Professional Documents

Culture Documents

NCV2931

Uploaded by

Vijai PrabhuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NCV2931

Uploaded by

Vijai PrabhuCopyright:

Available Formats

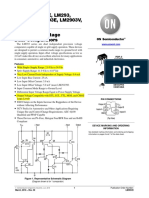

LM2931, NCV2931 Series 100 mA, Adjustable Output, LDO Voltage Regulator with 60 V Load Dump Protection

The LM2931 series consists of positive fixed and adjustable output voltage regulators that are specifically designed to maintain proper regulation with an extremely low inputtooutput voltage differential. These devices are capable of supplying output currents in excess of 100 mA and feature a low bias current of 0.4 mA at 10 mA output. Designed primarily to survive in the harsh automotive environment, these devices will protect all external load circuitry from input fault conditions caused by reverse battery connection, two battery jump starts, and excessive line transients during load dump. This series also includes internal current limiting, thermal shutdown, and additionally, is able to withstand temporary powerup with mirrorimage insertion. Due to the low dropout voltage and bias current specifications, the LM2931 series is ideally suited for battery powered industrial and consumer equipment where an extension of useful battery life is desirable. The C suffix adjustable output regulators feature an output inhibit pin which is extremely useful in microprocessorbased systems.

Features http://onsemi.com

FIXED OUTPUT VOLTAGE TO92 Z SUFFIX CASE 29 TO220 T SUFFIX CASE 221AB DPAK DT SUFFIX CASE 369C D2PAK D2T SUFFIX CASE 936 SOT223 ST SUFFIX CASE 318H Pin 1. Output 2. Ground 3. Input

1 2 3

1 2 3

Pin 1. Input 2. Ground 3. Output

InputtoOutput Voltage Differential of < 0.6 V @ 100 mA Output Current in Excess of 100 mA Low Bias Current 60 V Load Dump Protection 50 V Reverse Transient Protection Internal Current Limiting with Thermal Shutdown Temporary MirrorImage Protection Ideally Suited for Battery Powered Equipment Economical 5Lead TO220 Package with Two Optional Leadforms Available in Surface Mount SOP8, D2PAK and DPAK Packages High Accuracy (2.5%) Reference (LM2931AC) Available PbFree Packages are Available NCV Prefix for Automotive and Other Applications Requiring Site and Control Changes

ADJUSTABLE OUTPUT VOLTAGE TO220 TH SUFFIX CASE 314A TO220 1 TV SUFFIX CASE 314B TO220 T SUFFIX CASE 314D

Applications

Battery Powered Consumer Products Handheld Instruments Camcorders and Cameras

SOIC8 D SUFFIX CASE 751 FIXED N.C. GND Input 8 1 5 4 N.C. GND Output Output Inhibit GND Input 8 1

8 1

1 5

Pin 1. Adjust 2. Output Inhibit 3. Ground 4. Input 5. Output

D2PAK D2T SUFFIX 1 CASE 936A

ADJUSTABLE 5 4 Adjust GND Output

ORDERING INFORMATION

See detailed ordering and shipping information in the package dimensions section on page 12 of this data sheet.

DEVICE MARKING INFORMATION

See general marking and heatsink information in the device marking section on page 15 of this data sheet.

(Top View)

(Top View)

Semiconductor Components Industries, LLC, 2011

December, 2011 Rev. 25

Publication Order Number: LM2931/D

LM2931, NCV2931 Series

Representative Schematic Diagram

Input 6.0

6.0 k 350 500 Output 30 k 30 k * 3.94 k Adjust 3.0 k EPI Bias 30 k

30 k 6.8 V Output Inhibit 50 k 48 k 180 k 184 k 5.8 V

92.8 k * 11.5 k Ground *Deleted on Adjustable Regulators This device contains 26 active transistors. 35 k 10 k

http://onsemi.com

2

LM2931, NCV2931 Series

MAXIMUM RATINGS

Rating Input Voltage Continuous Transient Input Voltage (t 100 ms) Transient Reverse Polarity Input Voltage 1.0% Duty Cycle, t 100 ms Electrostatic Discharge Sensitivity (ESD) Human Body Model (HBM) Class 2, JESD22 A114C Machine Model (MM) Class A, JESD22 A115A Charged Device Model (CDM), JESD22 C101C Power Dissipation Case 29 (TO92 Type) TA = 25C Thermal Resistance, JunctiontoAmbient Thermal Resistance, JunctiontoCase Case 221A, 314A, 314B and 314D (TO220 Type) TA = 25C Thermal Resistance, JunctiontoAmbient Thermal Resistance, JunctiontoCase Case 318H (SOT223) TA = 25C Thermal Resistance, JunctiontoAmbient Thermal Resistance, JunctiontoCase Case 369A (DPAK) (Note 1) TA = 25C Thermal Resistance, JunctiontoAmbient Thermal Resistance, JunctiontoCase Case 751 (SOP8) (Note 2) TA = 25C Thermal Resistance, JunctiontoAmbient Thermal Resistance, JunctiontoCase Case 936 and 936A (D2PAK) (Note 3) TA = 25C Thermal Resistance, JunctiontoAmbient Thermal Resistance, JunctiontoCase Operating Ambient Temperature Range Operating Die Junction Temperature Storage Temperature Range Symbol VI VI(t) VI(t) Value 40 60 50 Unit Vdc Vpk Vpk

2000 200 2000

V V V

PD RqJA RqJC PD RqJA RqJC PD RqJA RqJC PD RqJA RqJC PD RqJA RqJC PD RqJA RqJC TA TJ Tstg

Internally Limited 178 83 Internally Limited 65 5.0 Internally Limited 242 21 Internally Limited 92 6.0 Internally Limited 160 25 Internally Limited 70 5.0 40 to +125 +150 65 to +150

W C/W C/W W C/W C/W W C/W C/W W C/W C/W W C/W C/W W C/W C/W C C C

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect device reliability. 1. DPAK JunctiontoAmbient Thermal Resistance is for vertical mounting. Refer to Figure 25 for board mounted Thermal Resistance. 2. SOP8 JunctiontoAmbient Thermal Resistance is for minimum recommended pad size. Refer to Figure 24 for Thermal Resistance variation versus pad size. 3. D2PAK JunctiontoAmbient Thermal Resistance is for vertical mounting. Refer to Figure 26 for board mounted Thermal Resistance. 4. NCV rated devices are subjected to and meet the AECQ100 quality standards.

http://onsemi.com

3

LM2931, NCV2931 Series

ELECTRICAL CHARACTERISTICS (Vin = 14 V, IO = 10 mA, CO = 100 mF, CO(ESR) = 0.3 W, TA = 25C [Note 5])

LM29315.0/NCV29315.0 Characteristic FIXED OUTPUT Output Voltage Vin = 14 V, IO = 10 mA, TA = 25C Vin = 6.0 V to 26 V, IO 100 mA, TA = 40 to +125C Line Regulation Vin = 9.0 V to 16 V Vin = 6.0 V to 26 V Load Regulation (IO = 5.0 mA to 100 mA) Output Impedance IO = 10 mA, DIO = 1.0 mA, f = 100 Hz to 10 kHz Bias Current Vin = 14 V, IO = 100 mA, TA = 25C Vin = 6.0 V to 26 V, IO = 10 mA, TA = 40 to +125C Output Noise Voltage (f = 10 Hz to 100 kHz) Long Term Stability Ripple Rejection (f = 120 Hz) Dropout Voltage IO = 10 mA IO = 100 mA OverVoltage Shutdown Threshold Output Voltage with Reverse Polarity Input (Vin = 15 V) Vth(OV) VO Vn S RR VIVO 26 0.3 0.015 0.16 29.5 0 0.2 0.6 40 26 0.3 0.015 0.16 29.5 0 0.2 0.6 40 V V IB 60 5.8 0.4 700 20 90 30 1.0 60 5.8 0.4 700 20 90 30 1.0 mVrms mV/kHR dB V Regload ZO 200 200 mA Regline 2.0 4.0 14 10 30 50 2.0 4.0 14 10 30 50 mV mW VO 4.75 4.50 5.0 5.25 5.50 4.81 4.75 5.0 5.19 5.25 mV V Symbol Min Typ Max LM2931A5.0/NCV2931A5.0 Min Typ Max Unit

5. Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible. 6. NCV devices are qualified for automotive use.

http://onsemi.com

4

LM2931, NCV2931 Series

ELECTRICAL CHARACTERISTICS (Vin = 14 V, IO = 10 mA, CO = 100 mF, CO(ESR) = 0.3 W, TA = 25C [Note 7])

LM2931C/NCV2931C Characteristic ADJUSTABLE OUTPUT Reference Voltage (Note 8, Figure 18) IO = 10 mA, TA = 25C IO 100 mA, TA = 40 to +125C Output Voltage Range Line Regulation (Vin = VO + 0.6 V to 26 V) Load Regulation (IO = 5.0 mA to 100 mA) Output Impedance IO = 10 mA, DIO = 1.0 mA, f = 10 Hz to 10 kHz Bias Current IO = 100 mA IO = 10 mA Output Inhibited (Vth(OI) = 2.5 V) Adjustment Pin Current Output Noise Voltage (f = 10 Hz to 100 kHz) LongTerm Stability Ripple Rejection (f = 120 Hz) Dropout Voltage IO = 10 mA IO = 100 mA OverVoltage Shutdown Threshold Output Voltage with Reverse Polarity Input (Vin = 15 V) Output Inhibit Threshold Voltages Output On: TA = 25C TA = 40 to +125C Output Off: TA = 25C TA = 40 to +125C Output Inhibit Threshold Current (Vth(OI) = 2.5 V) Vref V 1.14 1.08 3.0 to 24 0.10 26 0.3 1.20 2.7 to 29.5 0.2 0.3 40 6.0 0.4 0.2 0.2 140 0.4 0.003 0.015 0.16 29.5 0 1.26 1.32 1.5 1.0 1.0 1.0 0.2 0.6 40 1.17 1.15 3.0 to 24 0.10 26 0.3 1.20 2.7 to 29.5 0.2 0.3 40 6.0 0.4 0.2 0.2 140 0.4 0.003 0.015 0.16 29.5 0 1.23 1.25 1.5 1.0 mA 1.0 1.0 0.2 0.6 40 V V V 2.50 3.25 2.15 2.26 30 1.90 1.20 50 2.50 3.25 2.15 2.26 30 1.90 1.20 50 mA mA mVrms/V %/kHR %/V V V mV/V %/V mW/V Symbol Min Typ Max LM2931AC/NCV2931AC Min Typ Max Unit

VO range Regline Regload ZO IB

IAdj Vn S RR VIVO

Vth(OV) VO Vth(OI)

Ith(OI)

7. Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient as possible. 8. The reference voltage on the adjustable device is measured from the output to the adjust pin across R1.

http://onsemi.com

5

LM2931, NCV2931 Series

200 Vin -VO , DROPOUT VOLTAGE (mV) Vin -VO , DROPOUT VOLTAGE (mV) 160 120 80 40 0 Vin = 14 V DVout = 100 mV TJ = 25C 300 Vin = 14 V DVout = 100 mV 200

IO = 100 mA

100 IO = 50 mA IO = 10 mA 0 0 25 50 75 100 125

20

40 60 IO, OUTPUT CURRENT (mA)

80

100

TJ, JUNCTION TEMPERATURE (C)

Figure 1. Dropout Voltage versus Output Current

Figure 2. Dropout Voltage versus Junction Temperature

350 I O , OUTPUT CURRENT (mA)

6.0 5.0 4.0 3.0 2.0 1.0 0 RL = 50 W IO = 100 mA Vout = 5.0 V TA = 25C

250 TJ = 85C

TJ = 25C

150 Dashed lines below Vin = 5.0 V are for Adjustable output devices only. 50 0 5.0 10 15 20 Vin, INPUT VOLTAGE (V) 25 30

VO , OUTPUT VOLTAGE (V)

TJ = -40C

1.0

2.0 3.0 4.0 Vin, INPUT VOLTAGE (V)

5.0

6.0

Figure 3. Peak Output Current versus Input Voltage

Figure 4. Output Voltage versus Input Voltage

Vin , INPUT VOLTAGE (10 V/DIV)

6.0 VO , OUTPUT VOLTAGE (V) 5.0 4.0 3.0 2.0 1.0 0 -20 Vout = 5.0 V RL = 500 W TA = 25C -10 0 10 20 30 Vin, INPUT VOLTAGE (V) 40 50 60 VCC = 15 V VFB1 = 5.05 V

Vout = 5.0 V RL = 50 W CO = 100 mF t = 150 ms TA = 25C

VO, OUTPUT VOLTAGE (5.0 V/DIV)

t, TIME (50 ms/DIV)

Figure 5. Output Voltage versus Input Voltage

Figure 6. Load Dump Characteristics

http://onsemi.com

6

LM2931, NCV2931 Series

12 10 8.0 6.0 4.0 2.0 0 -20 RL = 100 W RL = 500 W 0 -10 0 10 20 30 Vin, INPUT VOLTAGE (V) 40 50 60 0 20 40 60 80 100 RL = 50 W Vout = 5.0 V TJ = 25C 8.0

IB , BIAS CURRENT (mA)

IB , BIAS CURRENT (mA)

6.0

Vin = 14 V Vout = 5.0 V TJ = 25C

4.0

2.0

IO, OUTPUT CURRENT (mA)

Figure 7. Bias Current versus Input Voltage

Figure 8. Bias Current versus Output Current

8.0 IO , OUTPUT IMPEDANCE ( ) Vin = 14 V Vout = 5.0 V IB , BIAS CURRENT (mA) 6.0 IO = 100 mA

2.0 1.6 1.2 0.8 0.4 0 -25 0 25 50 75 TJ, JUNCTION TEMPERATURE (C) 100 125 10 100 1.0 k 10 k 100 k f, FREQUENCY (Hz) 1.0 M 10 M CO(ESR) = 0.3 W Electrolytic Vin = 14 V Vout = 5.0 V IO = 10 mA DIO = 1.0 mA CO = 100 mF TJ = 25C

4.0 IO = 50 mA 2.0 IO = 0 mA 0 -55

CO(ESR) = 0.15 W Tantulum

Figure 9. Bias Current versus Junction Temperature

Figure 10. Output Impedance versus Frequency

95 RR, RIPPLE REJECTION RATIO (dB) RR, RIPPLE REJECTION RATIO (dB)

95

85 Vin = 14 V Vout = 5.0 V DVin = 100 mV RL = 500 W CO = 100 mF TJ = 25C CO(ESR) = 0.15 W Tantulum

85

75

75

65

CO(ESR) = 0.3 W Electrolytic 1.0 k 10 k 100 k 1.0 M 10 M

Vin = 14 V Vout = 5.0 V f = 120 Hz TJ = 25C

55 10 100 f, FREQUENCY (Hz)

