Professional Documents

Culture Documents

Devi Ahilya Vishwavidyalaya, Indore: Scheme For B.E. All Semester Examination Effective From July 2006

Uploaded by

Rahul SakareyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Devi Ahilya Vishwavidyalaya, Indore: Scheme For B.E. All Semester Examination Effective From July 2006

Uploaded by

Rahul SakareyCopyright:

Available Formats

DEVI AHILYA VISHWAVIDYALAYA, INDORE

FACULTY OF ENGINEERING

SCHEME OF EXAMINATION & COURSE OF CONTENTS

BE I Year Programme (Common to All Branches)

INSTITUTE OF ENGINEERING & TECHNOLOGY (www.iet.dauniv.ac.in)

Scheme for B.E. All Semester Examination effective from July 2006

DEVI AHILYA VISHWAVIDYALAYA, INDORE INSTITUTE OF ENGINEERING & TECHNOLOGY

SCHEMES OF EXAMINATION FOR BE I PROGRAMME (Subject to Revision)

B. E. I YEAR (Common to all branches)

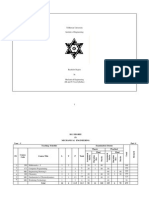

SCHEMES OF EXAMINATION FOR BE I YEAR SEMESTER A/B1 Sr No Sub-Code 1 2 3 4 5 6 1AM001 1AC052 1ME053 1ET054 1SS055 1ME056 Subject Applied Mathematics-I 2 Chemistry & Environment Science Elements of Mechanical Engg Basic Electronics Technical English Workshop Practice Total L 4 4 4 4 4 T P 2 2 2 4 Th CW Pr SW

Total

Max Min Max Min Max Min Max Min 100 100 100 100 100 --500 35 35 35 35 35 --50 50 50 50 50 --250 25 25 25 25 25 ----50 50 50 --75 225 --25 25 25 --38 --50 50 50 --75 225 --25 25 25 --38 150 250 250 250 150 150 1200

Semester B/A1

Sr No Sub-Code 1 2 3 4 5 6 1AM051 1AP002 1ME003 1EI004 1CO005 1SS006 Subject Applied Mathematics-II 3 Applied Physics Engineering Drawing Electrical Engineering Computer Programming Humanities Total L 4 4 2 4 4 2 T P 2 4 2 2 Th CW Pr SW

Total

Max Min Max Min Max Min Max Min 100 100 100 100 100 --500 35 35 35 35 35 --50 50 50 50 50 50 300 25 25 25 25 25 25 --50 50 50 50 --200 --25 25 25 25 ----50 50 50 50 --200 --25 25 25 25 ---

150 250 250 250 250 50 1200

(Semester A + Semester B)

1 2

Grand Total:

2400

Semester A for three sections and Semester B for other three sections for the teaching load balancing. Applied Mathematics-I shall be taught in Semester A to all six sections. 3 Applied Mathematics-II shall be taught in Semester B to all six sections.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1AM001 Applied Mathematics-I 4 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW PR Total 150 60

