Professional Documents

Culture Documents

10 Transportation

Uploaded by

sweetqistOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 Transportation

Uploaded by

sweetqistCopyright:

Available Formats

ECS716/QMT710: Operational Research Pn.

Paezah

The Transportation Problems

Outline I. The Nature of the Transportation Problem II. The Balanced Transportation Problem III. The Unbalanced Transportation Problem IV. Special Cases: Degeneracy Multiple Optimal Solutions V. Maximization Problems Learning Outcomes From the study of this topic, you will learn the followings: 1. The basic nature of the transportation problem. 2. The formulation of a linear programming model for the transportation problem. 3. Formulating a transportation problem 4. Obtaining an initial solution to the transportation problem by different techniques (the Northwest Corner Rule, the Least-Cost Method, VAM) 5. Solving the transportation problem by the technique of MODI (Modified Distribution) 6. Solving the following types of transportation problems: unbalanced special cases (degenerate, multiple optimal solutions) 7. Solving maximization problems using the transportation algorithm. 8. The meaning of the following terms: Balanced transportation problem Unbalanced transportation problem Northwest corner method Vogels approximation method (VAM) Least-cost method (LCM) Modified distribution method (MODI) Stepping-stone method Closed path Cost improvement index Degenerate transportation solution Multiple optimal solutions

I.

The Nature of the Transportation Problem

Managerial decision problems for many organizations include the problem of transportation of goods and services. The transportation model, which is a special type of linear programming model, can be used to solve such problems. The model deals with the determination of a minimum cost plan for transporting a single commodity from a number of sources to a number of destinations The transportation model has the following unique characteristics. 1. A product is transported from a number of sources to a number of destinations at the minimum possible cost. 2. Each source is able to supply a fixed number of units of the product. 3. Each destination has a fixed demand for the product. Since there is only one product, a destination can receive its demand from one or more sources.

II. The Balanced Transportation Problem

When total supply and demand are equal, the formulation is called a balanced model. However, not many real-world transportation problems are balanced cases. The following is an example of a balanced transportation problem. Example 1: Trimax Sdn. Bhd. is a distributor of construction materials. The company has a contract to deliver cement to four housing projects. The cement is purchased from three different factories in town 1, town 2, and town 3. Cement bags from the factories are delivered to the project sites by trucks. Because the shipping costs are a major expense, management is initiating a study to reduce them as much as possible. For the coming week, an estimate has been made on the cement to be purchased from each factory and the quantity to be allocated to each project. This information, along with the shipping cost per truckload (in RM00) from each factory to each project is given in the following table.

Table 1: Shipping Data for Trimax Shipping Cost (RM00/truckload) Project Factory 1 2 3 Demand (truckloads) 1 6 3 13 15 2 13 9 8 25 3 5 7 11 15 4 12 6 10 10 Supply (truckloads) 20 18 27

From the above table, a total of 65 truckloads of cement are to be distributed from three sources to four destinations. The problem now is to determine the distribution plan that would minimize the total shipping cost.

The general transportation model is as shown in the following parameter table, where xij = the units of commodity shipped from source i to destination j cij = the cost of shipping 1 unit from source i to destination j Si = the total units supplied from source i. Dj = the total units demanded at destination j To

The transportation model

From 1 2 3 Demand x11

1 c11 x12 c21 x21 c31 x31 D1 x32 x22

2 c12 x13 c22 x23 c32 x33 D2

3 c13 x14 c23 x24 c33 X34 D3

4 c14 c24 C34 D4

Supply S1 S2 S3

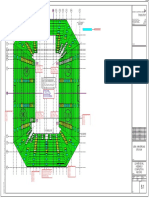

The network representation of Trimax transportation problem is shown below.

Source

Supply Town 1: 20

Destination

Demand

15: Project 1

Network model

Town 2: 18

25: Project 2

Town 3: 27

15: Project 3

4 65

10: Project 4

65

The following is the linear programming model for the problem. Z denotes the total shipping cost, and Xij (i = 1,2,3; j = 1,2,3,4) denotes the number of truckloads of cement to be shipped from town i to project j.