65 0 20 40 60 IO, OUTPUT CURRENT (mA) 80 100

Figure 11. Ripple Rejection versus Frequency

Figure 12. Ripple Rejection versus Output Current

http://onsemi.com

7

LM2931, NCV2931 Series

OUTPUT CURRENT, OUTPUT VOLTAGE DEVIATION, I out (mA) VO , (2.0 mV/DIV) OUTPUT VOLTAGE DEVIATION, VO , (2.0 mV/DIV)

18.5

Vout = 5.0 V RL = 500 W CO = 100 mF CO(ESR) = 0.3 W TA = 25C

Vin = 14 V Vout = 5.0 V Cin = 1000 mF 100 CO = 100 mF CO(ESR) = 0.3 W TA = 25C

INPUT VOLTAGE, V in, (V)

14 t, TIME (10 ms/DIV)

0 t, TIME (10 ms/DIV)

Figure 13. Line Regulation

Figure 14. Load Regulation

2.6 2.5 2.4 2.3 2.2 2.1 2.0 Output On" LM2931C Adjustable IO = 10 mA Vin = Vout + 1.0 V TA = 25C

1.240 Vref, REFERENCE VOLTAGE (V) LM2931C Adjustable IO = 10 mA Vin = Vout + 1.0 V TA = 25C

V th(on/off) , OUTPUT INHIBITTHRESHOLDS (V)

1.220

Output Off"

1.200

1.180

1.160 0 3.0 6.0 9.0 12 15 18 21 24 VO, OUTPUT VOLTAGE (V)

3.0

6.0

9.0 12 15 18 VO, OUTPUT VOLTAGE (V)

21

24

Figure 15. Reference Voltage versus Output Voltage

Figure 16. Output InhibitThresholds versus Output Voltage

APPLICATIONS INFORMATION The LM2931 series regulators are designed with many protection features making them essentially blowout proof. These features include internal current limiting, thermal shutdown, overvoltage and reverse polarity input protection, and the capability to withstand temporary powerup with mirrorimage insertion. Typical application circuits for the fixed and adjustable output device are shown in Figures 17 and 18. The input bypass capacitor Cin is recommended if the regulator is located an appreciable distance ( 4) from the supply input filter. This will reduce the circuits sensitivity to the input line impedance at high frequencies. This regulator series is not internally compensated and thus requires an external output capacitor for stability. The capacitance value required is dependent upon the load current, output voltage for the adjustable regulator, and the type of capacitor selected. The least stable condition is encountered at maximum load current and minimum output voltage. Figure 22 shows that for operation in the Stable region, under the conditions specified, the magnitude of the output capacitor impedance |ZO| must not exceed 0.4 W. This limit must be observed over the entire operating temperature range of the regulator circuit. With economical electrolytic capacitors, cold temperature operation can pose a serious stability problem. As the electrolyte freezes, around 30C, the capacitance will decrease and the equivalent series resistance (ESR) will increase drastically, causing the circuit to oscillate. Quality electrolytic capacitors with extended temperature ranges of 40 to +85C and 55 to +105C are readily available. Solid tantalum capacitors may be a better choice if small size is a requirement, however, the maximum ZO limit over temperature must be observed. Note that in the stable region, the output noise voltage is linearly proportional to ZO. In effect, CO dictates the high frequency rolloff point of the circuit. Operation in the area titled Marginally Stable will cause the output of the regulator to exhibit random bursts of oscillation that decay in an underdamped fashion. Continuous oscillation occurs when operating in the area titled Unstable. It is suggested that oven testing of the entire circuit be performed with maximum load, minimum input voltage, and minimum ambient temperature.

http://onsemi.com

8

LM2931, NCV2931 Series

Input Vin 51 k Cin 0.1 2 1 IB Input Vin Cin 0.1 LM2931-5.0 Fixed Output IB GND Output Vout Switch Position 1 = Output On", 2 = Output Off" V out + V ref 1 ) R2 R1 ) I R Adj 2 22.5 k w R1 R2 GND Output Inhibit LM2931C Adjustable Output R1 Adjust CO IAdj R2 Output Vout

CO

R1 ) R2

Figure 17. Fixed Output Regulator

Figure 18. Adjustable Output Regulator

Input 6.0 V 68 R

D45VH7

Input R 5.0 V @ 5.0 A LM2931-5.0

RSC

Output LM2931-5.0 + 100 100 +

+ 100 100

Output

The LM2931 series can be current boosted with a PNP transistor. The D45VH7, on a heatsink, will provide an output current of 5.0 A with an input to output voltage differential of approximately 1.0 V. Resistor R in conjunction with the VBE of the PNP determines when the pass transistor begins conducting. This circuit is not short circuit proof.

The circuit of Figure 19 can be modified to provide supply protection against short circuits by adding the current sense resistor RSC and an additional PNP transistor. The current sensing PNP must be capable of handling the short circuit current of the LM2931. Safe operating area of both transistors must be considered under worst case conditions.

Figure 19. (5.0 A) Low Differential Voltage Regulator

Figure 20. Current Boost Regulator with Short Circuit Projection

Input 6.4 V to 30 V

LM2931C

2.0 k 100 8.2 k

CM #345 + 100 33 k

6.2 V 0 fosc = 2.2 Hz

Figure 21. Constant Intensity Lamp Flasher

http://onsemi.com

9

LM2931, NCV2931 Series

Vn , OUTPUT NOISE VOLTAGE (mVrms) 100 Vin = 5.6 V Vout = 5.0 V IO = 100 mA Vnrms 10 Hz to 10 MHz |ZO| @ 40 kHz TA = 25C Unstable ESR (Ohms) Marginally Stable 10 mF 22 mF 47 mF 100 mF 0.40 0.50 0.30 Stable 0.20 0.1 Stable 0.10 0.00 Note - Optimum stability uses a 22 mF output capacitor. Output capacitor values below 10 mF are not recommended. 0 10 20 30 40 60 70 50 OUTPUT CURRENT (mA) 80 90 100 0.60

Unstable

10

1.0

0.01 10

100 1.0 k |ZO|, MAGNITUDE OF CAPACITOR IMPEDANCE (mW)

10 k

Figure 22. Output Noise Voltage vs. Output Capacitor Impedance

Figure 23. Output Capacitor ESR Stability vs. Output Load Current

JUNCTION-TO-AIR ( C/W)

150 130 110 90 70 50 30 0 10 RqJA 20

PD(max) for TA = 50C

2.8 2.4

Graph represents symmetrical layout L 2.0 oz. Copper L

2.0 1.6 1.2 0.8 0.4

3.0 mm

30

40

50

L, LENGTH OF COPPER (mm)

Figure 24. SOP8 Thermal Resistance and Maximum Power Dissipation versus P.C.B. Copper Length

R JA, THERMAL RESISTANCE

JUNCTION-TO-AIR ( C/W)

90 80 70 60 50

Free Air Mounted Vertically Minimum Size Pad

PD(max) for TA = 50C 2.0 2.0 oz. Copper L

1.6 1.2 0.8 0.4 0

RqJA 40 0 5.0 10 15 20 L, LENGTH OF COPPER (mm)

25

30

Figure 25. DPAK Thermal Resistance and Maximum Power Dissipation versus P.C.B. Copper Length

http://onsemi.com

10

PD, MAXIMUM POWER DISSIPATION (W)

100

2.4

PD, MAXIMUM POWER DISSIPATION (W)

170 R JA, THERMAL RESISTANCE

3.2

LM2931, NCV2931 Series

PD(max) for TA = 50C 70 60 50 40 RqJA 30 0 5.0 10 15 20 L, LENGTH OF COPPER (mm) Free Air Mounted Vertically Minimum Size Pad 3.0 2.0 oz. Copper L 2.5 2.0 1.5 1.0 PD, MAXIMUM POWER DISSIPATION (W) PD, MAXIMUM POWER DISSIPATION (W) 80 R JA, THERMAL RESISTANCE JUNCTION-TO-AIR ( C/W) 3.5

