Professional Documents

Culture Documents

MB 400 Base Plate

Uploaded by

Peace RainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MB 400 Base Plate

Uploaded by

Peace RainCopyright:

Available Formats

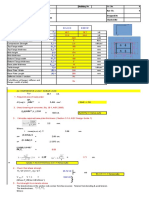

Project : DESIGN OF PIN COLUMN BASE FOR MB 400

Date :

Doc No : Page :

Basic Design Parameters

100

Column Section = 400

Depth = 400 mm Flange width = 140 mm

Design Load For Base Plate & Shear Key Design

Load Case Maximum Axial Comp C 14.0 T Maximum Axial Tension T 16.0 T Horizontal Force X-dir Hx 6.5 T Horizontal Force Z-dir Hz 3.7 T

y y y y y

400

75.0

X

75 140

n' = Without Wind/Seismic Condition and 'y' = With Wind/Seismic Condition Grade of Concrete = M 25 Yield stress of Steel fy = 250 MPa Bearing Stress

scc =

6.3 MPa

Refer Cl. 34.4 of IS:800 (without wind/seismic case) (with wind/seismic case)

= 64 Kg/cm2 = 85 Kg/cm2

Sizing of Base Plate

Load Cases Area of base required Length of base provided Width of base required

0

165 cm2 60 cm 2.8 cm

Provide Width of Base Plate = 30.0 cm

Calculation for Anchor Bolts

Bolt Property Class = 4.6 Yield Stress = #### Tensile Strength = #### No of Bolts = 4 Corrosion allowance = 0.0 mm

USE 600 X 300 MM PLATE FOR MB 400

Design Load For Base Plate & Shear Key Design

Load Case Horizontal Force X-dir Hx 6.5 T Dia of Bolts = 24 Horizontal Force Z-dir Hz 3.7 T Maximum Axial Tension T 16.0 T

y y y

Permissible Stress increase for Wind/Seismic Case = 25.0 %

n' = Without Wind/Seismic Condition and 'y' = With Wind/Seismic Condition

- As per IS : 800 Permissible Stress without Wind/Seismic Case Axial Tension Shear Effective Area of 24 Permissible Stress with Wind/Seismic Case Axial Tension Shear Tension = 362 mm^2 Shear = 452 mm^2 Consideration Hx to be taken by Shear Key : y Hz to be taken by Shear Key : y Load Cases Bolt Tension (Tb) Shear forces to be taken by Shear Keys Calculation of Stress in Bolts Tension stf,cal Allowable Stress 108 MPa 150 MPa 4.0 T - 'y' means YES - 'y' means YES

stf = tvf =

120 MPa 80 MPa

stf = tvf =

150 MPa 100 MPa

f Anchor Bolts for

- considering Net Area = 80% of Gross Area

stf

Safe

Shear

tvf,cal tvf

N/A

Alowable Stress

Check for Combined Shear & Tension as per Cl. 8.9.4.5

stf,cal / stf + tvf,cal / tvf

N/A

Provide

24

f Anchor Bolt - 4 Nos

Project : DESIGN OF PIN COLUMN BASE FOR MB 400

Date :

Doc No : Page :

Calculation for Base Plate Thickness

Load Cases Design Base Pressure swn Wind/Seismic Condition 8 Kg/cm2 y

Bending Strength of Plate (R) =

1682 Kg/cm2 (without wind/seismic case) 2238 Kg/cm2 (with wind/seismic case)

Base Plate thickness (tpl) required for Compression

Case-1 For Cantilever Portion (considering 1/2 load effective because of stiffener) Moment (M) kg-cm/cm tpl =(6*M/R)1/2 = 195.0 0.7 cm Minimum Thickness required for Case -1 tpl = 0.72 cm

