Professional Documents

Culture Documents

Kfi DX50

Uploaded by

Edwin Ng0 ratings0% found this document useful (0 votes)

172 views8 pagesEPA TI ER 3 / EU STAGE I I I a EMI SSI on COMPLI ANT DX50. Hydraulic load is automatically detected and only the appropriate amount of oil is supplied via a variable displacement pump. Standard sealed wet disc brake system is designed to withstand 10,000 hours of operation without maintenance.

Original Description:

Original Title

KFI_DX50

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEPA TI ER 3 / EU STAGE I I I a EMI SSI on COMPLI ANT DX50. Hydraulic load is automatically detected and only the appropriate amount of oil is supplied via a variable displacement pump. Standard sealed wet disc brake system is designed to withstand 10,000 hours of operation without maintenance.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

172 views8 pagesKfi DX50

Uploaded by

Edwin NgEPA TI ER 3 / EU STAGE I I I a EMI SSI on COMPLI ANT DX50. Hydraulic load is automatically detected and only the appropriate amount of oil is supplied via a variable displacement pump. Standard sealed wet disc brake system is designed to withstand 10,000 hours of operation without maintenance.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

PNEUMATI C TI RE FORKLI FT

13,200 18,000 LBS. CAPACI TY | DI ESEL

EPA TI ER 3 / EU STAGE I I I A EMI SSI ON COMPLI ANT

DX50

The Forklift With Proven Ability.

2nd year 1st year 4th year 8th year

Previous

NEW DX50

2

Previous NEW DX50

The Hydraulic load is automatically detected and only the appropriate

amount of oil is supplied via a variable displacement pump. This system

eliminates the loss of hydraulic oil and reduces the engine load.

Komatsu tested data, comparison with FD70-8.

The results may vary depending on conditions.

NTotal operating cost (*Image)

NRunning cost (Accumulated costs for 8 years)

Komatsu tested data,

comparison with FD70-8 model.

Operation hours: 5 h/day,

25 days/month (Total: Approx. 1500 h/year),

Maintenance intervals to manufacturers recommendation.

The results may vary depending on conditions.

Assuming FD70-8 as 100%;

LFuel costs

LBrake

maintenance

costs

LEngine oil

costs

Fuel Consumption

Max. 20% savings

Total operating cost

Approx. 14% savings

ni>

In order to minimize engine loading, the new DX50

has adopted Komatsu's unique open-center load

moderating (OLMS) hydraulic system, and the

compact 3.3-liter diesel engine to achieve superior

performance and up to a 20% reduction in fuel

consumption.

"Reducing Total Operating Costs" with

Komatsu Innovative Technologies

Komatsu's Hydraulic System and the NEW Diesel Engine Reduce Fuel Consumption

The standard sealed wet disc brake system is

designed to withstand 10,000* hours of operation

without maintenance, thereby eliminating downtime

and the added maintenance costs of frequent brake

shoe replacement. The engine oil replacement interval

has been extended to 500 hours, which reduces oil

costs. The reduced maintenance costs and significant

fuel savings provides a total operating cost reduction

of about 14% over eight years of usage.

Greatly Reduced Total Operating Costs

Diesel Engine FD70-10

Diesel Engine FD70-10

*A periodic check and oil replacement are necessary.

Control

valve

Hydraulic

oil tank

Engine

Variable

displacement pump

Engine

RPM

sensing

pump

Power Supply to Hydraulics

Power Supply to Traction

Optimized Oil Feed

Lightly Loaded

Control

valve

Hydraulic

oil tank

Engine

Variable

displacement pump

Engine

RPM

sensing

pump

Lifting

Accelerating

Optimally controlled hydraulic oil results in;

Optimized balancing of traveling and loading work

Lower fuel consumption with OLMS and the new

compact 3.3 liter diesel engine.

max.

73% savings

max.

14% savings

max.

20% savings

KOMATSU

EXCLUSIVE

KOMATSU

EXCLUSIVE

As engine speeds change, the engine RPM sensing control pump detects engine

revs and then controls the oil feed to reduce the load on the engine. This unique

hydraulic system offers optimized balancing of traveling and loading work, while

delivering increased hydraulic efficiencies in the most demanding applications.

