Professional Documents

Culture Documents

PT46 12

Uploaded by

Guojun LiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT46 12

Uploaded by

Guojun LiCopyright:

Available Formats

mooring and berthing

Assessing U.S. practices for waterfront steel sheet pile walls

Michael J. Garlich, S.E., P.E., Collins Engineers, Inc., Chicago, Illinois, USA

Introduction

Hot-rolled steel sheet piling (or steel sheet piling) has a long history of successful use in a wide variety of both permanent and temporary structures, including coastal and inland port facilities. In the United States, unlike structural steel and reinforced concrete, no national design codes cover steel sheet piling design. The U.S. Army Corps of Engineers (USACE) manual EM 11102-2504, Design of Sheet Pile Walls provides good overall design guidance; however, it is not an adopted specification. Recently, the North American Steel Sheet Piling Association (NASSPA) undertook a study to examine common practices and design standards utilized for design of hot-rolled steel sheet piling in North America. This work included an extensive literature search on information related to steel sheet piling materials, design provisions, loading conditions, and appurtenances such as bracing and anchor design. This paper summarizes some of those results as they relate to port facilities.

existing ASTM International Specifications (ASTM), which are referenced in the various design references. Material properties and data on bracing and anchorage materials are also readily available and covered by ASTM or other nationally recognized standards. Some design engineers continue to specify steel sheet piling with minimum yield strength of (F ) of 270 Mpa, (38.5 kips per square inch (ksi)), instead of what may be considered an industry standard of 345 MPa (50 ksi), or higher. Using larger yield strengths leads to more economical designs. For permanent structures, particularly if located in a marine environment, evaluating the potential corrosion losses and selecting appropriate protection measures, if needed, is an important component of the design process. Corrosion rate data is available in U.S. reference documents, but much of it is old, fragmented, and inconsistent. The Euro Code 3 Part 5: Piling does provide good guidance, but may not be acceptable to some American owners.

y

Materials

Steel sheet piling is available in a variety of profiles, whose design properties are published in the various manufacturers catalogs. Material production and properties are covered under

Geotechnical considerations

The design of steel sheet piling structures requires geotechnical information both to determine the loads to be resisted by the structure, and the soil capacity to resist these loads in combination

Figure 1. driving sheet piling for river barge facility.

P o rt t e c h n o l o g y I n t e r n at I o n a l

21

mooring and berthing

a given project. Otherwise, a project-specific set of load criteria should be developed and agreed to by both the owner and design consultant.

Design approach

The design of steel sheet piling structures in the United States has traditionally been performed using the working (allowable) stress design (WSD) method. In working stress design, a single global factor of safety is used to account for all aspects of uncertainty in the design process. In U.S. practice, factors of safety for steel sheet piling structures generally fall in the range of 1.5 to 2. The engineer ing profession throughout the world has increasingly moved away from the working stress design approach, as evidenced by the Eurocode and other specifications. While geotechnical design using Limit States Design (LSD) is more recent, structural design to LSD is common practice. Limit state design in the U.S. falls into two main groups. Ultimate limit states (ULS) address potential failure modes for the structure. For steel sheet piling structures, this would include conditions such as overturning, sliding, global stability, and sheet pile failure. The serviceability limit state (SLS) addresses the functionality of a structure. Examples of SLS for steel sheet piling structures include deformation, corrosion and leakage. Approaches to LSD have developed differently in North America and Europe. In the Eurocode 7, a factored strength approach is used. In this approach, specified partial factors are applied directly to the soil strength parameters, cohesion and friction angle. The resulting factored strength parameters are then used for the direct calculation of the factored geotechnical resistance at ULS design. North American practice has developed on a load and resistance factor design (LRFD) approach. In the LRFD approach, an overall specified resistance factor is applied to the ultimate geotechnical resistance calculated from unfactored soil strength parameters, for each applicable limit state. The calculated factored resistance is then compared to the calculated factored load effect. Current codes or specifications utilizing the LRFD approach in the United States include: The American Association of State Highway and Transportation Officials (AASHTO) LRFD Bridge Design Specialization The American Concrete Institute (ACI) 318-Building Code The Amer ican Institute of Steel Construction (AISC) Specifications for Str uctural Steel Buildings (AISC Specifications). The AASHTO specification does include LRFD provisions for geotechnical design, including steel sheet piling. It is likely that much of the resistance by American engineers to utilizing LRFD in design is in fact due to an increased complexity in the codes themselves that has coincidentally occurred with the LRFD, but not a direct result of the LRFD approach.

