Professional Documents

Culture Documents

Lab Repot Effect of Ripening TRT of Banana

Uploaded by

Azimah HamidonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Repot Effect of Ripening TRT of Banana

Uploaded by

Azimah HamidonCopyright:

Available Formats

LAB TITLE :

Effect of different ripening treatments on ripening quality of banana fruit

INTRODUCTION: Fruit ripening is a development controlled process that is regulated by plant hormones. Ripening is a process in fruits that causes them to become more edible. In general, a fruit becomes sweeter, less green, and softer as it ripens. Fruits are considered mature when they have stopped growing and once they have acquired the capacity to ripen. Indicators of maturity can be chronological, physical (e.g., a change in color or a decrease in fruit firmness), or chemical (e.g., a reduction in the amount of starch or acidity, or a gain soluble solids).Fruits can be categorized as climacteric and non-climacteric. Climacteric fruit is bananas, pears, and tomatoes while non-climacteric such as strawberries and oranges depending on whether or not they have a respiratory peak during their ripening process. The reason for a respiratory climacteric is still poorly understood. One hypothesis is that respiration is required for repair processes to avoid loss of mitochondrial function and uncoupling In storing the fruits, we should know how to keep them in good condition in order to maintain the quality and grade level. People have long been aware that overripe and rotting fruit could accelerate ripening of nearby fruit in the closed storage compartment during shipment. Accelerated fruit ripening during storage and shipment is due to the release of ethylene gas hormone by these fruits. As we know, ethylene is been used by the farmer or trader to keep the fruit ripening and quick harvesting period. So, they can pick the green and fresh fruit such as banana and mango before shipping. In the ship, they will apply ethylene gas to ensure ripening before reaching the supermarket counter. The picking of unripe fruit and artificial ripening later is not uncommon. In parts of Asia, a plastic cover is placed over unripe harvested mangoes. Calcium carbide is placed in open containers in strategic positions inside the bag. Moisture from the air converts the calcium carbide into acetylene which has the same fruit-ripening effect as ethylene. However, industrial-grade calcium carbide is sometimes contaminated with trace arsenic and phosphorous. The use of calcium carbide to stimulate fruit ripening is illegal in most countries. In other case, the degree of fruit ripening is caused by several factors such as low temperature and high ambient CO2 concentration in order to suppress respiration and continuous exchange of air to prevent ethylene gas build up. For example, Heidi mango fruits were harvested at the conventional stage and at an advanced stage of maturation from an orchard in South Africa. Following commercial pack line treatment, fruits were stored at 12.5C either under controlled atmosphere storage (low or high concentrations of CO2) or under normal atmosphere storage. After 21 days, fruits were allowed to

ripen at 20 under normal atmosphere. Quality was assessed on ripening. Fruits harvested at an advanced stage of maturation did not appear to benefit from CA storage. Pulp browning in these fruits was elevated. In fruits harvested at the conventional stage of maturation, CA storage reduced surface scald, pulp browning and internal breakdown, and enhanced shelf life and taste. The semi-commercial adoption of CA storage in Heidi mango is recommended for the coming season due to the competitive banana market, optimizing artificial banana ripening techniques has become a fundamental concern for the entire industry. The aim of this study is to determine the best ripening treatments on ripening quality characteristics of banana to give greater overall control over the shelf life of the fruit without diminishing its quality.

MATERIALS AND METHOD: Plant materials Banana was selected based on their uniformity of shape and colour, free of defects, bruises and damages. 18 bananas that were chosen, were cleaned and treated with 300 mg/L benomyl (dip for 5 minutes) and air dried the fruits. The initial weight of banana fruits were recorded. Treatment Banana fruits were treated with each of following treatments (Each of one treatment have 3 replication): PE bag with holes PE bag (MAP) PE bag + 10 % KOH PE bag + calcium carbide PE bag + 1000 L/L ethylene PE bag contain 10% KOH and 10% KMnO4 (separately) The fruits were placed in the room temperature (27 3c) for 7 days. Then the quality characteristics of the fruits were evaluated Physical quality characteristics 1. Fresh weight and final weight (kg) Fresh weight and final weight after ripening were recorded to know the weight loss of the banana fruit. The weight loss, on removal from a ripening temperature, was calculated as a percentage of initial weight. 2. Colour (L*, C* and h)

Colour of banana peel was ascertained by Minolta Chroma Meter to get the value of lightness (L*), Chroma (C*) and hue (h) of banana fruits. 3. Firmness (N) The bananas were cut off into 1 inch and the firmness were measured by using Instron. The readings were taken on the pulp of the fruits.

