Professional Documents

Culture Documents

Performance Ratio

Uploaded by

ShaileshnartiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Ratio

Uploaded by

ShaileshnartiCopyright:

Available Formats

Technical Information

Performance ratio

Quality factor for the PV plant

Contents

The performance ratio is one of the most important variables for evaluating the efficiency of a PV plant. Specifically, the performance ratio is the ratio of the actual and theoretically possible energy outputs. It is largely independent of the orientation of a PV plant and the incident solar irradiation on the PV plant. For this reason, the performance ratio can be used to compare PV plants supplying the grid at different locations all over the world. This document explains what the performance ratio is and its function. You will also discover how to calculate the performance ratio for your PV plant and which factors have an influence on it.

Perfratio-UEN100810

Version 1.0

1/9

Technical Information

What is the performance ratio?

1 What is the performance ratio?

The performance ratio is a measure of the quality of a PV plant that is independent of location and it therefore often described as a a quality factor. The performance ratio (PR) is stated as percent and describes the relationship between the actual and theoretical energy outputs of the PV plant. It thus shows the proportion of the energy that is actually available for export to the grid after deduction of energy loss (e.g. due to thermal losses and conduction losses ) and of energy consumption for operation. The closer the PR value determined for a PV plant approaches 100 %, the more efficiently the respective PV plant is operating. In real life, a value of 100 % cannot be achieved, as unavoidable losses always arise with the operation of the PV plant (e.g. thermal loss due to heating of the PV modules). High-performance PV plants can however reach a performance ratio of up to 80 %.

2 What is the function of the performance ratio?

The performance ratio informs you as to how energy efficient and reliable your PV plant is. With the performance ratio you can compare the energy output of your PV plant with that of other PV plants or monitor the status of your PV plant over a prolonged period. The determination of the performance ratio at fixed regular intervals does not provide an absolute comparison. Instead, it provides the operator with the option of checking performance and output: if it is assumed that the PV plant is running optimally on being commissioned, and hence that the initial value for the performance ratio is 100%, then taking of further PR values over time enables the identification of deviations, meaning that appropriate countermeasures can be promptly initiated. Deviations in the PR value in the form of values below the normal range therefore indicate a possible fault in your PV plant at an early stage. The factors that can lead to a deviation in the PR value are described in Chapter 4 "Which factors influence the performance ratio?" (page7).

SMA Solar Technology AG

2/9

Technical Information

How is the performance ratio calculated?

3 How is the performance ratio calculated?

You need different variables to be able to calculate the performance ratio of your PV plant. On the one hand, these are the solar-irradiation values for the site of the PV plant. You can determine these values using a measuring gage (e.g. Sunny SensorBox) that measures the incident solar irradiation at your PV plant. On the other hand, you need the factor of the modular area of your PV plant and the relative efficiency of your PV modules. The modular efficiency of the data sheet for the PV module can be obtained in the data sheet. You can calculate the performance ratio by yourself (see Page 3) or automatically (see Page 6).

Requirements for calculation

If you use a measuring gage (e.g. Sunny SensorBox) for your PV plant that measures the direct incident solar irradiation, the orientation of the PV modules and the meter must be the same before you can calculate the PR value correctly. You therefore ensure that the PV modules and the measuring gage are exposed to the same quantities of incident solar irradiation and the same temperatures.

Analysis period

The optimum analysis period for calculating the performance ratio is 1 year. However, you can also select shorter time periods, e.g. if you want to compare your PV plant directly with other PV plants. That being said, you should select a minimum analysis period of 1 month to ensure that ambient conditions such as low solar elevations, low temperatures and shadows falling on the PV modules and / or measuring gage do not strongly influence the calculation.

3.1Manual calculation

If you wish to calculate the performance ratio by yourself, you can use the following simplified formula: Formula for manual calculation of the performance ratio Actual reading of plant output in kWh p.a. PR = Calculated, nominal plant output in kWh p.a. The actual plant energy production in kWh can be read at the end of the year from the grid export meter. The calculated annual nominal plant output is composed as follows: Formula for calculation of the nominal plant output Annual incident solar irradiation at the generator surface of the PV plant x relative efficiency of the PV plant modules

SMA Solar Technology AG

3/9

Technical Information

How is the performance ratio calculated?