Figure 26. 3Pin and 5Pin D2PAK Thermal Resistance and Maximum Power Dissipation versus P.C.B. Copper Length

300 RqJA, THERMAL RESISTANCE, JUNCTIONTOAIR (CW) 250 200 150 100 50 0 0 5.0 RqJA PD(max) for TA = 50C 2.0 oz. Copper L L

10 15 20 25 L, LENGTH OF COPPER (mm)

Figure 27. SOT223 Thermal Resistance and Maximum Power Dissipation vs. P.C.B. Copper Length

DEFINITIONS Dropout Voltage The input/output voltage differential at which the regulator output no longer maintains regulation against further reductions in input voltage. Measured when the output decreases 100 mV from nominal value at 14 V input, dropout voltage is affected by junction temperature and load current. Line Regulation The change in output voltage for a change in the input voltage. The measurement is made under conditions of low dissipation or by using pulse techniques such that the average chip temperature is not significantly affected. Load Regulation The change in output voltage for a change in load current at constant chip temperature. Maximum Power Dissipation The maximum total device dissipation for which the regulator will operate within specifications. Bias Current That part of the input current that is not delivered to the load. Output Noise Voltage The rms AC voltage at the output, with constant load and no input ripple, measured over a specified frequency range. LongTerm Stability Output voltage stability under accelerated life test conditions with the maximum rated voltage listed in the devices electrical characteristics and maximum power dissipation.

http://onsemi.com

11

25 30

1.8 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 30

LM2931, NCV2931 Series

ORDERING INFORMATION

Output Device LM2931AD5.0 LM2931AD5.0G LM2931AD5.0R2 LM2931AD5.0R2G LM2931ADT5.0 LM2931ADT5.0G LM2931ADT5.0RK LM2931ADT5.0RKG LM2931AD2T5.0 LM2931AD2T5.0G LM2931AD2T5.0R4 LM2931AD2T5R4G LM2931AT5.0 LM2931AT5.0G LM2931AZ5.0 LM2931AZ5.0G LM2931AZ5.0RA LM2931AZ5.0RAG LM2931AZ5.0RP LM2931AZ5.0RPG LM2931D5.0 LM2931D5.0G LM2931D5.0R2 LM2931D5.0R2G LM2931D2T5.0 LM2931D2T5.0G LM2931D2T5.0R4 LM2931D2T5.0R4G Voltage 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V Tolerance "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% Package SOIC8 SOIC8 (PbFree) SOIC8 SOIC8 (PbFree) DPAK DPAK (PbFree) DPAK DPAK (PbFree) D2PAK D2PAK (PbFree) D2PAK D2PAK (PbFree) TO220 TO220 (PbFree) TO92 TO92 (PbFree) TO92 TO92 (PbFree) TO92 TO92 (PbFree) SOIC8 SOIC8 (PbFree) SOIC8 SOIC8 (PbFree) D2PAK (PbFree) D2PAK (PbFree) D2PAK D2PAK Shipping 98 Units / Rail 98 Units / Rail 2500 / Tape & Reel 2500 / Tape & Reel 75 Units / Rail 75 Units / Rail 2500 / VacPk Reel 2500 / VacPk Reel 50 Units / Rail 50 Units / Rail 800 / VacPk Reel 800 / VacPk Reel 50 Units / Rail 50 Units / Rail 2000 / Inner Bag 2000 / Inner Bag 2000 / Tape & Reel 2000 / Tape & Reel 2000 / Ammo Pack 2000 / Ammo Pack 98 Units / Rail 98 Units / Rail 2500 / Tape & Reel 2500 / Tape & Reel 50 Units / Rail 50 Units / Rail 800 / VacPk Reel 800 / VacPk Reel

For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging Specifications Brochure, BRD8011/D. *NCV2931: Tlow = 40C, Thigh = +125C. Guaranteed by design. NCV prefix is for automotive and other applications requiring site and change control.

http://onsemi.com

12

LM2931, NCV2931 Series

ORDERING INFORMATION

Output Device LM2931DT5.0 LM2931DT5.0G LM2931T5.0 LM2931T5.0G LM2931Z5.0 LM2931Z5.0G LM2931Z5.0RA LM2931Z5.0RAG LM2931Z5.0RP LM2931Z5.0RPG LM2931CD LM2931CDG LM2931CDR2 LM2931CDR2G LM2931CD2T LM2931CD2TG LM2931CD2TR4 LM2931CD2TR4G LM2931CT LM2931CTG LM2931ACD LM2931ACDG LM2931ACDR2 LM2931ACDR2G LM2931ACD2TR4 LM2931ACD2TR4G LM2931ACTV LM2931ACTVG Voltage 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Adjustable Tolerance "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "5.0% "2.0% "2.0% "2.0% "2.0% "2.0% "2.0% "2.0% "2.0% Package DPAK DPAK (PbFree) TO220 TO220 (PbFree) TO92 TO92 (PbFree) TO92 TO92 (PbFree) TO92 TO92 (PbFree) SOIC8 SOIC8 (PbFree) SOIC8 SOIC8 (PbFree) D2PAK D2PAK (PbFree) D2PAK D2PAK (PbFree) TO220 TO220 (PbFree) SOIC8 SOIC8 (PbFree) SOIC8 SOIC8 (PbFree) D2PAK (PbFree) TO220 TO220 (PbFree) D2PAK Shipping 75 Units / Rail 75 Units / Rail 50 Units / Rail 50 Units / Rail 2000 / Inner Bag 2000 / Inner Bag 2000 / Tape & Reel 2000 / Tape & Reel 2000 / Ammo Pack 2000 / Ammo Pack 98 Units / Rail 98 Units / Rail 2500 / Tape & Reel 2500 / Tape & Reel 50 Units / Rail 50 Units / Rail 800 / VacPk Reel 800 / VacPk Reel 50 Units / Rail 50 Units / Rail 98 Units / Rail 98 Units / Rail 2500 / Tape & Reel 2500 / Tape & Reel 800 / VacPk Reel 800 / VacPk Reel 50 Units / Rail 50 Units / Rail

For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging Specifications Brochure, BRD8011/D. *NCV2931: Tlow = 40C, Thigh = +125C. Guaranteed by design. NCV prefix is for automotive and other applications requiring site and change control.

http://onsemi.com

13

LM2931, NCV2931 Series

ORDERING INFORMATION

Output Device NCV2931ACDR2* NCV2931ACDR2G* NCV2931AD5.0R2* NCV2931AD5.0R2G* NCV2931AST5.0T3* NCV2931AST5.0T3G* NCV2931AZ5.0G* NCV2931AZ5.0RAG* NCV2931CDR2* NCV2931CDR2G* NCV2931D5.0R2* NCV2931D5.0R2G* NCV2931ADT5.0RK* NCV2931ADT5.0RKG* NCV2931DT5.0RK* NCV2931DT5.0RKG* Voltage Adjustable Adjustable 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V Adjustable Adjustable 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V 5.0 V Adjustable 5.0 V 5.0 V Tolerance "2.5% "2.5% "3.8% "3.8% "3.8% "3.8% "3.8% "3.8% "5.0% "5.0% "5.0% "5.0% "3.8% "3.8% "5.0% "5.0% "2.5% "5.0% "5.0% Package SOIC8 SOIC8 (PbFree) SOIC8 SOIC8 (PbFree) SOT223 SOT223 (PbFree) TO92 (PbFree) TO92 (PbFree) SOIC8 SOIC8 (PbFree) SOIC8 SOIC8 (PbFree) DPAK DPAK (PbFree) DPAK DPAK (PbFree) D2PAK (PbFree) D2PAK (PbFree) D2PAK Shipping 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 4000 / Tape & Reel 4000 / Tape & Reel 2000 / Inner Bag 2000 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel 2500 / Tape & Reel

