Professional Documents

Culture Documents

Amine Filtration

Uploaded by

QuarkantOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amine Filtration

Uploaded by

QuarkantCopyright:

Available Formats

Amine Filtration

application bulletin

Tubular Backwashing or Pressure Leaf Both FSD Systems Eliminate Bags and Cartridges

Expertise

FSD incorporates over 60 years of filtration experience in every amine filtration system we build. Founded in 1933, FSD manufactures a broad line of self-cleaning Tubular Backwashing Filters, Pressure Leaf Filters, Pressure Nutsches, Filter Presses and Sludge Dryers. FSD's worldwide customer list includes companies such as Koch Refining, Texaco/Star, Aramco, Bechtel, Black & Veatch/Pritchard and Parsons Engineering. Systems range ] in size from 5 gpm to 3,000 gpm (lm'/hr - 700m /hr) and incorporate pre-coat, admix, piping, pump and automation skids.

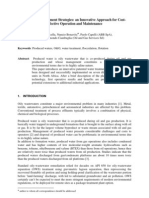

Tubular Backwashing Amine Filter System for Parsons Engineering features self-cleaning, reusable filter elements and refinery-grade features such as nitrogen purge.

Application

Oil and natural gas often contain high levels of sulphur that require removal (sweetening) in order to lower the environmental impact and increase value. Amine systems are commonly employed to perform this "sweetening."

Challenge

Amine systems become contaminated with organic and inorganic solids that cause severe foaming in the contactor and stripper, resulting in poor system performance. Filtration systems are challenged to provide safe operation (eliminate personnel H2S exposure) and efficient solids removal. (0.5-20 micron filtration)

Solution

Tubular backwashing filter systems and pressure leaf filter systems are self-cleaning and provide safe, low cost filtration that eliminates the cost and hazards of replaceable bags and cartridges.

Pressure

Leaf Amine for Koch dry-cake systems, platforms

Filtration System Refining featuring discharge, pre-coat & admix full automation and

Tubular Backwashing Amine Filtration Systems

Continuous Duty, High Flow Rates

FSD Tubular Backwashing Amine Filtration Systems offer continuous and self-cleaning operation through sequential backwashing of individual filter elements. They eliminate the hazards and costs associated with bag and cartridge filter replacement. In addition, isolating the amine from the backwash water through the use of control and nitrogen purge limits the COD load to waste treatment. High Pressure Housings Total Range of Control Options Flanged, Removable Filter Elements Fire Safe Features including ANSI flanged valves and double acting, spring retum actuators

ASME, HIC and NACE Construction - FSD systems meet the most stringent refinery specifications and intemational requirements High Temperature and Pressure Designs to meet the demands of refinery service Filter Media including perforated, slotted, wire mesh and fabric to match the specific application

Particle Retention Down to Sub Micron Levels with precoat. Typical non-precoated retention to 20 mIcron Modular Configuration providing large filtration area and future expandability. Skid Mounted to provide low-cost field installation

Technical Data

Application Equipment.. Materials of Construction Backwash Fluid Removal of organic and inorganic solids from MEA, DEA, TGA, and proprietary rich and lean amine/glycol solutions Custom engineered tubular backwashing filter system with Sequential, Extemal Backwash and Nitrogen Purge Steel, Alloy Steel, and Stainless Steel Water (isolated from amine via nitrogen purge)

Filtration Data

Suspended Solids Flow Rate Patiicle Retention Cycle Length (typical) Rust, Pipe Scale and' Other Solids up to 300ppm Up to 240 gpm (55m3/hr) per module 20 micron nominal (sub micron with precoat) Continuous

------------

--

Pressure Leaf Amine Filtration Systems

-,,",,",!,!,

Sub-Micron Removal

FSD Pressure Leaf Amine Filtration Systems are ideal when sub-micron particle retention is required. These systems eliminate operator contact with waste and handle high flow rates and upset solids. Other Features and Benefits include: Dual Sluicers for efficient media cleaning and wet cake discharge without opening filter vessel ASME, NACE and API Standards to meet the strictest specifications Wheel Guards to eliminate pinch points and hazards High Temperature and Pressure Designs Constant Flow Batch Operation Multiple day cycle times Skidded, Modular Piping reduces installation time and cost Stress-Relieved, Post-Weld Heat Treated Piping when required High Flow Rates with less than 1% solids loading

H2S

Closed System limits personnel exposure to and amines

Side Stream or Full Stream Filtration

Technical Data

Application Equipment.. Removal of organic and inorganic solids from MEA, DEA, TGA, and proprietary rich and lean amine/glycol solutions Custom engineered horizontal tank or vertical tank pressure leaf filter system with wet cake discharge and precoat/admix stations

Materials of Construction .... Steel, Alloy Steel and Stainless Steel (NACE, HIe)