Case-2 For 3 side Supported Portion (As per Roark's Hand Book) a = 15.0 cm b = 20.0 cm a/b = 0.750

b 1= 0.173

At x = 0, z = 0 tpl = At x = 0, z = b tpl = At x = a/2, z = b tpl = 0.5 cm

b 2= 0.148

b 3= 0.236

sb = -b1* swn*b2 / tpl2 sa =

0.5 cm

b 2* swn*b /

tpl2

sa=

0.6 cm

-b 3* swn*b2 / tpl2

Minimum Thickness required for Case -2 tpl = 0.6 cm

Base Plate thickness (tpl) a = 15.0 cm c = 15.0 cm a1 = 7.5 cm

required for Bolt Tension

b1 = 12.5 cm b2 = 7.5 cm b=

b1 + b2 = 20.0 cm

a b1

a1 b2

[ 'a' should not be greater than a1+b1; using design value of 'a' ] Design value of a = 15.0 cm [ 'c' should not be greater than a1+b2; using design value of 'c' ] Design value of c = 15.0 cm Case-1 Bending of Side -'a' Moment (M) kg-cm/cm tpl =(6*M/R) Case-2 Bending of Side -'b' Moment (M) kg-cm/cm tpl =(6*M/R) Case-3 Bending of Side -'c' Moment (M) kg-cm/cm tpl =(6*M/R)1/2 = 10000 1.34 cm

1/2 1/2

16667 1.73 cm

Minimum Thickness required considering Case -1, 2 & 3 10000 1.16 cm tpl = 1.7 cm

Summary :

Minimum thickness required for compression = 0.7 cm Minimum thickness required for tension = 1.73 cm

Provide

25

th. Base Plate.

Project : DESIGN OF PIN COLUMN BASE FOR MB 400

Date :

Doc No : Page :

Calculation for Shear Key

Base Plate Embedment Grout

Grout = 50.0 mm Embedment in Concrete = #####

Shear Key for Hx : Required Shear Key Shear Key for Hz : Required

Design of Shear Key along Z-direction (for Hx)

Length of Shear Key = 300 mm Load Cases Hx Wind/Seismic Condition

0

6.5 T

y

- considering no contribution of Grout

Uniformly Distributed Load on Shear Key 22 Kg/Sq. cm

Safe

Bending Moment in Shear Key (kg-cm/cm) Required thickness of Shear Key 2166.7 2.41 cm

Safe

Safe

Safe

Minimum Thickness required tpl = 2.4 cm - thickness to be recalculated for fy = 240, since t For modified fy, required thickness = 2.46 cm >= 20mm & <= 40mm

Provide

150 mm x

25 th. -

300 mm long Shear key along Z direction

Design of Shear Key along X-direction (for Hz)

Length of Shear Key = 200 mm Load Cases Hz Wind/Seismic Condition Uniformly Distributed Load on Shear Key

0

3.7 T

y

19 Kg/Sq. cm - considering no contribution of Grout

Safe

Bending Moment in Shear Key (kg-cm/cm) Required thickness of Shear Key 1850.0 2.23 cm

Safe

Safe

Safe

Minimum Thickness required tpl = 2.2 cm - thickness to be recalculated for fy = 240, since t For modified fy, required thickness = 2.27 cm >= 20mm & <= 40mm

Provide 150 mm x

25 th. -

200 mm long Shear key along X direction

You might also like

- 15 Ton Tank Concrete PlatformDocument1 page15 Ton Tank Concrete PlatformerickquintoNo ratings yet

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasNo ratings yet

- Design of Column and Lacings for Axial and Bending LoadsDocument160 pagesDesign of Column and Lacings for Axial and Bending LoadsVignesh VenkatasubramanianNo ratings yet

- Aisc Asd Gusset Plate Aisc341 16Document12 pagesAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- Base Plate Design for Column Base ConnectionDocument6 pagesBase Plate Design for Column Base ConnectionThuyTranNo ratings yet

- Larsen & Toubro Limited: 4/8/2012 A Issued For Review NSB BVR SDRDocument2 pagesLarsen & Toubro Limited: 4/8/2012 A Issued For Review NSB BVR SDRvrajan1988No ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- Dimensional Solutions Mat3DDocument69 pagesDimensional Solutions Mat3DTimothy HancockNo ratings yet

- Capacities of UB SectionsDocument48 pagesCapacities of UB SectionsRohan KarandeNo ratings yet

- Transmission Line Design and Steel Pole StructuresDocument27 pagesTransmission Line Design and Steel Pole StructuresDanNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- STIFF (Version 1)Document33 pagesSTIFF (Version 1)maheshbandhamNo ratings yet