Komatsu's Unique OLMS Hydraulic System

Contributes To Lower Fuel Consumption

3

Low fuel consumption and low environmental impact are enabled by

elimination of excess combustion and the use of the combined technologies of

the high pressure common rail system, electronic control system,

new combustion system and air to air charge air cooling system.

SAA4D95LE-5-A

Displacement:

3.3 liter

Rated Output:

92.5 HP @ 2,250 rpm

Maximum Torque:

253 lb.-ft. @ 1,600 rpm

Previous NEW DX50

Komatsu tested data, comparison with FD70-8 model.

The results may vary depending on conditions.

CO2

78,100 lbs.-CO2

CO2

62,480 lbs.-CO2

A technologically advanced Diesel Engine that

Conforms to the Latest EPA Emission Regulations

Annual CO2 emissions

About 7.8 tons reduction

The new DX50 Series feature the SAA4D95LE-5-A compact

3.3 liter engine in combination with Komatsu's efficient OLMS

hydraulic system to enable the reduction of CO2 emissions by

approximately 7.8 tons annually.

Advanced Technology Offers Reduced CO2 Emissions

Diesel Engine FD70-10

EPA Tier 3 / EU Stage IIIA Emission Compliant

KOMATSU

EXCLUSIVE

KOMATSU

EXCLUSIVE

4

Superior "Productivity" and "Reliability"

Satisfy Demanding Operational Needs

Durable Wet Disc Brakes to Withstand Severe Conditions

The wet disc brake system is sealed with oil to block dust

penetration, providing durable, water resistant and fade resistant

characteristics. Smooth, stable braking provides Productivity

and Reliability in demanding operations.

The oil in the wet disc brake system is circulated through the brake oil

cooler. This mechanism ensures stable braking under a heavy work load

and prevents deterioration of the braking force that could be caused by

raised oil temperatures.

NSteady braking is always achieved.

NOverheating of the brakes is prevented.

NDowntime and maintenance costs are reduced.

The FHPS (Fully Hydrostatic Power Steering) system facilitates

fully stationary steering as well as switchback operations using

the small diameter steering wheel. The system has a superior

response capability so that the operator can maneuver easily

with a load even in a tight area.

Fully Hydrostatic Power Steering

for Superb Maneuverability

The 18,000 lb. model features a shorter wheelbase and swift

mobility while maintaining the power and speed capable of

achieving high productivity. The DX50 18,000 lb. model is an

ideal choice for confined spaces.

The 18,000 lb model offers a significant size

reduction

The new DX50 Series utilizes a technologically advanced,

compact 3.3-liter engine in conjunction with Komatsu's

advanced OLMS hydraulic system. This advanced design

achieves high productivity and first class cycle times.

First-class Cycle Time

LLifting Speed (Loaded)

88.5 fpm

Diesel Engine FD70-10

LLength

193 in.

201 in. [Previous 18,000 lb. model]

LWidth

81 in.

83 in. [Previous 18,000 lb. model]

LTurning radius

136 in.

142 in.

[Previous 18,000 lb. model]

LTraveling Speed (Unloaded)

19.3 mph

Diesel Engine FD70-10

A Cooling System to Achieve

Increased Braking Stability

First-class Productivity is Achieved

Komatsu tested data,

comparison with

FD70-8 model.

The results may vary

depending on conditions.

The NEW DX50 Series achieves high productivity

equivalent to the previous DX20 Series.

Diesel Engine FD70-10

KOMATSU

EXCLUSIVE

KOMATSU

EXCLUSIVE

NEW DX50

Displacement

3.33

Previous

Displacement

5.93

Cycle time

Fuel consumption

Displacement Lifting Speed

Oil pump

Wet disc brake

Brake oil cooler

N

E

W

5

Relay and fuse boxes are

conveniently located.

Fuel

pre-filter

Main fuel filter

Engine failure indicator

Locking engine

hood provides

protection while

servicing

Excellent Durability To Handle Demanding Work Cycles

The high rigidity mast, frame, front and rear axles ensure

outstanding reliability even when performing heavy-duty work.

