Professional Documents

Culture Documents

DSM 6-3 Power Distribution Network

Uploaded by

gurwindermann536Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DSM 6-3 Power Distribution Network

Uploaded by

gurwindermann536Copyright:

Available Formats

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

TECHNICAL LOSS REDUCTION IN POWER DISTRIBUTION NETWORKS

M. V. S. Birinchi, CORE International inc.

The selection of proper size of the conductor plays a very important role in determining voltage regulation and power loss. Historically lower size conductors were used as load levels were low and also due to dearth of funds to augment the system commensurate with load growth. A diversity factor of 1.5 was adopted in the earlier years the diversity is lost due to feeding of loads for limited hours. The design of the distribution systems mainly depends on the chosen classification of single or three phase, radial or loop network, overhead line or underground cables The essential factors to be kept in mind while designing a distribution system are: Safety: The safety factor requires the distributors to be laid following i. Proper clearances ii. Voltage safe enough to be used for consumers gadgets. 2. Smooth and Even flow of power: A steady, uniform, non-fluctuating flow of power is necessary to feed loads of all categories of consumers. 3. Economy: The third factor is economy. This usually calls for use of higher voltages to ensure minimum losses while distributing power.

1.

Load

E 2E E

Load Load

Indian Electricity Rules: The IE Rules among other things deal with the following important points. 1. Preliminary definitions 2. Inspection of Electrical Installations

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

3. 4. 5. 6. 7.

General safety precautions General conditions relating to supply and use of energy Electric supply lines, systems and apparatus for low and medium voltages Electric supply lines, systems and apparatus for high and extra high voltages Over head lines

Determination of size of conductor for a Distribution system: 11 kv feeders carry comparatively bulk power from secondary sub station (33/11kv) to distribution substation DTRs and distributors carry power from DTRs through service lines which deliver power from suppliers nearest support to consumers premises upto energy meter, through a weather proof service wire. All lines have inherent resistances, inductances and capacitances, resulting in a voltage drop in the line. The declared voltage at the consumer premises are 415/240v. All appliances and motors give good performance for long duration if this voltage is maintained. In case of large variation in the voltages (more than 6% of declared voltage) appliances will get damaged or will give poor performance. Therefore, regulations are laid down fixing up limits of variation in voltage as permissible at the consumers terminals. The question regarding the voltage drop in lines, thus, assumes importance and must be considered while designing the lines. The main basis of the selection of the size of a distributor is the voltage drop. Obviously, the distributor must also be capable of carrying the required current without excessive temperature rise. However, it is found in practice that a distributor is of ample size if its voltage drop is within required limits. This is also important so as to limit the technical losses to the minimum. ACSR and AAAC conductors are used for secondary distribution systems. ACSR conductors are preferred to AAC for long spans owing to their greater tensile strength. In selection of conductor size, the following should be considered. 1. 2. Current carrying capacity. Tensile strength of the conductor

The size of conductor for a distributor is determined in the following manner. Based on the load incident on the conductor (including anticipated load growth) the current that the distributor has to carry is calculated. From standard tables the conductor size, capable of carrying this current at the ambient temperature of the area is selected. The voltage drop as per example given in calculated taking products of loads and their distances. Refer Table 1 (All Aluminium (Standard) Conductor (AAC)); Table 2 (ACSR Conductors); Table 3 (All Aluminium Alloy Conductors (AAAC))

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Current carrying capacity of ACSR conductors is mentioned below : Squirrel Weasel Rabbit VOLTAGE REGULATION Declared voltage of supply to consumers 1. Not greater than 250 volts 2. Medium voltage not greater than 650 volts 3. H.V not greater than 33,000 volts 4. Extra High Voltage above 33,000 volts Procedure The voltage regulation is usually expressed as a percentage drop with reference to the receiving end voltage. Percentage regulation = 100(Es Er) / Er where Es = Sending end voltage Er = Receiving end voltage Sample Calculations: Voltage Drop calculations for 11 KV lines Let us consider a 11kv feeder emanating from a 33/11kv S/S with 7/2.59mm (Weasel) ACSR for the main feeder and 7/2.11mm (Squirrel) ACSR for tap lines with the connected distribution transformers and distances as indicated below:

25 100 100 100 63 O 33/11 KV SS A 1.0 1.5 B 1.5 H 0.5 C I 1.0 1.0 D 2.0 R 2.0 63 0.5 25 63 0.5 63 M 100 63 100 25 E 2.5 1.0 100 100 25 100 F 1.0 G 100 100 63 25

7/2.11 115 A 7/2.59 150 A 7/3.35 208 A

6% 6% + 6 to -9% 12.5%

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Total connected transformer capacity on the 11kv line is: 1) 10 x 100 = 1000kva 2) 6 x 63 = 378kva 3) 5 x 25 = 125kva ---------Total 1503kva ---------The Maximum Demand = Total KVA / Diversity Factor = 1503 / 2.5 = 601 KVA Feeder Current = Maximum Demand / ( 3 x 11) = 31.5 A For calculating the voltage regulation of the main feeder, it is assumed that the loads on the tap lines are concentrated at the point of tapping and taking moments about the section we have 1503.0 2104.5 1822.5 557.5 927.5 764.0 1202.0 826.0 720.0 100.0 --------Total KVA Km 10526.5 --------% Regulation = Total KVA Km x Voltage drop per KVA Km / DF Assuming a diversity factor of 2.5 Regulation constant for 7/2.59 (Weasel) ACSR at 0.85 Power factor for 6% voltage drop voltage drop per MVA Km is 6.27 (See Table 5) % Regulation = 10526.5 x (6/6.27) /1000 x 2.5 = 4.03% Similarly the regulation of the tap lines also can be calculated. Let us consider the farthest tap lines and find out the regulation taking moments in KVA KM for the main feeder with 7/2.59 mm (Weasel) ACSR; we have 1503 x 1 1403 x 1.5

Space for Institution Logo

OA AB BH HC CI ID DR RE EF FG

= = = = = = = = = =

1503 x 1 1403 x 1.5 1215 x 1.5 1115 x 0.5 927 x 1 764 x 1 601 x 2 413 x 2 288 x 2.5 100 x 1

= = = = = = = = = =

= =

1503.0 2104.5

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

1215 x 1.5 1115 x 0.5 927 x 1 764 x 1 601 x 2 413 x 2 288 x 2.5

= = = = = = =

Total KVA KM

1822.5 557.5 927.5 764.0 1202.0 826.0 720.0 ----------10,426.5 -----------

For tap line FM with 7/2.11 mm (Squirrel) ACSR we have 188 x 1.0 = 188 88 x 0.5 = 44 25 x 0.5 = 12.5 ---------Total KVA KM 244.5 --------% Regulation on 11kv main feeder = 10426.5 x (6/6.27) / (1000 x 2.5) = 3.99% % Regulation 11kv tap line = 244.5 x (6/4.41) / 1000 x 2.5 = 0.134% % Regulation at the point M of tap line = 3.99 + 0.134 = 4.124% UNDERGROUND POWER CABLES (Construction, design, storing, laying, jointing, testing, and fault location etc) INTRODUCTION Due to the fast growth in load densities (MW per Sq km) in major towns and cities, 33 KV, 11 KV & LEFT underground cables are used to meet the ever growing demand pf electric power. The underground cable system has attained much importance in transmission, distribution, and communication networks mainly due to: Non-availability of right of way to erect overhead systems. To extend supply from source to load centers on any route profile. To maintain fairly uninterrupted and reliable power supply. To maintain the aesthetic beauty of the town/city as a whole.