Minimize Z = 6x11 + 13x12 + 5x13 + 12x14 + 3x21 + 9x22 + 7x23 + 6x24 + 13x31 + 8x32 + 11x33 + 10x34 subject to: x11 + x12 + x13 + x14 = 20 (supply from Factory 1) x21 + x22 + x23 + x24 = 18 (supply from Factory 2) LP Model (for balanced problem) x31 + x32 + x33 + x34 = 27 (supply from Factory 3) x11 + x21 + x31 = 15 (demand from Project 1) x12 + x22 + x32 = 25 (demand from Project 2) x13 + x23 + x33 = 15 (demand from Project 3) x14 + x24 + x34 = 10 (demand from Project 4) X11 , X12 , X13 , X14 , X21 , X22 X23 , X24 , X31 , X32 , X33 , X34 0

Formulating a Transportation Model Exercise1: Formulate the transportation problem for Trimax by completing the following parameter table. To From

Supply

Demand

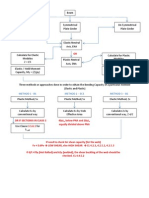

The above transportation problem can be solved by using a special simplex algorithm called the transportation algorithm. The following is a flowchart showing the transportation algorithm.

The Transportation Algorithm

Start

Phase 1

`11 Develop an Initial Feasible Solution (Vogels Approximation Method (VAM))

Phase 2 `11 Test for Optimality (Modified Distribution (MODI) method)

optimal

Interpret

Stop

Not optimal Phase 3 `11 Generate an Improved Solution (Stepping-stone method)

In general, the procedure for solving a transportation problem involves three phases. Phase 1 to determine an initial feasible solution Phase 2 to test for optimality Phase 3 to improve the solution [Phase 3 is applied when the procedure in Phase 2 does not result in an optimal solution.]

Phase 1: Developing an Initial Feasible Solution The transportation requires that the problem is balanced, i.e. the total supply = total demand. (The unbalanced problem will be discussed later). An initial feasible solution can be obtained by using Vogels Approximation Method (VAM). Vogels Approximation Method (VAM): Step 1: Calculate a penalty for each row or column by subtracting the lowest unit cost in the row or column from the next lowest unit cost for the same row or column. Step 2: Identify the row or column with the largest penalty. Break ties arbitrarily. Allocate as much as possible to the cell with the least unit cost in this row or column. Adjust the free demand and supply totals and cross out the row or column whose demand or supply is entirely used up. If both the row and the column have no supply or demand left only cross out one. Step 3: If all columns and rows have been satisfied then we have an initial solution. Otherwise recalculate the penalties for uncrossed out rows and columns without counting rows and columns with zero free demand or supply.

Exercise 2: Solve Trimaxs problem to determine the optimal distribution plan. Use VAM for the starting solution. What is the minimum total cost? . Initial solution by VAM: To From Supply

Demand

Initial solution: From Factory To Project No. of Truckloads

Total cost =

Phase 2: Testing for Optimality Testing for optimality can be done using the Modified Distribution (MODI) method. This procedure is based on the dual of the transportation problem (recall: every LP problem has a dual. Hence, a transportation problem which is a special type of LP problem also has a dual). When the dual is solved, its solution yields two types of variables: Ri = shadow price of source i (i.e. value of one more unit at source i) Kj = shadow price of destination j (i.e. value of one more unit at destination i) The MODI procedure uses the value of Ri and Kj to find the cell improvement indices (cell evaluators). The MODI Method MODI requires that we evaluate each empty cell to determine the transportation cost of transferring 1 unit of goods from an occupied cell to an empty cell. MODI may only be applied if a transportation table has at least m+n -1 cells occupied, where m = no. of sources, and n = no. of destinations. If the number of occupied cells < m+n-1, then the problem becomes degenerate (to be discussed later)

MODI method: Step 1: Assign the following values: Ri to row i, and Kj to row j. Let Cij = unit cost for cell (i, j). Step 2: For each occupied cell (used route)-, form an equation Ri + Kj = Cij. Step 3: Let R1 = 0. Solve all the equations formed in Step 2 for each Ri and Kj. Step 4: Test for Optimality. For each empty cell, determine the improvement index Iij using the formula Iij = Cij Ri Kj. The improvement index Iij is the net cost of shipping 1 unit on a route not used in the current transportation solution. If Iij 0 for all the empty cells, then the current solution is optimal. (Note: For a maximization problem, a solution is optimal when all the empty cells have Iij 0 )

If the solution is optimal, interpret it and stop. If not optimal, proceed to Phase 3 to improve the solution.