NCV2931ACD2TR4G* NCV2931D2T5.0R4* NCV2931D2T5.0R4G*

800 / VacPk Reel 800 / VacPk Reel 800 / VacPk Reel

For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging Specifications Brochure, BRD8011/D. *NCV2931: Tlow = 40C, Thigh = +125C. Guaranteed by design. NCV prefix is for automotive and other applications requiring site and change control.

http://onsemi.com

14

LM2931, NCV2931 Series

MARKING DIAGRAMS

DPAK DT SUFFIX CASE 369A 931A5G ALYWW

DPAK DT SUFFIX CASE 369A * 2931G ALYWW

D2PAK D2T SUFFIX CASE 936 LM 2931AD2T5 AWLYWWG

D2PAK D2T SUFFIX CASE 936 LM 2931AD2T5.0 AWLYWWG

D2PAK D2T SUFFIX CASE 936 LM 2931D2T5 AWLYWWG *

Heatsink surface (shown as terminal 4 in case outline drawing) is connected to Pin 2.

TO220 T SUFFIX CASE 221A

TO220 T SUFFIX CASE 221A

TO220 T SUFFIX CASE 314D

D2PAK D2T SUFFIX CASE 936A

D2PAK D2T SUFFIX CASE 936A

LM 2931AT5 AWLYWWG

LM 2931T5.0 AWLYWWG

LM 2931ACTV AWLYWWG

LM 2931ACD2T AWLYWWG

LM 2931CT AWLYWWG

Heatsink surface connected to Pin 2.

Heatsink surface connected to Pin 3.

Heatsink surface (shown as terminal 6 in case outline drawing) is connected to Pin 3.

SOIC8 D SUFFIX CASE 751 8 2931A ALYW G 8

SOIC8 D SUFFIX CASE 751 8 2931A ALYW5 G *

SOIC8 D SUFFIX CASE 751 8 2931C ALYW G *

SOIC8 D SUFFIX CASE 751 2931 ALYW5 G

TO92 Z SUFFIX CASE 029 2931A Z5.0 ALYWG G

TO92 Z SUFFIX CASE 029 2931Z 5.0 ALYWG G

SOT223 ST SUFFIX CASE 318H * A WL, L YY, Y WW, W G or G = Assembly Location = Wafer Lot = Year = Work Week = PbFree Device

ALYW 2931AG G 1 2 3

*This marking diagram also applies to NCV2931.

http://onsemi.com

15

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

TO92 (TO226) CASE 2911 ISSUE AM

3 STRAIGHT LEAD BULK PACK

12

3 BENT LEAD TAPE & REEL AMMO PACK

A R P L

SEATING PLANE

STRAIGHT LEAD BULK PACK

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. CONTOUR OF PACKAGE BEYOND DIMENSION R IS UNCONTROLLED. 4. LEAD DIMENSION IS UNCONTROLLED IN P AND BEYOND DIMENSION K MINIMUM. INCHES MIN MAX 0.175 0.205 0.170 0.210 0.125 0.165 0.016 0.021 0.045 0.055 0.095 0.105 0.015 0.020 0.500 --0.250 --0.080 0.105 --0.100 0.115 --0.135 --MILLIMETERS MIN MAX 4.45 5.20 4.32 5.33 3.18 4.19 0.407 0.533 1.15 1.39 2.42 2.66 0.39 0.50 12.70 --6.35 --2.04 2.66 --2.54 2.93 --3.43 ---

X X H V

1

D G J C N N SECTION XX

DIM A B C D G H J K L N P R V

BENT LEAD TAPE & REEL AMMO PACK

P T

SEATING PLANE

NOTES: 1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. 2. CONTROLLING DIMENSION: MILLIMETERS. 3. CONTOUR OF PACKAGE BEYOND DIMENSION R IS UNCONTROLLED. 4. LEAD DIMENSION IS UNCONTROLLED IN P AND BEYOND DIMENSION K MINIMUM. MILLIMETERS MIN MAX 4.45 5.20 4.32 5.33 3.18 4.19 0.40 0.54 2.40 2.80 0.39 0.50 12.70 --2.04 2.66 1.50 4.00 2.93 --3.43 ---

X X V

1

D J C N SECTION XX

DIM A B C D G J K N P R V

http://onsemi.com

16

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

TO220, SINGLE GAUGE CASE 221AB01 ISSUE A

T B

4 SEATING PLANE NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCHES. 3. DIMENSION Z DEFINES A ZONE WHERE ALL BODY AND LEAD IRREGULARITIES ARE ALLOWED. 4. PRODUCT SHIPPED PRIOR TO 2008 HAD DIMENSIONS S = 0.045 - 0.055 INCHES (1.143 - 1.397 MM) DIM A B C D F G H J K L N Q R S T U V Z INCHES MIN MAX 0.570 0.620 0.380 0.405 0.160 0.190 0.025 0.035 0.142 0.147 0.095 0.105 0.110 0.155 0.018 0.025 0.500 0.562 0.045 0.060 0.190 0.210 0.100 0.120 0.080 0.110 0.020 0.024 0.235 0.255 0.000 0.050 0.045 ----0.080 MILLIMETERS MIN MAX 14.48 15.75 9.66 10.28 4.07 4.82 0.64 0.88 3.61 3.73 2.42 2.66 2.80 3.93 0.46 0.64 12.70 14.27 1.15 1.52 4.83 5.33 2.54 3.04 2.04 2.79 0.508 0.61 5.97 6.47 0.00 1.27 1.15 ----2.04

C S

Q

1 2 3

A U K

H Z L V G D N

R J

http://onsemi.com

17

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

TO220 TH SUFFIX CASE 314A03 ISSUE E

B P C

OPTIONAL CHAMFER

SEATING PLANE

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION D DOES NOT INCLUDE INTERCONNECT BAR (DAMBAR) PROTRUSION. DIMENSION D INCLUDING PROTRUSION SHALL NOT EXCEED 0.043 (1.092) MAXIMUM. INCHES MIN MAX 0.572 0.613 0.390 0.415 0.170 0.180 0.025 0.038 0.048 0.055 0.570 0.585 0.067 BSC 0.015 0.025 0.730 0.745 0.320 0.365 0.140 0.153 0.210 0.260 0.468 0.505 MILLIMETERS MIN MAX 14.529 15.570 9.906 10.541 4.318 4.572 0.635 0.965 1.219 1.397 14.478 14.859 1.702 BSC 0.381 0.635 18.542 18.923 8.128 9.271 3.556 3.886 5.334 6.604 11.888 12.827

L G

5X

D 0.014 (0.356)

M

T P

5X M

DIM A B C D E F G J K L Q S U

TO220 TV SUFFIX CASE 314B05 ISSUE L

B P C

OPTIONAL CHAMFER NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION D DOES NOT INCLUDE INTERCONNECT BAR (DAMBAR) PROTRUSION. DIMENSION D INCLUDING PROTRUSION SHALL NOT EXCEED 0.043 (1.092) MAXIMUM. DIM A B C D E F G H J K L N Q S U V W INCHES MIN MAX 0.572 0.613 0.390 0.415 0.170 0.180 0.025 0.038 0.048 0.055 0.850 0.935 0.067 BSC 0.166 BSC 0.015 0.025 0.900 1.100 0.320 0.365 0.320 BSC 0.140 0.153 --0.620 0.468 0.505 --0.735 0.090 0.110 MILLIMETERS MIN MAX 14.529 15.570 9.906 10.541 4.318 4.572 0.635 0.965 1.219 1.397 21.590 23.749 1.702 BSC 4.216 BSC 0.381 0.635 22.860 27.940 8.128 9.271 8.128 BSC 3.556 3.886 --- 15.748 11.888 12.827 --- 18.669 2.286 2.794