Figure 2. Sheet piling closure installation at a waterfront recreational park.

with the structure. In some cases, the steel sheet piling designer may be provided with soil load and resistance design data by a geotechnical consultant; in other cases, particularly for smaller projects, the steel sheet piling designer determines these parameters from soil exploration data. In either case, the steel sheet piling system designer must ensure that sufficient and proper soil data is available and properly interpreted. Various soil pressure diagrams are utilized in design, depending upon the wall configuration and type of bracing, if present. Engineers have considerable leeway in selecting soil parameters and wall load models. Engineers with insufficient understanding of the flexible nature of steel sheet pile structures may use earth pressures for rigid wall systems in their designs, resulting in excessive wall soil loads and inefficient designs. The use of soil structure interaction models and finite element techniques to analyze earth structures is becoming increasingly common, especially for large or complex structures. Proper input and modeling within the computer programs are clearly needed if good results are to be produced. The use of soil spring models and finite element methods of analysis account for the interaction, or flexibility, of the support system directly and hence do not require a predetermined earth pressure distribution model. When more sophisticated methods of analysis are utilized, the results should be checked using hand methods. The extent and type of soil data required in these methods may generally limit use of these approaches to larger or more complex structures, and results should be developed over a range of likely soil properties.

Loads

Loads resisted by waterfront steel sheet piling structures include lateral loads due to soil, water, mooring and berthing loads and surcharge effects, as well as any vertical loads from supported structures or inclined anchorage systems. For permanent steel sheet piling structures, design loads are provided in the governing code or specification such as the International Building Code (IBC), and the American Society of Civil Engineers Standard Minimum Design Loads for Buildings and Other Structures. However, these documents provide only limited coverage for waterfront facilities. U.S. Navy publications provide design guidance for mooring, berthing and other marine loads, but are not really intended for private facilities, though they are often used for them. For larger projects and owners with extensive waterfront assets, owner-provided specifications generally stipulate design loads for

22 P o rt t e c h n o l o g y I n t e r n at I o n a l

Steel sheet piling design

The design of a steel sheet piling structure must address both geotechnical and structural requirements. Geotechnical requirements include resistance to overturning and sliding; basal heave, control of ground water, restraint of ground movements, and vertical and in-plane load capacity. Structural requirements include resistance to primarily bending movements; web shear, axial capacity, and transverse bending of sheets. Vertical loads to be carried by steel sheet piling may be directly applied from supported structures or may result from inclined anchor forces. While U. S. standards note the need to check piling for vertical loads or components of inclined anchors, no

www.porttechnology.org

mooring and berthing

direct design guidance on the vertical resistance of sheet piling is provided. The Recommendations of the Committee for Waterfront Structures, Harbors and Waterways EAU 2004 contains guidance on vertical load capacity determination as follows: Available skin resistance is computed as for steel H-piles. End bearing and skin resistance is included. The length of pile available to provide skin resistance is the length below the theoretical toe required for lateral resistance of the wall. The EAU 2004 recommendations can be applied as guidance for U.S. practice, along with specification requirements on bearing pile design. Guidance on treating loads acting parallel to the face of sheet pile walls does not appear in U.S. references. Soil mechanics principles for wall friction forces can, of course, be utilized to show that sufficient horizontal load transfer to the ground is possible. However, the design approach is subject to the individual design engineers procedures. The Recommendations of the Committee for Waterfront Structures, Harbors and Waterways EAU 2004 does provide analysis methods for in-plane loads, but it can be difficult to achieve acceptance of European practice from reviewers in the United States. Installation of steel sheet piling using staggered toe elevations is another design consideration that does not appear to be addressed in North American specifications, although it is used in practice. Staggered steel sheet piling takes advantage of the same discrete elements passive soil pressure distribution, as is used for soldier pile installations, in order to reduce the quantity of steel sheet piling and embedment required. The Recommendations of the Committee for Waterfront Structures Harbors and Waterways EAU 2004 does address staggered toe elevations. The moment capacity of the deeper steel sheet piling must be sufficient to resist the resulting moment from two pairs of sheets at the point of the upper sheeting toe cut-off. Inclusion of similar provisions in US standards could facilitate the usage of staggered toes. U.S. standards generally indicate that steel sheet piling is to be designed using the allowable stress provisions of the AISC Specification for Structural Steel Buildings. While this appears to have produced acceptable designs, the AISC Specification was not written for steel sheet piling, and may not cover all design aspects. In contrast, the Eurocode 3 Design of steel structures, Part 5: Piling provides extensive information specifically for steel sheet piling design. In U.S. practice, allowable stresses for bending are typically taken as 0.65 Fy, consistent with AISC provisions for compact sections. The USACE, and some other owners use an allowable stress reduction factor of 5/6.