In the towns and cities almost all the roads are already occupied by LT, HT overhead lines, telephone lines, street light, advertising boards, etc., on either side of the roads. Further, due to upcoming of the major high-rise buildings, it has become difficult to go

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

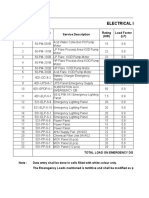

for overhead systems for sub transmission, distribution and underground cable system has become a necessity. Further, multistoried complexes both domestic and commercial are coming up where some portion in the cellar is made available for housing the transformer. It is becoming increasingly difficult to take the overhead lines up to the cellar and to extend supply from the cellar to individual flats. The overhead system with bare conductors is prone for frequent breakdowns causing interruption in power supply and by employing underground cable ring system uninterrupted power supply can be maintained. Selection of Cable: The factors that influence the selection of Cable are (i). Load. (ii). System Voltage. (iii). Type of insulation. (iv). Short Circuit rating. (v). Mode of installation. (vi). Economic and Safety. Modernisation of Power Distribution For the same conductor size the maximum continuous current carrying capacity depends on depth of laying, ground temperature, silicon oil resistively, ambient temperature, proximity of other cables, type of ducts used to load cycle. The maximum permissible conductor temperature is as follows: Paper insulated Lead Covered PVC XLPE 33KV 65 C 70 C 90 C 11KV 70 C 70 C 90 C LT 80 C 70 C 90 C

Depending upon the voltage at which the power is transmitted or distributed, the cables are designed as EHV Cables Medium and HV Cables LT Cables 66 KV and above 3.3 KV to 33 KV Insulated to 1100 Volts

The initial cost of laying the underground cable system us very high but the maintenance charges are minimum and also have long life. It is estimated that the cost of underground cable system at any voltage and for the same current capacity is ten times the cost of an overhead system. Design Criteria of the Cables: The following are the important factors in designing the cable to meet the requirements.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Conductor: The conductor (core) is to be designed such that it can continuously carry the rated current and the short circuit current for shorter duration without overheading and voltage drop to be within the limits prescribed. Insulation: The materials used for insulation shall have good dielectric strength and proper thickness and shall be suitable for operating at optimum voltage continuously with high degree of stability, reliability and safety. Materials: All the materials used in manufacturing the cables shall have good mechanical and physical properties to ensure longer life. Finishing: All the materials used for finishing shall have good mechanical and chemical properties to prevent damage and also to suit environmental conditions. Sizing of Cables: The sizing of cables depends on the following: 1. Current carrying capacity 2. Short Circuit current. 3. Voltage drop. 4. Losses. Short Circuit Current: The short circuit rating of the cables (Isc)is expressed as : Isc = KxA

t

Where A is the Cross Sectional area of the conductor in Sq mm, t is the duration of short circuit in seconds and K is a constant depending on dielectric used for installation. Voltage Drop: This is an important consideration in selection of the cable. The voltage drop shall be within the limits prescribed. Losses in the Cables:

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

There are two types of losses in the cables i.e., 1. Dielectric loss. 2. Sheath and screen loss. Jointing and Terminations: The cables are laid in lengths supplied over reels and are to be made through, and terminated at the ends to connect the same to the system for use. Since the cable consists many items right from the conductors to the outer sheath, all these are to be made through in the straight through joints and the joint shall have the same features/characteristics of the original cable. Thus the straight joints are done by: 1. 2. 3. 4. 5. 6. Providing for core continuity. Providing of stress controlling screens. Providing of insulation. Providing continuity of earth potential parts of the cable by clamping and running the earth lead. Providing mechanical protection by installing the brass or aluminum covers. Providing of finishing over the mechanical protective cover.

Similarly the cable ends are terminated by: 1. 2. 3. 4. 5. Providing stress control screens Providing the earthing clamp lead etc., Providing of insulation. Providing of lugs. Providing of rain sheds.

To make the joints and terminations it is essential to know the size and type of the cable to select suitable kit for joints and terminations. The kits contain the accessories required for making joints and terminations with instruction sheet for step-by-step procedure for making joint and terminations. The cable is to be prepared as per the dimensional drawing given in the instruction sheet and step-by-step procedure is to be followed to make and complete jointing. Similar procedure is to be adopted for making the end terminations also. Types of Joints and Terminations: The following are different types of Joints and Terminations: 1. Cast Iron molded joints and terminations:

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

In this type, cast iron moulds are used for top and bottom covers. Conductors strands are soldered, taped and bitumen compound is used for insulation. These type of joint & terminations are used only for paper insulation cables and are now obsolete. 2. Epoxy resin type joints and terminations:

These are widely used for all types of cables wherein resin and hardener are used for providing insulation in PVC top & bottom moulded covers. The insulating materials after setting becomes hard, which also gives mechanical protection and will not allow water or moisture to enter through it. 3. Heat shrinkable joints and terminations:

In this type of joints and terminations all the insulating, screen materials are supplied in tubes having the characteristics of shrinking in hot condition. The cable is prepared as per the dimensional drawing and all the tubes are slided and are shrunk to the cores by using blowlamp. In hot condition, these tubes shrink to the cores and acre should be taken for shrinking the tubes properly with correct temperature and without allowing any air pockets inside the tubes, which are weak points and may cause breakdowns. Aluminum or brass covers called canister are used for mechanical protection over which PVC outer sheath sleeves are shrunk. 4. Cold Shrinkable Joints and Terminations:

In this type of joints & terminations, the tubes are provided, which are having the features of shrinking in cold condition. The tubes are held in suitable dimensions by means of helical nylon spirals inside and after preparation of the cores, these tubes are slided to one side. The core continuity is made and step-by-step procedure is followed for sliding the tubes. On removing/pulling of the nylon spirals the tubes get shrunk to the core providing necessary screening insulation etc. Thus these joints and terminations are called cold shrinkable joints and terminations. 5. Push On type Joints and Terminations:

In this type of joints and terminations after preparation of the cores, the pre-moulded tubes are pressure fitted or pushed on to the cores and making earthing arrangements similar to the other joints and terminations. The heat shrinkable, cold shrinkable and Push on type joint and terminations do not need any setting time and can be taken into service immediately.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

OVERHEAD LINES vs CABLES S.No Description Overhead Cables 1. Cost of Lesser initial cost and easy Initial cost is high and needs Installation installation more time for installation. Approximately ten times the cost of OH line of same voltage and current carrying capacity for some length. 2. Cost of High Low maintenance 3. Breakdowns More frequent breakdowns Minimum, except for damage & Incidence due to various reasons caused by other agencies. of faults causing damage to equipment 4. Restoration Supply can be restored in Takes more time for identify minimum time. Skills the fault and rectification. required are also minimum Skills of highest order and special equipment are needed for location of fault as well as rectification. 5. Interruption Maximum and uninterrupted Minimum and fairly supply cannot be assured uninterrupted supply can be maintained 6. Life of service Less High 7. Losses Maximum and theft prone Negligible and theft free. by hooking to bare conductors 8. Accidents Possibilities of accidents Very rare. are more and risk of life is involved 9. Facility for Needs more land for Can be installed on minimum installation of installation of sub-stations. land. But costly due to need in line subfor RMUs etc. stations. 10. Aesthetic Cannot be maintained Can be maintained. beauty

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

10

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

WORKMANSHIP, PROPER JOINTING etc. Stringing of the Line Conductor: REC has standardized the following sizes of conductors for 33 KV, 11 KV and LT lines. Voltage No. and Diameter of Wire Class 33 KV lines i) 7/3.35 mm (50 mm2) ii) 7/4.09 mm (80 mm2) iii) 6/4.72 mm + 7 / 1.57 mm (100 mm2) 11 KV lines i) 7/2.11 mm (20 mm2) ii) 7/2.59 mm (30 mm2) iii) 7/3.35 mm (50 mm2) LT lines i) 7/2.11 mm (20 mm2) ii) 7/2.59 mm (30 mm2) iii) 7/3.35 mm (50 mm2) iv) 7/2.21 mm (25 mm2) v) 7/3.10 mm (50 mm2) Conductor Erection: The erection of overhead line conductor is very important phase In construction. The erection of conductor can be divided into 4 parts. 1. Transport of conductors to work site 2. Paving and stringing of conductors 3. Tensioning and sagging of conductors and 4. Jointing of conductors Having transported the conductor drum to the tension point, the drum should either be mounted on the cable drum supports or jacks or hung by means of chain pully of suitable capacity suspended from a tripod. The conductor should be passed over the pole on wooden or aluminum snatched pully blocks provided with low friction bearings. The conductor shall be raised to a minimum height of 5 mt. above ground by rough sagging. The mid span joints of conductors can be carried out by twisting joint or compression joints. The twisting joints for aluminum conductors and ACSR consist of relatively thin walled aluminum sleeves, the end of the wire should project a few centimeters beyond the end of the sleeves. The projected wires are given a sharp bend to keep them from slipping out of the sleeve. Twisting Tongues are preferably to be used for joints and jumpers. Type of Conductor ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) ACSR (AAAC) AAC (AAAC) AAC (AAAC)