Filtration Data

Suspended Solids Flow Rate Pmiicle Retention Cycle Length (typical) Precoat Rust, Pipe Scale and Other Solids Up to 2,000 gpm (455m3/hr) per unit 0.5 micron Multiple Days Depending on Solids Loading 20 lb Diatomaceous Earth/l OOfe

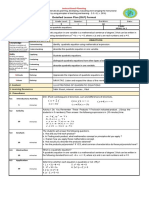

Amine Filtration Systems Typical Amine Filtration Flowsheet

OVERHEAD CONDENSER TO SULFUR

LIQUID PRODUCT

~GETANK

II

cob

AMINE AMINE TANK

RECOVERY UNIT

~~~~H LEAN

SURVE

LEAN TUBULAR WASHING

AMINE BACKFILTER

CARBON FILTER

PRESSURE LETDOWN VALVE REFLUX PUMP

TUBULAR

OVERHEAD ACCUMULATOR

AMINE REGENERATOR (STRIPPER)

FUEL GAS

CONDENSATE

LIQUID FEED

GAS FEED

~

RICH FLASH AMINE DRUM RICH TUBULAR WASHING AMINE BACKFILTER RICH TUBULAR WASHING AMINE BACKFILTER

OR

TUBULAR

AMINE GUARD FILTER

0--0--0AMINE SELF-

AMINE CARBON FILTER

CLEANING PRESSURE

FILTER

LEAF

PRESSURE LEAF

Ascension Industries

1254 Erie Avenue North Tonawanda, NY 14120 Phone: 716-693-9381 Fax: 716-693-9882 Website: www.asmfab.com

)cally represented by:

PRODUCTS/SERVICES

Modular Design & Fabrication PressureVessels. Heat Exchangers Structural Fabrication Instrumentation & Electrical Systems ASME Certified Sanitary/Polishing. CNC Boring, Milling & Drilling CNC Laser Cutting/Press Brake. Sheet Metal Fabrication Machine Building St. Mary Spin Rolls Filtration Products: Filter Press, Backwash Tubular Filters, D.E. PressureFilters

You might also like

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsFrom EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengNo ratings yet

- Random PackingDocument4 pagesRandom PackingAadam AryanNo ratings yet

- Catrdige Filter Cost Chang OutDocument4 pagesCatrdige Filter Cost Chang OutmigelNo ratings yet

- Effluent Treatment Plant (ETP) - Process Flow DiagramDocument4 pagesEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthNo ratings yet

- Corrugated Plate Separator (CPS) enDocument2 pagesCorrugated Plate Separator (CPS) enspattacutNo ratings yet

- Side Stream FiltrationDocument8 pagesSide Stream FiltrationAhmed WagihNo ratings yet

- Superfrac High Perfomance TraysDocument16 pagesSuperfrac High Perfomance Traysnatee8632No ratings yet

- Desalter Emulsion MonitorDocument2 pagesDesalter Emulsion MonitorAbdus Saboor KhalidNo ratings yet

- Desalination Plant of TobrukDocument21 pagesDesalination Plant of TobrukMotaz ZgogoNo ratings yet

- FAUDI Seawater FiltrationDocument4 pagesFAUDI Seawater FiltrationReyes SanchezNo ratings yet

- Equipment Catalogue API Oil SeparatorDocument2 pagesEquipment Catalogue API Oil Separatorbesant vargheesNo ratings yet

- WelChem BubbleCapTray 2020-2Document6 pagesWelChem BubbleCapTray 2020-2Joel OkohNo ratings yet

- Oily Water TreatmentDocument9 pagesOily Water TreatmentaamikiNo ratings yet

- Cpi O&m ManualDocument36 pagesCpi O&m Manualprasad336No ratings yet

- Biogas Processes For Sustainable DevelopmentDocument246 pagesBiogas Processes For Sustainable DevelopmentQuarterbore100% (4)

- Inline Technology New Solutions For Gas Liquid Separation PDFDocument13 pagesInline Technology New Solutions For Gas Liquid Separation PDFengrkris100% (1)

- Amine SlimeDocument24 pagesAmine SlimeganeshpicoNo ratings yet

- Membrane MBR - Depliant 1Document8 pagesMembrane MBR - Depliant 1gsaviNo ratings yet

- Oil Demulsifier Selection and Optimization - PetroWikiDocument10 pagesOil Demulsifier Selection and Optimization - PetroWikiahmedNo ratings yet

- Replacing Gas-Assisted Glycol Pumps With Electric Pumps: Lessons LearnedDocument11 pagesReplacing Gas-Assisted Glycol Pumps With Electric Pumps: Lessons LearnedAmji ShahNo ratings yet

- Design and Operation Considerations For Condensate Polishing - T5S5O3-paper PDFDocument17 pagesDesign and Operation Considerations For Condensate Polishing - T5S5O3-paper PDFNhhVuNo ratings yet