Phase 3: Generating an Improved Solution (the Stepping-Stone Method) One way to improve the solution of a transportation problem is by applying the stepping stone method.

Stepping-Stone Method: Step 1: Choose an empty cell (unused square) with the best improvement index Iij. For a minimization problem, the best index is the MOST NEGATIVE Iij,, indicating the greatest decrease in cost. Starting from the empty cell with the best index, trace a closed path back to this cell by stepping on occupied cells, moving with only horizontal and/or vertical moves. Here are some examples of possible shapes of closed paths.

Step 2:

(The shape of a closed path obtained depends on the location of occupied cells) Step 2: Step 3: Starting from the cell with the best index, place plus (+) and minus (-) signs alternately at occupied cells on the corners of the closed path. From the cells with minus signs, select the SMALLEST QUANTITY of goods. This smallest quantity is the maximum value to be allocated into the cell with the best index. ADD the smallest quantity selected to the existing quantity in each cell with a (+) sign, and SUBTRACT this smallest quantity from the quantity in each cell with a (-) sign. Step 4: Draw a new transportation table showing the result of Step 4. This should produce a new shipment schedule with a better (lower) total transportation cost.

III. The Unbalanced Transportation Problem

A transportation problem is considered unbalanced when total supply total demand. Thus, either total supply < total demand, or total demand < total supply. To use the transportation algorithm, we must make a minor modification in the transportation table so that the problem is balanced. Total Supply < Total Demand Create an imaginary source, called a dummy source (or dummy row) with the necessary supply. Set the unit costs in the dummy row to zero, since the dummy source is only imaginary.

Total Demand < Total Supply Add a dummy destination (or dummy column) with the necessary demand to balance total supply and total demand. Set the unit costs in the dummy column to zero.

Example 2: Suppose Factory 3 can sell only 25 truckloads of cement to Trimax. Determine the optimal shipment. What is the minimum total cost? Identify the project with cement shortage..

IV. Special Cases

A. DEGENERACY Degeneracy in transportation problems occur under the following condition: number of occupied cells < m + n - 1 , where m = no. of sources, n = no. of destinations A transportation table of a degenerate problem does not have enough cells occupied to allow the formation of closed paths for all unused cells. Hence, we would not be able to determine the Ri and Kj values needed for the MODI technique, or evaluate each unused cell for improvement. Degeneracy may occur two ways: 1. At the initial solution if the supply equals demand for which an assignment is to be made. 2. At an intermediate solution if the quantities of two or more losing cells at the non-degenerate solution are the same. Consequently the cells will become empty simultaneously when the solution is improved.

How to handle degeneracy? Create artificially occupied cells by placing artificial zeroes into empty cells so that number of occupied cells = m + n -1 There are obviously many cells into which a zero could be entered. There are no rules for entering these zeros. However choosing a low cost cell is generally a good idea. Pretend as if those cells with artificial zeroes are occupied, and proceed as a normal, non-degenerate case.

Example 3a: The following table gives the unit costs (RM), supply (units) and demand (units) for a certain product.

Customer 1 1 Plant 2 3 Demand 6 3 10 150 2 10 9 8 100 3 5 7 11 200 4 12 6 10 100 Supply 200 150 200

Obtain an optimal distribution schedule.

Example 3b: Given the following transportation table, obtain an optimal solution. To From Factory A Factory B Factory C Warehouse Requirement

Warehouse 1 8 70 15 50 3 30 150

Warehouse 2 5 10 80 9

Warehouse 3 16 7

Factory capacity 70 130

10 50 80 280 50

80

B.

MULTIPLE OPTIMAL SOLUTIONS

A solution to a transportation problem can be either unique or multiple. A transportation problem may have alternate optimal solutions if the optimal table has at least one empty cell with improvement index Iij = 0. An alternate optimal solution can be found by applying the stepping stone method starting from the empty cell with zero improvement index.

Example 4: Given a transportation table with the following unit costs (RM), supply and demand, find the optimal solution. To From A B C D Demand(units) 1 10 15 13 10 1200 2 15 13 12 9 1200 3 18 16 10 12 600 Supply(units) 500 500 1000 1000

V.

MAXIMIZATION PROBLEMS

So far we have studied minimization problems. The transportation algorithm can be applied to maximization problems. However, slight modifications to the algorithm are needed to solve such problem. General Rules for Solving a Maximization Problem If a transportation table has unit profits, instead of unit costs, the initial solution can be obtained by applying a Maximum-Profit method, which is the opposite of the Least-Cost method.