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

11

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Sagging and Tensioning: On completion of the paving of conductors and making mid span joints if any, tensioning operation will commence. Temporary guys will have to be provided for both anchoring supports. At the tensioning end one of the conductors is pulled manually up to a certain point and then come-along clamp is fixed to the conductor to be tensioned. The grip of the come along clamp is attached to double sheave pully block or the pull lift (TIRFOR) machine and gradually tensioned. The conductor should then be sagged in accordance with the sag temperature chart for a particular conductor and span. The sag should then be adjusted in the middle span of the section. The stretch of the conductor has to be taken out before stringing in order to avoid the gradual increase in sag due to setting down of the individual wires. There are two ways of accomplishing this 1. Prestressing 2. Over tensioning

1.

Prestressing: In this method, the conductor is pulled upto a tension considerably above the EL correct figure, but never exceeding fifty percent of breaking load for a short period of say 20 minutes. As this method requires more time and involves the use of stronger tackle to secure high tension, the other method of over-tensioning is commonly adopted. Over-tensioning: The method consists of pulling up the conductor to a tension a little above the theoretical tension for the prevailing temperature and fixed it up at that tension with a correspondingly reduced sag. After a certain time the conductor will settle down to the correct sag and tension. A tension of 5% to 8% more than the theoretical value has been found to be suitable for the sizes of ACSR and AAC conductors. The ambient temperature during the sagging may recorded correctly.

2.

Conductors can be sagged correctly only when the tension is the same in each span throughout the entire length of the section. Use of snatch blocks reduces the friction and chances of inequality of tension in various spans. Sagging can be accomplished by different methods, but most commonly used method for the 11 KV line is "SIGHTING" by use of targets placed on the supports below the cross arms. The targets are light strips of wood clamped to the pole at a distance equal to the sag below the conductor when the conductor is placed in snatch blocks. The lineman sees the sag from the next pole. The tension of the conductor is then reduced or increased; until the lowest part of the conductor in the span coincides with the lineman's line of sight.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

12

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

When sagging is completed, the tension clamps shall be fixed. The clamps can be fitted on the conductor without realising the tension. A mark is made on the conductor at a distance from the cross arm equal to the length of complete strain insulators. Before the insulator set is raised to position all nuts should be free. A come along clamp is placed on the conductor beyond the conductor clamp and attached to the pulling unit. The conductor is pulled in sufficiently to allow the insulator assembly to be fitted to the clamp. After the conductor is clamped to the insulator assembly unit may be released gradually. After the stringing is completed all poles, cross arms, insulators, fittings etc. are checked up to ensure that there have been no deformities. The next step is to place the conductor on the top of the pin insulator from the snatch block and removing snatch blocks. Conductors are then fastened to insulator by the use of aluminum wires. Before tying the conductor to the insulator, two layers of aluminum taps should be wrapped over the conductor in the portion where it touches the insulator. Normally in straight lines the conductors are run on the top of the insulators. When there is a small angle of deviation the conductor is placed inside groove and binded. OVER HEAD LINES - CROSSINGS - RAILWAYS/RIVERS/P&T LINES/ ROADS-REGULATIONS Railway Crossings: Before commencing work on any crossing, approval of the Railway and the Electrical Inspector in writing shall be obtained for the proposed location and detailed design of the crossing. For this propose, data, designs and drawings relating to the crossing shall be submitted in duplicate by the owner to the Railway and the Electrical Inspector. Classification of Crossings: For the purpose of these regulations, electric overhead lines crossings are classified in accordance with the clearances required under the following categories. 1. 2. 3. Category 'A' : Tracks electrified.

Category 'B' : Tracks already electrified or likely to be converted to or electrified on 25 KV AC system within the foreseeable future. Category 'C': future. Tracks not likely to be electrified in the foreseeable

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

13

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Minimum clearance between the over head lines and Railway Tracks: (i) Crossing over tracks already electrified shall normally be located at mid spans of the overhead traction conductors, but in any case shall not be less than 6 meters from the nearest traction mast. (ii) The minimum height above rail level of the lowest portion of any conductor under conditions of maximum sag shall be as follows. i) For category A & C: Broad Guage Inside Outside Station Station Upto and 10.0 m 7.6 m including 11 KV Above 11KV 10.0 m 7.6 m including 33 KV Voltage Metre / Narrow Guage Inside Outside Station Station 8.6 m 6.3 m 8.8 m 6.4 m

Note: Low and Medium voltage (upto 650V) crossing of category A only will be obligatory by means of underground cables, (m - metre)

ii) For Category B: For Broad, Meter and Narrow Guages Voltage Inside Station Outside Station limits limits Upto 650 Only by Cable Only by Cable volts Above 650 12.5 m 10.5 m volts upto 33 KV

Note: If the crossing is located on a metre guage or a narrow guage section, likely to be converted to broad guage; clearance applicable to broad guage shall be adopted.

Minimum clearance between conductors and any Railway Structure: The minimum vertical and horizontal clearances between any conductors and any Railway buildings and structures other than traction supports and overhead equipment under the most adverse conditions shall be in accordance with Rule 80 of IE Rules, 1956.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

14

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Minimum clearance between owners and Railway conductor: The minimum clearance between any of the owners conductor or guard wires and the railway conductor shall not be less than 2 metres. Insulators: Categories A&B: Double set of strain insulator strings shall be used in the crossing span in conjunction with a yoke plate where necessary. It is recommended that each string of such strain insulator shall have one insulator disc - more than that used in normal span of the overhead line. Category 'C': Strain insulators, suspension insulators or pin insulators may used as required. Guarding: The minimum height above the rail level to the lowest level of any cradle guard and guard wires under conditions of maximum sag shall be as follows: Category 'A&B': The same clearances as given in clause 19(1) shall apply. Category 'C': The minimum height of 6.9 m shall apply for broad guage and 6.1, for metre and narrow gauges. B. RIVER CROSSINGS: For the rivers on which the crossing is to be done, the dates of high flood level of atleast the previous 20 years is to be obtained from the revenue authorities and the structures are to be erected so that in rainy season also they will be approachable under the flooded conditions of the river. In case of navigable rivers, the structures should be so designed as to give sufficient clearance between the lowest conductor and the highest flood level. Consultation which Navigation authorities is necessary. In case of nonnavigable rivers, the structures should be designed in such a way that the lowest conductor should be 3 mts above the maximum flood level. This is necessary because floodwater may carry trees and their branches. C. CROSSINGS OVER TELEGRAPH OR TELEPHONE LINES AND P.T.C.C. Communication circuits coming under the influence of electric field of high voltage power lines experience extraneous induction, which may introduce noise in communication equipment and cause danger to the equipment and persons handling them. Therefore, it is very essential that whenever power lines and communication lines pass close to each other suitable measures are taken. Approval of PTCC (Power Telecommunications Co-ordination Committee) may be obtained.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