- NGL Extraction TechnologiesDocument10 pagesNGL Extraction Technologieswylie010% (1)

- CECO Peerless Produced Water TreatmentDocument10 pagesCECO Peerless Produced Water TreatmentIdris Siddiqui100% (1)

- Mono BeltDocument4 pagesMono BeltAlexandru IgnatNo ratings yet

- Jaeger Column InternalsDocument15 pagesJaeger Column Internalslazy5No ratings yet

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDocument6 pages4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMNo ratings yet

- Chemical AGRUDocument4 pagesChemical AGRUDwi CahyonoNo ratings yet

- 19.2. Dewatering of Sludge by FiltrationDocument46 pages19.2. Dewatering of Sludge by FiltrationClaudia AvramNo ratings yet

- Separators 2Document55 pagesSeparators 2Wael BadriNo ratings yet

- IPTC 10735 Process Optimization in Gas Sweetening Unit-A Case StudyDocument7 pagesIPTC 10735 Process Optimization in Gas Sweetening Unit-A Case StudyGary Kiel Palacios EspinozaNo ratings yet

- LNG Feed Pretreatment TechnologyDocument6 pagesLNG Feed Pretreatment TechnologyCSNo ratings yet

- 2006 Mohammed AzadDocument82 pages2006 Mohammed AzadIGNyomanAnomWijayaNo ratings yet

- UOP Separex Membrane Technology Tech PresentationDocument44 pagesUOP Separex Membrane Technology Tech PresentationKarunakarNo ratings yet

- Slop Oil 1197 ENDocument6 pagesSlop Oil 1197 ENsasankar_yhNo ratings yet

- Att2 Baretti InternalsDocument36 pagesAtt2 Baretti InternalsAli MetinNo ratings yet

- EVAC Advanced Wastewater Treatment Plant: Membrane Bio Reactor (MBR) 40-360Document2 pagesEVAC Advanced Wastewater Treatment Plant: Membrane Bio Reactor (MBR) 40-360Paliwal A100% (1)

- Schoepentoeter SEPARADORDocument4 pagesSchoepentoeter SEPARADOREsau EstebanNo ratings yet

- Vocus "VOC Control"Document2 pagesVocus "VOC Control"Pure air solutionsNo ratings yet

- VEL2162 0814 MANUAL Filter Separator Vessel WebDocument40 pagesVEL2162 0814 MANUAL Filter Separator Vessel WebfajaraminwahyullahNo ratings yet

- SPT Mozley Desanding Hydrocyclones BrochureDocument2 pagesSPT Mozley Desanding Hydrocyclones BrochureperrychemNo ratings yet

- Wet Air OxidationDocument42 pagesWet Air OxidationSiddharth ChoksiNo ratings yet

- Investigating The Performance of Dehydration Unit With ColdfingerDocument13 pagesInvestigating The Performance of Dehydration Unit With ColdfingerarispriyatmonoNo ratings yet

- Dowex Ion Exchange Resins Water Conditioning Manual L PDFDocument93 pagesDowex Ion Exchange Resins Water Conditioning Manual L PDFRizkaLestariNo ratings yet

- 3M™ Activated Carbon Filters - Data Sheet (PDF 670.8 K) PDFDocument2 pages3M™ Activated Carbon Filters - Data Sheet (PDF 670.8 K) PDFshwethakunjilna100% (1)

- DCD 6 - Plate Design PDFDocument53 pagesDCD 6 - Plate Design PDFChristopher RileyNo ratings yet

- Cyclonic Wellhead DesanderDocument2 pagesCyclonic Wellhead DesanderKapwell LimitedNo ratings yet

- Condensate Polishing Solutions For The Power Generation IndustryDocument4 pagesCondensate Polishing Solutions For The Power Generation IndustrytxagusNo ratings yet

- System OperationDocument34 pagesSystem OperationFranklin Revill100% (2)

- Coke Slurry PresentationDocument27 pagesCoke Slurry PresentationAnupam VermaNo ratings yet

- SAGD Where Valves Are UsedDocument4 pagesSAGD Where Valves Are UsedAnonymous ntK705RtNo ratings yet

- Enhanced Gravity OWS Sizing SpreadsheetDocument1 pageEnhanced Gravity OWS Sizing Spreadsheetdeion29No ratings yet

- Pre-Screening Sorting PlantDocument7 pagesPre-Screening Sorting PlantMuktafa AkmalNo ratings yet

- Membrane Separation ProcessesDocument93 pagesMembrane Separation ProcessesMohammad ShafiNo ratings yet

- Chapter 3. Acid Gas RemovalDocument88 pagesChapter 3. Acid Gas RemovalTu Dang TrongNo ratings yet

- Operation Manual For Perfluorinated Ion-Exchange Membrane Which Used in Chlor-Alkali IndustryDocument10 pagesOperation Manual For Perfluorinated Ion-Exchange Membrane Which Used in Chlor-Alkali IndustryBoris GNo ratings yet