Testing for optimality can be done by the MODI method. However, the best improvement index is the LARGEST positive Iij value. Improve a solution using the Stepping Stone method (same as before). An optimal solution is reached when all Iij 0, i.e. when there is NO POSITIVE Iij.

Example 5 SML Food Industries produces its latest health food product at its three factories. It has three major customers. The profit per unit (RM), estimated monthly demand and capacity of each factory are given below. Customer Factory A B C X 12 6 6 Y 10 9 10 Z 7 6 9

Factory A B C

Capacity (units) 1300 1000 1200

Customer A B C a)

Demand (units) 1100 900 1300

Use the transportation algorithm to determine the optimal allocation of the health food product to the customers from the factories in order to maximize the total profit. Calculate the maximum total profit. Is the optimal solution unique? Explain. Obtain an alternative optimal solution, if any.

b)

10

Textbook problems 8.1-2, 8.1.4, 8.1-6.8.2-9 (a),(d)

Supplementary Exercises 1. Consider the following transportation problem. Manufacturer 1: PJ 1: Penang 2: Shah Alam 3: Pekan Demand (units) 13 8 10 80 Shipping Cost (RM/Unit) Warehouse 2: Ipoh 10 10 12 65 3: Kota Bahru 18 18 15 70 4: J.Bahru 15 12 18 85 75 125 100 Supply (units)

In this problem, a total of 300 units of laser jet printers are to be distributed from three sources to four destinations. Determine the optimal distribution plan. 2. Solve each of the following transportation problems. Calculate the minimum total cost. (i) From 1 2 3 Demand (units) A 22 15 28 520 Cost (RM) To B 17 35 21 250 C 30 20 16 400 D 18 25 14 380 Supply(units) 420 610 340

(ii) $10 $2 $1 7 $4 $3 $2 6 $2 $4 $0 6 8 5 6

(iii) $7 $1 5 $3 $4 $8 6 $5 $9 $6 19 4 7 19

11

3. Seri Rampai Sdn Bhd is a supplier of cosmetic products. The company has three distribution centers which are located at the northern, central, and southern regions of the country. For the coming month, the company has to distribute one particular cosmetic product to four major customers. The data on the supply available at each distribution center and the customer demand are as follows: Distribution Center Northern Central Southern Customer 1 2 3 4 Supply (units) 10,000 15,000 18,000 Demand (units) 10,000 12,000 15,000 8,000

The total unit cost (RM) of producing and distributing the product from each distribution center to each customer is shown in the following table. Customer Distribution Center Northern Central Southern 1 16 12 14 2 16 15 10 3 10 9 13 4 15 8 12

The product will be sold to the customers at the price of RM25 each. a) Determine the optimal distribution schedule that will maximize Seri Rampais total profit and calculate the maximum total profit. b) Identify any customer with unfulfilled demand and state the shortage. 4. Frontline Logistics Sdn Bhd has a contract to supply cements to three construction firms in the Klang Valley. Cements are purchased from manufacturers at three different plants and transported to the three firms as orders are placed. Shipping costs per bag of cement from each plant to each firm have been estimated as follows: Cost (RM/bag) Shah Alam Plant 1 Plant 2 Plant 3 9 11 6 Cheras 14 8 6 Putrajaya 12 10 11

Each plant can supply 200 bags of cement. Frontline has received orders from the three construction firms, and they have requested the following bags of cement: Shah Alam 270, Cheras 150, and Putrajaya 150.

a) Determine the optimal shipment. What is the minimum cost? b) Suppose the firm in Putrajaya requires an additional 60 bags of cement. Determine the optimal solution. What is the minimum total cost?