15

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Further, while crossing the telecom lines, the following points may be observed. 1) The power lines cross over the telecom lines because the Dia of power line conductors is generally greater than telecom line conductors. 2) The angle of crossing shall be as far as possible 90; but shall not be less than 60. 3) A safe clearance between the communication lines and overhead power lines has to be maintained in accordance with the PTCC code of practice. 4) Power contact protectors are to be installed on all conductors of telecom lines at crossings with HV power lines. 5) The telecom lines shall be erected close to the support of the OH power lines for increased clearances. D. ROAD CROSSINGS: The ground clearance of the guard wire and strength of the supports on either side of the road have to be considered in installing a cradle guard at the road crossings. The supports on either side of the road on which the cradle guard terminates are earthed separately and the line should not cross at an angle less than 60. The safe minimum distances between the support of OH lines and road had to be kept in view while planning road crossing. The clearances above ground level of the lowest conductor shall be in accordance with Rule No.77 of IE Rules 1956. See Also Tables for 1. Permissible Spans 2. Clearances at Railway Xings 3. Clearances at Road Xings 4. Clearances & Spacings from Buildings 5. Clearances at Highways 6. Clearances between power and Telephone Lines etc Section of Conductor Size and Impact on Losses Like in any other system, the power system should be efficient. This means that the ratio of the power utilised by the ultimate consumers of electric power to the power produced at the generating stations must be as high as possible. In other words the losses occurring in carrying electric power from the generator to the consumers must be kept at the minimum. These losses are called "Line Losses" and occur in the

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

16

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

transmission and sub-transmission lines, Step up and step down transformers primary and secondary distribution line and distribution transformers. These losses are I2R losses in the resistance of the conductor and equipment in the line, iron losses in the transformers etc. Low line losses result in a low cost per unit to the consumer. For the country as a whole, low line losses mean better utilisation of the sources of energy, In India, line losses vary form region to region from 15-30%. This is extremely high compared to about 8-10% in the developed countries of Europe, America and Japan. This shows that the percentage losses need to be brought down to reasonable level in order to improve the efficiency of the distribution system. This assumes great urgency and importance in view of the acute shortage of power. Factors contributing towards Increased Line Losses: The major amount of losses in a power system are in primary and secondary distribution lines; while transmission and sub-transmission lines account for only about 30% of the total losses. Therefore the primary and secondary distribution systems must be properly planned to ensure losses within acceptable limits. The factors contributing to the increase in the line losses in the primary and secondary systems: 1. Lengthy Distribution Lines: The primary and secondary distribution lines in rural areas; by and large radially laid, usually extend over long distances. This results in high line resistance and therefore high 12R losses in the line. Because of the above reason, the rural loads contribute towards increased line losses. 2. Inadequate Size of Conductors:

Rural loads are usually scattered and generally fed by radial feeders. The conductor size of these feeders should be properly selected. The size of the conductor should be selected on the basis of KVA x KM capacity of standard conductor for required voltage regulation. Table provided below indicate the length of lines for 11 KV and 415 volts corresponding to different loads for the voltage regulation prescribed by IE Rules; for different sizes of conductors respectively.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

17

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Table-1: Length of 11 KV line corresponding to different loads Size of conductor (with Code No.) 50 MM2 ACSR Rabbit 30 MM2 ACSR Weasel 20 MM2 ACSR Squirrel KVA-KM for 8% Maximum voltage drop at length of 0.8 PF (KM) 10,640 30 7,200 5,120 20 15 of Load that can be line connected (KW) 355 360 341

The figures are for a conductor temperature of 60 C. For a conductor temperature of 50 C, the above figures shall be about 3% higher and for a temperature of 70 C about 3% lower. Table-2: Length of 415 volts line corresponding to different loads Size of conductor (with Code No.) 30 MM2 ACSR Rabbit 20 MM2 ACSR Weasel 13 MM2 ACSR 30 MM2 AAC ANT 16 MM2 AAC Gnat KVA-KM for 8% Maximum voltage drop at length of 0.8 PF (KM) 11.76 1.6 7.86 5.58 12.06 6.96 1.0 1.0 1.6 1.0 of Load that can be line connected (KW) 7.35 4.86 5.58 7.54 6.96

The figures are for a conductor temperature of 60 C. For a conductor temperature of 50 C, the above figures shall be about 3% higher and for a temperature of 70 C about 3% lower. 3. Distribution Transformers not Located at Load centre on the Secondary Distribution System:

Often DTs are not located centrally with respect to consumers. Consequently, the farthest consumers obtain an extremely low voltage even though a reasonably good voltage level is maintained at the transformers secondaries. This again leads to a higher line losses. (The reason for the line losses' increasing as a result of decreased voltage at the consumers terminally are explained in para - 5)

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

18

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Therefore in order to reduce the voltage drop In the line to the farthest consumers, the distribution transformer should be located at the load centre to keep voltage drop within permissible limits and thus minimise the losses. 4. Over-rated Distribution Transformers and Leading to Under-Utilisation:

Studies on 11 KV feeder have revealed that often the rating of DTs is much higher than the maximum KVA demand on the feeder. Over rated transformers draw an unnecessarily high iron losses. In addition to this iron losses in over rated transformers the capital costs locked up is also high. From the above it is clear that the rating of DT should be judiciously selected to keep the losses with in permissible limits. For an existing distribution system the appropriate capacity of distribution transformer may be taken as very nearly equal to the maximum KVA demand at good PF (say 0.85) Such an exercise has been carried out for a number of distribution systems and transformers with capacity of 25, 63,100,160, 315 KVA and standardised for different systems with power factors and diversity factors. 5. Low Voltage (less than declared voltage) at Transformers and Consumers Terminals: Whenever the voltage applied to induction motor varied from rated voltage, its performance is affected. Within permissible voltage variation of +/- 6% in practice, the supply voltage varies by more than 10% in many distribution systems. A reduced voltage in case of induction motor results in higher currents drawn for the same output. For a voltage drop of 10%, the full load current drawn by the induction motors increase by about 10% to 15% the starting torque decreases by nearly 19% and the line losses in the distributor increases by about 20%. As the bulk toad of rural areas and small scale industrial areas consists of induction motors, the line losses in the concerned distribution systems may even touch 20%. The above situation is corrected by operating an "on-toad-tap changing" in the power transformer situated at high voltage sub-stations 66/11 KV and 33/11 KV sub-stations and providing on the 11 KV feeders a combination of switched capacitors and automatic voltage regulators. Further, the "off load tap changing" in distribution transformers is adjusted prior to the commencement of agricultural load season which is readjusted before the on-set of monsoons when the rural load is small if the off-load tap changing gear is available.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

19

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

6.

Low Power Factor:

In most of the LT distribution circuits, it is found that the PF ranges from 0.65 to 0.75. A low PF contributes towards high distribution losses. For a given load, if the PF is low, the current drawn is high. Consequently, the losses proportional to square of the current, will be more. Thus, line losses owing to the poor PF can be reduced by improving the PF. This can be done by installing of shunt capacitors. Shunt capacitors can be connected in the following ways: (i) Shunt capacitors are connected on the secondary side (11 KV side) of the 33/11 KV power transformers.

Table 3 shows from the studies carried out on 11 KV lines, how the improvement of power factor results in considerable reduction of losses. Table-3: Reduction of Line Losses with Improvement in Power Factor Load (KW) 300 300 (ii) PF 0.7 1.0 KVA 428 300 Current (A) 38.9 27.2 Line Loss (KW) 27.2 13.4 Remark s Before After

Line losses in LT distribution lines may also be considerably reduced by installing shunt capacitors of optimum rating at vantage points as decided during load stations.

The optimum rating of capacitor banks for a distribution system is 2/3rd of the average KVAR requirement of that distribution system. The vantage point is at 2/3rd the length of the main distributor from the transformer. A study made in an urban distribution system fed from a 200 KVA, 11 KV/415 volts transformer with 300 HP CL of more than 200 consumers having small loom loads showed the range of PF of the distribution system varied from 0.65 to 0.70. The reactive power requirement was 135 KVR. The inductive loads occurred on the distribution system between 7 AM and 8 PM; on all the working days with almost constant loadcycle. The capacitor bank rating 42.5 KVAR were installed at 2/3rd the distance from the transformer on the main distributor and were switched on and off manually at 7 AM and 8 PM respectively on all working days. The loss reduction was thus found to be 67%. The released capacity in this particular study was 42 HP, which could be supplied to the additional consumers.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

20

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

(iii)

A more appropriate manner of improving this PF of the distribution system and thereby reduce the line losses is to connect capacitors across the terminals of the motors (inductive load). The extent of reduction of line losses in this manner depends mainly on the extent to which the PF of consumer is improved. In this case, the capacitor is connected in parallel directly to the terminals, the capacitor being switched on and off together with the equipment itself.