Chemical quality characteristics 1. Soluble solids concentration (% brix) 20 grams of pulp were blended with 80 ml of water using home blender. A drop or two of the portion were drip on the refractometer and the readings were taken. 2. pH The pH of the previous portion were measured using pH meter. 3. Titratable acidity (%) 5 mL of previous portion were drip with 1 or 2 drops of phenolftalein and titrate with 0.1 N NaOH. The readings then were calculated using formula: Titre x 0.1 x vol. Made up (50 ml) x 64g (Equivalent wt. of Citric acid) x 100 Sample weight (10g) x vol. Sample for titration (5 ml) x 1000 4. Ascorbic acids Weight 10 g sample and blend with 40 ml of HPO3 (metaphosphoric acid) and filter. Add HPO3 in the filtrate to a volume of 50 ml. Take 5 ml of filtrate and titrate the dye until pink. Record the volume of dye (titrate) used. Calculation of Vitamin C (mg/100 g): Titre x Dye Factor (0.125) x vol. Made up (50 ml) x 100 Sample (10 g) x vol. Sample for titration (5 ml)

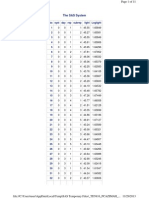

RESULTS AND DISCUSSION: In this experiment, we are using bananas to determine the best ripening treatments on ripening quality characteristics of banana to give greater overall control over the shelf life of the fruit without diminishing its quality. At first, each fruit is weighed to determined initial mass by using analytical balance. Then there are placed in some treatment or ripening agent by using PE bags, KOH, KOH and KMnO4 and Calcium carbide. This treatment will measure the rate of ripening in different condition in Modified Atmosphere Packaging. There were no significant differences in fresh weight, final weight and hue angle of banana peel colour (Table 1). However, there was a significant difference in weight loss between banana treated with 10% KOH and 10% KMnO4 in PE bag and banana treated with ethylene, MAP condition and banana in PE bag with holes (Table 1). Banana treated with 10% KOH and 10% KMnO4 in PE bag might be loss a lot of water during transpiration and respiration during the analysis. Analysis on firmness, there was significant differences between all treatments on banana (Table 1). This shown that, banana treated with 10% KOH in PE bags is the most firm than the rest, and banana treated with 10% KOH and 10% KMnO4 in PE bag is less firm than the rest treated banana. On peel colour of banana, banana treated with calcium carbide, ethylene and control were shown significant different with banana treated with 10% KOH and 10% KMnO4 in PE bag (Table 1). However, there were no significant differences between banana treated with calcium carbide, ethylene and control with banana in MAP condition and banana treated with 10% KOH (Table 1). There were no significant between control with banana in MAP condition, banana treated with KOH, calcium carbide and ethylene (Table 1). However, there was a significant difference between control and banana treated with 10% KOH and 10% KMnO4 in PE bag (Table 1). TABLE 1 Effect of different ripening treatments on physical quality characteristics of ripen banana Treatment Fresh Final Weight Firmness Peel colour weight (g) weight (g) loss (%) (N) Lightness Chrome Hue (h) (L*) (C*) PE bag with 78.983 a 75.620 a 4.310 b 3.2767 ab 67.363 a 35.233 a 84.910 a holes PE bag (MAP) 78.247 a 75.477 a 3.534 b 2.4567 c 60.487 bc 33.003 ab 82.823 a PE bag + 10 79.893 a 74.863 a 6.343 ab 3.5667 a 63.793 ab 32.817 ab 83.810 a % KOH PE bag + 78.360 a 74.130 a 5.427 ab 2.8733 bc 67.447 a 32.557 ab 85.987 a calcium carbide PE bag + 79.293 a 75.373 a 4.970 b 2.3767 c 65.357 a 33.820 ab 80.680 a 1000 L/L

