Professional Documents

Culture Documents

Brackish Water

Uploaded by

Ashraf Adel Nashed ZakiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brackish Water

Uploaded by

Ashraf Adel Nashed ZakiCopyright:

Available Formats

brackish water reverse osmosis s y s t e m s

series

57 58

brackish water reverse osmosis systems

Description

METITO 57 Series Reverse Osmosis (RO) Units cover nominal treated water capacities form 135-720 cubic metres per day. It is a compact design for a medium size plant with all the equipment mounted on a single skid for easy installation. The equipment comprises chemical conditioning, cartridge filtration, high pressure pump, RO membranes, pressure vessels and the necessary instruments and controls. The units is complete with interconnecting piping and wiring, and tested at our factory. The 58 Series is for larger outputs, in the range of 760-3000 cubic metres per day. It is split into three components to facilitate transport and ease of installation. There is a pre-treatment skid for the chemical dosing equipment and cartridge filters; a skid for the RO membranes and pressure vessels, pipework and controls whilst the high pressure pumps are mounted separately. The concept allows for different installation arrangements depending on the available layout of the building. The H range of the 57 and 58 Series have a nominal water recovery (ration of product to feed) of 75%; whilst METITO also offers the V range of the 58 Series with a very high water recovery of 85%. The recovery of course, is dependent on the feedwater composition. Smaller outputs are provided by other units in the METITO 50 series range whilst larger outputs can be achieved by using multiple units or a METITO custom-built design.

MULTI-MEDIA FILTERS

SCALE INHIBITOR ACID

WASTE HIGH PRESSURE PUMP BRACKISH WATER CARTRIDGE FILTER BACKWASH

REVERSE OSMOSIS

REJECT BRINE

PRODUCT

Typical Flow Diagram for Brackish Water Reverse Osmosis

brackish water reverse osmosis systems

Process

The feedwater, after appropriate pretreatment is dosed with sulphuric acid and METITO M-50 sequestering agent to prevent scale formation. The amounts required will depend on the water analysis. However the METITO dosing system has adequate adjustment to allow for all requirements. A pH meter with high and low alarms monitors the acidified water to ensure that the dosage is suitable for correct plant operation. The water is then passed through five micron cartridge filters to ensure that suspended particles do not enter the high pressure pump or membranes. METITO incorporates an automatic flushing The water is then pressurised by the high pressure pump, and the membrane separates it into the permeate (product) the reject (waste) streams. system which passes the feedwater at low pressure to the inlet of the membranes. This flushing system operates on each plant shutdown to protect and prolong the life of the membranes. The product should be piped to a product water storage tank prior to the distribution system. It can be degassed, pH corrected and sterilised as appropriate. The permeate from all the membranes is collected in manifold and piped to the skid termination point at a pressure suitable for lifting the product water to storage. The product pressure will depend on each application but increasing the product pressure will require a corresponding increase in the feed pressure.

Series 58 Reverse Osmosis Unit

brackish water reverse osmosis systems

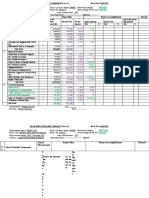

Specifications 58 Series

Pre-treatment Skid

The following equipment is mounted on an epoxy-coated welded-steel frame: (manual stroke M50 tank, dosing pumpinjection fitting. and speed adjustment) and (manual stroke and Acid tank, dosing pumpPVC injection fitting. speed adjustment) and with five-micron PVC pre-filterscartridge elements, vent polypropylene valve, and pressure gauges.

Mounted on Concrete Plinth

pressure pump Stainless steel high TEFC motor. with close or flexible coupled

Feed flow control valve.

In Addition

and Maintenance manual An Operationbe provided with each unit.(in English) will

Low pressure switch for pump protection. pH meter with high and low alarms.

Series 58 R.O. Unit with Pre-treatment Skid and Pump Unit

brackish water reverse osmosis systems

RO Skid

Feed flow indicator. Pump discharge pressure gauge. Reverse osmosis membranes spiral wound-in GRP pressure vessels. High pressure piping in stainless steel. Low pressure piping in PVC. control Rejectrecovery.valve to regulate the system water Product flow indicator. Flushing pipework and valves. measure, Pressure gauges to pressures.permeator feed, interstage or reject Control panel constructed to NEMA 12 or

IP54 including microprocessor, star-delta starter, integral disconnect switch, status and fault indication lights. Standard power supply 380-440V, 3 phase, 50 or 60 Hz.

brackish water reverse osmosis systems

Typical 2 Pass Reverse Osm

ACID DOSING COOLING TOWER DE-CHLORINATION CHLORINATION COAGULANT DOSING FLOCCULANT DOSING

CHLORINE DOSING

H2S GAS STRIPPING TOWER

FILTER FEED PUMPS

FILTER BACKWASH PUMPS

DEEP WELL PUMP (HIGHLY BRACKISH WATER)