U K F

A S L W V

5X

J T H N T

SEATING PLANE

G

5X

D

M

0.24 (0.610)

0.10 (0.254)

T P

http://onsemi.com

18

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

TO220 5LEAD CASE 314D04 ISSUE H

T Q B B1

DETAIL A-A SEATING PLANE

U K

1234 5

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. DIMENSION D DOES NOT INCLUDE INTERCONNECT BAR (DAMBAR) PROTRUSION. DIMENSION D INCLUDING PROTRUSION SHALL NOT EXCEED 10.92 (0.043) MAXIMUM. INCHES MIN MAX 0.572 0.613 0.390 0.415 0.375 0.415 0.170 0.180 0.025 0.038 0.048 0.055 0.067 BSC 0.087 0.112 0.015 0.025 0.977 1.045 0.320 0.365 0.140 0.153 0.105 0.117 MILLIMETERS MIN MAX 14.529 15.570 9.906 10.541 9.525 10.541 4.318 4.572 0.635 0.965 1.219 1.397 1.702 BSC 2.210 2.845 0.381 0.635 24.810 26.543 8.128 9.271 3.556 3.886 2.667 2.972

G

5 PL

J H

M

0.356 (0.014)

T Q

B B1

DIM A B B1 C D E G H J K L Q U

DETAIL AA

SOT223 ST SUFFIX CASE 318H01 ISSUE O

H 0.2 E

M

0.08 C B

S

C

3

b2 0.1

M

C A

E1

0.1

e1

C A

A D

NOTES: 1. DIMENSIONS ARE IN MILLIMETERS. 2. INTERPRET DIMENSIONS AND TOLERANCES PER ASME Y14.5M, 1994. 3. DIMENSION E1 DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSION. INTERLEAD FLASH OR PROTRUSION SHALL NOT EXCEED 0.23 PER SIDE. 4. DIMENSIONS b AND b2 DO NOT INCLUDE DAMBAR PROTRUSION. ALLOWABLE DAMBAR PROTRUSION SHALL BE 0.08 TOTAL IN EXCESS OF THE b AND b2 DIMENSIONS AT MAXIMUM MATERIAL CONDITION. 5. TERMINAL NUMBERS ARE SHOWN FOR REFERENCE ONLY. 6. DIMENSIONS D AND E1 ARE TO BE DETERMINED AT DATUM PLANE H. MILLIMETERS MIN MAX --1.80 0.02 0.11 0.60 0.88 0.60 0.80 2.90 3.10 2.90 3.05 0.24 0.35 0.24 0.30 6.30 6.70 6.70 7.30 3.30 3.70 2.30 4.60 --0.25 0_ 10_

A1 A (b)

(b2)

T

L

c1

b3

b1

DIM A A1 b b1 b2 b3 c c1 D E E1 e

SECTION BB

SECTION AA

http://onsemi.com

19

e1 L

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

DPAK DT SUFFIX CASE 369C01 ISSUE D

C A B c2

NOTES: 1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994. 2. CONTROLLING DIMENSION: INCHES. 3. THERMAL PAD CONTOUR OPTIONAL WITHIN DIMENSIONS b3, L3 and Z. 4. DIMENSIONS D AND E DO NOT INCLUDE MOLD FLASH, PROTRUSIONS, OR BURRS. MOLD FLASH, PROTRUSIONS, OR GATE BURRS SHALL NOT EXCEED 0.006 INCHES PER SIDE. 5. DIMENSIONS D AND E ARE DETERMINED AT THE OUTERMOST EXTREMES OF THE PLASTIC BODY. 6. DATUMS A AND B ARE DETERMINED AT DATUM PLANE H. DIM A A1 b b2 b3 c c2 D E e H L L1 L2 L3 L4 Z INCHES MIN MAX 0.086 0.094 0.000 0.005 0.025 0.035 0.030 0.045 0.180 0.215 0.018 0.024 0.018 0.024 0.235 0.245 0.250 0.265 0.090 BSC 0.370 0.410 0.055 0.070 0.108 REF 0.020 BSC 0.035 0.050 0.040 0.155 MILLIMETERS MIN MAX 2.18 2.38 0.00 0.13 0.63 0.89 0.76 1.14 4.57 5.46 0.46 0.61 0.46 0.61 5.97 6.22 6.35 6.73 2.29 BSC 9.40 10.41 1.40 1.78 2.74 REF 0.51 BSC 0.89 1.27 1.01 3.93

E b3 L3

1 4

D

2 3

Z

DETAIL A

L4

b2 e

b 0.005 (0.13)

M

c C L2

GAUGE PLANE

H C L L1 DETAIL A

SEATING PLANE

A1

ROTATED 90 CW 5

SOLDERING FOOTPRINT*

6.20 0.244 3.00 0.118

2.58 0.102

5.80 0.228

1.60 0.063

6.17 0.243

SCALE 3:1

mm inches

*For additional information on our PbFree strategy and soldering details, please download the ON Semiconductor Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

20

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

SOIC8 NB CASE 75107 ISSUE AK

X A

8 5 NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: MILLIMETER. 3. DIMENSION A AND B DO NOT INCLUDE MOLD PROTRUSION. 4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER SIDE. 5. DIMENSION D DOES NOT INCLUDE DAMBAR PROTRUSION. ALLOWABLE DAMBAR PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN EXCESS OF THE D DIMENSION AT MAXIMUM MATERIAL CONDITION. 6. 75101 THRU 75106 ARE OBSOLETE. NEW STANDARD IS 75107. DIM A B C D G H J K M N S MILLIMETERS MIN MAX 4.80 5.00 3.80 4.00 1.35 1.75 0.33 0.51 1.27 BSC 0.10 0.25 0.19 0.25 0.40 1.27 0_ 8_ 0.25 0.50 5.80 6.20 INCHES MIN MAX 0.189 0.197 0.150 0.157 0.053 0.069 0.013 0.020 0.050 BSC 0.004 0.010 0.007 0.010 0.016 0.050 0 _ 8 _ 0.010 0.020 0.228 0.244

B

1

S

4

0.25 (0.010)

Y G

C Z H D 0.25 (0.010)

M SEATING PLANE

X 45 _

0.10 (0.004)

Z Y

SOLDERING FOOTPRINT*

1.52 0.060

7.0 0.275

4.0 0.155

0.6 0.024

1.270 0.050

SCALE 6:1 mm inches

*For additional information on our PbFree strategy and soldering details, please download the ON Semiconductor Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