ethylene PE bag + 10% 78.280 a 70.757 a 9.649 a 1.4933 d 58.447 c 29.813 b 80.897 a KOH + 10% KMnO4 Z Means followed by the same letter within columns are not significantly different using LSD at P 0.05. On chemical characteristics of ripen banana, there was significant differences between control with banana treated in MAP condition, KOH, calcium carbide, ethylene and also banana treated with 10% KOH and 10% KMnO4 in PE bag (Table 2) on SSC% parameter. This shown that SSC% in control condition which is banana was in PE bag with holes is higher than the rest of treatments of banana. PE bag with holes around should be less efficient compared to the sealed PE bag. It is because the holes allow ethylene gas release out the bag while sealed PE bag will clump the air and increasing the rate of fruit ripening inside the bag. However in this experiment, PE bags with holes have higher %SSC in banana than any other treatments of banana (Table 2). In pH parameter, there were significant different between control and banana treated with KOH, ethylene and banana treated with 10% KOH and 10% KMnO4 in PE bag (Table 2). On the other hand, there were significant differences among treatments of banana in titratable acidity (Table 2), where banana treated with 10% KOH and 10% KMnO4 in PE bag is higher in titratable acidity content and banana treated with KOH and Calcium carbide is lower in titratable acidity. However, there were no significant differences in ascorbic acids among treatments of banana. TABLE 2 Effect of different ripening treatment on chemical quality characteristics of ripen banana. Temperature (c) SSC (%) pH Titratable acidity Ascorbic acids PE bag with holes 14.1333 a 3.45000 c 2.66667 b 21.333 a PE bag (MAP) 5.3333 b 3.69333 ab 2.56000 b 29.333 a PE bag + 10 % KOH 4.5333 b 3.87000 a 2.43200 c 24.000 a PE bag + calcium 6.1333 b 3.52667 bc 2.60267 b 26.667 a carbide PE bag + 1000 L/L 5.6000 b 3.81000 a 2.43200 c 21.333 a ethylene PE bag + 10% KOH 4.4000 b 3.83667 a 2.88000 a 18.667 a + 10% KMnO4 Z Means followed by the same letter within columns are not significantly different using LSD at P 0.05. Calcium carbide is used for ripening the fruit artificially in some countries. Industrial-grade calcium carbide may contain traces of arsenic and phosphorus and thus use of this chemical for this purpose is illegal in most countries. Calcium carbide once dissolved in water produces acetylene which is

the essential gas for ripening process. The moisture in the air reacted with the calcium carbide to release the gas acetylene, which apparently has the same effect as ethylene gas. The effect of potassium permanganate (KMnO4) on the ripening process of papaya fruits and other fruit samples by monitoring the ethylene emission rates is reported. The ethylene emission was monitored by a photoacoustic spectrometer. The use of the ethylene absorber reduces the autocatalytic process of ethylene during papaya fruit ripening. For 20 g of KMnO4 the maximal intensity of the ethylene emission decreases by a factor two. Using the same amount of KMnO4, a reduction of about 2.2% in the concentration of ethylene for a mixture of 1ppmv of ethylene in synthetic air was observed. KOH also plays similar roles like KMnO4. The combination of these both ripening agent will make rapid ripening to the fruit samples.

CONCLUSION Banana is the most common fruit used in trading materials. When bananas are ripening, they release carbon dioxide which will build up in a ripening room. The CO2 production begins as the fruit ripens enters the climacteric phase, or the period when bananas release ethylene and have an elevated rate of respiration (along with a great deal of other physiological changes). Respiration involves the uptake of oxygen, the release of carbon dioxide, and the breakdown of starches. Carbon dioxide concentrations above 1% (10,000 ppm) will retard ripening, delay the effects of ethylene and cause quality problems. Therefore, it is recommended to vent rooms by opening the doors for 20 minutes every 12 hours, after the first 24 hours of ripening. Other venting methods are by automatic fan (either timed or sensor-based) or "flow-though" (constant) ventilation. Finally, when fruits undergo ripening process, they will change in colour and weight. Colour will turn from the light or dark green to the more attractive colour like yellow, orange or reddish. For example, banana will turn to the light yellow when getting ripe. Weight for each sample also become decrease due to denatures of linkage in fruit tissue make in lighter than younger fruit. Then, we use digital refractometer in order to measure the sugar content of fruits ( % Brix) . However, in this experiment, the result is not as we expected. It might be because of the analysis is carried out in ambient temperature and the period of experiment takes a long process. Futher studies should be carried out in the future.

REFERENCES 1) http://www.catalyticgenerators.com/tomriptip.html 2) http://chemistry.about.com/od/chemistryexperiments/ss/ethyleneexp_4.htm 3) http://jp4.journaldephysique.org/index.php?option=article&access=standard&Itemid=129&url=/articles /jp4/pdf/2005/03/jp4125201.pdf 4) http://hort.oregonstate.edu/stotzhe/pdf/FRUIT%20RIPENING.pdf

You might also like

- Effect of Coating and Wrapping Materials On The Shelf Life of Apple Malus Domestica CV BorkhDocument11 pagesEffect of Coating and Wrapping Materials On The Shelf Life of Apple Malus Domestica CV BorkhNadia Aprili PutriNo ratings yet

- Sdarticle (4) Fresh AppleDocument5 pagesSdarticle (4) Fresh AppleSergio BeltranNo ratings yet