Course Objectives: To introduce the mathematical concepts of calculus for solving engineering problems that shall be used in various branches of engineering. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Differential Calculus: Expansion of functions by Taylors and Maclaurins Theorem; Indeterminate forms; Tangents and Normals. Application: Curvature in Cartesian and Polar Coordinates; Asymptotes; Envelopes; Evolutes and Involutes. Unit-II Integral Calculus: Integration of Irrational and Transcendental Functions; Reduction Formulae; Integral as the limit of a Sum; Definite Integral and Properties. Application: Area; Length of Curve; Volume; Surface of Revolution; Theorem of Pappus and Guldin. Unit-III Advanced Differential Calculus: Function of Several Variables; Partial Differentiation; Jacobians; Taylors Series of Two Variables. Application: Maxima and Minima of Function of Two and More Variables; Lagranges Method of Undetermined Multipliers. Unit-IV Advanced Integral Calculus: Multiple integrals: Double and Triple Integration; Change of Order of Integration. Application: Area; Volume; Centre of Gravity; Moment of Inertia. Unit-V Vector Calculus-I: Differentiation of a Vector; Gradient; Divergence and Curl. Vector Calculus-II: Integration of a Vector Function; Gausss, Greens and Stokes Theorems. BOOKS RECOMMENDED [1] E Mendelson, G J Hademenos, F Ayres, Schaum's Easy Outline: Calculus, McGraw-Hill, 2000. [2] R C Wrede, M Spiegel, Schaum's Outline of Advanced Calculus, 2/e, McGraw-Hill, 2002. [3] B.S.Grewal, Engineering Mathematics, 39/e, Khanna Publishers, 2006. [4] S S Sastry, Engineering Mathematics, Vol I & II, 3/e, Prentice Hall, 2004.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1AP002 Applied Physics 4 2 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To introduce the fundamental concepts of physics that are useful in solving problems of engineering especially for semiconductors, optics, electromagnetism and quantum mechanics. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Optics-I: Interference of Light Waves: Methods-Division of Wave front and Division of Amplitude, Youngs double slit experiment, Thin film, Newtons Ring experiment; Diffraction of Light Waves: Fresnels & Fraunhoffer diffraction, Zone plate, Single slit experiment, Diffraction at Circular aperture, Plane transmission Grating. Unit-II Optics-II: Polarization of Light Waves, Double refraction, Nicol Prism, Half Wave & Quarter Wave plates, Circularly & elliptically polarized light, Polarimeter; LASER: Stimulated & spontaneous emission, Population Inversion, Optical Resonator, Einsteins coefficients, He-Ne Laser, Ruby Laser, Semiconductor Laser; Optical Fiber: types of Fibers, Acceptance angle, Numerical aperture, V-Number, Propagation of Light through Fibers, Applications. Unit-III Crystal Structure and Semiconductors: Seven crystal systems, Bravais Lattice, Symmetry & properties of Simple crystal structure, Millers Indices; Semiconductors: Band theory of Semiconductors, Intrinsic & extrinsic semiconductors, Fermi level , pn junction diode, LED, Zener diode, npn & pnp Transistors . Unit-IV Electromagnetism: Continuity equation for Charge & Current, Inconsistency of Amperes law for time varying field, Concept of Displacement current, Maxwells equations; Wave equations for E & H, Propagation of one dimensional electromagnetic waves in dielectric medium, Energy density in electromagnetic field, Poynting Vector. Unit-V Quantum Physics: Planks law, Comptons effect, Concept of Matter Waves, Devison & Germers experiment, Phase velocity & Group velocity, Heisenbergs Uncertainty Principle; Schrodingers Wave Equation, Interpretation of Wave function , Time dependent & Time Independent equations, Schrodingers Wave equation for a free particle in a box. BOOKS RECOMMENDED: [1] R Feyaman, Feyaman Lectures on Physics, 2/e, Narosa Publication, 1998 [2] D Halliday and R Resnick, Physics Vol-II, Wiley Eastern, 1993 [3] H White, Modern Physics: Van Nostrand; 15/ e [4] D P Khandelwal, Optics and Atomic Physics. [5] R K Gaur & S L Gupta, Engineering Physics, Dhanpat Rai & Sons, 2006 [6] A S Vasudev, Modern Engineering Physics, 4/e, S.Chand & Co, 2007