The AISC allowable stress for shear in the webs of beams of 0.40 Fy is commonly used to check web shear, along with the USACEs equation for the effective shear stress area, Av = twh/w where, Av = shear area per foot of wall tw = thickness of web of sheet pile h = height of sheet pile w = width of sheet pile No requirements for sheet piling web thickness to height limits or shear buckling calculations are found in the U.S. references; though it could be implied that the AISC Specification provisions for beam webs should be complied with. When Z-profile steel sheet piling is loaded, transverse-bending stresses can develop that reduce the overall bending resistance of the steel sheet piling. Particular manufacturers have addressed calculation of transverse bending effects in the U.S. However, those calculation methods are not included in U.S. codes. The Eurocode addresses these effects in the Eurocode 3, Part 5. For most applications, the vertical loads to be carried by sheet piles are small and can safely be neglected. Eurocode 3 (Part 5: Piling) provides a limit of 0.04 times the Euler buckling strength below which axial load may be neglected. USACE EM 1110-2-2504 suggests that for axially imposed moments less than 0.10 of the lateral sheet piling moment, pile bucking may be neglected. For stresses above this level, the sheets should be designed for combined stresses in accordance with the AISC procedures. Effective lengths of sheet pile for axial analysis may be taken as follows: For a cantilever wall, the USACE EM 1110-1-2504, assume a fixed base condition at the wall toe depth determined for a factor of safety of 1 on soil loads, see Figure 3. For an anchored wall, EM 1110-1-2504 provides the model shown in Figure 4. U-shape steel sheet pile sections are not now widely used in the United States. However, many older walls were constructed with U-shape piles, where the neutral axis of the wall lies along the line of the piling interlocks. Methods for analyzing these walls that account for possible shear transfer in the interlocks are not presented in U.S. specifications. Guidance on these walls, such as is contained in the Eurocode 3: Part 5, would be very useful and could show that walls now considered overstressed when interlock shear transfer is ignored, may actually be acceptable.

Figure 3. diagram of combined stresses on a cantilever wall.

Figure 4. diagram of combined stresses on an anchored wall.

24 P o rt t e c h n o l o g y I n t e r n at I o n a l

www.porttechnology.org

mooring and berthing

Bracing and anchors

Many steel sheet piling structures utilize some type of bracing or anchorage to allow for higher walls or heavy surcharged loads. Anchor systems commonly include tie rods and dead-man or prestressed soil or rock anchors. Design of tie rods and dead-man anchorages is addressed in the USACE EM-1110-2504, and NAVFAC DM 7.2, and other publications. These references are reasonably consistent in tie rod and dead-man design requirements. Wales and anchors are normally designed to the AISC specifications using the allowable stress approach. The USACE EM-1110-2504 uses an allowable stress equal to 5/6 of the AISC value. Several references provide for an increased allowable stress in wales for intermediate stages of construction. Wales may be subject to axial loads as well as bending. Typical practice is to consider that the flanges of wales connected to steel sheet piling are braced against lateral buckling in the weak axis. Analysis for combined loading is treated in AISC steel design specifications. Tie rods and their connections are normally designed for an increased load (or reduced allowable stress) to account for possible load redistribution and vertical (fill) loads, as well as their critical function in the wall system. An increase in load of 20 percent is often used when anchor loads are determined using traditional earth pressure models. When tie rod loads are deter mined from soil spr ing or FEM methods, load redistribution is computed directly and tie rod loads need not be factored for this effect. The Post-Tensioning Institutes (PTI) Recommendations for Prestressed Rock and Soil Anchors and the Federal Highway Administrations Geotechnical Circular Number 4 are the primary documents covering pre-stressed anchor design and installation. Neither of these documents constitutes a code or specification, however. Provisions for corrosion protection of anchors are included. The installation contractor generally performs detailed design of prestressed anchors, based on the project design engineers given loads.