- 11-Douglas Seijum Kohatsu1Document3 pages11-Douglas Seijum Kohatsu1Douglas KohatsuNo ratings yet

- Effects of An Innovative Dipping Treatment On The Cold Storage ApplesDocument7 pagesEffects of An Innovative Dipping Treatment On The Cold Storage ApplesAlexandraLópez100% (1)

- Jurnal Mangga PDFDocument8 pagesJurnal Mangga PDFyenny theresiaNo ratings yet

- Retention of Ascorbic Acid During Apple Chips Production and StorageDocument5 pagesRetention of Ascorbic Acid During Apple Chips Production and StorageAhzai WongNo ratings yet

- The Effect of Psyllium Seed Gum As An Edible Coating and in Comparison To Chitosan PDFDocument5 pagesThe Effect of Psyllium Seed Gum As An Edible Coating and in Comparison To Chitosan PDFAnonymous xGc8MRRysNo ratings yet

- Vit C Content of Freeze DriedDocument6 pagesVit C Content of Freeze DriedAnonymous N32czQLt0No ratings yet

- Effect of Post-Harvest Dips and Packing Treatments On Shelf Life of Papaya (Carica Papaya L.)Document3 pagesEffect of Post-Harvest Dips and Packing Treatments On Shelf Life of Papaya (Carica Papaya L.)nithyaNo ratings yet

- Nama: Muhammad Aldy Royhan NPM: E1G019093 Mata Kuliah: Bahasa Inggris Akademik Jurnal: 5Document4 pagesNama: Muhammad Aldy Royhan NPM: E1G019093 Mata Kuliah: Bahasa Inggris Akademik Jurnal: 5M. Aldy RoyhanNo ratings yet

- Practical Research 2Document10 pagesPractical Research 2Jazzle TanNo ratings yet

- V.K. Patel, Et AlDocument10 pagesV.K. Patel, Et AlRavindra AgarwalNo ratings yet

- Active Edible Coating To Maintain The Quality of Fresh MangoDocument8 pagesActive Edible Coating To Maintain The Quality of Fresh Mangosubdireccion licenciaturaNo ratings yet

- Happiemaga2008 PDFDocument9 pagesHappiemaga2008 PDFGabriel FigueroaNo ratings yet

- Effect of Storage Atmospheres On The Fruit QualityDocument12 pagesEffect of Storage Atmospheres On The Fruit Qualityslumber24100% (3)

- Application of Antibrowning Agents in Minimally Processed Cabbage EuYoDocument5 pagesApplication of Antibrowning Agents in Minimally Processed Cabbage EuYoGaganpreetNo ratings yet

- Application of Citric AcidDocument17 pagesApplication of Citric Acidsatish.viswaNo ratings yet

- International Journal of Pharma and Bio Sciences: Research Article Analytical ChemistryDocument7 pagesInternational Journal of Pharma and Bio Sciences: Research Article Analytical ChemistryMie YaNo ratings yet

- 3.3 PFPP-Lab ManualDocument28 pages3.3 PFPP-Lab ManualSB TEKNo ratings yet

- Investigation On The Effect of Nano Zeolite and Potassium Permanganate On The Shelf Life Extending and Quality of Red Delicious AppleDocument7 pagesInvestigation On The Effect of Nano Zeolite and Potassium Permanganate On The Shelf Life Extending and Quality of Red Delicious AppleInternational Network For Natural SciencesNo ratings yet

- Effect of Gum Arabic As An Edible Coating On Antioxidant Capacity of Tomato (Solanum Lycopersicum L.) Fruit During StorageDocument6 pagesEffect of Gum Arabic As An Edible Coating On Antioxidant Capacity of Tomato (Solanum Lycopersicum L.) Fruit During StorageChu BagunuNo ratings yet

- Extraction of Pectin From Lemon Peel: Technology DevelopmentDocument6 pagesExtraction of Pectin From Lemon Peel: Technology Developmenthntsa mikaNo ratings yet

- Agsc 201 HW 1Document5 pagesAgsc 201 HW 1Wael OsmanNo ratings yet

- Agsc 201 HW 1Document5 pagesAgsc 201 HW 1Wael OsmanNo ratings yet

- AC y Vapor de EtanolDocument5 pagesAC y Vapor de EtanolJacob Arturo Bustos PérezNo ratings yet