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1ME003 Engineering Drawing 2 4 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To understand the concepts of imagining, envisioning and visualizing the objects & machine parts and drawing them with the instruments & tools. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Basics: Introduction; Need of Engineering Drawing for Engineers, Introduction & Classification of Engineering Drawings, Drawing Instruments and their uses, Indian Standards for Drawing; Geometrical Construction: Basic Geometrical Constructions, Terms used in Geometrical Constructions; Conventions: Lines, Materials, Common Features, Various Machine Parts; Technical Lettering: Drawing Sheet Layout, Dimensioning. Engineering Scales: Introduction Engineering Scales, Graphical scale, Representative Fraction, Types of scales Plain, Diagonal, Comparative, Vernier and Scale of Chords. Engineering Curves: Loci of Points Locus as circle, Straight lines, and Perpendicular bisector; Conic Section: Ellipse, Parabola, Hyperbola; Cycloid Curves: Cycloid, Epi-cycloids, Hypo-cycloid; Involutes Curves: Involutes of Circle and Polygons; Spirals Curves Archimedeans, Logarithmic or Equiangular: Normal and Tangent to above curves. Unit -II Planes: Projection of Points & Straight Lines. Projection of Planes. Unit-III Projections: Orthographic Projections: First & Third Angle Projections, Conventions used Orthographic Projection of Simple Solids, Conversion of 3-D View to Orthographic Views; Isometric Projection Simple Solids, Isometric view, Conversion of Orthographic to Isometric View; Introduction to Oblique Projection and Perspective Projections. Practice of Computer Aided Drawings using AutoCAD. Unit-IV Solids: Projection of Solids. Section of Solids & Development of Surfaces. Unit-V Machine parts: Interpenetration of Solids. Cone, Cylinder, Prism & Pyramids; Freehand Sketching of Machine Parts Simple Nuts and Bolts, Keys, Cotters, Pins, Screw Threads, Riveted joints, Welded joints, Assembly of Simple Machine Parts. NOTE: Drawing Sheets (10 Approximately) as above, Sketch Book & AutoCAD Drawings containing problems based on above shall be maintained and submitted at the time of practical examination. BOOKS RECOMMENDED: [1] P S Gill, Engineering Drawing, 12/e, S. K. Kataria & Sons, Reprint-2007. [2] N D Bhatt, Engineering Drawing, 47/e, Charoter Publishing House, Reprint-2007. [3] P S Gill, Machine Drawing, 17/e, S. K. Kataria & Sons, Reprint-2007. [4] N D Bhatt, Machine Drawing, 24/e, Charoter Publishing House, Reprint-2007.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1EI004 Electrical Engineering 4 2 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To understand the concepts and practical ideas of AC/DC circuits, Electromagnetic Circuits, Transformers and Electric Machines those are basic to all the engineering streams. Prerequisite(s): nil COURSE OF CONTENTS Unit-I AC circuits: Generation of EMF, Phasor Quantities, RMS, Average, Form Factor, Peak Factor Etc, Phasor Diagrams; Single Phase AC Circuits: R, L, C And Combinations, Resonance, Q-Factor, Bandwidth; Three Phase AC Circuits: Generation, EMF, Phase Sequence, Analysis of Star and Delta Connections, and Power Measurement In Single Phase& Three Phase Circuit. Unit-II Circuit analysis tools: Kirchoffs laws, Analysis of DC and AC circuits, Thevenins theorem, Nortons theorem, Max power transfer theorem, Superposition theorem, and Source transformation . Unit-III Magnetic Circuits: Electromagnetism, Magnetic flux, Magnetic flux density, Intensity of magnetization, B-H curves, hysteresis and eddy current losses, Magnetic circuit calculations, laws of Electro-magnetic induction, Magnetic induction, Lifting power of an electromagnet. Unit-IV Transformer: Construction, principle, ideal transformer, EMF equations, Analysis of transformer on no load and load conditions, Equivalent resistance and reactance, voltage regulations, transformer losses Transformer testing, transformer efficiency, Types of transformer, Cooling methods, Auto transformer. Unit-V Rotating electric Machines: Construction, working principles, EMF equations, Characteristics, Torque equations of DC machines (generators & motors), 3-phase synchronous and induction motor, single phase induction motor. BOOKS RECOMMENDED: [1] V Del Toro, Electrical Engineering Fundamentals, 2/e, PHI, 2000. [2] D P Kothari, I J Nagrath, Basic Electrical Engineering, 2/e, Tata McGraw Hill, 2002 (Fifth Reprint 2003). [3] A Sudhakar, Network Theory, 2/e, Tata McGraw Hill, 2004 [4] P S Bimbhara, Electrical Machinery, 7/e, Khanna Publishers, New Delhi, 2006.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1CO005 Computer Programming 4 2 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To understand the concepts of problem solving on computers and to learn the programming concepts & practices that are useful in engineering domain. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Introduction: Block Diagram of Computer; Problem-Solving Basics; Algorithms; Flowcharts; Classification of Programming Languages. Unit-II C++ Programming: Data Representation- Fundamental Types, Variables & Constants; Expressions- Numeric, Assignments; Input/Output; Control Structures- Repetition Statements, Selective Statements; Programming with Libraries. Unit-III Arrays Functions And Pointers: Single and Multidimensional Array- Declaration and Usage, FunctionDeclaration & Usage; Parameter Passing and Scope Rules; Pointer Declaration and Usage; File Handling in C++. Unit-IV Classes And Objects: Declaration, Constructor and Destructor; Access Functions; Structures,; Pointers to Objects; String Handling using Classes. Unit-V Advance C++ Features: Operator Overloading; Inheritance; Polymorphism. BOOKS RECOMMENDED: [1] H Schildt, The Complete Reference, 4/e, Tata McGraw Hill, 2006. [2] BJarne Stroustrup, The C++ Programming Language, 3/e Addision Wesely, 2000. [3] Ravichandran, Programming with C++, 2/e, Tata McGraw Hill, 2007 [4] G Droomey G, How to Solve it by Computer, 1/e, Prentice Halll, 2001. [5] D Gries, Programming Methodology, Springer Verlog, 1978.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1SS006 Humanities 2 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min CW 50 25 SW PR Total 50 25