- Any Materials Permitted (602.5) 1 1 1 1 1: Windows (T-715.5) Door&Shutter (T-715.3)Document19 pagesAny Materials Permitted (602.5) 1 1 1 1 1: Windows (T-715.5) Door&Shutter (T-715.3)Manju BirjeNo ratings yet

- Vertical Equation Foundation-Spread Sheet PDFDocument6 pagesVertical Equation Foundation-Spread Sheet PDFmassive85No ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Foundation Calculation Sheet: Title DescriptionDocument22 pagesFoundation Calculation Sheet: Title Descriptionvananhlt18No ratings yet

- 500 KW - Design ReportDocument21 pages500 KW - Design ReportSambhav PoddarNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- ECCENTRICALLY LOADED WELD GROUP ANALYSISDocument11 pagesECCENTRICALLY LOADED WELD GROUP ANALYSISSneyder NeyNo ratings yet

- Effective length factors for stepped crane column modelDocument3 pagesEffective length factors for stepped crane column modelbuildcon100% (1)

- Staad Analysis For StackDocument39 pagesStaad Analysis For StackABIDEEN BAMNENo ratings yet

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- Petrofac Spreadsheet ValidationDocument33 pagesPetrofac Spreadsheet ValidationALBERTNo ratings yet

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathNo ratings yet

- Shear Capacity of Pier Cap Corbel DesignDocument5 pagesShear Capacity of Pier Cap Corbel DesignBharathi ThadigotlaNo ratings yet

- Structural design calculations of splice plate and base plateDocument24 pagesStructural design calculations of splice plate and base plateAkshay Patil100% (1)

- Bending Moment Diagram CalculationDocument97 pagesBending Moment Diagram CalculationCharles HutabaratNo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Equal angle steel profiles data sheetDocument2 pagesEqual angle steel profiles data sheetGalih PutraNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- Clamp Design-2Document6 pagesClamp Design-2Harpreet SinghNo ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Column Effective LengthDocument1 pageColumn Effective LengthjanethNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - Columnsfeiz asgarNo ratings yet

- Pile DriveabilityDocument11 pagesPile DriveabilityEmmanuel Fosteris100% (1)

- Calculating Bracket & Clip-Rev.1Document13 pagesCalculating Bracket & Clip-Rev.1Endika Alfan100% (1)

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- THAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ADocument15 pagesTHAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ACivil StructureNo ratings yet

- AnchorboltsDocument2 pagesAnchorboltsrammohanNo ratings yet

- Section Properties:-: Try With Section Ixx Iyy ZXX Zyy A R R T TDocument4 pagesSection Properties:-: Try With Section Ixx Iyy ZXX Zyy A R R T TbuildconNo ratings yet

- Steel Structure Design Report for Loading Station ShelterDocument35 pagesSteel Structure Design Report for Loading Station ShelterAkram FerchichiNo ratings yet

- 380-R2-20191112 - Wind Load Calculation As Per GFF Method For 60 M Microwave TowerDocument12 pages380-R2-20191112 - Wind Load Calculation As Per GFF Method For 60 M Microwave TowerNeelesh DabholkarNo ratings yet

- Stacks and Tanks WInd LoadDocument2 pagesStacks and Tanks WInd LoaddantevariasNo ratings yet

- Pin Design AISCDocument3 pagesPin Design AISCFernando SimaNo ratings yet

- Sendai Project Lifting Lug DesignDocument6 pagesSendai Project Lifting Lug DesignkalpanaadhiNo ratings yet

- Calc Report Building Multilayer ParkingDocument53 pagesCalc Report Building Multilayer ParkingcadsultanNo ratings yet

- Ixx Iyy CalcDocument13 pagesIxx Iyy CalcjurieskNo ratings yet

- Crane lifting checklist for LPG terminal projectDocument1 pageCrane lifting checklist for LPG terminal projectjohan purbaNo ratings yet

- GratingDocument2 pagesGratingAnand3101No ratings yet

- App-A - Design of Ring Beam - 5150-T-005 - 0Document13 pagesApp-A - Design of Ring Beam - 5150-T-005 - 0Yatendra TyagiNo ratings yet

- Pile Foundation Design V 82510 - R1Document39 pagesPile Foundation Design V 82510 - R1Tarique MosharrufNo ratings yet