- Aplikasi Penyalut Edibel Berbasis Pati Kulit Pisang Dengan Penambahan Natrium Metabisulfit Pada Buah Salak Pondoh KupasDocument8 pagesAplikasi Penyalut Edibel Berbasis Pati Kulit Pisang Dengan Penambahan Natrium Metabisulfit Pada Buah Salak Pondoh Kupasfaris naufalNo ratings yet

- Ramos-Ramírez EmmaGloria 32Document4 pagesRamos-Ramírez EmmaGloria 32Alan Ortega GutierrezNo ratings yet

- Recubrimientos ComestiblesDocument12 pagesRecubrimientos ComestiblesAreitos DelgadoNo ratings yet

- Improving The Storage Quality of EggplanDocument9 pagesImproving The Storage Quality of EggplanBanca de Resurse Genetice Vegetale BZNo ratings yet

- Evaluation of Calamansi PeelDocument22 pagesEvaluation of Calamansi PeelKezia Derain Anciado100% (3)

- Thesis On Physiological Basis of Extending Shelf Life of TomatoDocument41 pagesThesis On Physiological Basis of Extending Shelf Life of Tomatobeautyf67% (3)

- Banana Ripening ProcessDocument16 pagesBanana Ripening ProcessFajar SungkarNo ratings yet

- Preparation of Fruits Candy From Jackfruit and Mango Using A Mechanical DryerDocument11 pagesPreparation of Fruits Candy From Jackfruit and Mango Using A Mechanical DryerKrishna DangiNo ratings yet

- 1 Improving Quality and Shelf Life of Vegetables and Fruits Antonio L. Acedo, Jr. 1997 PDFDocument12 pages1 Improving Quality and Shelf Life of Vegetables and Fruits Antonio L. Acedo, Jr. 1997 PDFNang BebNo ratings yet

- Concept Paper - Bioethanol YieldDocument8 pagesConcept Paper - Bioethanol YieldWingel LullabyNo ratings yet

- 1 s2.0 S0925521404002017 Main PDFDocument7 pages1 s2.0 S0925521404002017 Main PDFJefferson Bittencourt VenâncioNo ratings yet

- Effect of Anti Browning Agents and Slice Thickness On Drying and Quality of Apple Slices Var. Red ChiefDocument4 pagesEffect of Anti Browning Agents and Slice Thickness On Drying and Quality of Apple Slices Var. Red ChiefShailendra RajanNo ratings yet

- Food Chemistry: Shi-Ping Tian, Ai-Li Jiang, Yong Xu, You-Sheng WangDocument7 pagesFood Chemistry: Shi-Ping Tian, Ai-Li Jiang, Yong Xu, You-Sheng WangpascapanenipbNo ratings yet

- IJHB Higuera BouzoDocument6 pagesIJHB Higuera BouzoZiyad AlharbiNo ratings yet

- (ảnh hưởng tủ đông) 200843-Article Text-503801-1-10-20201027Document7 pages(ảnh hưởng tủ đông) 200843-Article Text-503801-1-10-20201027Thii HvNo ratings yet

- Activity No. 5 Effect of Refrigeration and Freezing On FoodsDocument9 pagesActivity No. 5 Effect of Refrigeration and Freezing On FoodsAbe LimNo ratings yet

- Essential Chemicals in Selected Fruit Peels From Manila, PhilippinesDocument5 pagesEssential Chemicals in Selected Fruit Peels From Manila, PhilippinesPeterson RonquilloNo ratings yet

- AWWupP789JfbKXPdf24 1O0CDocument5 pagesAWWupP789JfbKXPdf24 1O0CNguyễn ThuNo ratings yet

- Babarinde G.O., Fabunmi O.ADocument6 pagesBabarinde G.O., Fabunmi O.Anetiiyah netiiNo ratings yet

- Ijnpr 3 (4) 493-500Document8 pagesIjnpr 3 (4) 493-500Hieu NguyenNo ratings yet

- Effect of The Addition of Plant Extracts On The Microbiota of Minimally Processed Strawberry Jam and Its Physicochemical and Sensorial PropertiesDocument9 pagesEffect of The Addition of Plant Extracts On The Microbiota of Minimally Processed Strawberry Jam and Its Physicochemical and Sensorial PropertiesCosette VargasNo ratings yet

- Banana RipeningDocument5 pagesBanana RipeningrahmaNo ratings yet

- PROJECTDocument5 pagesPROJECTRAHUL RAJNo ratings yet

- PDFDocument6 pagesPDFAhmad Arbi AninditoNo ratings yet

- 1 PBDocument7 pages1 PBMarsa ChairaniNo ratings yet

- Ts-1 Effect of Anti Browning Agents On Banana Slices and Vacuum-Fried SlicesDocument7 pagesTs-1 Effect of Anti Browning Agents On Banana Slices and Vacuum-Fried Slicesdennica25100% (2)