The solar-irradiation value obtained by the measuring gage is measured at modular level, ideally over the whole year. Before this irradiation value can be determined, the mean value of the irradiation values measured by the measuring gage (e.g. Sunny SensorBox) must be determined. The determined irradiation value per m2 is then extrapolated to the entire modular surface of the PV plant (= generator area). You can obtain the modular efficiency in the data sheet for the PV plant. Example: Calculation of the performance ratio for an analysis period of 1 year This example describes the manual calculation of the performance ratio using data from the Sunny SensorBox and the Sunny WebBox. The manual calculation should be seen as an alternative option. SMA Solar Technology AG offers automatic calculation of the performance ratio in the Sunny Portal (see Page 6). How to register your PV plant in Sunny Portal is described in the operating instructions for the Sunny WebBox. If however you prefer to calculate the performance ratio manually, proceed as follows. You will require the following information for the manual calculation: Analysis period You define the analysis period in advance. The optimum analysis period is 1 year. Generator area of the PV plant The factor of the generator area of your PV plant is known. Efficiency factor of the PV modules You can obtain the modular relative efficiency of your PV plant from the data sheet of the PV modules. Actually measured plant output You read this value from your power export meter at the end of year. Calculated, nominal plant output To calculate this value, you will need the formula for calculation of the nominal plant output (see Page 3) Incident solar irradiation measured in the analysis period To determine this value, you need the irradiation values transmitted by the Sunny SensorBox to the Sunny WebBox. The Sunny WebBox regularly requests the individual values measured by the SensorBox. The Sunny WebBox then calculates daily average values from these individual values. To determine the average solar irradiation in the analysis period, you must extrapolate the daily average values for solar radiation. To do this, proceed as follows. The Sunny WebBox saves the daily average values for incident solar irradiation at your PV plant, depending on the settings on the user interface at intervals of 5 minutes, 10 minutes or 15 minutes. The Sunny WebBox saves the daily average values for each month together with other average values for your PV plant in the corresponding directories as .csv files or .xml files.

SMA Solar Technology AG

4/9

Technical Information

How is the performance ratio calculated?

To calculate the irradiation value for 1 year, for example, you first have to calculate the monthly averages. To do this add the daily average values for a given month. You then divide this amount determined by the number of days in the month, which gives you the monthly average value. In this way you can calculate the monthly average values for all 12 months of the year. To calculate the annual average value, you simply add the 12 monthly averages and divide the total by the number of months, i.e. 12. You then extrapolate the average value calculated to the generator area of your PV plant. In this way, you obtain the nominal plant output for the analysis period of 1 year, which you can enter with the previously known values in the formula for calculating the performance ratio. The following specific conditions and values are given for the example: Analysis period: 1 year Measured average solar irradiation intensity in 1 year: 120 kWh/m2 Generator area of the PV plant: 10 m2 Efficiency factor of the PV modules: 15 % Electrical energy actually exported by plant to grid: 110 kWh The irradiation values measured on location yields an average solar irradiation for the entire analysis period of 120 kWh/m2. This irradiation value is extrapolated to the modular area of the PV plant as follows: Irradiation value in kWh/m2 x plant area in m2 = 120 kWh/m2 x 10 m2 = 1,200 kWh In order to subsequently calculate the nominal plant output, the irradiation value for the PV plant is multiplied by the modular efficiency: 1,200 kWh x 15 % = 1,200 kWh x 0.15 = 180 kWh An anticipated nominal plant output of 1,200 kWh is therefore obtained for the selected analysis period. This anticipated nominal plant output corresponds to a performance ratio of 100 %. However, the actual value for electrical energy exported by the PV plant to the grid is only 110 kWh. If this value and the calculated nominal plant output are fed into the formula for calculating the performance ratio, the following result is obtained: PR = 110 kWh 180 kWh = approx. 0.61 = approx. 61 %

The PR value is approx. 61 %. This means that approx. 39 % of the incident solar energy in the analysis period is not converted into usable energy due to circumstances such as conduction loss, thermal loss or, for example, defects in components. Here the performance ratio acts as an indicator and can prompt more detailed inspection of the PV plant so that, for example, soiling of the PV modules is removed or defective components can be repaired or replaced.

SMA Solar Technology AG

5/9

Technical Information

How is the performance ratio calculated?