- Iran Gas ProjectsDocument37 pagesIran Gas ProjectsAnusuya SwamyNo ratings yet

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsFrom EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo ratings yet

- Polymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental ImpactsFrom EverandPolymer Composite Systems in Pipeline Repair: Design, Manufacture, Application, and Environmental ImpactsSanjay Mavinkere RangappaNo ratings yet

- Minggu 5 Teori AktDocument69 pagesMinggu 5 Teori AktHILDANo ratings yet

- SortDocument174 pagesSortPeter CampellNo ratings yet

- Exam Syllabus For Genius20Document2 pagesExam Syllabus For Genius20Vaishali PandeyNo ratings yet

- Detailed Lesson Plan (DLP) Format: Nowledge ObjectivesDocument2 pagesDetailed Lesson Plan (DLP) Format: Nowledge ObjectivesErwin B. NavarroNo ratings yet

- Activity One: Student WorksheetDocument6 pagesActivity One: Student WorksheetMichael Edward De VillaNo ratings yet

- Lecture 24Document8 pagesLecture 24gewaray536No ratings yet

- Mulligan Vs ART PDFDocument4 pagesMulligan Vs ART PDFwernsickleNo ratings yet

- S Cubed DatasheetDocument2 pagesS Cubed DatasheetGulf JobzNo ratings yet

- 6-Heat Transfer in Multi Phase Materials PDFDocument460 pages6-Heat Transfer in Multi Phase Materials PDFJoselinaSosaZavalaNo ratings yet

- Exambank HigherDocument62 pagesExambank HigherJust WadeNo ratings yet

- Minimization of Blast Furnace Fuel Rate by Optimizing Burden and Gas DistributionsDocument1 pageMinimization of Blast Furnace Fuel Rate by Optimizing Burden and Gas DistributionsOsama AlwakkafNo ratings yet

- Sainsbury 2010 PDFDocument13 pagesSainsbury 2010 PDFronaldNo ratings yet

- Beam Number: Project Name: 17-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateDocument1 pageBeam Number: Project Name: 17-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateMark Christian EsguerraNo ratings yet

- Systemmeldungen GBDocument28 pagesSystemmeldungen GBAhmet0% (1)

- Non Trailable2EnglishDocument6 pagesNon Trailable2EnglishSuman ThakurNo ratings yet

- Chan SHP Final-NolinksDocument3 pagesChan SHP Final-NolinksaliNo ratings yet

- Solutions Manual 4th EditionDocument57 pagesSolutions Manual 4th Editionabdul5721100% (6)

- Basic Electrical Engineering: Fall 2015 Instructor: Dr. Hassan DawoodDocument34 pagesBasic Electrical Engineering: Fall 2015 Instructor: Dr. Hassan Dawoodbakhtawar saeedNo ratings yet

- Theoretical FrameworkDocument5 pagesTheoretical FrameworkPatziedawn GonzalvoNo ratings yet

- Coca Cola Potentiometric TitrationDocument5 pagesCoca Cola Potentiometric TitrationDaniela Delgadillo RestrepoNo ratings yet

- Sand ControlDocument12 pagesSand ControlNIRAJ DUBEYNo ratings yet

- Predictive Data Mining and Discovering Hidden Values of Data WarehouseDocument5 pagesPredictive Data Mining and Discovering Hidden Values of Data WarehouseLangit Merah Di SelatanNo ratings yet

- Computer Shortcut Keys SystemDocument5 pagesComputer Shortcut Keys SystemNo RebelNo ratings yet

- Fire Pump ControllerDocument45 pagesFire Pump ControllerRamasamy Kalyanasundaram RameshNo ratings yet

- AN78M20FDocument10 pagesAN78M20FFrantsiskoNo ratings yet

- Chapter 8 RevaDocument20 pagesChapter 8 RevaanildhakeNo ratings yet

- DSP Floating Point FormatsDocument29 pagesDSP Floating Point FormatsManjot KaurNo ratings yet

- 785 Truck Electrical System: 8GB418-UPDocument2 pages785 Truck Electrical System: 8GB418-UPEdwin Ruiz VargasNo ratings yet

- Q2. Answer The Following Questions by Referring To The Tables Given Below. (15 Marks)Document3 pagesQ2. Answer The Following Questions by Referring To The Tables Given Below. (15 Marks)ammar abbasNo ratings yet

- Basics of Robotics 24.06.2020Document25 pagesBasics of Robotics 24.06.2020prabhaNo ratings yet