- Food Chemistry: Amir Gull, Nusrat Bhat, Sajad Mohd Wani, Farooq Ahmad Masoodi, Tawheed Amin, Shaiq Ahmad GanaiDocument9 pagesFood Chemistry: Amir Gull, Nusrat Bhat, Sajad Mohd Wani, Farooq Ahmad Masoodi, Tawheed Amin, Shaiq Ahmad Ganaifawole olaniyiNo ratings yet

- Canning LabDocument10 pagesCanning LabRazim Adila0% (1)

- The Effect of Extraction Conditions On Total Phenolic Content and FreeDocument23 pagesThe Effect of Extraction Conditions On Total Phenolic Content and FreeClarisa DianNo ratings yet

- Lycopene Concentration and Physico-Chemical Properties of Tropical FruitsDocument5 pagesLycopene Concentration and Physico-Chemical Properties of Tropical FruitsSanTilinNo ratings yet

- Review of LiteratureDocument22 pagesReview of Literaturejavedsaqi64% (11)

- 19 IFRJ 20 (02) 2013 WanDocument6 pages19 IFRJ 20 (02) 2013 WanNguyễn Thành VinhNo ratings yet

- The Improvement Lycopene Availability and Antioxidant Activities of Tomato (Lycopersicum Esculentum, Mill) Jelly DrinkDocument7 pagesThe Improvement Lycopene Availability and Antioxidant Activities of Tomato (Lycopersicum Esculentum, Mill) Jelly DrinkAnthony SinagaNo ratings yet

- Mustafa and BaburaDocument3 pagesMustafa and BaburadessyNo ratings yet

- ASHS ManualDocument72 pagesASHS ManualAzimah HamidonNo ratings yet

- Amaranth PlusDocument1 pageAmaranth PlusAzimah HamidonNo ratings yet

- Transform Light Sawi 291113Document11 pagesTransform Light Sawi 291113Azimah HamidonNo ratings yet

- Sawi Mean N Standard ErrorDocument11 pagesSawi Mean N Standard ErrorAzimah HamidonNo ratings yet

- Literature Review No3 No2Document1 pageLiterature Review No3 No2Azimah HamidonNo ratings yet

- Highest NO Content in Bayam Is 1617.04 MG/KG From HY. - ConventionalDocument5 pagesHighest NO Content in Bayam Is 1617.04 MG/KG From HY. - ConventionalAzimah HamidonNo ratings yet

- Nitrite and Nitrate AnalysesDocument26 pagesNitrite and Nitrate AnalysesAzimah HamidonNo ratings yet

- Poster MSPPC Sonia 23082013Document1 pagePoster MSPPC Sonia 23082013Azimah HamidonNo ratings yet

- 4thsurvey ResultsDocument106 pages4thsurvey ResultsAzimah HamidonNo ratings yet

- Preharvest and Postharvest Factors Influencing Vitamin CDocument14 pagesPreharvest and Postharvest Factors Influencing Vitamin CAzimah HamidonNo ratings yet

- Chemicals and Physicals AnalysisDocument13 pagesChemicals and Physicals AnalysisAzimah HamidonNo ratings yet

- Diagnosis On Okra AntraknoseDocument7 pagesDiagnosis On Okra AntraknoseAzimah HamidonNo ratings yet

- 2008 Final English QuestionnaireDocument11 pages2008 Final English QuestionnaireAzimah HamidonNo ratings yet

- Nitrates and NitritesDocument1 pageNitrates and NitritesAzimah HamidonNo ratings yet

- Assignment Hrt5801 1stDocument6 pagesAssignment Hrt5801 1stAzimah HamidonNo ratings yet

- Chapter 2 Rev Sha 812013Document36 pagesChapter 2 Rev Sha 812013Azimah HamidonNo ratings yet

- Chemicals and Physicals AnalysisDocument13 pagesChemicals and Physicals AnalysisAzimah HamidonNo ratings yet

- Paper Gajah Mada 4 Feb 2010 SHA-R Corrected Summitted For ProceedingDocument10 pagesPaper Gajah Mada 4 Feb 2010 SHA-R Corrected Summitted For ProceedingAzimah HamidonNo ratings yet

- HACCPDocument7 pagesHACCPAzimah HamidonNo ratings yet

- Extended Abstract Progress AZIMAH 210513Document3 pagesExtended Abstract Progress AZIMAH 210513Azimah HamidonNo ratings yet

- Poster National Hort ConfDocument1 pagePoster National Hort ConfAzimah HamidonNo ratings yet