Rugged Design with High Rigidity

The main hydraulic pipe connectors are face-sealed using

O-rings. Waterproof connectors are provided to the main

harnesses and the system controller in order to provide

higher resistance to water and dust.

Hydraulic and electrical piping systems

are in separate configurations to

improve the reliability and servicing.

Improved Reliabilities for the Hydraulic and

Electrical Systems

The electronic engine controls upgrade the performance of

the engine protection (fail-safe functions).

Engine Protection Systems To Keep

the Engine in the Best Operating Condition

LTrouble diagnosis:

Engine malfunctions are automatically detected and

an alarm lamp blinks.

LOverheating prevention:

The engine output and RPMs are reduced when

the coolant temperature exceeds limits.

LAutomatic engine warm-up:

The RPMs are accelerated to warm up the engine at

low temperatures.

LAutomatic air pre-heating:

The engine is automatically pre-heated when starting at low temperatures.

[Mast]

A heavy mast rail profile for excellent rigidity.

[Frame]

The successful high rigidity structure of previous models is adopted.

[Front axle]

New field proven design adopted from Komatsu Wheel Leader

Construction Equipment.

[Rear axle]

The durability of the power steering cylinder is improved.

Careful Designs Make Serviceability Easier

Wide Opening Engine Hood

with a Lock for Easy Servicing

A fully-opening floor plate.

Filter Layout Optimized

for Improved Serviceability

Easy Radiator Cleaning

Six-step reclining backrest

6.7 slide distance

backward and forward

Seat cushion adjustment dial

Retractable seat belt

KOPS Plus Hydraulic

Lock Indicator

6

*The traveling interlocking function only disengages traction and does not automatically apply the brakes.

*KOPS Plus - Komatsu Operator Presence System ISO3691-1 compliant

Neutral indicator

for at-a-glance

information

The DX50 features KOPS Plus to protect people and equipment if

the operator leaves the seat. If the seat is vacant for more than

three seconds, KOPS Plus automatically locks out all lift, lower, tilt

and travel functions. The operator must return to the seat to unlock

the system. A flashing yellow warning light alerts the operator

when KOPS Plus is activated. In addition, the DX50 forks cannot

be lowered with the key in the off position.

KOPS Plus - "Komatsu Operator Presence System"

Parking Brake Alarm

A double acting

type brake lever

prevents mishandling

ISO-Compliant Enhanced

Overhead Guard for Operator's Protection

The engine cannot be started unless the F-R switch

is in the neutral position.

A Neutral Safety Function To Prevent

an Inadvertent Start

If the operator fails to engage the parking brake, an

alarm will sound.

Advanced Design in Pursuit of

"Safety and Comfort"

Effective Risk Reduction Systems

KOPS Plus is

activated when the

operator leaves the

seat for more than

three seconds.

The deluxe full suspension seat features improved vibration

resistance and reduced stress on the body. The floating cab

structure enables the entire cab to be isolated from the frame

and the rubber cushioning of the engine mounts reduces the

vibrations transmitted from the

engine and road surface. The

overall design concept is

operator and load friendly.

Full Suspension Seat and Floating Cab Structure

Absorb Vibrations

Greater Operator Comfort and Reduced Fatigue In Even The Toughest Applications

The organ-type pedal allows an

operator to control braking

comfortably without lifting the

heel from the floor.

Comfortable Braking with the Organ-type Pedal

The low-noise design of the compact engine reduces

unpleasant noise levels during operation.

Low Noise Design

NDimensions NLoad capacity curve

C

a

p

a

c

i

t

y

l

b

(

k

g

)

4,400

(2000)

6,600

(3000)

8,800

(4000)

11,000

(5000)

13,200

(6000)

Load center in (mm)

24

(600)

39

(1000)

55

(1400)

71

(1800)

24

(600)

39

(1000)

55

(1400)

71

(1800)

24

(600)

39

(1000)

55

(1400)

71

(1800)

NFD60

6,600

(3000)

8,800

(4000)

11,000

(5000)

13,200

(6000)

15,400

(7000)

Load center in (mm)