codes or standards. Preparation of a comprehensive design guide or specifications could address such issues and improve design consistency.

acknowledGeMent

This paper is based upon work conducted by the author under contract with the North American Steel Sheet Piling Association (NASSPA), and the authors paper Steel Sheet Piling Current Design Practice, presented at the NASSPA Steel Sheet Piling Symposium in Kansas City, Kansas 2009.

references

Conclusions

A review of current U.S. steel sheet piling practices for waterfront walls shows that aspects of steel sheet piling design practices are addressed in various documents, and that these often cover only particular areas of design. In addition, design issues such as vertical load capacity, in-plane loading, staggered toe elevations and transverse bending stress effects represent some of the areas that are not well addressed in North American

about the author

Michael Garlich is a Senior Vice President of Collins Engineers, Inc., and has forty years of experience in design, inspection, and rehabilitation of marine and transportation. He holds BSCE and MSCE degrees in structural engineering from Purdue University, is a licensed Structural Engineer in Illinois, and a registered Professional Engineer in several states. Mr. Garlich is a Fellow of the American Society of Civil Engineers and serves on various technical committees. He has presented numerous technical papers and taught courses for universities, government and private agencies.

American Institute of Steel Construction. Specification for Structural Steel Buildings, 2005. AISC, Chicago, Illinois. American Association of State Highway and Transportation Officials. AASHTO LRFD Bridge Design Specifications, 4th Edition, 2007. AASHTO, Washington, D.C. Committee for Waterfront Structures of the Society for Harbour Engineering, German Society for Soil Mechanics and Foundation Engineering. Recommendations of the Committee for Waterfront Structures EAU 2004, 8th Edition. Germany: Die Deutsche Bibliothek. European Committee for Standardization. Eurocode 3 Design of Steel Structures Part 5: Piling (EN 1993-5:2007). CEN, Brussels, Belgium. International Code Council, International Building Code 2006. International Code Council. Country Club Hills, Illinois. Naval Facilities Engineer ing Command. NAVFAC DM7 02. Foundation and Earth Structures 1986. Naval Facilities Engineering Command, Washington, D.C. Post-Tensioning Institute, Recommendations for Prestressed Rock and Soil Anchors, PTI, 2004. Sabatini, P.J. et. al. GEC No. 4 Ground Anchors and Anchored Systems (FHWA-IF-99-015) 1999. Office of Bridge Technology Federal Highway Administration. Washington, D.C. Structural Engineering Institute of the American Society of Civil Engineers. Minimum Design Loads for Buildings and Other Structures (ASCE 07-05). ASCE. Reston,Virginia. USACE. Design of Sheet Pile Walls (EM 1110-2-2504) 1994. Department of the Army, U.S. Army Corps of Engineers, Washington, D.C.

enquiries

Collins Engineering HQ (Illinois ) Tel: +1 (312) 704 9300 Fax: +1 (312) 704 9320 Email: mgarlich@collinsengr.com CEI Collins Engineers, Ltd. (Dublin) Tel: +35 314 264 984

26 P o rt t e c h n o l o g y I n t e r n at I o n a l

www.porttechnology.org

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Zsoka PDFDocument13 pagesZsoka PDFMasliana SahadNo ratings yet

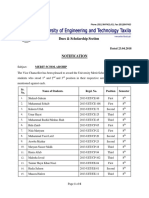

- Dues & Scholarship Section: NotificationDocument6 pagesDues & Scholarship Section: NotificationMUNEEB WAHEEDNo ratings yet

