evidence Based PolicymakingMartin Malakian ObrekeNo ratings yet

- School of Mechanical and Manufacturing EngineeringDocument15 pagesSchool of Mechanical and Manufacturing EngineeringEkoms GamingNo ratings yet

- Novelty Complexity and Hedonic ValueDocument8 pagesNovelty Complexity and Hedonic ValueRicardo MansillaNo ratings yet

- Semi-Supervised Self-Training of Object Detection ModelsDocument8 pagesSemi-Supervised Self-Training of Object Detection ModelsHarsh DiwakarNo ratings yet

- Memory and Research Methods Unit Outline DRDocument3 pagesMemory and Research Methods Unit Outline DRBaris DasNo ratings yet

- Res12 Module 2Document20 pagesRes12 Module 2Yanchen KylaNo ratings yet

- Practical Research 2: Quarter 1 - Module 1Document37 pagesPractical Research 2: Quarter 1 - Module 1bernadette domoloanNo ratings yet

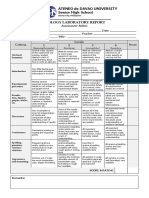

- Rubric For Laboratory ActivityDocument1 pageRubric For Laboratory ActivityJohn De BritoNo ratings yet

- Science 7 - Summative Test 1st QuarterDocument4 pagesScience 7 - Summative Test 1st QuarterEsther Mae Ann Trugillo0% (1)

- Implementation of Chemistry Practical Work in Senior Secondary Schools in Ogun State, NigeriaDocument16 pagesImplementation of Chemistry Practical Work in Senior Secondary Schools in Ogun State, NigeriaBamigboye BabatundeNo ratings yet

- 1 A Student Carries Out An Experiment To Investigate The Relationship Between Current andDocument5 pages1 A Student Carries Out An Experiment To Investigate The Relationship Between Current andneoo1No ratings yet

- Sawyer - Decision Performance and Diversity StructureDocument15 pagesSawyer - Decision Performance and Diversity StructureBlauwe BoonNo ratings yet

- FR1 Chem 28.1 Expt 1Document11 pagesFR1 Chem 28.1 Expt 1Marrod CruzNo ratings yet

- Social Psychology Notes - Edexcel (IAL) Psychology A-LevelDocument18 pagesSocial Psychology Notes - Edexcel (IAL) Psychology A-LevelAyse Kerim100% (1)

- AP Psychology Midterm ReviewDocument4 pagesAP Psychology Midterm ReviewPostcardsFromAlbertaNo ratings yet

- CENG566L Syllabus Machine Learing Lab: Course DescriptionDocument3 pagesCENG566L Syllabus Machine Learing Lab: Course DescriptionMahdi BraitehNo ratings yet

- Quantitative ResearchDocument26 pagesQuantitative ResearchAntonio Jarligo Compra50% (2)

- Criteria For Science SBA Updated-1Document20 pagesCriteria For Science SBA Updated-1rudrasankar2007No ratings yet