Course Objectives: To learn the human values and ethical values that are essential for an engineer to practise in the day to day life during the field work while working with the society. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Role of Humanities in Engineering: Engineering Ethics: Basics of Ethics; Professional Engineer; Professional Engineering Bodies; Code of Ethics. Unit-II Engineers and Society: Society and Its Features; Social Institutions; Social Stratification and Change; Crosscultural Issues; Unit-III Engineering & Environment: Environment Basics; Natural Resources; Ecology and Horticulture. Unit-IV Government & Engineers: Political parties; Types & Forms of Government; Government Artifacts; NGOs. Unit-V e-Society & Knowledge Society; Digital Government (e-Governance); Digital Divide. BOOKS RECOMMENDED: [1] D J Kemper, Introduction to Engineering Profession, 2/e, Suanders Publication, 1998. [2] A S Chauhan , A Text Book of Social Science Jain Brothers 9/e,2008 [3] R C Agrawal, Principle of Political Science,

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1AM051 Applied Mathematics-II 4 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW PR Total 150 60

Course Objectives: To introduce the mathematical concepts of Matrix Algebra, Probability, and Differential Equation for solving engineering problems that shall be used in various branches of engineering. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Matrix Algebra: Review of Matrices; Elementary Operations on Rows and Columns; Matrix Inversion by Partitioning and Crouts Method; Normal Form; Linear Dependence. Applications: Rank; Application of Rank Theory in Solving System of Linear Equations; Linear Transformation; Orthogonal, Unitary and Hermitian Matrices; Characteristic Equation; Eigen- Values and Eigen-Vectors; Caley-Hamilton Theorem; Quadratic and Linear forms. Unit-II Probability: Review of Probability; Additive and Multiplicative Laws; Conditional Probability, Bayes Theorem. Statistics: Binomial, Poisson and Normal Probability Distributions, Method of Least Squares and Curve Fitting. Unit-III First Order Ordinary Differential Equation: Differential Equations of First Order and First Degree; Exact Differential Equation; Equations Solvable for X and Y; Clairauts Form. Higher Order Ordinary Differential Equation: Linear Differential Equations with Constant & Variable Coefficients; Simultaneous Differential Equations; Application to Simple Problems. Unit-IV First Order Partial Differential Equations: Formation of Partial Differential Equations; Partial Differential Equations of First Order and First Degree i.e. Pp +Qq=R. Higher Order Partial Differential Equations: Linear Homogenous Partial Differential Equations of nth Order with Constant Coefficients; Method of Separation of Variables & Their Simple Applications. Unit-V Fourier series: Periodic functions, Dirichlet conditions, Expansion of function in Fourier series. Half Range Fourier series: Half range sine and cosine series, Change of interval. BOOKS RECOMMENDED: [1] G Paria, Matrix and Tensors, 2/e, Scholar Publication, 2004. [2] Matrix Operations, Schaums Outlines [3] Probability & Statistics, 2/e, Schaums Outlines, 2004 [4] Differential Equations, Schaums Outlines, 2/e, TMH, 2005. [5] Partial Differential Equations, Schaums Outlines [6] Fourier Analyssi, Schaums outlines, 1/e, TMH, 2005 [7] G Paria, Ordinary Differential Equations with Laplace Transform, 3/e, Scholar Publications, 1998 [8] G Paria, Partial Differential Equations and Complex Variable, 2/e, Scholar Publications, 1998

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1AC052 Chemistry & Environmental Science Duration of Theory Paper: 3 Hours 4 2

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To understand and learn the concepts of engineering chemistry along with the need and requirements of environment and to become aware of the changing environment. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Water: Sources; Impurities; Hardness- Its Expression & Determination; Boiler Troubles & Their Causes; Industrial Water Requirement; Treatment of Water for Industrial Purpose; De-Ionization of Water; Alkalinity in Water; Numerical Problems on Water Analysis & Water Softening Processes. Unit-II Engineering Materials: Introduction, Classification & Requirement of Engineering Materials. Polymers: Chemistry of Polymer Materials & Their Diversification; Types of Polymerization & their Brief Account; Examples of Polymers; Cement, Glass And Refractory: Different Types; Composition; Properties & Uses. Unit-III Lubricants: Introduction; Types of Lubricants & Principle of Lubrication, Properties & Tests of Lubricants; Greases; Graphite; Cooling Liquids & Cutting Fluid. Unit-IV Instrumental Techniques In Chemical Analysis: Introduction; Infrared; Ultraviolet; Nuclear Magnetic Resonance Spectro-photometry; Calorimetry; Lamberts & Beers Law, Chromatography. Unit-V Environmental Science: Components of Environment & Their Interactions; Natural Resources; Ecosystem; Impacts of Development of Environment; Environment Protection Act; Concept of ISO 14000; Pollution & Its Types; Description of Air, Water; Land & Noise Pollution; Chemical Toxicology & Its Effects; Control Measures; Global Warming; Depletion of Ozone Layer; Acid Rains, Eutrophication; Pollution Case Studies. BOOKS RECOMMENDED: [1] P C Jain & Monica Jain, Engineering Chemistry, 16/e, Dhanpat Rai Publications, 2007. [2] J C Kuriacose & J Rajaram, Engineering Chemistry, Tata McGraw-HillCo, New Delhi, 2004. [3] B Joseph, Environmental Studies: Core Engineering Series, Tata McGraw Hill, [4] A K De, Environmental Chemistry, 2/e, New Age International, 2005.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name 1ME053 Elements of Mechanical Engineering Duration of Theory Paper: 3 Hours