Many electricity supply authorities are including a clause in terms & conditions of supply making it compulsory for the consumers to provide capacitors of adequate rating for all types of installations with connected loads of 5 HP and above. By connecting the capacitors across all individual inductive loads it is observed that 10% voltage improvement 20% reduction in current and reduction of losses upto 9% can be achieved depending upon the extent of PF improvement. 7. Bad Workmanship Resulting in Poor Contacts at Joints and Connections:

Bad Workmanship contributes significantly towards increase in distribution losses. In this context, the following points should be borne in mind. i) ii) iii) 7.1 Joints are a source of power loss. Therefore the number of joints should be kept to a minimum. Proper jointing techniques should-be used to ensure firm connections. Connections to the transformer bushing-stem, drop-out fuse, isolator, LT switch etc. should be periodically inspected and proper joint ensured to avoid sparking and heating of contacts. Replacement of deteriorated wires and services should also be made timely to avoid any cause of leakage and loss of power.

First Segment Leaving Substation.

In a radial distribution system the first segment leaving the substation carries all the load. This first segment is the one or several spans from the substation to the first tap (junction) point. In many cases this first segment contributes to (a) most of the technical losses (kWH, = I2Rt heating), and (b) to excessive voltage drop ( = IR). A strategy is to increase the conductor size of this first segment. Larger conductor (in terms of cross sectional area). Double or triple conductor with the same size conductor.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

21

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Since losses (kWH, and voltage drop) are directly proportional to resistance (see the above formulae), doubling the cross sectional area halves the losses (kWH and voltage drop) in the segment. The above technique works for both MV and LT systems., though its affect is more noticeable on the LT feeders. Contrast this technical improvement where the conversion from LT (400 volts) to 11 kV HVDS results in a 756 fold decrease in losses [ = (11000/400)2 ]. Pilferage of Energy: In addition to the above, pilferage of energy through manipulation of metering, direct tapping, application of wrong multiplying factors, non performing meters, under performing meters etc cause commercial losses. Since it is often not possible to measure the stolen energy and, therefore, cannot be charged to any one. Stolen energy is, therefore, considered as a part of T&D losses. Unscrupulous consumers extract energy illegally either by-passing the energy meter or by connecting leads directly to the distribution lines. Electricity supply authorities take various measures to stop theft of energy as below: 1) Surprise inspections are carried out by vigilance squads. 2) The energy meter is housed in a separate box sealed and made inaccessible to the consumers. The fuse cut-outs are provided after the meter. 3) The separate box shall be located outside of the customers premise (property line) in a location that is (a) readily accessible to utility personnel (meter readers, maintenance staff, inspectors and auditors, etc.) at all times (nights, weekends, holidays, as well as workdays), and (b) which is in a public location visible to all persons. 4) Multicore PVC cables are used as service mains instead of single core VIR wires. 5) The energy meter manufacturers are asked to provide the potential link inside the body of the energy meter and not inside terminal cover. This prevents the potential link to be disconnected by the consumer. 6) Heavy fines are imposed on consumers found committing theft of energy including imprisonment.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

22

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

It must be stated that the consumer stealing energy is imposing extra financial burden on honest law-abiding consumers. Further high line losses result in increased consumption of fuel, oil etc. used in the generation of electric power. Therefore, it is necessary that line losses (including pilferage of energy) are to be kept down to minimum. A unit saved is one and a half units saved for the system and this slogan is well worth remembering. 1) To enable the designing and operating personnel in each power supply undertaking to determine the specific causes of interruptions and take suitable remedial measures to improve the standard of supply. 2) To determine whether any improvement in service continuity is necessary to any consumer or group of consumers and to ensure that expenditure on improvements is incurred when it is most needed. 3) To keep a Discom informed of the performance of its various operating systems or divisions. INTEGRATED OPTIMUM SYSTEM PLANNING (IOSP) (Distribution Net Work) Introduction The distribution system in developing countries is faced with low voltage and high loss. The twin problem of the losses and voltage drop in distribution feeders are interdependent and varies with the pattern of loading on the feeders. Power losses of primary distribution system shall be between 3% to 5%. The maximum limits of voltage variation at customer premises as per the Indian Electricity Rules are +6% and 9% at high voltage and 6% at low voltage. The loss reduction and voltage improvement can be achieved by adding system facilities like erection of additional substations, setting up of non-conventional energy sources, etc., or through short term measures like network reconfiguration, reconductoring, employing shunt of series capacitors, or voltage boosters. The short term measures are cost effective and can be executed in a shorter period. An integrated approach to be adopted for the LRVI problem of large scale practical distribution network is discussed in this chapter for an optimal cost effective strategy to upgrade the existing primary network such that losses are within the desired range of 3-5% and also satisfy the statutory voltage limits at customer premises. Short Term Measures i) The Distribution Network in developing countries were expanded in adhoc manner to minimize the initial investment cost; and long range planning studies are not generally

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

23

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

undertaken. This situation has given a vast scope for reconfiguring the network to minimize the losses. The term network reconfiguration includes any one or all the works indicated below: a) Formation of new links to minimize within a feeder to form a tree stracture. b) Erection of interlinking lines to change the area of feed from one substation to another and balance the load among the substation. c) Bifurcation of existing feeder to form parallel paths of power flow. Network reconfiguration among feeders is effective only when the voltage drop between the nodes to be linked is rich and the distance between the nodes is short. The nodes to be linked have to be selected taking the quotient of voltage difference and the distance between the nodes as criteria. Network reconfiguration within a feeder is effective only when zig-zag factor is high. Zig-zag factor is defined as the ratio of total length of feeder to the bee line distance between the Distribution substation and minimum voltage point. The links have to be chosen so as to create a tree structure. Shunt Compensation The load incident on the distribution system is mostly inductive, requiring large reactive power. The best method is to compensate the reactive power at the load end itself but it is difficult to implement in practice. Hence, providing compensation on the distribution system is essential. The shunt capacitor supplies constant reactive power at its location, independent of the load. So, optimal compensation provided for peak load condition may result in over compensation during light load conditions, necessitating automatic switching schemes. The problem of determining the number, size and location of shunt capacitors required to be provided is formulated as an optimization problem. Objective function is the cost of energy saved due to reduction of power losses by the installation of capacitor banks less the annual cost of capacitors installed. The voltage constraints need not be considered, as the capacitors are switched on and off along with load to avoid over voltage during low load operation; and capacitor alone cannot economically improve the voltage during peak load period to satisfy the statutory lower limit. Series Compensation The maintenance of voltage at customer premises within statutory limits at ll loads is the responsibility of utility. Series capacitor introduces negative reactance in the line and improve the voltage which in turn also reduces the power losses. The main advantage of series capacitor is the quantum of compensation is highly responsive of series capacitor is that the quantum of compensation is highly responsive to load current and series capacitor can be kept in the circuit during the complete load cycle, without causing any adverse effect of over voltages, during low load conditions. The problem of determination of optimal location and capacity of series capacitor is formulated as an optimization problem. The objective function is similar to that of shunt compensation.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