21

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

D2PAK D2T SUFFIX CASE 93603 ISSUE D

T K A S B

1 2 3

C

OPTIONAL CHAMFER

TERMINAL 4

T C

OPTIONAL CHAMFER

ED V

ES

DETAIL C

DETAIL C

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCHES. 3. TAB CONTOUR OPTIONAL WITHIN DIMENSIONS A AND K. 4. DIMENSIONS U AND V ESTABLISH A MINIMUM MOUNTING SURFACE FOR TERMINAL 4. 5. DIMENSIONS A AND B DO NOT INCLUDE MOLD FLASH OR GATE PROTRUSIONS. MOLD FLASH AND GATE PROTRUSIONS NOT TO EXCEED 0.025 (0.635) MAXIMUM. 6. SINGLE GAUGE DESIGN WILL BE SHIPPED AFTER FPCN EXPIRATION IN OCTOBER 2011. DIM A B C D ED ES F G H J K L M N P R S U V INCHES MIN MAX 0.386 0.403 0.356 0.368 0.170 0.180 0.026 0.036 0.045 0.055 0.018 0.026 0.051 REF 0.100 BSC 0.539 0.579 0.125 MAX 0.050 REF 0.000 0.010 0.088 0.102 0.018 0.026 0.058 0.078 5 _ REF 0.116 REF 0.200 MIN 0.250 MIN MILLIMETERS MIN MAX 9.804 10.236 9.042 9.347 4.318 4.572 0.660 0.914 1.143 1.397 0.457 0.660 1.295 REF 2.540 BSC 13.691 14.707 3.175 MAX 1.270 REF 0.000 0.254 2.235 2.591 0.457 0.660 1.473 1.981 5 _ REF 2.946 REF 5.080 MIN 6.350 MIN

F G TOP VIEW

2X

D 0.010 (0.254)

DUAL GAUGE CONSTRUCTION M

SIDE VIEW T

BOTTOM VIEW

SINGLE GAUGE CONSTRUCTION

SIDE VIEW

N L

M P

T

SEATING PLANE

DETAIL C

OPTIONAL CONSTRUCTIONS

BOTTOM VIEW

SOLDERING FOOTPRINT*

10.490

8.380 16.155

3.504

2X

2X

1.016 5.080 PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our PbFree strategy and soldering details, please download the ON Semiconductor Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

22

LM2931, NCV2931 Series

PACKAGE DIMENSIONS

D2PAK D2T SUFFIX CASE 936A02 ISSUE C

NOTES: 1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982. 2. CONTROLLING DIMENSION: INCH. 3. TAB CONTOUR OPTIONAL WITHIN DIMENSIONS A AND K. 4. DIMENSIONS U AND V ESTABLISH A MINIMUM MOUNTING SURFACE FOR TERMINAL 6. 5. DIMENSIONS A AND B DO NOT INCLUDE MOLD FLASH OR GATE PROTRUSIONS. MOLD FLASH AND GATE PROTRUSIONS NOT TO EXCEED 0.025 (0.635) MAXIMUM. INCHES MIN MAX 0.386 0.403 0.356 0.368 0.170 0.180 0.026 0.036 0.045 0.055 0.067 BSC 0.539 0.579 0.050 REF 0.000 0.010 0.088 0.102 0.018 0.026 0.058 0.078 5 _ REF 0.116 REF 0.200 MIN 0.250 MIN MILLIMETERS MIN MAX 9.804 10.236 9.042 9.347 4.318 4.572 0.660 0.914 1.143 1.397 1.702 BSC 13.691 14.707 1.270 REF 0.000 0.254 2.235 2.591 0.457 0.660 1.473 1.981 5 _ REF 2.946 REF 5.080 MIN 6.350 MIN

T A K B

1 2 3 4 5 OPTIONAL CHAMFER

TERMINAL 6

E V

S H M L

D 0.010 (0.254)

M

N G R

SOLDERING FOOTPRINT*

8.38 0.33 1.702 0.067 10.66 0.42

DIM A B C D E G H K L M N P R S U V

16.02 0.63

3.05 0.12

1.016 0.04

SCALE 3:1

mm inches

*For additional information on our PbFree strategy and soldering details, please download the ON Semiconductor Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Typical parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including Typicals must be validated for each customer application by customers technical experts. SCILLC does not convey any license under its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT: Literature Distribution Center for ON Semiconductor P.O. Box 5163, Denver, Colorado 80217 USA Phone: 3036752175 or 8003443860 Toll Free USA/Canada Fax: 3036752176 or 8003443867 Toll Free USA/Canada Email: orderlit@onsemi.com N. American Technical Support: 8002829855 Toll Free USA/Canada Europe, Middle East and Africa Technical Support: Phone: 421 33 790 2910 Japan Customer Focus Center Phone: 81358171050 ON Semiconductor Website: www.onsemi.com Order Literature: http://www.onsemi.com/orderlit For additional information, please contact your local Sales Representative

http://onsemi.com

23

LM2931/D

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- L75B (LM2937) Low Dropout RegulatorDocument11 pagesL75B (LM2937) Low Dropout Regulatorel_george0079491No ratings yet

- LM317, DatasheetDocument12 pagesLM317, DatasheetBocah IlangNo ratings yet

- Datasheet de LM337Document11 pagesDatasheet de LM337Gabriel J. Carrillo MendozaNo ratings yet

- LM317M DDocument14 pagesLM317M DVinícius BardellaNo ratings yet

- High Accuracy, Low I, Anycap Adjustable Low Dropout RegulatorDocument12 pagesHigh Accuracy, Low I, Anycap Adjustable Low Dropout Regulatortrillion5No ratings yet

- LM350 3.0 A, Adjustable Output, Positive Voltage RegulatorDocument10 pagesLM350 3.0 A, Adjustable Output, Positive Voltage RegulatorAlvaro Martin RamaNo ratings yet

- CA3140Document20 pagesCA3140Brzata PticaNo ratings yet

- 7824 Data SheetDocument34 pages7824 Data Sheethjkhj4219No ratings yet

- 1A Low Dropout Voltage Regulator DatasheetDocument8 pages1A Low Dropout Voltage Regulator DatasheetMauricio Raul RotmanNo ratings yet

- Reg - LM2931Document18 pagesReg - LM2931Ludwig SchmidtNo ratings yet

- LM350 DatasheetDocument12 pagesLM350 DatasheetOmarVelasquezC.No ratings yet

- 317mbg PDFDocument13 pages317mbg PDFrazali1982No ratings yet

- Ua 7810Document23 pagesUa 7810Cotri RonaldNo ratings yet

- Ua 7812Document24 pagesUa 7812Manuel TorresNo ratings yet

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDocument19 pagesCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesRicardo Teixeira de AbreuNo ratings yet

- LM 339Document11 pagesLM 339Adi PamungkasNo ratings yet

- Opa 2353Document27 pagesOpa 2353Hoang Văn ThịnhNo ratings yet

- Lm78Xx / Lm78Xxa 3-Terminal 1 A Positive Voltage Regulator: Features DescriptionDocument24 pagesLm78Xx / Lm78Xxa 3-Terminal 1 A Positive Voltage Regulator: Features DescriptionStep StepNo ratings yet

- Jameco Part Number 1390194: Distributed byDocument31 pagesJameco Part Number 1390194: Distributed byfox7878No ratings yet

- DDP400 Open-Frame and U-Chassis :: ROAL Living EnergyDocument12 pagesDDP400 Open-Frame and U-Chassis :: ROAL Living EnergyroalscribdNo ratings yet

- ADP3338 Data SheetsDocument16 pagesADP3338 Data SheetstarpinoNo ratings yet

- LM293Document10 pagesLM293Bruno NascimentoNo ratings yet

- LM723 Voltage RegulatorDocument14 pagesLM723 Voltage Regulatorvanminh91bkNo ratings yet

- Regulating Pulse Width Modulators with Improved PerformanceDocument7 pagesRegulating Pulse Width Modulators with Improved PerformancekkaytugNo ratings yet

- TOKO IC ProductsDocument429 pagesTOKO IC ProductsferenzosquintNo ratings yet

- Datasheet lm337Document8 pagesDatasheet lm337eduardo1011No ratings yet

- Mic 29310Document12 pagesMic 29310chingatucolaNo ratings yet

- LM79XX Series 3-Terminal Negative Regulators: General DescriptionDocument10 pagesLM79XX Series 3-Terminal Negative Regulators: General DescriptionDaniel JaimesNo ratings yet