5 MICRON CARTRIDGE FILTERS HIGH PRESSURE PUMP REVERSE OSMOSIS UNIT 57 SERIES PRODUCT WATER BREAK TANK

brackish water reverse osmosis systems

mosis Water Treatment Plant

CHLORINE DOSING

CAUSTIC SODA DOSING

5 MICRON CARTRIDGE FILTERS

FLUSHING PUMP

HIGH PRESSURE PUMP

FIRST PASS PRODUCT WATER TANK REVERSE OSMOSIS UNIT 58 SERIES PRODUCT WATER BREAK TANK TRANSFER PUMPS

DEGASSER FEED PUMPS DEIONIZER FEED PUMPS CO2 DEGASSER MIXED BED DEIONIZER HIGH PURITY PROCESS WATER TANK

DISTRIBUTION PUMPS

brackish water reverse osmosis systems

Specifications 57 Series

The following equipment is mounted on an epoxy- coated welded-steel frame. (manual stroke M50 tank, dosing pumpinjection fitting. and speed adjustment) and pump (manual stroke and Acid dosing and PVC injection fitting. speed adjustment)

Low pressure switch for high pressure pump protection. pH meter with high and low alarms. Feed flow indicator. Product flow indicator. Flushing pipework and valves. high pressure Pressure gauges to measure feed or reject pump discharge, permeator

pressures.

PVC pre-filter(s) with five micron vent polypropylene cartridge elements,

valve, and pressure gauges.

Series 57 Reverse Osmosis Unit

pressure pump Stainless steel high TEFC motor. with close or flexible coupled

Feed flow control valve. osmosis membranes-spiral wound Reversepressure vessels. in GRP Low pressure piping in PVC. control Rejectrecovery.valve to regulate the system water

High pressure piping in stainless steel.

Control panel constructed to NEMA 12 or IP54 including microprocessor, star-delta

starter, integral disconnect switch , control circuit transformer, control switches, status and fault indicator lights. power StandardHZ. supply 380-440V, 3 phase, 50 or 60

In Addition

and maintenance manual An Operationbe provided with each unit.(in English) will

brackish water reverse osmosis systems

Options & Accessories

Feedwater Temperature

Units can operate over a wide variety of feedwater temperatures, up to a maximum of 45 O C. The plant capacities quoted refer to operating temperatures between 25-30 O C. Higher temperatures give an increase in output and lower temperatures a corresponding decrease. The product TDS is also influenced by temperature; high temperatures giving higher product TDS values. METITO plants produce water of World Health Organisation standard for wide variations in TDS and water temperatures.

Alternative panel specification Temperature indicator Temperature switch (high) Portable conductivity meter Portable pH meter Silt density index (SDI) test kit Chlorine test kit Auto isolating valve to close feed line at system

Alternative voltages shutdown.

Operating instructions in other languages pH chart recorder Conductivity indicator Conductivity chart recorder Filtration-sand, activated carbon or iron removal Pre-and/or post chlorination Raw and/or product water storage tanks Bulk chemical storage tank Pumping/ pressure systems Degassing tower Post-treatment chemical dosing (pH correction, etc.) Cleaning skid.

Commitment to a Cleaner Environment

The Americas (Houston, Texas) METITO INTERNATIONAL INC. 11931 Wickchester Lane, Suite 201 Houston, Texas 77043 U.S.A. Tel.: +1 (281) 293 8500 Fax: +1 (281) 759 3646 E-mail: metito@vonl.com

Africa (Cairo, Egypt) METITO EGYPT LTD. 22 Shehab Street, Mohandiseen, Giza Cairo, Egypt Tel.: +20 (2) 749 7126 Fax: +20 (2) 749 7128 E-mail: metito@intouch.com

Asia (Jakarta, Indonesia) PT METITO INDONESIA JI. Ampera Raya No. 18 A Cilandak TimurPasar Minggu Jakarta 12560, Indonesia Tel.: +62 (21) 7800 394 Fax: +62 (21) 780 0395 E-mail: metito@indo.net.id

Headquarters for Europe, Africa and Asia (Sharjah, U.A.E.) METITO (OVERSEAS) LTD. Al Sayegh Tower, Corniche Road P.O. Box 22701, Sharjah, UAE Tel.: +971 (6) 556 1818 Fax: +971 (6) 556 4777 E-mail: metito@emirates.net.ae website: metito.com

METITO WORLDWIDE LOCATIONS l Houston, Texas, USA l Nicosia, Cyprus l Jakarta, Indonesia l Beirut, Lebanon l Tehran, Iran l Sharjah, United Arab Emirates l Abu Dhabi, United Arab l Tunis, Tunisia l Emirates l Cairo, Egypt l Baghdad, Iraq l Tripoli, Libya l Amman, Jordan l Tokyo, Japan l Mumbai, India l Kuala Lumpur, Malaysia Seoul, S. Korea

79025-04

You might also like

- PumpDocument5 pagesPumpAshraf Adel Nashed ZakiNo ratings yet

- USACE ASTM E 779 Air Leakage Test ProtocolDocument32 pagesUSACE ASTM E 779 Air Leakage Test ProtocolAshraf Adel Nashed ZakiNo ratings yet