3.2Automatic calculation

You can also calculate the performance ratio automatically by transmitting the corresponding data from your PV plant to Sunny Portal. In the Sunny Portal you also can see the performance ratio clear presented in graphical form. How to automatically calculate the performance ratio and display the PR values in graphic form is described in the operating instructions for the Sunny Portal on www.SunnyPortal.com. Requirements for automatic calculation in Sunny Portal The following requirements must be fulfilled before you can calculate the performance ratio in the Sunny Portal: You have a Sunny WebBox that transmits the required data to the Sunny Portal. A Sunny SensorBox is connected to your Sunny WebBox. You use the Sunny SensorBox solar irradiation sensors. The Sunny SensorBox measures a minimum incident solar irradiation of 60 W/m2 per hour at the installation location of your PV plant. How to register at the Sunny Portal via the Sunny WebBox is described in the operating instructions for the Sunny WebBox.

SMA Solar Technology AG

6/9

Technical Information

Which factors influence the performance ratio?

4 Which factors influence the performance ratio?

The performance ratio is a purely definition-based variable which, under the influence of certain factors, may even exceed values of 100 %. This is because performance characteristics of the PV modules are used in the calculation of the performance ratio that have been determined under standard test conditions (1,000 W/m solar irradiation and 25 C module temperature). Deviating conditions in real operating conditions therefore influence the performance ratio. The following factors can have influence to the PR value: Environmental factors Temperature of the PV module Solar irradiation and power dissipation The measuring gage (e.g. Sunny SensorBox) is in the shade or soiled PV module in the shade or soiled Other factors Recording period Conduction losses Efficiency factor of the PV modules Efficiency factor of the inverter Differences in solar cell technologies of the measuring gage (e.g. Sunny SensorBox) and of the PV modules Orientation of the measurement gage (e.g. Sunny SensorBox)

4.1Environmental factors

Temperature of the PV module

Performance and efficiency of a solar cell depend, amongst others, on the temperature of the PV module. At lower temperatures, a PV module is especially efficient. For example, the PV module is cold when the sky is occluded in winter. If under these conditions, full solar irradiation is incident on the cold PV module, then it operates very efficiently. This can generate a high PR value briefly. After a certain time, the PV module heats up and the efficiency falls again.

Solar irradiation and power dissipation

In the morning, evening and especially in winter, when the sun is low in the sky, the value for the incident solar irradiation approaches that of power dissipation (= difference between power input and output) more closely than at other times of day and of the year. For this reason, the PR value is lower than usual at these times.

SMA Solar Technology AG

7/9

Technical Information

Which factors influence the performance ratio?

Measuring gage (e.g. Sunny SensorBox) in the shade or soiled

Depending on the installation location, plants and buildings can throw shadows on your PV plant's measuring gage (e.g. Sunny SensorBox) and hence the measuring gage can be temporarily or even permanently in the shade. Especially when the sun is low, parts of the PV plant itself can cast shadows over the measuring gage. The partial or complete placing in shadow of the measuring gage can result in PR values of over 100 %. In addition environmental factors such as snow, dust or pollen can lead to soiling of your PV plant and thus also result in PR values of over 100 %.

Shading or contamination of the PV modules

Depending on the installation location, plants and buildings can throw shadows on your PV plant's measuring gage (e.g. Sunny SensorBox) and hence the measuring gage can be temporarily or even permanently in in the shade. Also soiling by e.g. dust, pollen, snow etc. can lead to shading of the PV modules. This shading leads to the PV module absorbing less solar irradiation than usual. The efficiency of the PV modules and accordingly also the PR value of the PV plant falls.

4.2Other factors

Measurement period

If the measurement period is too short (i.e. less than 1 month), there are insufficient measurements for reliable calculation of the performance ratio. Low solar elevations, low and high temperatures and shading influence the calculation result in this case more strongly, as these values may not completely recorded.

Conduction losses

With the transmission of energy from the inverter to the energy export meter of the grid operator, conduction losses may occur depending on the type and material of the cable used. The PR value can be reduced by the conduction losses.

Efficiency factor of the PV modules

The efficiency factor of the PV modules has a decisive influence on the performance ratio of your PV plant. The higher the efficiency of the PV modules, the higher the PR value (with corresponding ambient conditions such as higher solar irradiation at the location, etc.).