24

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

The voltage constraint is that the voltage at the location of capacitor shall not exceed permissible upper is less than the difference between the permissible upper limit of voltage and voltage at the location of capacitor without series capacitor. Solution to the problem of determination of optimal capacity and location of series capacitor is obtained through an interactive approach. Automatic Voltage Booster The functioning of Automatic booster (AVB) is similar to that of series capacitor. AVB is an on load tap changer It boosts the voltage at its point of location in discrete steps and this in turn improves the voltage profile and reduces the losses in the section beyond its point of location towards receiving end. An AVB generally has a total voltage boost of 10% in four equal steps. The loss reduction is directly proportional to voltage boost and maximum permissible voltage boost is limited by the difference between the permissible maximum voltage and voltage at the point of location of AVB. The problem of determination of optimal location and percentage of boost of boost of AVB is formulated as an optimization problem. The objective function is the cost of energy saved due to desirable constraints are that the voltages at all sections should not exceed the statutory upper and lower limits. An interactive type of algorithm is adopted in the proposed solution approach. Network Reconductoring Network Reconductoring is replacement of the existing conductor on the feeder with optimal conductor size for optimal length of the feeder. This scheme arises where existing conductor is no more optimal due to rapid load growth. This is particularly relevant to developing countries, where annual growth rates are high and the conductor sizes are chosen to minimize the initial capital investment. Studies of several distribution feeders indicate that the looses in the first few main sections (4 to 5 say) from source constitute a major part of the losses in the feeder and by reinforcing these sections with conductor of optimal size, the losses can minimize the total cost, that is, cost of investment and cost of energy losses over a period of 5 to 10 years. Rule-Based Optimal Integrated Strategy Based on the investigations made on several practical distributions feeders and considering the inherent characteristics of short term strategies the following observations are focused: 1. Reconfiguration among feeders is effective only if there is unequal loading among the feeders of the network. Reconfiguration within the feeder is dependent upon the structure of feeder. The Network Reconfiguration is cost effective, as the rate of return is high. It should be the first choice, as it improves the utility of other shortterm measures.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

25

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

2. Shunt compensation reduces losses to the extent of 40% to 60%, if the power factor is low (lower than 0.8). It also reduces the loading on feeder sections and thus may avoid reconductoring. The voltage improvement due to shunt compensation is marginal except in case of very heavily loaded feeders. Shunt compensation alone cannot correct voltage drop. 3. Reconductoring of feeders reduces both losses and voltage drop when the initial sections of feeder are loaded beyond economic or break even loading limits. The existing supports generally have no strength to carry heavier conductor size and may need reelection of feeders or insertion of intermediate supports. This measure may cause some difficulties in implementation in practice. 4. AVB reduces the voltage drop by 10% and is very effective tool to solve voltage drop problem. The reduction of losses due to installation of AVB is marginal and as such rate is poor. 5. Series capacitor performance is like AVB with regard to LRVI problem. Generally multiple series capacitors are not installed on feeders, where multiple AVB are common and thus the capability of Series capacitor to improve voltage profile is limited. Further, series capacitor requires elaborate protection and is costlier than AVB and thus it is not cost effective. It is an effective solution, only when the loads are of rapidly fluctuating type. Hence it is not recommended to tackle the LRVI problem of primary network. A Rigorous Mathematical Model, which integrates all of the strategies into one stage, is complex and is difficult to solve using optimization techniques. Hence a set of rules based on the investigations of several practical distribution feeders to solve LRVI problem is suggested. The rules can be formulated in the form of expert systems. Since rigorous optimization techniques are employed for the solution of each short-term measure and the Rules are proposed only at the stage of integration of these strategies, the overall optimality of the solution is ensured. The following rules are suggested to tackles the LRVI problem for an optimal integrated solution: Rule-1: Check the loading on the feeders in the network. IF the feeders are unequally loaded viz., some feeders are heavily loaded compared to others, then reconfigure the network for minimal losses. Otherwise, go to Rule-2. The above measure automatically equalizes the loading on the feeders. Then check for losses and voltage drop. If the target values for any feeder are not achieved, go to Rule-2. Rule-2: Check the power factor of the feeders. IF it is below 0.95, determine the optimal number, location and capacity of the shunt capacitor banks to be placed on the network. Otherwise go to Rule-3. Check losses and voltage drop and if violated go to Rule-3. Rule-3: Check violation of which targets comparatively severe. If voltage drop violation is severe and losses are violated marginally, then install AVB on the feeders to improve

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

26

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

voltage profile and maximize loss reduction. If loss violation severe and voltage violation is marginal proceed for re-conductoring. MAINTENANCE SCHEDULE OF DISTRIBUTION TRANSFORMERS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Cleaning of bushing and external surface of tank coiling pipes Checking of oil levels in the conservator and gauge glass Checking of silicased in the breather and replacement is necessary Checking of oil level in the oil seal of breather & top up if necessary Checking of HG fuse & L.T fuse and renew if necessary (correct gauge shall be maintained) checking breaker operation in case of CSP transformer Checking of vent pipe diaphragm Checking of terminal loose connections is any and tightening the same Checking for any oil leaks & rectification (including replacement of oil seals if required) Taking tong tester reading during peak load hours and remedial action whenever load exceeds 80% rated capacity Noting down neutral currents and load balancing in all the three phase Measurement of IR values Testing of oil for BDV, acidity Checking of lightening arrestors and replacement is required preferably once before monsoon Measurement of earth resistance checking of earth in system and rectification if required Overhaul of transformer Monthly Monthly Monthly Monthly Monthly Monthly Monthly Monthly Quarterly Quarterly Half yearly Half yearly Half yearly Half yearly One in 5 years

MAINTENANCE SCHEDULE OF FOR POWER TRANSFORMERS 1. 2. 3. 4. Checking the color of silicagel in the breather and also oil level of the oil seal. If silicagel color changes from blue to pink by 50% the silicagel is to be reconditioned or replaced. Observation of oil levels in (a) main conservator tank (b) OLTC conservator (c) bushings and examining for oil leaks if any from the transformer Visual check for overheating if any at terminal connections (red hots) and observation for any unusual internal noises. Checking for noise, vibration or any abnormality in cooling fans & oil pumps of power transformers standby pumps & fans are also to be run condtion to be observed

Space for Institution Logo

Daily Daily Daily in each shift Daily

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

27

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

5. 6. 7. 8. 9. 10.

11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30.

Observation of oil and winding temperatures and recording Visual check of explosion vent diaphragm for any cracks Checking for any water leakage into cooler in case of forced cooling system Physical examination of diaphragm for any cracks Cleaning of bushings, inspect for any cracks or chippings of the porcelain and checking of tightness of clamps and jumpers Measurement of I.R values of transformer with 2.5 KV megger upto 33 KV rating and 5.0 KV megger above 33 KV rating. Recording of the values specify the temperature which measurements are taken. Cleaning of Silicagel breather Checking of temperature alarms by shorting contacts by operating the knob. Testing of main tank oil for BDV and moisture content Testing OLTC oil for BDV and moisture content Testing of Bucholtz surge relays & low oil level trips for correct operation Checking auto start of cooling fans and pumps Checking of operation of bucholtz relay for any gas collection and testing the gas collected Checking of operation of bucholtz relay by air injection ensuring actuation alarm and trip Noting the oil level in the inspection glass of bucholtz relay and arresting of oil leakages if any Checking of all connection on the transformer for tightness such as bushing, tank earth connection Lubricating/Greasing all moving parts of OLTC mechanism Checking of control circuiting, interlocks of oil pumps and cooling fans for auto start and stop operation at correct temperatures and also for manual operation Testing of motors, pumps and calibrating gauge Pressure testing of oil coolers Testing of oil samples for dissolved gas analysis (for 100 MVA transformers) Testing of oil for dissolved gas analysis EHV transformer upto 100 KVA capacity Overhauling or oil pumps and their motors also cooling fans and their motors Testing of oil in main tank for acidity, tan delta, interface tension specific resistively Bushing testing for tan delta Calibration of oil & winding temperature indicators

Hourly Daily Daily Monthly Monthly Monthly

Monthly Monthly Quarterly Quarterly Quarterly Quarterly Quarterly / during fault Half yearly shutdown Monthly Quarterly Quarterly

Half yearly Half yearly Half yearly Once in year Once in year Once in year Once in year Repeates