C

a

p

a

c

i

t

y

l

b

(

k

g

)

NFD70

7

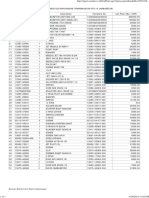

DX50 Series Specifications

25 15 28 16

32

21

18

20

24

23

29 30

19

22

FW

17

BK

26 (w)

4

26 (l)

5

26 (t)

8,800

(4000)

11,000

(5000)

13,200

(6000)

15,400

(7000)

18,000

(8000)

Load center in (mm)

C

a

p

a

c

i

t

y

l

b

(

k

g

)

NFD80

GENERAL FD60T-10 FD70T-10 FD80T-10

Power Type 1 Diesel Diesel Diesel

Operation Type 2 Sit-Down Sit-Down Sit-Down

Capacity @ 24 in. (600 mm) load center * lbs. (kg) 3 13,200 (6,000) 15,400 (7,000) 18,000 (8,000)

Load Distance - Front Axle Center to Fork Face in. (mm) 4 22.8 (580) 23 (585) 25 (635)

Wheelbase in. (mm) 5 90.6 (2,300) 90.6 (2,300) 90.6 (2,300)

WEIGHT

Service weight (includes 2-stage std. mast & forks) lbs. (kg) 6 18,860 (8,555) 20,380 (9,245) 24,050 (10,910)

Axle Loading

Loaded Front lbs. (kg) 7 28,550 (12,950) 31,590 (14,330) 36,520 (16,565)

Rear lbs. (kg) 8 3,540 (1,605) 4,220 (1,915) 5,170 (2,345)

Unloaded Front lbs. (kg) 9 8,580 (3,890) 8,210 (3,725) 9,410 (4,270)

Rear lbs. (kg) 10 10,280 (4,665) 12,170 (5,520) 14,640 (6,640)

TIRE

Tire type 11 Pneumatic Pneumatic Pneumatic

Tire size, front 12 8.25 - 15 - 12PR (l) 8.25 - 15 - 14PR (l) 8.25 - 15 - 18PR (I)

Tire size, rear 13 8.25 - 15 - 12PR (l) 8.25 - 15 - 14PR (l) 8.25 - 15 - 18PR (I)

Number of wheel, front / rear x= driven 14 4x / 2 4x / 2 4x / 2

Tread (center of tires) Front in. (mm) 15 57.9 (1,470) 57.9 (1,470) 60.6 (1,540)

Rear in. (mm) 16 64.6 (1,640) 64.6 (1,640) 64.6 (1,640)

DIMENSIONS

Tilting angle, 2-stage (FV) masts, forward / backward deg. 17 6 / 12 6 / 12 6 / 12

Mast height, lowered (2-stage std. mast) in. (mm) 18 98.4 (2,500) 101.8 (2,585) 106.7 (2,710)

Free lift height (2-stage std. mast) in. (mm) 19 8.5 (215) 8.7 (220) 8.7 (220)

Mast height, extended (2-stage std. mast) in. (mm) 20 171.3 (4,350) 171.3 (4,350) 171.3 (4,350)

Maximum fork height (2-stage std. mast) ** in. (mm) 21 118 (3,000) 118 (3,000) 118 (3,000)

Height overhead guard in. (mm) 22 96.1 (2,440) 96.1 (2,440) 96.1 (2,440)

Length, with Std. Forks in. (mm) 23 185 (4,700) 188.4 (4,785) 192.5 (4,890)

Length to fork face (2-stage mast) in. (mm) 24 137 (3,480) 140.4 (3,565) 144.5 (3,670)

Overall width, at drive tires (single) in. (mm) 25 78 (1,980) 78 (1,980) 80.7 (2,050)

Forks, thickness x width x length in. 26 2.6 x 5.9 x 48 2.6 x 5.9 x 48 2.6 x 6.7 x 48

Forks, thickness x width x length mm 27 65 x 150 x 1,220 65 x 150 x 1,220 65 x 170 x 1,220

Carriage width / ITA Class in. (mm) 28 66.5 (1,690) / IV 66.5 (1,690) / IV 70.9 (1,800) / IV