- NFPA Web Phase 3 - ESFR Sprinklers and Obstructions 12.15.16Document75 pagesNFPA Web Phase 3 - ESFR Sprinklers and Obstructions 12.15.16Ashraf Adel Nashed ZakiNo ratings yet

- Control Valve Primer 4th Ed - Baumann - TOCDocument4 pagesControl Valve Primer 4th Ed - Baumann - TOCAshraf Adel Nashed ZakiNo ratings yet

- TechB 1011 Foam Systems Discharge Test Check ListDocument4 pagesTechB 1011 Foam Systems Discharge Test Check ListAshraf Adel Nashed ZakiNo ratings yet

- P 4740100 InstallDocument13 pagesP 4740100 InstallAshraf Adel Nashed ZakiNo ratings yet

- TSTATDocument8 pagesTSTATAshraf Adel Nashed ZakiNo ratings yet

- APP-CMC002 EN Handout PDFDocument11 pagesAPP-CMC002 EN Handout PDFAshraf Adel Nashed ZakiNo ratings yet

- 08ts Ta26 070103Document2 pages08ts Ta26 070103Ashraf Adel Nashed ZakiNo ratings yet

- Active Passive Beams Engineering GuideDocument48 pagesActive Passive Beams Engineering GuideAshraf Adel Nashed ZakiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Reading Assignment Nuclear ChemistryDocument2 pagesReading Assignment Nuclear Chemistryapi-249441006No ratings yet

- Owner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13Document18 pagesOwner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13mediacampaigncc24No ratings yet

- CampingDocument25 pagesCampingChristine May SusanaNo ratings yet

- II092 - Horiz & Vert ULSs With Serial InputsDocument4 pagesII092 - Horiz & Vert ULSs With Serial InputsJibjab7No ratings yet

- VOC & CO - EnglishDocument50 pagesVOC & CO - EnglishAnandKumarPNo ratings yet

- Denagard-CTC US Knowledge ReportDocument4 pagesDenagard-CTC US Knowledge Reportnick224No ratings yet

- Technology For Teaching and Learning 2 OBE SyllabusDocument9 pagesTechnology For Teaching and Learning 2 OBE Syllabusjesreel canalNo ratings yet

- Creamy and Thick Mushroom Soup: IngredientsDocument8 pagesCreamy and Thick Mushroom Soup: IngredientsSheila Mae AramanNo ratings yet

- E3sconf 2F20187307002Document4 pagesE3sconf 2F20187307002Nguyễn Thành VinhNo ratings yet

- AppendicitisDocument7 pagesAppendicitisTim LuoNo ratings yet

- Compensation ManagementDocument2 pagesCompensation Managementshreekumar_scdlNo ratings yet

- Social Connectedness and Role of HopelessnessDocument8 pagesSocial Connectedness and Role of HopelessnessEmman CabiilanNo ratings yet

- BARCODESDocument7 pagesBARCODESChitPerRhosNo ratings yet

- Module 2: Environmental Science: EcosystemDocument8 pagesModule 2: Environmental Science: EcosystemHanna Dia MalateNo ratings yet

- Seven-Year Financial Pro Jection: ProblemDocument10 pagesSeven-Year Financial Pro Jection: Problemnyashadzashe munyatiNo ratings yet

- Assignment 2 - CE 669A - 22-23Document1 pageAssignment 2 - CE 669A - 22-23Sonam MeenaNo ratings yet

- Ammonia Synthesis ConverterDocument26 pagesAmmonia Synthesis ConverterKvspavan Kumar100% (1)

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- Injection MouldingDocument241 pagesInjection MouldingRAJESH TIWARINo ratings yet

- MSU-Iligan Institute of TechnologyDocument5 pagesMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDONo ratings yet

- Brachiocephalic TrunkDocument3 pagesBrachiocephalic TrunkstephNo ratings yet

- EDAH EnglishDocument2 pagesEDAH EnglishMaría SanchoNo ratings yet

- Gmail - RedBus Ticket - TN7R20093672Document2 pagesGmail - RedBus Ticket - TN7R20093672Bappa RoyNo ratings yet

- DSM-5 Personality Disorders PDFDocument2 pagesDSM-5 Personality Disorders PDFIqbal Baryar0% (1)

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Document3 pagesCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanNo ratings yet

- Tracheo Esophageal FistulaDocument6 pagesTracheo Esophageal Fistulablast2111No ratings yet

- Data Performance 2Document148 pagesData Performance 2Ibnu Abdillah MuhammadNo ratings yet

- LWT - Food Science and Technology: A A B ADocument6 pagesLWT - Food Science and Technology: A A B ACarlos BispoNo ratings yet

- Water TreatmentDocument27 pagesWater TreatmentArya Singh Rathod100% (1)

- Richard Teerlink and Paul Trane - Part 1Document14 pagesRichard Teerlink and Paul Trane - Part 1Scratch HunterNo ratings yet