- Workshop Future Diretion and Business Opportunities in Food Production in NAP3'Document11 pagesWorkshop Future Diretion and Business Opportunities in Food Production in NAP3'Azimah HamidonNo ratings yet

- Effects of Biochar On Growth and Phytochemical Contents of Lemon Grass (Cymbopogon Citratus) 131011Document6 pagesEffects of Biochar On Growth and Phytochemical Contents of Lemon Grass (Cymbopogon Citratus) 131011Azimah HamidonNo ratings yet

- Chauhan2017mulberry SericultureDocument67 pagesChauhan2017mulberry SericultureNarasimha Murthy S VNo ratings yet

- G.B.Pant University of Agriculture & Technology, Pantnagar-263145, Distt. Udham Singh Nagar (Uttarakhand) University Website: WWW - Gbpuat.ac - inDocument4 pagesG.B.Pant University of Agriculture & Technology, Pantnagar-263145, Distt. Udham Singh Nagar (Uttarakhand) University Website: WWW - Gbpuat.ac - inJeshiNo ratings yet

- 8610 - 1 Maham AslamDocument21 pages8610 - 1 Maham AslamMuhammad BasitNo ratings yet

- Manage Your Personal Energy PDFDocument46 pagesManage Your Personal Energy PDFezhil manickamNo ratings yet

- Sri Roth 2000Document11 pagesSri Roth 2000ottoojuniiorNo ratings yet

- Taxonomy of Haematococcus PluvialisDocument2 pagesTaxonomy of Haematococcus PluvialisKomathi BalasupramaniamNo ratings yet

- Survival and Dissemination of Plant PathogensDocument24 pagesSurvival and Dissemination of Plant PathogensSuprabuddha KunduNo ratings yet

- Social Institutions - Kinship, Family&Marriage PDFDocument47 pagesSocial Institutions - Kinship, Family&Marriage PDFAbhijith KNo ratings yet

- Pathomorophology. (Medicine, 3 Course)Document10 pagesPathomorophology. (Medicine, 3 Course)Joy JoyNo ratings yet

- MHE RDG Wonders LVRDR G3 ELL U4W3 18Document24 pagesMHE RDG Wonders LVRDR G3 ELL U4W3 18Kenneth N AngelineNo ratings yet

- Human Genetics Concepts and Applications 11Th Edition Ricki Lewis Test Bank Full Chapter PDFDocument36 pagesHuman Genetics Concepts and Applications 11Th Edition Ricki Lewis Test Bank Full Chapter PDFdavid.cordero230100% (14)

- Escueoloside A2 From TomatoDocument8 pagesEscueoloside A2 From TomatoShyam ReddyNo ratings yet

- Tushar FinalDocument29 pagesTushar FinalRaj Prixit RathoreNo ratings yet

- CV Christopher Lean Jan 2024 Without ReferencesDocument5 pagesCV Christopher Lean Jan 2024 Without Referencesapi-399765628No ratings yet

- Determination of Sensitive Proteins in Beer by Nephelometry - Submitted On Behalf of The Analysis Committee of The European Brewery ConventionDocument4 pagesDetermination of Sensitive Proteins in Beer by Nephelometry - Submitted On Behalf of The Analysis Committee of The European Brewery ConventionChí HữuNo ratings yet

- Penilaian Sumatif Satuan Pendidikan (PSSP) Mata Pelajaran Bahasa Inggris Ta. 20222023Document1 pagePenilaian Sumatif Satuan Pendidikan (PSSP) Mata Pelajaran Bahasa Inggris Ta. 20222023Malfa FaradisNo ratings yet

- Weekly Home Learning Plan: Day/Time Learning Competency Learning Tasks Mode of DeliveryDocument4 pagesWeekly Home Learning Plan: Day/Time Learning Competency Learning Tasks Mode of DeliveryEricha SolomonNo ratings yet

- SOIL AND IRRIGATION WATER MANUAL, Model SIW-1, Kit 2496000 PDFDocument60 pagesSOIL AND IRRIGATION WATER MANUAL, Model SIW-1, Kit 2496000 PDFIvonné AlvarezNo ratings yet

- Artikel SkripsiDocument12 pagesArtikel SkripsiSari RofiqohNo ratings yet

- Guideline For Prevention of Surgical Wound InfectionsDocument14 pagesGuideline For Prevention of Surgical Wound InfectionsosaqerNo ratings yet

- Cat ExamDocument25 pagesCat Examlahsivlahsiv684No ratings yet

- Qualitative and QuantitativeDocument2 pagesQualitative and Quantitativetimmierivera100% (1)