- Design of steel staircase componentsDocument6 pagesDesign of steel staircase componentsserafini75% (4)

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Tengku Nizarul AslamiNo ratings yet

- API 650 Storage Tank Design CalculationDocument14 pagesAPI 650 Storage Tank Design CalculationMohammed EljammalNo ratings yet

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Catalytic Reforming ProcessDocument28 pagesCatalytic Reforming ProcessSiddesh PatilNo ratings yet

- 3.. Gypsum Product 2012Document54 pages3.. Gypsum Product 2012Rahmadika Kemala FirdausiaNo ratings yet

- Bridge Cost SummaryDocument19 pagesBridge Cost SummaryShashank SrivastavaNo ratings yet

- 2017 H1 Chemistry Prelim SA2 Raffles InstitutionDocument32 pages2017 H1 Chemistry Prelim SA2 Raffles InstitutionSasha AnandNo ratings yet

- Perhitungan RBIDocument3 pagesPerhitungan RBIdwi sutiknoNo ratings yet

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiNo ratings yet

- Flexible Pavement Design SK RaoDocument62 pagesFlexible Pavement Design SK Raokrishnarao krishnarao329100% (3)

- Marvin Elevate-Catalog Feb 2023 19981914Document27 pagesMarvin Elevate-Catalog Feb 2023 19981914DiegoNo ratings yet

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonNo ratings yet

- Gandhar - Reliance Industries Limited.Document2 pagesGandhar - Reliance Industries Limited.ash61117No ratings yet

- 3 2 6 A BeamdesignDocument10 pages3 2 6 A Beamdesignapi-300375532100% (2)

- Basement WaterproofingDocument22 pagesBasement WaterproofinglallanasaintsNo ratings yet

- Strength-Durability Correlation of OsteosynthesisDocument17 pagesStrength-Durability Correlation of OsteosynthesisdeniNo ratings yet

- Microstructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialDocument17 pagesMicrostructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialEditor IJTSRDNo ratings yet

- Asme BPVC - Ssc.i.ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.i.ii.v.ix - Xiii-2023mmendozagNo ratings yet

- How To Construct A Concrete Swimming Pool - (PDF) - The ConstructorDocument13 pagesHow To Construct A Concrete Swimming Pool - (PDF) - The ConstructorBunkun15No ratings yet

- Staircase AssignmentDocument10 pagesStaircase AssignmentNabila Faiqah Zayn100% (1)

- Ractangular Over Head Water Tank (Complete)Document43 pagesRactangular Over Head Water Tank (Complete)Hailemariyam SewagegnNo ratings yet

- Assignment On Soil PollutionDocument18 pagesAssignment On Soil PollutionImran Hussain100% (1)

- PRN-D Reverse Flame Tube BoilerDocument6 pagesPRN-D Reverse Flame Tube BoilerartemisboilersNo ratings yet

- Product Data Sheet: Sikacor® Eg-1Document4 pagesProduct Data Sheet: Sikacor® Eg-1Thompson LaiNo ratings yet

- Options and Accessories: Complete Wear Part ListDocument1 pageOptions and Accessories: Complete Wear Part ListIvánNo ratings yet

- Daily Report - 1Document6 pagesDaily Report - 1Akli Ale ManNo ratings yet

- B LineDocument29 pagesB Linehesham3bbasNo ratings yet

- Chapter 6 MOSFET: Slide 6-1Document74 pagesChapter 6 MOSFET: Slide 6-1Windarto Properti SoloNo ratings yet

- Soap and Detergent: Properties, Preparation, and FunctionsDocument6 pagesSoap and Detergent: Properties, Preparation, and FunctionsJunren KhooNo ratings yet

- Physics and Technology For Engineers... 2023Document546 pagesPhysics and Technology For Engineers... 2023david floresNo ratings yet

- Wash Care Label RequirementsDocument11 pagesWash Care Label Requirementsnishkarsh mauryaNo ratings yet

- Hot IceDocument4 pagesHot IceeunoiasantosNo ratings yet

- 21.coordination Compound, D & F Block Transition ElementsDocument21 pages21.coordination Compound, D & F Block Transition ElementsQwerty100% (1)