12

You might also like

- PETAL Sentence StartersDocument1 pagePETAL Sentence StartersSnip x Hunt manNo ratings yet

- History of TQMDocument23 pagesHistory of TQMVarsha PandeyNo ratings yet

- CeDocument3 pagesCeRowie Ann Arista SiribanNo ratings yet

- Ge 4 - Examination Answer SheetDocument1 pageGe 4 - Examination Answer SheetNicole Joy FidelesNo ratings yet

- Life and Works of Rizal (Concept Paper)Document9 pagesLife and Works of Rizal (Concept Paper)Gimboy navarretteNo ratings yet

- CII Sohrabji Godrej GreenDocument30 pagesCII Sohrabji Godrej GreenRITHANYAA100% (2)

- Session 12 - The Transportation ModelDocument46 pagesSession 12 - The Transportation ModelNicolás SilvaNo ratings yet

- Lesson 3: Worksheet 3: Remedial Lesson 3: Adjusting EntriesDocument2 pagesLesson 3: Worksheet 3: Remedial Lesson 3: Adjusting EntriesAleana joy PabelicNo ratings yet

- Practical Exercise 6.1Document14 pagesPractical Exercise 6.1roseleenNo ratings yet

- Week 04-Class 08-Product and Service DesignDocument17 pagesWeek 04-Class 08-Product and Service DesignSWAPNIL TYAGINo ratings yet

- What Are The Factors Affecting MovementDocument3 pagesWhat Are The Factors Affecting MovementMaja Dera50% (2)

- Task Performance IN Math: MembersDocument6 pagesTask Performance IN Math: Membersjohn kirt cortezNo ratings yet

- Activity Number 5 Elasticity of Demand & SupplyDocument5 pagesActivity Number 5 Elasticity of Demand & SupplyLovely Madrid0% (1)

- MMW - Problem SolvingDocument29 pagesMMW - Problem SolvingyoyoyoNo ratings yet

- Thematic RRL of Teachers' Level of Expertise On Modern Day TechnologyDocument11 pagesThematic RRL of Teachers' Level of Expertise On Modern Day TechnologyLourainne Faith AloceljaNo ratings yet

- Basic Microeconomics: Chapter 3: Elasticity of Demand and SupplyDocument12 pagesBasic Microeconomics: Chapter 3: Elasticity of Demand and SupplyJane Gonzaga100% (1)

- Chapter 3Document41 pagesChapter 3Diana100% (3)

- 1.5 Lesson 9 & 10 Contemporary WorldDocument4 pages1.5 Lesson 9 & 10 Contemporary WorldJoenard Sadorra CabaelNo ratings yet

- Cooperative Management PRELIM ExaminationDocument2 pagesCooperative Management PRELIM ExaminationFatmah CandaoNo ratings yet

- Roxas Claire B. Science Technology and Society 09 Activity 1Document1 pageRoxas Claire B. Science Technology and Society 09 Activity 1Eldrick Neil Reyes100% (1)

- CH 9 - Completing The Cycle - MerchandisingDocument38 pagesCH 9 - Completing The Cycle - MerchandisingJem Bobiles100% (1)

- Problem Solving and Reasoning - Polya's Problem Solving StrategyDocument22 pagesProblem Solving and Reasoning - Polya's Problem Solving Strategymisssunshine112No ratings yet

- Business Plan-CafeteriaDocument17 pagesBusiness Plan-CafeteriawondwosenNo ratings yet

- Lesson 1 - NSTPDocument16 pagesLesson 1 - NSTPIan Conan Juanico100% (1)

- ColgateDocument9 pagesColgatepuneet71988No ratings yet

- Service Rate 3 Minutes/call or 10 Calls/30 minutes/CSR Utilization (U) Demand Rate/ ( (Service Rate) (Number of Servers) )Document8 pagesService Rate 3 Minutes/call or 10 Calls/30 minutes/CSR Utilization (U) Demand Rate/ ( (Service Rate) (Number of Servers) )Nilisha DeshbhratarNo ratings yet

- Language and SymbolsDocument3 pagesLanguage and SymbolsJunior RalfNo ratings yet

- Prelim Exam Answer KeyDocument2 pagesPrelim Exam Answer KeyFrancis EstebanNo ratings yet

- Assignment On Simplex Linear ProgrammingDocument1 pageAssignment On Simplex Linear ProgrammingJames De Torres Carillo100% (1)

- Lesson 2: Linear Programming: ObjectivesDocument11 pagesLesson 2: Linear Programming: ObjectivesHarvey Aguilar100% (1)

- Ge108 EthicsDocument1 pageGe108 EthicsVincent Delos Santos100% (1)

- Managerial Accounting and Cost ConceptDocument20 pagesManagerial Accounting and Cost ConceptNavidEhsanNo ratings yet

- Economic Dev. Chapter 4Document66 pagesEconomic Dev. Chapter 4oliiiiiveeeNo ratings yet