- Branch ListDocument65 pagesBranch Listannamichelle1001No ratings yet

- God Love Value CoreDocument11 pagesGod Love Value CoreligayaNo ratings yet

- ILOILO Grade IV Non MajorsDocument17 pagesILOILO Grade IV Non MajorsNelyn LosteNo ratings yet

- First Preliminary Examination in Tle 8 - Mechanical DraftingDocument6 pagesFirst Preliminary Examination in Tle 8 - Mechanical DraftingNefritiri BlanceNo ratings yet

- Specification Table - Stocks and ETF CFDsDocument53 pagesSpecification Table - Stocks and ETF CFDsHouse GardenNo ratings yet

- TOPIC - 1 - Intro To Tourism PDFDocument16 pagesTOPIC - 1 - Intro To Tourism PDFdevvy anneNo ratings yet

- Centre's Letter To States On DigiLockerDocument21 pagesCentre's Letter To States On DigiLockerNDTVNo ratings yet

- GPAODocument2 pagesGPAOZakariaChardoudiNo ratings yet

- Batman Vs Riddler RiddlesDocument3 pagesBatman Vs Riddler RiddlesRoy Lustre AgbonNo ratings yet

- Hidaat Alem The Medical Rights and Reform Act of 2009 University of Maryland University CollegeDocument12 pagesHidaat Alem The Medical Rights and Reform Act of 2009 University of Maryland University Collegepy007No ratings yet

- Swedenborg's Formative Influences: Jewish Mysticism, Christian Cabala and PietismDocument9 pagesSwedenborg's Formative Influences: Jewish Mysticism, Christian Cabala and PietismPorfirio MoriNo ratings yet

- Treviranus ThesisDocument292 pagesTreviranus ThesisClaudio BritoNo ratings yet

- UAE Cooling Tower Blow DownDocument3 pagesUAE Cooling Tower Blow DownRamkiNo ratings yet

- Adam Smith Abso Theory - PDF Swati AgarwalDocument3 pagesAdam Smith Abso Theory - PDF Swati AgarwalSagarNo ratings yet

- Das MarterkapitalDocument22 pagesDas MarterkapitalMatthew Shen GoodmanNo ratings yet

- Executive Support SystemDocument12 pagesExecutive Support SystemSachin Kumar Bassi100% (2)

- English: Quarter 1 - Module 1Document16 pagesEnglish: Quarter 1 - Module 1Ryze100% (1)

- Villadolid, Thea Marie J - 1st CENTURY SKILLS CATEGORIESDocument4 pagesVilladolid, Thea Marie J - 1st CENTURY SKILLS CATEGORIESThea Marie Villadolid100% (1)

- Project Management-New Product DevelopmentDocument13 pagesProject Management-New Product DevelopmentRahul SinghNo ratings yet

- Written Test Unit 7 & 8 - Set ADocument4 pagesWritten Test Unit 7 & 8 - Set ALaura FarinaNo ratings yet

- Career Guidance Program Modules MonitoringDocument7 pagesCareer Guidance Program Modules MonitoringJevin GonzalesNo ratings yet

- Sustainable Marketing and Consumers Preferences in Tourism 2167Document5 pagesSustainable Marketing and Consumers Preferences in Tourism 2167DanielNo ratings yet

- Factors Affecting Job Satisfaction of EngineersDocument35 pagesFactors Affecting Job Satisfaction of Engineerslingg8850% (2)

- AReviewof Environmental Impactof Azo Dyes International PublicationDocument18 pagesAReviewof Environmental Impactof Azo Dyes International PublicationPvd CoatingNo ratings yet

- ANA Stars Program 2022Document2 pagesANA Stars Program 2022AmericanNumismaticNo ratings yet

- Cloud Computing Basics and Service ModelsDocument29 pagesCloud Computing Basics and Service ModelsBhupendra singh TomarNo ratings yet

- Miss Daydreame1Document1 pageMiss Daydreame1Mary Joy AlbandiaNo ratings yet

- Balochistan Conservation Strategy VDocument388 pagesBalochistan Conservation Strategy VHãšãñ Trq100% (1)