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

28

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

31. Measurement of magnetizing current at normap tap and extreme taps 32. Measurement of D.C winding resistance 33. Turns ratio at all taps 34. Inspection of OLTC mechanism and contacts its divertor switch 35. Overhaul of tap changer and mechanism 36. Replacement of oil in OLTC 37. Calibration of thermometers (temperature indicators) and tap position indicator 38. Remaining old oil in thermometer pockets, cleaning the pockets and filling with new oil 39. Checking oil in the air cell (for transformers of 100 MVA & above capacity) 40. Bushing partial discharge test and capacitance (EHV transformers) 41. Filteration of oil/replacement of oil and filtration

Once in year Once in year Once in year Once in year Once in year Once in year Yearly Yearly Yearly Once in 5 years

Whenever the IR values of transformer are below limits. 42. General overhaul (consisting) (1) Inspection of core & Once in 10 years winding (2) Through washing of windings (3) Core tightening (4) Check-up of core bolt insulation (5) replacement of gaskets (6) Overhaul of OLTC SHUNT & SERIES CAPACITORS The type of usage have different applications, operation problems which are as discussed below: Shunt Capacitors 1. Supply fixed amount of reactive power to the system at the point where they are installed. Its effect if felt in the circuit from the location towards source only. 2. Causes reduction in reactive power following in the line and causes (a) Improvement of Power factor of system (b) Voltage profile improvement. (c) Decrease KVA loading on source (i.e.) generators, transformers and line upto location and

Space for Institution Logo

Series Capacitors 1. Quantum of compensation is dependent on load current and instaneous changes occur. Its effect is from its location towards load end. 2. It is effective (a) On radial feedes improve regulation, automatically. (b) On tie lines; power transfers are greater. (c) Specifically suitable when flickers due to respective

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

29

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

thus provide additional capacity.

load functions occur.

3. The location has to be as near the load point as possible. In practice due to high compensation required it is found 3. As a thumb rule, best location is 1/3 rd economical to provide group electrical impedance from source bus. compensation on lines and at S.S. 4. As fixed KVAR is supplied this may some times result in over compensation during light load period. Switched banks, 4. As full load current is to pass through; comparatively costlier becomes the capacity (current rating) should be necessary. more than the load current. 5. As series capacitors feed faults also special protection is required 5. As the power factor approaches unity, larger compensation is required for incremental improvement of power factor. 6. Causes sudden rise in voltage at its 6. Where lines are heavily loaded location. compensation required will be more. 7. Cost of series capacitor is higher than 7. Cost is lesser compensation to series shunt capacitor. capacitor. 8. Transformers draw high transient exciting current when charged and this causes Ferro resonance. Spark gap of capacitor to take care of the contingency. 9. Due to sub synchronous resonance; motors when started through series capacitors, may get locked in and continue to rotate at low speed. This is prevented by providing resistor in parallel across capacitors or resistor in series with supply leads to motor at the time of starting.

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

30

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Table 1 All Aluminum (Standard) Conductor (AAC), IS: 398-1961 (1974)

Conductor Code Name Nominal Copper area mm2 Calculate Equivalent area of aluminum mm2 Electrical Properties Calculated Approximate current resistance carrying capacity (A) at 20 deg C when 40 deg C 45 deg C corrected to ambient ambient standard temp. temp. weight ohms/km 0.67210 178 165 0.54440 204 189 0.45260 229 212 0.39060 252 234 0.36620 264 245 0.34220 275 255 0.30090 298 276 0.27150 318 295 0.15550 460 386 0.13560 504 468 0.12170 540 500 0.10880 575 534 0.08959 655 608 0.07749 720 660 0.06743 790 734 0.05982 850 790 0.05488 895 830 Stranding and wire diameter No. Dia mm Conductor diameter mm Mechanical properties Conductor Approx. weight area mm2 kg/km Approx. ultimate strength kg

Lady Bird Ant Fly Blue bottle Earwig Grasshopper Clegg Wasp Caterpillar Chafer Spider Cockroach Butterfly Moth Locust Maybug Scorpion

25 30 40 45 48 50 60 65 110 130 140 160 185 225 260 300 325

42.33 52.26 62.86 72.84 77.70 83.13 94.56 104.80 183.00 209.90 233.80 261.50 317.50 367.20 421.90 473.60 518.40

7 7 7 7 7 7 7 7 19 19 19 19 19 19 19 37 37

2.79 3.10 3.40 3.66 3.78 3.91 4.17 4.39 3.53 3.78 3.99 4.22 4.65 5.00 5.36 4.09 4.27

8.37 9.30 10.20 10.95 11.34 11.73 12.51 13.17 17.65 18.90 19.95 21.10 23.25 25.00 26.80 28.63 29.89

42.80 52.84 63.55 73.65 78.55 84.05 95.60 106.00 186.00 213.20 237.60 265.80 322.70 373.10 428.70 486.10 529.80

117 144 174 201 215 230 261 290 511 586 652 730 886 1025 1176 1343 1464

737 892 1051 1203 1272 1356 1523 1673 2985 3381 3736 4144 4947 5695 6516 7289 7878

Note : (i) The resistance (Rt) of conductor at any other tempeture (t) may be determined by relation : Rt = R20 [1 + 0.004 (t-20)], where R = resistance at tempeture t; R20 = resistance at tempeture at 20 deg C given in the table

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

31

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Table 2 ACSR Conductors IS: 398-1976

Conductor Code Name Nominal Copper area mm2 Calculate Equivalent area of aluminum mm2 Electrical Properties Calculated Approximate current resistance carrying capacity (A) at 20 deg C when 40 deg C 45 deg C corrected to ambient ambient standard temp. temp. weight ohms/km 2.71800 1.37400 115 107 1.09800 133 123 0.91160 150 139 0.54490 208 193 0.45650 234 217 0.36560 270 250 0.27450 324 300 0.21930 375 348 0.22210 382 354 0.18440 430 398 0.15890 475 440 0.13750 520 482 0.12230 555 515 0.11020 595 552 Stranding and wire diameter No. Dia mm Conductor diameter mm Mechanical properties Conductor Approx. weight area mm2 kg/km Approx. ultimate strength kg

Mole Squirrel Gopher Weasel Rabbit Mink Raccoon Dog Leopard Tiger Wolf Lynx Panther Lion Bear

6.5 13 16 20 30 40 48 65 80 80 95 110 130 140 160

10.47 20.71 25.91 31.21 52.21 62.32 77.83 103.60 129.70 128.10 154.30 179.00 207.00 232.50 258.10

6 6 6 6 6 6 6 6 6 30 30 30 30 30 30

1.50 2.11 2.36 2.59 3.35 3.66 4.09 4.72 5.28 2.36 2.59 2.79 3.00 3.18 3.35

4.50 6.33 7.08 7.77 10.05 10.98 12.27 14.16 15.84 16.52 18.13 19.53 21.00 22.26 23.45

12.37 24.48 30.62 36.88 61.70 73.65 91.97 118.50 148.40 161.80 195.00 226.20 261.60 293.90 326.10

43 85 106 128 214 255 318 394 493 604 727 844 976 1097 1219

407 771 952 1136 1860 2207 2746 3299 4137 5758 6880 7950 9127 10210 11310

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

32

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Table 3 All Aluminum Alloy Conductors (AAAC)

Conductor Code Name Equivalent to ACSR Electrical Properties Calculated resistance Approximate current at 20 deg C when carrying capacity (A) corrected to standard weight ohms/km 40 deg C 45 deg C ambient ambient temp. temp. 2.70 80 74 1.370 123 113 0.913 158 142 0.5465 214 196 0.3663 278 252 0.2768 329 300 0.1840 422 383 0.1375 504 460 Stranding and wire diameter No. Dia mm 7 7 7 7 19 19 37 37 1.49 2.09 2.56 3.31 2.46 2.83 2.49 2.88 Conductor diameter mm Mechanical properties Conductor Approx. weight area mm2 kg/km Approx. ultimate strength kg 348 685 1024 1715 2577 3405 5125 6882