- Historical Museums in PHDocument32 pagesHistorical Museums in PHKristine Lhea Delos TrinoNo ratings yet

- ACTIVITy No 3 Applying UnderstandingDocument2 pagesACTIVITy No 3 Applying UnderstandingArthur Brian PanitNo ratings yet

- Japanese Quality InnovatorsDocument3 pagesJapanese Quality InnovatorsJennifer SamaniegoNo ratings yet

- StatDocument8 pagesStatAbegail TorremochaNo ratings yet

- Chapter 3: The Use of Design Thinking Design ThinkingDocument9 pagesChapter 3: The Use of Design Thinking Design Thinkingmae KuanNo ratings yet

- Polya S SolvingDocument10 pagesPolya S SolvingWendel RoiNo ratings yet

- Given The Learning Materials and Activities of This Chapter, They Will Be Able ToDocument14 pagesGiven The Learning Materials and Activities of This Chapter, They Will Be Able Toedniel maratasNo ratings yet

- Man Made PollutionDocument4 pagesMan Made PollutionHdNo ratings yet

- Problem Solving Using Linear ProgrammingDocument1 pageProblem Solving Using Linear ProgrammingTan Teck LeeNo ratings yet

- Chapter 6 - A Glimpse of Graph TheoryDocument15 pagesChapter 6 - A Glimpse of Graph TheoryAlquien Engaling Capuyan100% (1)

- Handout 2Document5 pagesHandout 2Lian MagatNo ratings yet

- Chapter IDocument1 pageChapter IVincent louise G. AgustinNo ratings yet

- CBME1 Module 1Document3 pagesCBME1 Module 1Joash Lee AcebronNo ratings yet

- Probability: 由 Nordridesign 提供Document40 pagesProbability: 由 Nordridesign 提供SahilNo ratings yet

- Semi FinalDocument2 pagesSemi FinalCarlo Jay BasulNo ratings yet

- Calculate Compound InterestDocument5 pagesCalculate Compound InterestKyler GreenwayNo ratings yet

- MidtermDocument9 pagesMidtermbimmer311No ratings yet

- Content in Art (Levels of Meaning)Document14 pagesContent in Art (Levels of Meaning)pb PhoebeNo ratings yet

- International Trade and Business ExamDocument2 pagesInternational Trade and Business ExamKristina Jane De CastroNo ratings yet

- Practice Set 3 D e GDocument9 pagesPractice Set 3 D e GDaphnie NeiblaNo ratings yet

- Rizal S Second Sojourn in Paris and The U Ni V e R Sal ExpositionDocument32 pagesRizal S Second Sojourn in Paris and The U Ni V e R Sal ExpositionEileen LagrisolaNo ratings yet

- GARCIA Module 4 Final PE 3Document4 pagesGARCIA Module 4 Final PE 3pat patNo ratings yet

- Name: Class Schedule: General Direction: Write Your Answer On The Answer SheetDocument3 pagesName: Class Schedule: General Direction: Write Your Answer On The Answer SheetEvia AbegaleNo ratings yet

- Group - 2 Correlation and Regression - Assgn1Document16 pagesGroup - 2 Correlation and Regression - Assgn1Ketan PoddarNo ratings yet

- Lesson: 7 Cost of CapitalDocument22 pagesLesson: 7 Cost of CapitalEshaan ChadhaNo ratings yet

- Nstp. Cyra A. Consigo BEED - 1ST YEARDocument1 pageNstp. Cyra A. Consigo BEED - 1ST YEARCyra ArquezNo ratings yet

- Central TendencyDocument2 pagesCentral Tendencyirene apilada50% (4)

- Behavioral Portfolio TheoryDocument31 pagesBehavioral Portfolio TheoryOla AtefNo ratings yet

- Finite Element Analysis: Axially Loaded Steel Fibre Reinforced Concrete Ribbed WallDocument11 pagesFinite Element Analysis: Axially Loaded Steel Fibre Reinforced Concrete Ribbed WallsweetqistNo ratings yet

- Appendix C: C1 Modified Prototype Bridge Model Loading CalculationDocument6 pagesAppendix C: C1 Modified Prototype Bridge Model Loading CalculationsweetqistNo ratings yet

- Appendix A: Figure A1: Hazard Map For Thailand and Malaysia Peninsula Showing The PeakDocument8 pagesAppendix A: Figure A1: Hazard Map For Thailand and Malaysia Peninsula Showing The PeaksweetqistNo ratings yet