Ground clearance, under mast in. (mm) 29 8.7 (220) 8.7 (220) 9.3 (235)

Ground clearance, center of wheelbase in. (mm) 30 11.6 (295) 11.6 (295) 11.6 (295)

Right angle stacking aisle in. (mm) 31 150.8 (3,830) 154.9 (3,935) 160.8 (4,085)

Turning radius, outside in. (mm) 32 128 (3,250) 131.9 (3,350) 135.8 (3,450)

PERFORMANCE

Travel speed, forward, loaded - 1st / 2nd mph (km/h) 33 6.8 / 18 (11 / 29) 6.8 / 18 (11 / 29) 6.8 / 16.2 (11 / 26)

Travel speed, forward, unloaded - 1st / 2nd mph (km/h) 34 7.5 / 19.3 (12 / 31) 7.5 / 19.3 (12 / 31) 7.5 / 19.3 (12 / 31)

Lifting speed, loaded / unloaded (2-stage mast) fpm (mm/s) 35 98 (500) / 110 (560) 89 (450) / 98 (500) 79 (400) / 89 (450)

Lowering speed, loaded / unloaded (2-stage mast) fpm (mm/s) 36 108 (550) / 114 (580) 94 (480) / 98 (500) 91 (460) / 98 (500)

Maximum drawbar pull, loaded lbs. (kN) 37 9,890 (44) 9,890 (44) 9,890 (44)

Maximum gradability % 38 29.0 29.0 24.0

Service brake, operation/control 39 Foot / Hydraulic Foot / Hydraulic Foot / Hydraulic

Parking brake, operation/control 40 Hand / Mechanical Hand / Mechanical Hand / Mechanical

Steering, type 41 FHPS FHPS FHPS

Battery / Voltage / Capacity at 5-hour rating V / Ah 42 24 / 52 24 / 52 24 / 52

DRIVE

Engine Manufacturer / Engine model 43 Komatsu SAA4D95LE-5-A Komatsu SAA4D95LE-5-A Komatsu SAA4D95LE-5-A

Rated output (SAE Net) HP (kW) @ rpm 44 93 (69) @ 2,250 93 (69) @ 2,250 93 (69) @ 2,250

Maximum torque (SAE Net) lb-ft (Nm) @ rpm 45 253 (343) @ 1,600 253 (343) @ 1,600 253 (343) @ 1,600

No. of cylinder / displacement cu. in. (cm3) 46 4 / 199 (3,260) 4 / 199 (3,260) 4 / 199 (3,260)

Fuel tank capacity U.S. gallons (liters) 47 37 (140) 37 (140) 37 (140)

OTHER

Relief pressure, maximum psi (bar) 48 2,600 (181) 2,600 (181) 2,600 (181)

Transmission 49 TORQFLOW TORQFLOW TORQFLOW

NOTE: Most values shown in this publication are rounded. Therefore, direct conversion between metric and English or Imperial may be slightly different from those shown. The performance

of machines is affected by the condition of the truck and how it is equipped, as well as the nature and condition of the operating area. If these specifcations are critical or if your needs

exceed the specifcations shown here, discuss the proposed application with your authorized dealer.

*Optional masts, attachments, longer load dimensions, and higher lifting heights may result in downrating of the capacity. Contact your authorized dealer.

**Other mast heights available. See MAST DATA chart for other standard mast heights. Contact your authorized dealer.

Includes 48-inch (1,220 mm) high load backrest. Contact your authorized dealer.

Add load length plus clearance

Major equipment

Wet disc brake

EPA Tier 3/EU Stage IIIA compliant Diesel engine

Electronic engine control system

Heavy duty High Pressure Common Rail system

New combustion system

Air to air charge air cooling system

Overheat prevention function

Auto engine warm-up function

Auto air pre-heat function

Large capacity radiator

Dual floating structure

New Full Suspension Seat

Tiltable steering column

Electric forward/reverse lever

Combination switch (turn signal light & light switch)

Indicator auto-return mechanism

Wide slip-resistant step

Paper binder at engine hood

Meter panel

Hourmeter (6-digit)