Efficiency factor of the inverter

If the inverter employed in your PV plant is highly efficient, this can result in high PR values. SMA inverters with an efficiency of 90 % enable PR values of over 80 %.

SMA Solar Technology AG

8/9

Technical Information

Which factors influence the performance ratio?

Use of different solar cell technologies in the PV modules and measuring gage (e.g. Sunny SensorBox)

There are different solar cell types for PV modules. The three following solar cell types are used most frequently: monocrystal silicon cells, polycrystalline silicon cells and thin layer cells. If the measuring gage installed in the PV plant (e.g. Sunny SensorBox) uses a different solar cell technology than your PV modules, this can result in deviations in the performance ratio.

Degradation of the solar cells

The age-related degradation of the solar cells results in a lower PR value over time. Monocrystalline solar cells and polycrystalline solar cells age up to 20 % in 20 years.

Orientation of the measuring gage (e.g. Sunny SensorBox)

If your PV plant includes a measuring gage (e.g. Sunny SensorBox) and this is not correspondingly aligned with the PV modules of your PV plant, this can result in PV values of over 100 % due to different solar irradiations.

SMA Solar Technology AG

9/9

You might also like

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Power market operation-발표Document37 pagesPower market operation-발표sjcgraceNo ratings yet

- EPRI MicroGridDocument9 pagesEPRI MicroGridAndrei HorhoianuNo ratings yet

- Adequacy and Flexibility Study For Belgium 2020 2030 Elia PDFDocument209 pagesAdequacy and Flexibility Study For Belgium 2020 2030 Elia PDFMohammad Umair TareenNo ratings yet

- Smart Energy Solutions To Smart Grid ChallengesDocument191 pagesSmart Energy Solutions To Smart Grid Challengesenergi utNo ratings yet

- ELENS Online PDF VersionDocument28 pagesELENS Online PDF VersionDaniel PrataNo ratings yet

- The Impact of Financial Structure On The Cost of Solar EnergyDocument40 pagesThe Impact of Financial Structure On The Cost of Solar EnergyAlexander VovaNo ratings yet

- Asset ManagementDocument4 pagesAsset ManagementJohan TadlasNo ratings yet

- BYD Battery-Box Operating Manual LVL 15.4: PremiumDocument37 pagesBYD Battery-Box Operating Manual LVL 15.4: PremiumDINONo ratings yet

- Peak Shaving Through Battery Storage For Low-VoltaDocument17 pagesPeak Shaving Through Battery Storage For Low-VoltartorrescoralNo ratings yet

- Project guide for solar panel system designDocument17 pagesProject guide for solar panel system designAditya Pant100% (1)

- Peak Shaving Control Method For Energy StorageDocument6 pagesPeak Shaving Control Method For Energy Storagesalemg82No ratings yet

- Assessing PV system performance metrics to aid bankabilityDocument28 pagesAssessing PV system performance metrics to aid bankabilityMuhammad Agus BudiansyahNo ratings yet

- Density of Individual Airborne Wind Energy Systems in AWES FarmsDocument6 pagesDensity of Individual Airborne Wind Energy Systems in AWES FarmsEnrique MartinezNo ratings yet

- Final - ESGC Cost Performance Report 12-11-2020Document117 pagesFinal - ESGC Cost Performance Report 12-11-2020Manjitha Geethadhara GunarathneNo ratings yet

- Hybrid Power Systems PDFDocument29 pagesHybrid Power Systems PDFFinn BalorNo ratings yet

- Plug-In Hybrid Electric Vehicles As A Source of Distributed Frequency RegulationDocument154 pagesPlug-In Hybrid Electric Vehicles As A Source of Distributed Frequency RegulationRajasekhar ReddyNo ratings yet

- 41 Self ConsumptionDocument2 pages41 Self Consumptioncrico1535No ratings yet

- Guide to Photovoltaics (39Document15 pagesGuide to Photovoltaics (39Abhinandan PatilNo ratings yet

- A Simple Design Method For Island Microgrid in Rural AreaDocument11 pagesA Simple Design Method For Island Microgrid in Rural AreaIJRASETPublicationsNo ratings yet

- Impact of Industry Restructuring On System Dynamic PerformanceDocument83 pagesImpact of Industry Restructuring On System Dynamic PerformanceCarlos PortugalNo ratings yet