- Aims Stress - The SeedDocument27 pagesAims Stress - The SeedFx KovacsNo ratings yet

- Chemical Equilibrium and Le Chatelier's Principle: Chemistry 1Document17 pagesChemical Equilibrium and Le Chatelier's Principle: Chemistry 1azamatNo ratings yet

- Microscopy and StainingDocument7 pagesMicroscopy and StainingDenmark ManlusocNo ratings yet

- Blood Doping PPT PresentationDocument26 pagesBlood Doping PPT Presentationee4254100% (1)

- 6.1 MicrobiologyDocument32 pages6.1 MicrobiologyYsabelle BautistaNo ratings yet

- Determination of Formaldehyde in Tofu From Ciputat Traditional Market With Colorimetry MethodDocument6 pagesDetermination of Formaldehyde in Tofu From Ciputat Traditional Market With Colorimetry Methodhali taekookNo ratings yet

- CLS Aipmt 15 16 XIII Zoo Study Package 2 Set 1 Chapter 3Document30 pagesCLS Aipmt 15 16 XIII Zoo Study Package 2 Set 1 Chapter 3Santu Karmakar100% (1)

- Psychophysics As New Priority in Modern Science - Physical Basics of Informational InteractionDocument15 pagesPsychophysics As New Priority in Modern Science - Physical Basics of Informational InteractionBoris PetrovicNo ratings yet

- A Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouFrom EverandA Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouRating: 4.5 out of 5 stars4.5/5 (62)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (3)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- Tales from Both Sides of the Brain: A Life in NeuroscienceFrom EverandTales from Both Sides of the Brain: A Life in NeuroscienceRating: 3 out of 5 stars3/5 (18)

- Gut: the new and revised Sunday Times bestsellerFrom EverandGut: the new and revised Sunday Times bestsellerRating: 4 out of 5 stars4/5 (392)

- Undeniable: How Biology Confirms Our Intuition That Life Is DesignedFrom EverandUndeniable: How Biology Confirms Our Intuition That Life Is DesignedRating: 4 out of 5 stars4/5 (11)

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceFrom EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceRating: 4.5 out of 5 stars4.5/5 (516)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)From EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Rating: 4 out of 5 stars4/5 (378)

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessFrom Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessRating: 4 out of 5 stars4/5 (33)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- Inside of a Dog: What Dogs See, Smell, and KnowFrom EverandInside of a Dog: What Dogs See, Smell, and KnowRating: 4 out of 5 stars4/5 (390)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsFrom EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsRating: 4 out of 5 stars4/5 (5)

- Human: The Science Behind What Makes Your Brain UniqueFrom EverandHuman: The Science Behind What Makes Your Brain UniqueRating: 3.5 out of 5 stars3.5/5 (38)

- Fast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperFrom EverandFast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperRating: 4.5 out of 5 stars4.5/5 (15)

- Good Without God: What a Billion Nonreligious People Do BelieveFrom EverandGood Without God: What a Billion Nonreligious People Do BelieveRating: 4 out of 5 stars4/5 (66)

- The Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorFrom EverandThe Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorNo ratings yet

- Crypt: Life, Death and Disease in the Middle Ages and BeyondFrom EverandCrypt: Life, Death and Disease in the Middle Ages and BeyondRating: 4 out of 5 stars4/5 (4)

- Buddha's Brain: The Practical Neuroscience of Happiness, Love & WisdomFrom EverandBuddha's Brain: The Practical Neuroscience of Happiness, Love & WisdomRating: 4 out of 5 stars4/5 (215)

- Who's in Charge?: Free Will and the Science of the BrainFrom EverandWho's in Charge?: Free Will and the Science of the BrainRating: 4 out of 5 stars4/5 (65)

- All That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesFrom EverandAll That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesRating: 4.5 out of 5 stars4.5/5 (397)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- The Second Brain: A Groundbreaking New Understanding of Nervous Disorders of the Stomach and IntestineFrom EverandThe Second Brain: A Groundbreaking New Understanding of Nervous Disorders of the Stomach and IntestineRating: 4 out of 5 stars4/5 (17)

- Moral Tribes: Emotion, Reason, and the Gap Between Us and ThemFrom EverandMoral Tribes: Emotion, Reason, and the Gap Between Us and ThemRating: 4.5 out of 5 stars4.5/5 (115)

- The Invention of Tomorrow: A Natural History of ForesightFrom EverandThe Invention of Tomorrow: A Natural History of ForesightRating: 4.5 out of 5 stars4.5/5 (5)