Engine cooling water temperature gauge

Torque converter oil temperature gauge

Fuel gauge

Lifting interlock lamp

Charge warning lamp

Neutral indicator

Failure indicator

Engine failure indicator

Air cleaner element warning lamp

Cooling water level warning lamp

Glow indicator

Large capacity alternator

Quick auto glow system

Neutral safety function

Auto fuse

Low maintenance battery

Engine key stop function

Halogen headlight

Rear combination light

Back-up alarm

KOPS Plus - Komatsu Operator Presence System

Sedimenter with priming pump

Cyclone air cleaner (double element)

Parking brake with release button

Fully hydrostatic power steering

Non-asbestos parking brake linings

Key-off lift lock

Floor mat

Assist grip

Overhead guard with front/rear conduits

Rearview mirrors (pair)

Full shield solid-state engine hood

Easy-removable floor panel

Easy-removable radiator cover

Engine hood lock

Radiator reservoir tank

Jacking points

Engine

DX50 Series

Diesel

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

G

;

;

;

;

;

;

;

;

;

;

G

;

;

;

;

;

;

Options

Engine & power train related

LAir intake pre-cleaner

LAutomatic transmission

Exterior

LSteel cab

LSteel cab with heater

LSteel cab with AC

LCanvas cab with front windshield

and wiper

LTilt cylinder boots

LPower steering cylinder boots

LLifting hook

LLocking fuel cap

Electrical equipment

LHeadlights, 2-stage (High-Low)

LRear working light

LYellow strobe light

Meters & gauges

LSpeedometer

LSpeedometer with alarm

LMast tilt angle gauge

Tire

LSolid Pneumatic Tires

(13,200 lb. & 15,400 lb.)

Attachments

LSide shifter

The forks may be shifted sideways

together with its backrest, both to

the right and to the left.

LFork positioner

The operator is able to adjust the

fork spread width from the

operator's seat.

LFork positioner with side

shifter

The combination of fork positioner

and side shifter.

LFork positioner with side shift

function

This attachment is a fork positioner

which has a simultaneous fork

movement function to act as a side

shifter.

Mast

L2-stage free view mast

The mast enables a wide view with

excellent forward visibility.

L2-stage full free view mast

This is ideal for sites with height

limitations, where maximum free lift

is required.

L3-stage full free view mast

The mast extends in three stages

and high level loading is easily

performed.

E

n

g

i

n

e

-

r

e

l

a

t

e

d

T

r

a

v

e

l

i

n

g

-

r

e

l

a

t

e

d

M

e

t

e

r

s

S

a

f

e

t

y

i

n

d

i

c

a

t

o

r

s

E

l

e

c

t

r

i

c

c

o

m

p

o

n

e

n

t

s

M

e

c

h

a

n

i

s

m

E

x

t

e

r

i

o

r

;: Standard G: Option

KOMATSU FORKLIFT U.S.A., INC.

14481 Lochridge Boulevard, Covington, GA 30014

TELEPHONE: 770.787.5100 | FAX: 770.385.6003

1.800.821.9365

www.kusa.com

Copyright Komatsu Forklift U.S.A., Inc. 2008. All rights reserved. Komatsu, The Ability Bolt, EZview, EZlift, The Forklift With Proven Ability, Komfort Zone and the Clean Air Technology logo are all trademarks of Komatsu Forklift U.S.A., Inc. and the Komatsu Group Companies. Komatsu Forklift U.S.A., Inc. products and specica-

tions are subject to continuous improvement and change without prior notice. The illustrations do not necessarily show the standard version and features of the equipment. The actual operating conditions, including equipment conguration, may affect visibility, performance and/or specications and may suggest the use of certain

options, attachments or special operating procedures. Please consult your authorized Komatsu dealer for specications and availability. Komatsu owns and operates facilities in Covington, GA. Only those products made in Komatsus Georgia plant are built under ISO 9001 guidelines. Printed in the U.S.A.