- Power Quality Improvement in Grid Connected PV SystemDocument6 pagesPower Quality Improvement in Grid Connected PV SystemEditor IJTSRDNo ratings yet

- Reducing Energy Costs With Peak ShavingDocument17 pagesReducing Energy Costs With Peak ShavingWahyu BhinukoNo ratings yet

- Distributed GenerationDocument6 pagesDistributed GenerationBibhudatta PatnaikNo ratings yet

- Overview of Sabah and Labuan Grid Code 16 June 2014Document81 pagesOverview of Sabah and Labuan Grid Code 16 June 2014kiddjoe1470100% (1)

- Performance Optimization of Wind TurbinesDocument193 pagesPerformance Optimization of Wind Turbineskanda71No ratings yet

- Economic Dispatch For A Microgrid Considering Renewable Energy Cost FunctionsDocument7 pagesEconomic Dispatch For A Microgrid Considering Renewable Energy Cost FunctionsibtihalislamNo ratings yet

- The Future of Energy: Australia's Energy ChoiceDocument28 pagesThe Future of Energy: Australia's Energy ChoicemapstonegardensNo ratings yet

- Modern Distribution Grid Volume IIIDocument90 pagesModern Distribution Grid Volume IIIRobinsonNo ratings yet

- PV Panel Emulator Literature ReviewDocument12 pagesPV Panel Emulator Literature ReviewEsala Hirumal SenevirathneNo ratings yet

- Renewable Energy StrategyDocument8 pagesRenewable Energy StrategyThe Royal Society of Edinburgh100% (1)

- Princeton University Microgrid DesignDocument15 pagesPrinceton University Microgrid DesignRafael MelendezNo ratings yet

- Solar Panel Tracking and Monitoring SystemDocument8 pagesSolar Panel Tracking and Monitoring SystemGRD JournalsNo ratings yet

- Solar Energy CompendiumfDocument86 pagesSolar Energy Compendiumfjchavez3221No ratings yet

- Protecting Electricity Networks From Natural Hazards: Organization For Security and Co-Operation in EuropeDocument124 pagesProtecting Electricity Networks From Natural Hazards: Organization For Security and Co-Operation in EuropeSahliMohamedNo ratings yet

- Maximum Power Point Tracking with CompactRIODocument7 pagesMaximum Power Point Tracking with CompactRIOrosy01710No ratings yet

- Modeling and Simulation of Renewable Hybrid PowerDocument6 pagesModeling and Simulation of Renewable Hybrid Powerakhil nigamNo ratings yet

- Microgrid Architectures For Low Voltage Distributed GenerationDocument10 pagesMicrogrid Architectures For Low Voltage Distributed Generationhafiz858No ratings yet

- Building Integrated Solar Thermal CollecDocument20 pagesBuilding Integrated Solar Thermal CollecMenandros GeorgiouNo ratings yet

- Elum Energy Monitoring & Control Solutions for Solar Hybrid PlantsDocument17 pagesElum Energy Monitoring & Control Solutions for Solar Hybrid PlantsCyrilColinNo ratings yet

- RENEWABLE ENERGY Market & Policy Trends in IEA CountriesDocument382 pagesRENEWABLE ENERGY Market & Policy Trends in IEA CountriesagbekasNo ratings yet

- FR2 Cat Hybrid Microgrids 2015manilaDocument49 pagesFR2 Cat Hybrid Microgrids 2015manilajuan dela cruzNo ratings yet

- Maintenance ManagementDocument13 pagesMaintenance ManagementMohola Tebello GriffithNo ratings yet

- Unit IV Wind and Solar Energy System 7thDocument12 pagesUnit IV Wind and Solar Energy System 7thmalik shafkatNo ratings yet

- Energy Conversion PDFDocument20 pagesEnergy Conversion PDFpushpendra singhNo ratings yet

- A Regulatory Framework For MicrogridsDocument26 pagesA Regulatory Framework For MicrogridsYuliana LiuNo ratings yet

- BEES MatlabDocument54 pagesBEES Matlabcracking khalif100% (1)

- Icasolar CatalogDocument67 pagesIcasolar Catalogicaanmpz100% (2)