Mole Squirrel Weasel Rabbit Raccoon Dog Wolf Panther

4.47 6.27 7.68 9.93 12.30 14.15 17.43 20.16

12.21 24.02 36.03 60.24 90.31 119.50 180.20 241.00

33.38 65.68 98.56 164.70 248.10 328.40 496.30 663.80

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

33

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

Table: 4 Voltage regulation -400 V System uniformly distributed load Km-KVA for line regulation at 0.85 pf ( Temperature rise 300 ),700 c conductor temp 5% 6% 7% 8% 6.05 7.43 8.89 10.40 8.60 10.55 12.60 14.80 10.90 13.30 15.92 18.55 14.50 17.80 21.20 24.75 16.75 20.60 24.60 28.75 20.00 24.50 29.20 34.50 Table: 5 Voltage regulation -11kv over head lines S.n o Conductor (eq. Nominal cu.area) Km-MVA for line regulation at 0.85 pf ( Temperature rise 300 ),700 C conductor temp

S.n o 1 2 3 4 5 6

Conductor Squirrel Weasel Ferret Mink Raccoon Dog

5% 6% 7% 8% 9% 10% 1 Squirrel (13 mm2) 3.63 4.41 5.21 5.95 6.78 7.63 2 2 Gopher (16 mm ) 4.42 5.36 6.32 7.30 8.30 9.32 3 Weasel (20 mm2) 5.17 6.27 7.38 8.52 9.67 10.84 4 Ferret (25 mm2) 6.51 7.87 9.32 10.73 12.25 13.71 2 5 Rabbit (30 mm ) 7.60 9.24 10.85 12.56 14.30 15.99 6 Mink (40mm2) 8.75 10.62 12.53 14.48 16.47 18.50 2 7 Raccoon (48 mm ) 10.23 12.40 14.60 16.85 19.22 21.56 8 Dog (65 mm2) 12.43 15.08 17.73 20.50 23.32 26.20 Note: For single phase lines: phase to phase and phase to neutral system, voltage

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

34

Distribution Efficiency and Demand Side Management (DSM) Distribution Reform, Upgrades and Management (DRUM) Training Program

regulation will be respectively 0.5 and .28 times the values given in this table Table: 6 Voltage regulation -33kv sub transmission lines (temperature rise 300c ) 700c conductor temperature S.n o 1 2 3 4 5 6 7 8 Conductor (eq. Nominal cu.area) Rabbit (30 mm2) Mink (40 mm2) Raccoon (48mm2) Dog (65 mm2) Leopard (80 mm2) Wolf (95mm2) Lynx (110mm2) Panther (130 mm2) Km-MVA for line regulation at 0.85 pf ( Temperature rise 300 ),700 C conductor temp 6% 7% 8% 9% 10% 81.61 93.97 110.21 132.23 150.68 170.66 184.27 195.83 96.26 110.82 129.89 155.27 175.79 199.11 214.98 228.47 111.21 128.09 149.87 177.46 200.91 227.55 245.69 261.10 126.46 145.62 168.60 199.64 226.02 256.00 276.40 293.70 142.11 162.00 187.33 221.82 251.13 284.44 307.11 326.38

5% 67.50 77.51 90.86 109.10 124.51 141.95 153.56 163.19

Space for Institution Logo

Power Finance Corporation Ltd.

(A Govt. of India Undertaking)

35

You might also like

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Transmission & Distribution SystemsDocument211 pagesTransmission & Distribution SystemsVanaVihari DasNo ratings yet

- O & M of Sub-Station Equipment: Narender Kumar Me Mba MieDocument31 pagesO & M of Sub-Station Equipment: Narender Kumar Me Mba MiewaleedalzaidiNo ratings yet

- Switching: AND Its TechniquesDocument25 pagesSwitching: AND Its TechniquesHimanshu DhamejaNo ratings yet

- Report on 220 KV Grid Substation AlwarDocument50 pagesReport on 220 KV Grid Substation AlwarIqbal DeenNo ratings yet

- EE-455 Electrical PowerSystem Protection - F2013Document48 pagesEE-455 Electrical PowerSystem Protection - F2013Vinícius Mota SilvaNo ratings yet

- InternshipDocument14 pagesInternshipshah BilalNo ratings yet

- Substation Automation Basics - The Next GenerationDocument8 pagesSubstation Automation Basics - The Next GenerationAlly RaxaNo ratings yet

- Study of Elements of A 22013233kv SubstationDocument67 pagesStudy of Elements of A 22013233kv SubstationARVIND100% (2)

- Distribution Feeder PrinciplesDocument9 pagesDistribution Feeder Principlesanoopeluvathingal100No ratings yet

- Fault Detection in Transmission LinesDocument90 pagesFault Detection in Transmission LinesMohd SameerNo ratings yet

- 3 Distribution System DesignDocument15 pages3 Distribution System DesignAHMED YOUSEFNo ratings yet

- TR-209 Vol-II PDFDocument218 pagesTR-209 Vol-II PDFSandeepNo ratings yet

- Kishenpur Grid Station CompleteDocument39 pagesKishenpur Grid Station CompletepunitkapoorNo ratings yet

- Ssasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Document167 pagesSsasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Sunil Singh100% (1)

- SAS - Substation Automation System OverviewDocument73 pagesSAS - Substation Automation System OverviewstjpksNo ratings yet

- Expand of Alkhoms 30KV Power Distribution NetworkDocument5 pagesExpand of Alkhoms 30KV Power Distribution Networkعبدالله أبورويصNo ratings yet

- Ch-1 How Electric Power Grid WorksDocument44 pagesCh-1 How Electric Power Grid Worksyaso42No ratings yet

- Module 4: Substation Equipment's Details and Operations: July 2021Document14 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- 500 KV TRANSMISSION LINE DESIGN AND FAULT ANALYSISDocument96 pages500 KV TRANSMISSION LINE DESIGN AND FAULT ANALYSISkariboo karibooxNo ratings yet

- 550 K VGISDocument18 pages550 K VGISMinh VienNo ratings yet

- Taswar Abbas 1Document62 pagesTaswar Abbas 1Sumaira SaifNo ratings yet

- Circuit BreakerDocument70 pagesCircuit BreakerBADAL CHOUDHARYNo ratings yet

- MVDC - The New Technology For Distribution NetworksDocument5 pagesMVDC - The New Technology For Distribution NetworksClaudio Antonio Paredes CarrascoNo ratings yet

- Sem Hand BookDocument118 pagesSem Hand BookrajuwithualwaysNo ratings yet

- Draft Letter For SAS Intrigration LetterDocument2 pagesDraft Letter For SAS Intrigration LettermanishNo ratings yet

- Session-3 Distribution NetworkDocument28 pagesSession-3 Distribution NetworkChristos Apostolopoulos100% (1)

- Pdu Lab Manual 104Document94 pagesPdu Lab Manual 104Rana FaizanNo ratings yet

- SLDCDocument51 pagesSLDCsharmiNo ratings yet

- Designing of HV Power Substation and LayoutDocument6 pagesDesigning of HV Power Substation and LayoutRagavanNo ratings yet

- Genaral Details of A TransformerDocument3 pagesGenaral Details of A TransformershaluNo ratings yet

- Interconnected SystemDocument17 pagesInterconnected SystemChowdhury, A HasibNo ratings yet

- 132kV Network ReconfigurationDocument35 pages132kV Network ReconfigurationAkinwumi OluwatosinNo ratings yet

- Introduction to Electric Power TRANSMISSION & DISTRIBUTIONDocument100 pagesIntroduction to Electric Power TRANSMISSION & DISTRIBUTIONUmair BeygNo ratings yet

- SF6 Circuit Breakers - Construction, Types and WorkingDocument13 pagesSF6 Circuit Breakers - Construction, Types and WorkingSankara SubramanianNo ratings yet