YOUR AUTHORIZED DEALER OF KOMATSU FORKLIFTS

BRDX50-1 12/08

THE KOMATSU HERITAGE

As part of the Komatsu family, we have a proud heritage of excellence and supe-

riority in equipment design and manufacturing. Since 1921 Komatsu has been a

global leader in the construction and mining equipment industry. And since 1945,

we have built upon that heritage by producing innovative, high-quality, durable

forklifts to meet and exceed the needs of our customers. Today our ISO 9001-

certied plant in Covington, Georgia builds forklifts for North and South America,

Canada, Mexico, and Latin America.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Chairman Progress Report To LCEC On 4.10.15 (4 PGS)Document4 pagesChairman Progress Report To LCEC On 4.10.15 (4 PGS)Edwin NgNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Donation Pledge Form (R - Nov 15)Document1 pageDonation Pledge Form (R - Nov 15)Edwin NgNo ratings yet

- Treasurer Report (See Email DD 13.10.15) 6 PgsDocument6 pagesTreasurer Report (See Email DD 13.10.15) 6 PgsEdwin NgNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Artist Impression of The Re-Developed ChurchDocument1 pageArtist Impression of The Re-Developed ChurchEdwin NgNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Chairman Report (6 PGS) Inc Donation Pledge For BricksDocument6 pagesChairman Report (6 PGS) Inc Donation Pledge For BricksEdwin NgNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Online Donation UpdatesDocument3 pagesOnline Donation UpdatesEdwin NgNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Click Here For Career Opportunities at Mayland GroupDocument1 pageClick Here For Career Opportunities at Mayland GroupEdwin NgNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Online Donation Church Brief PDFDocument2 pagesOnline Donation Church Brief PDFEdwin NgNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Bulletin 11102015Document12 pagesBulletin 11102015Edwin NgNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- HSC Christmas 2012Document1 pageHSC Christmas 2012Edwin NgNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- HSC Christmas 2012Document1 pageHSC Christmas 2012Edwin NgNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Fcg36 8 Brochure SpecDocument4 pagesFcg36 8 Brochure SpecEdwin NgNo ratings yet

- Bulletin 25102015Document13 pagesBulletin 25102015Edwin NgNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- HSC Christmas 2012Document1 pageHSC Christmas 2012Edwin NgNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fd100 4h Fd160s 4ex BrochureDocument4 pagesFd100 4h Fd160s 4ex BrochureEdwin NgNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ex 50Document12 pagesEx 50Edwin NgNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Watch Night Service 31 DEC 2011Document6 pagesWatch Night Service 31 DEC 2011Edwin NgNo ratings yet

- Ftb16 20 BrochureDocument5 pagesFtb16 20 BrochureEdwin NgNo ratings yet

- FXGX 20Document5 pagesFXGX 20Edwin NgNo ratings yet

- AX50PDocument4 pagesAX50PEdwin NgNo ratings yet

- fd60 100 2brochureDocument4 pagesfd60 100 2brochureEdwin NgNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FHG d15 35s BrochureDocument7 pagesFHG d15 35s BrochureEdwin NgNo ratings yet

- Fcb15 30 BrochureDocument7 pagesFcb15 30 BrochureEdwin NgNo ratings yet

- PKSI023EN CX50 SpechBrochureDocument12 pagesPKSI023EN CX50 SpechBrochureEdwin NgNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fcg15 30 BrochureDocument7 pagesFcg15 30 BrochureEdwin NgNo ratings yet

- 08-Toyota 6FBREDocument8 pages08-Toyota 6FBREEdwin Ng67% (3)

- 10 Toyota 7FBDocument12 pages10 Toyota 7FBcachep213No ratings yet

- 02-Toyota 7FGK 2-3Document4 pages02-Toyota 7FGK 2-3Edwin NgNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- 09-Toyota 7FBEDocument8 pages09-Toyota 7FBEEdwin NgNo ratings yet

- Intarder Operating ManualDocument12 pagesIntarder Operating ManualOumarba KamandaNo ratings yet

- Engine RemovalDocument4 pagesEngine RemovalKiddNo ratings yet

- 2013 848evo DucatiOmahaDocument140 pages2013 848evo DucatiOmahaFabian Alejandro Ramos SandovalNo ratings yet