- Annexe 2 - ESKOM Cost Estimate Letter No IPP293459467 - Legoko 3 PV PlantDocument46 pagesAnnexe 2 - ESKOM Cost Estimate Letter No IPP293459467 - Legoko 3 PV PlantalfredoNo ratings yet

- Deployments and Deployment Attempts: Futuregrid, and The More Modern Intergrid and IntragridDocument22 pagesDeployments and Deployment Attempts: Futuregrid, and The More Modern Intergrid and Intragridagrawalrohit_228384No ratings yet

- Renewable Energy in TunisiaDocument9 pagesRenewable Energy in TunisiaMian IrfanNo ratings yet

- IRENA Planning For The Renewable Future 2017 PDFDocument136 pagesIRENA Planning For The Renewable Future 2017 PDFel_ruso__83No ratings yet

- Photovoltaics Business Models: L. Frantzis, S. Graham, R. Katofsky, and H. SawyerDocument98 pagesPhotovoltaics Business Models: L. Frantzis, S. Graham, R. Katofsky, and H. SawyerRuhollah norouzi dehnashiNo ratings yet

- Electric Vehicle Charging Guide For Cities: Icct Consulting ReportDocument24 pagesElectric Vehicle Charging Guide For Cities: Icct Consulting Reportgdanon100% (1)

- Electrical Vehicle (EV) Charging Station SolutionsDocument7 pagesElectrical Vehicle (EV) Charging Station Solutionsc3controlsNo ratings yet

- Ieee Smart Grid Sept2011Document8 pagesIeee Smart Grid Sept2011Arul SelvanNo ratings yet

- New Desgined Solar PV Installation PDFDocument124 pagesNew Desgined Solar PV Installation PDFsalemabu9No ratings yet

- POLB Microgrid Whitepaper Final August 2016Document51 pagesPOLB Microgrid Whitepaper Final August 2016Sonu DesaiNo ratings yet

- Navigant Microgrid Multi Client Final Report 2015 12 04 Public Release Version PDFDocument29 pagesNavigant Microgrid Multi Client Final Report 2015 12 04 Public Release Version PDFRodrigo Ignacio Rodriguez MerinoNo ratings yet

- Sungrow Inverter Datat Sheet - 250 KWDocument2 pagesSungrow Inverter Datat Sheet - 250 KWShaileshnartiNo ratings yet

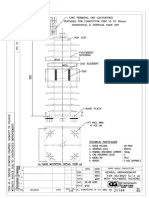

- 33 KV Bay Extension by TSTRANSCODocument1 page33 KV Bay Extension by TSTRANSCOShaileshnartiNo ratings yet

- PVS800 InvertersDocument13 pagesPVS800 InvertersShaileshnartiNo ratings yet

- La DrawingDocument1 pageLa DrawingShaileshnartiNo ratings yet

- KippZonen Brochure PyranometersDocument4 pagesKippZonen Brochure PyranometerscostpopNo ratings yet

- Rugged Wind Speed Sensor Measures up to 250 km/hrDocument2 pagesRugged Wind Speed Sensor Measures up to 250 km/hrShaileshnartiNo ratings yet

- Weather Station MappingDocument1 pageWeather Station MappingShaileshnartiNo ratings yet

- Catalogue - Data Logger and SensorsDocument24 pagesCatalogue - Data Logger and SensorsShaileshnartiNo ratings yet

- TD-W8968 V1.0 User GuideDocument117 pagesTD-W8968 V1.0 User GuideShaileshnartiNo ratings yet

- TD-W8968 V1.0 User GuideDocument117 pagesTD-W8968 V1.0 User GuideShaileshnartiNo ratings yet

- Lapp PI 27600304 ENDocument3 pagesLapp PI 27600304 ENShaileshnartiNo ratings yet

- Unitronic LiYD11YDocument1 pageUnitronic LiYD11YShaileshnartiNo ratings yet

- PVI 17 Performance FirstSolar PV PlantsDocument6 pagesPVI 17 Performance FirstSolar PV PlantsShaileshnartiNo ratings yet

- Title: Improving Access To Affordable, Sustainable, and Clean Water Powered by Renewable Energy in Namibia's Informal SettlementsDocument1 pageTitle: Improving Access To Affordable, Sustainable, and Clean Water Powered by Renewable Energy in Namibia's Informal SettlementsEmmanuel Bernard MuzingwaniNo ratings yet