- 3A Low Dropout Voltage Regulator DatasheetDocument9 pages3A Low Dropout Voltage Regulator DatasheetRobertoJavierANo ratings yet

- SCR 2n5061Document8 pagesSCR 2n5061Gary NugasNo ratings yet

- SCR 2N5060Document9 pagesSCR 2N5060juliocesarmotaNo ratings yet

- 7915Document24 pages7915Balkrushna KankotiyaNo ratings yet

- SFA350 :: ROAL Living EnergyDocument6 pagesSFA350 :: ROAL Living EnergyroalscribdNo ratings yet

- Opa381 PDFDocument19 pagesOpa381 PDFVictoria Guerrero100% (1)

- 7805TDocument7 pages7805TGoti TorcalNo ratings yet

- AMS1117-5.0-Adjustable and Fixed Voltage Regulators de 1 ADocument8 pagesAMS1117-5.0-Adjustable and Fixed Voltage Regulators de 1 AKrista Tran100% (1)

- Advanced Monolithic Systems: Rohs CompliantDocument8 pagesAdvanced Monolithic Systems: Rohs CompliantWilliam BlackNo ratings yet

- LM2675Document26 pagesLM2675Chandra Sekhar YadlapalliNo ratings yet

- Test IngDocument24 pagesTest IngtekellamerZ aka tekellamerNo ratings yet

- Uc2854b EpDocument13 pagesUc2854b EpBruno NascimentoNo ratings yet

- LM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903 Low Offset Voltage Dual ComparatorsDocument10 pagesLM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903 Low Offset Voltage Dual Comparatorssam2No ratings yet

- LM78XX, LM78XXA - 3-Terminal 1 A Positive Voltage RegulatorDocument5 pagesLM78XX, LM78XXA - 3-Terminal 1 A Positive Voltage RegulatorcontrasterNo ratings yet

- FOD3120 - High Noise Immunity, 2.5A Output Current, Gate Drive Optocoupler - Fairchild SemiconductorDocument22 pagesFOD3120 - High Noise Immunity, 2.5A Output Current, Gate Drive Optocoupler - Fairchild Semiconductor06111981No ratings yet

- LM78LXX Series 3-Terminal Positive Regulators: General DescriptionDocument12 pagesLM78LXX Series 3-Terminal Positive Regulators: General DescriptionCícero Gomes PereiraNo ratings yet

- Regulador Dual Cs8371-dDocument11 pagesRegulador Dual Cs8371-dAdrian Biasussi BiasuzziNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- IesengghDocument7 pagesIesengghNaveen Kumar ReddyNo ratings yet

- ABB India PresentationDocument19 pagesABB India PresentationVijai PrabhuNo ratings yet

- Question Bank For Satellite CommunicationDocument4 pagesQuestion Bank For Satellite CommunicationVijai PrabhuNo ratings yet

- INA210 INA211 INA212 INA213 INA214 Voltage Output, High or Low Side Measurement, Bi-Directional Zerø-Drift Series Current Shunt MonitorDocument23 pagesINA210 INA211 INA212 INA213 INA214 Voltage Output, High or Low Side Measurement, Bi-Directional Zerø-Drift Series Current Shunt MonitorVijai PrabhuNo ratings yet

- Freesmachine Falcon HandleidingDocument198 pagesFreesmachine Falcon Handleidingmad zollaNo ratings yet

- Case Study #3 - Gigantone, JustineDocument2 pagesCase Study #3 - Gigantone, JustineJustine LinesNo ratings yet

- XLA RMDocument12 pagesXLA RMNahla EsamNo ratings yet

- Bandgap ReferencesDocument15 pagesBandgap ReferencesAyaz Masud SezanNo ratings yet

- Sony dsr-pdx10 Ver-1.8 SMDocument526 pagesSony dsr-pdx10 Ver-1.8 SMSaulvcr64 PorleyNo ratings yet

- Bus 2019 HELLA en Lampi AutocarDocument112 pagesBus 2019 HELLA en Lampi AutocarDumitru CorneliuNo ratings yet

- Bahir Dar Institute of Technology: Faculty of Electrical Engineering ArduinoDocument44 pagesBahir Dar Institute of Technology: Faculty of Electrical Engineering ArduinoGech ManNo ratings yet

- The Hubbard Energy Transformer by Gaston BurridgeDocument6 pagesThe Hubbard Energy Transformer by Gaston BurridgepboserupNo ratings yet

- Conceptual Questions: Problem Set 1: Electric Forces and FieldsDocument5 pagesConceptual Questions: Problem Set 1: Electric Forces and FieldsretterateNo ratings yet

- FPV Protocols Explained (CRSF, SBUS, DSHOT, ACCST, PPM, PWM and More) - Oscar LiangDocument38 pagesFPV Protocols Explained (CRSF, SBUS, DSHOT, ACCST, PPM, PWM and More) - Oscar LiangBilly TherionNo ratings yet

- Presentation Sf6 Circuit BreakerDocument19 pagesPresentation Sf6 Circuit BreakerPalanisamy RNo ratings yet

- CAT Battery Test ProcedureDocument22 pagesCAT Battery Test ProceduremkNo ratings yet

- Altium - Simulation Tutorial - EnglishDocument15 pagesAltium - Simulation Tutorial - Englishcarlos garcíaNo ratings yet

- Ultra Fast Avalanche Sinterglass Diode Specifications and Data SheetDocument7 pagesUltra Fast Avalanche Sinterglass Diode Specifications and Data SheetRey TiburonNo ratings yet

- PARTNER Contact Closure Adjunct: Installation InstructionsDocument6 pagesPARTNER Contact Closure Adjunct: Installation InstructionslaurahotNo ratings yet

- BarronDocument21 pagesBarronMltm DrmNo ratings yet

- Motor Management and Control Devices Simocode ProDocument1 pageMotor Management and Control Devices Simocode ProArief RakhmadNo ratings yet

- Presentation On Ic 555 Timer: By: Pragya Mitra Shivnandan Kumar Sandeep KumarDocument22 pagesPresentation On Ic 555 Timer: By: Pragya Mitra Shivnandan Kumar Sandeep KumarSandeep Kamti BrzeeNo ratings yet

- DC Motors ApplicationsDocument4 pagesDC Motors ApplicationsidealparrotNo ratings yet

- WarrantyDocument12 pagesWarrantySonaina KhanNo ratings yet

- HVX 12-17.5-24kV User GuideDocument48 pagesHVX 12-17.5-24kV User Guidestunnchuck100% (1)

- Sub 1Document4 pagesSub 1AH TaiNo ratings yet

- KTI20Document888 pagesKTI20NunoNo ratings yet

- 20KW 96v Front & Rear Drive EV Project ReportDocument6 pages20KW 96v Front & Rear Drive EV Project ReportPutera AlviraNo ratings yet

- Operating Instructions Tms tmm22 Inclination Sensors en Im0096391Document21 pagesOperating Instructions Tms tmm22 Inclination Sensors en Im0096391Daniel Maran BrottoNo ratings yet

- Polycab Cable Price List 1 2011Document10 pagesPolycab Cable Price List 1 2011SANKPLYNo ratings yet

- Jimma University: Jimma Institute of Technology (Jit)Document40 pagesJimma University: Jimma Institute of Technology (Jit)Haymanot LegesseNo ratings yet

- PVS-100-TL SX2 FULL Inverter: General InformationDocument3 pagesPVS-100-TL SX2 FULL Inverter: General InformationAdda1No ratings yet

- WindingsDocument2 pagesWindingsCarlo Jay VizcarraNo ratings yet