- Carburetor Spin Part ListDocument1 pageCarburetor Spin Part ListAlha Ega AnadaNo ratings yet

- Wiring Diagram - ME-SFI Fuel Injection and Ignition System 3Document9 pagesWiring Diagram - ME-SFI Fuel Injection and Ignition System 3Алексей СемикинNo ratings yet

- S12A2MPTKDocument3 pagesS12A2MPTKvikas_ojha5470650% (2)

- Msa15 To Edc15Document4 pagesMsa15 To Edc15Bianca Andrei100% (1)

- Parts List Xrv750yDocument61 pagesParts List Xrv750yGiorgos KoretsisNo ratings yet

- W Wiir Riin NG GD Diia AG GR RA AM M: - English - 9/2016Document586 pagesW Wiir Riin NG GD Diia AG GR RA AM M: - English - 9/2016Pavel100% (1)

- Catterpillar 924H - 924HZDocument671 pagesCatterpillar 924H - 924HZfelipe100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Main Engine Manual s70mcDocument287 pagesMain Engine Manual s70mcarun100% (1)

- DTC Rexton2Document225 pagesDTC Rexton2andre100% (1)

- BMW Engine B37B47 PDFDocument184 pagesBMW Engine B37B47 PDFdjiki21100% (2)

- Double Drum Bomag BW 202 AD-4Document3 pagesDouble Drum Bomag BW 202 AD-4Mohamed SaiedNo ratings yet

- Pneumatic Maneuvering SystemDocument65 pagesPneumatic Maneuvering Systemminhankyaw100% (3)

- DC16 Engine 478kWDocument4 pagesDC16 Engine 478kWmuniNo ratings yet

- Piaggio Beverly 125 (EN)Document278 pagesPiaggio Beverly 125 (EN)ManuallesNo ratings yet

- Dv8.5005 Ispl Book For Dv8 Engine For Power GenerationDocument135 pagesDv8.5005 Ispl Book For Dv8 Engine For Power GenerationMECHO STORENo ratings yet

- Why Does The Shift Shock Phenomenon Occur in Lower Gears As Compared To Higher Gears in Automatic Transmission EngineDocument2 pagesWhy Does The Shift Shock Phenomenon Occur in Lower Gears As Compared To Higher Gears in Automatic Transmission EnginethisisjineshNo ratings yet

- Workshop Manual: Abs/Pbs-2 Braking System Functioning PrincipleDocument24 pagesWorkshop Manual: Abs/Pbs-2 Braking System Functioning PrincipleAussi SidNo ratings yet

- Unit, Direct Support, and General Support Maintenance Repair Parts and Special Tools Lists FORDocument511 pagesUnit, Direct Support, and General Support Maintenance Repair Parts and Special Tools Lists FORRoland GoetzaNo ratings yet

- List of Isuzu EnginesDocument10 pagesList of Isuzu EnginesSMWilson33% (3)

- DC1671A - 480-483kW Scania Data SheetDocument2 pagesDC1671A - 480-483kW Scania Data SheetDenzal Wishington0% (1)

- Dodge Caliber Bsy 2007 Desmontaje de La Bomba de Aceite PiñonesDocument3 pagesDodge Caliber Bsy 2007 Desmontaje de La Bomba de Aceite PiñonesFlorin MoneaNo ratings yet

- двигател АВИА АИ-9Document2 pagesдвигател АВИА АИ-9Alexander NossovNo ratings yet

- Q and A For 2 Marks New Thermal EngineeringDocument43 pagesQ and A For 2 Marks New Thermal EngineeringPaul Arokiam S0% (1)

- CRDI (Common Rail Direct Injection)Document2 pagesCRDI (Common Rail Direct Injection)eafz111No ratings yet

- Audi 2.0 Tfsi Cdma: Timing Belt: Removal/installationDocument16 pagesAudi 2.0 Tfsi Cdma: Timing Belt: Removal/installationalejandroNo ratings yet

- Axel Dejo PenDocument8 pagesAxel Dejo PenCarlos Moreno AguilarNo ratings yet

- CJ 6A Checklist Version 1Document10 pagesCJ 6A Checklist Version 1mustang12484No ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)