- Iraq - Wireless Hardware Acceptance Check List - V1: # Site InformationDocument1 pageIraq - Wireless Hardware Acceptance Check List - V1: # Site InformationAws HameedNo ratings yet

- ELDORA 100P Micro DatasheetDocument2 pagesELDORA 100P Micro DatasheetANURODH YADAVNo ratings yet

- 1N5283 5314Document2 pages1N5283 5314Ex WueNo ratings yet

- Gic SM 301Document3 pagesGic SM 301srinivasgateNo ratings yet

- Electrical Design AnalysisDocument2 pagesElectrical Design AnalysisMaritel SumatraNo ratings yet

- Schedule Maintenance Preventive 2023 (Major)Document1 pageSchedule Maintenance Preventive 2023 (Major)BennyNo ratings yet

- JFY PV Inverters Catalog PDFDocument38 pagesJFY PV Inverters Catalog PDFSteveMateNo ratings yet

- Steam Turbine SimulatorDocument4 pagesSteam Turbine SimulatorvasavakurupNo ratings yet

- Status of Energy Sector in BarmmDocument8 pagesStatus of Energy Sector in BarmmEduardo LongakitNo ratings yet

- Dse704 4120 Data Sheet Us PDFDocument2 pagesDse704 4120 Data Sheet Us PDFzakki ahmadNo ratings yet

- MCQ PGTDocument17 pagesMCQ PGTmahajanpb2012No ratings yet

- Bangladesh's First Nuclear Power Plant: Rooppur NPPDocument8 pagesBangladesh's First Nuclear Power Plant: Rooppur NPPFarhan AriyanNo ratings yet

- Siemens Air Cooled Generators Sgen 2000h Brochure Ensiemens-Air-Cooled-Generators-Sgen-2000hDocument4 pagesSiemens Air Cooled Generators Sgen 2000h Brochure Ensiemens-Air-Cooled-Generators-Sgen-2000hronaldosallesNo ratings yet

- Pip-Msd - MST 5K 20151124Document47 pagesPip-Msd - MST 5K 20151124Feanor SilmarilNo ratings yet

- Pump Selection Table Diesel Driven 3Document15 pagesPump Selection Table Diesel Driven 3Neomax BuildersNo ratings yet

- 11 S4 VFTDocument1 page11 S4 VFTduc hai phamNo ratings yet

- Stps2045 CT CF CGDocument7 pagesStps2045 CT CF CGCah NgaloefNo ratings yet

- ArresterFacts 022 The Underbuilt Line ArresterDocument6 pagesArresterFacts 022 The Underbuilt Line ArresterNatalie LimNo ratings yet

- Dse7110 Mkii Dse7120 Mkii Data SheetDocument2 pagesDse7110 Mkii Dse7120 Mkii Data Sheetmnvijaybabu100% (1)

- Bangladesh Bank Presentation On Green BankingDocument14 pagesBangladesh Bank Presentation On Green BankingMahbooba ShafiNo ratings yet

- Sepam Series 80 NPP - 59735Document3 pagesSepam Series 80 NPP - 59735anon_568723957No ratings yet

- ESP Price List 01 Feb 2021 (L&T)Document116 pagesESP Price List 01 Feb 2021 (L&T)Kavin Sengodan100% (2)

- Iso 2314-2009 PDFDocument11 pagesIso 2314-2009 PDFIdris MulyanaNo ratings yet

- South Korea Wood Pellet Market Analysis by FutureMetrics July 2019Document9 pagesSouth Korea Wood Pellet Market Analysis by FutureMetrics July 2019Hiếu Phạm100% (1)

- Heinzmann Actuators Eng 285167 PDFDocument8 pagesHeinzmann Actuators Eng 285167 PDFPaulo MandingaNo ratings yet

- Download-Guide To Install PDFDocument40 pagesDownload-Guide To Install PDFTran Cong HauNo ratings yet

- Magazine PDFDocument84 pagesMagazine PDFEdisonNo ratings yet

- Taylor Wilson - Nuclear ReactorDocument3 pagesTaylor Wilson - Nuclear ReactorDiogo MulderNo ratings yet

- 2018-01-09 Daimler HDV RegulationsDocument22 pages2018-01-09 Daimler HDV RegulationsvivekpattniNo ratings yet