- Mai Technical ReportDocument14 pagesMai Technical ReportsweetqistNo ratings yet

- Analysis of Multi-Column of Unskewed Bridge Using STAAD Pro Under Static and Dynamic LoadDocument8 pagesAnalysis of Multi-Column of Unskewed Bridge Using STAAD Pro Under Static and Dynamic LoadsweetqistNo ratings yet

- Summary Chapter 5Document1 pageSummary Chapter 5sweetqistNo ratings yet

- Header For Transportation Prob3-Dah SiapDocument4 pagesHeader For Transportation Prob3-Dah SiapsweetqistNo ratings yet

- Derivational and Inflectional Morpheme in English LanguageDocument11 pagesDerivational and Inflectional Morpheme in English LanguageEdificator BroNo ratings yet

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomNo ratings yet

- Crypto Wall Crypto Snipershot OB Strategy - Day Trade SwingDocument29 pagesCrypto Wall Crypto Snipershot OB Strategy - Day Trade SwingArete JinseiNo ratings yet

- Niveshdaily: From Research DeskDocument53 pagesNiveshdaily: From Research DeskADNo ratings yet

- IT Level 4 COCDocument2 pagesIT Level 4 COCfikru tesefaye0% (1)

- Create A Visual DopplerDocument1 pageCreate A Visual DopplerRahul GandhiNo ratings yet

- Fuzzy Gain Scheduled Pi Controller For ADocument5 pagesFuzzy Gain Scheduled Pi Controller For AOumayNo ratings yet

- Angle Modulation: Hệ thống viễn thông (Communication Systems)Document41 pagesAngle Modulation: Hệ thống viễn thông (Communication Systems)Thành VỹNo ratings yet

- Tutorial Chapter 5 - Power System ControlDocument2 pagesTutorial Chapter 5 - Power System ControlsahibNo ratings yet

- Genil v. Rivera DigestDocument3 pagesGenil v. Rivera DigestCharmila SiplonNo ratings yet

- Python in Hidrology BookDocument153 pagesPython in Hidrology BookJuan david Gonzalez vasquez100% (1)

- Been There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerDocument8 pagesBeen There, Done That, Wrote The Blog: The Choices and Challenges of Supporting Adolescents and Young Adults With CancerNanis DimmitrisNo ratings yet

- COK - Training PlanDocument22 pagesCOK - Training PlanralphNo ratings yet

- Praise and Worship Songs Volume 2 PDFDocument92 pagesPraise and Worship Songs Volume 2 PDFDaniel AnayaNo ratings yet

- European Asphalt Standards DatasheetDocument1 pageEuropean Asphalt Standards DatasheetmandraktreceNo ratings yet

- The Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityDocument7 pagesThe Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityIJAR JOURNALNo ratings yet

- 0012 Mergers and Acquisitions Current Scenario andDocument20 pages0012 Mergers and Acquisitions Current Scenario andJuke LastNo ratings yet

- Lesson 1 3 Transes in Reading in Philippine HistoryDocument17 pagesLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GONo ratings yet

- Common Core Content and Training Objectives For Basic AIS Training - Phase 2 - SpecialistDocument82 pagesCommon Core Content and Training Objectives For Basic AIS Training - Phase 2 - SpecialistjlferreiraNo ratings yet

- J.K. Brimacombe - Design of Continuous Casting MachinesDocument13 pagesJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezNo ratings yet

- PlateNo 1Document7 pagesPlateNo 1Franz Anfernee Felipe GenerosoNo ratings yet

- PostScript Quick ReferenceDocument2 pagesPostScript Quick ReferenceSneetsher CrispyNo ratings yet

- DirectionDocument1 pageDirectionJessica BacaniNo ratings yet

- John DrydenDocument3 pagesJohn DrydenDunas SvetlanaNo ratings yet

- A P P E N D I X Powers of Ten and Scientific NotationDocument5 pagesA P P E N D I X Powers of Ten and Scientific NotationAnthony BensonNo ratings yet

- 40 Sink and FloatDocument38 pages40 Sink and Floatleandro hualverdeNo ratings yet

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocument6 pagesThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Sap Consultant Cover LetterDocument3 pagesSap Consultant Cover LetterrasgeetsinghNo ratings yet