Instructions Hours per Week L T P 4 2

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To understand and learn the basic aspects of mechanical engineering in terms of thermal engineering (steam and hot air) and production engineering (metal casting, welding and machine elements) that are essentials in all engineering streams. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Fundamentals of Thermodynamics: Properties and processes, Heat and work, Zeroth law of thermodynamics; Enthalpy and internal energy of gases, First law applied to flow processes, Simple analysis of first law applied to a closed and open systems. Unit-II Properties of Steam: Properties, Wet, Dry and Super heated steam; Enthalpy and Internal energy of steam, Critical point and Triple point, Property table, Measurement of Dryness fraction of steam. Unit-III Gas Power Cycle: Air standard cycles: Otto cycle, Diesel cycle and Dual cycle; Calculation of efficiency and state points for the cycles; Deviation from theoretical cycles; Effects of variable specific heat and dissociation. Unit-IV Metal Casting: Introduction, Advantages, Limitation and applications of metal casting, Pattern making, moulding materials and moulding processes, Cores, Elements of gating, Systems, Melting and pouring of metals, Solidification and cooling of castings; casting processes-: Sand casting, Expandable mould casting and Permanent mould casting, Casting cleaning and finishing, Casting defects. Unit-V Welding and Machining: Fundamentals of welding weld ability, Types of welded joints, Classification and overview of welding process, Arc welding processes, Oxy Acetylene gas welding processes, Resistance and solid state welding processes, Weld quality and safety, Barging & soldering; Fundamental of metal machining, introduction of turning and related operations, Drilling and hole machining, Milling and shaping, Construction features of lathe, Radial drilling machine & shaper , Cutting tools type and materials. BOOKS REOMMENDED: [1] P K Nag, Engineering Thermodynamics, 3/e, Tata McGraw-Hill, 2005. [2] R K Rajput, Thermal Engineering,, 2/e, S.K.Kataria & Sons, 2006. [3] Hajra & Chaudhary, Work Shop Technology, Vol. 1 & 2, 13/e, Media Promoters & Pub, 2004. [4] P N Rao, Manufacturing Technology, Tata McGraw Hill, 2006.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1ET054 Basic Electronics 4 2 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW 50 25 PR 50 25 Total 250 110

Course Objectives: To introduce the basic concepts of electronics along with the understanding of working fundamental circuit devises such as diode, transistors and logic gates. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Structure & properties of conductors, semiconductors & insulators. Transport phenomenon in semiconductors, Mechanism of current flow in semiconductors, Hall Effect, Mobility, Conductivity equation, Junction- Diode Characteristics, Current Components V-I Characteristics, load line Concept, piecewise linear diode model Unit-II Characteristics, applications like Clippers, Clampers, Comparators, Voltage Doublers, Samplers, Rectifiers, Peak Detectors, Various types of diodes, their application & V-I Characteristics:- Zener, Avalanche, Photodiode, Tunnel, LED, PIN, Schottky, Seven Segment display, Varacter diode. Unit-III The Junction transistors, BJT current Components, Transistor as an amplifier Transistor Construction, Potential Profile in NPN & PNP Structures, Ebers Moll Model, CB,CE & CC Configuration, Static & Dynamic Characteristics, Transistor ratings, Photo transistor, Transistor Biasing & thermal Stabilization, Transistor as a Switch. Unit-IV Introduction to JFET, JFET operation and volt-ampere characteristics, transfer characteristics, introduction to MOSFET (depletion type and enhancement type), operation and characteristics of MOSFETS, FET biasing, FET small signal model, JFET CD and CG configuration Unit-V Binary number, Digital systems, Boolean algebra, logic gates, logic functions, realization of logic gates by electronic devices, Positive and negative logic, representation of binary numbers, half adder, full adder, flipflop synchronous and asynchronous circuit, counters registers, memories. BOOKS RECOMMENDED: [1] Milliman & Halkies,, Integrated Electronics, TMH, 2007. [2] R Boylested, Electronics Devices & Circuits, 9/e, Prentice Hall, 2006. [3] A Motorshed, Electronics Devices & Circuit, Prentice Hall, 2006 [4] Malvino, Electronics Principles, , 7/e, TMH, 2007. [5] P Malvino, Digital Electronics, TMH pub.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1SS055 Technical English 4 Duration of Theory Paper: 3 Hours

BE I Year (Common to all branches) Semester Marks TH Max Min 100 35 CW 50 25 SW PR Total 150 60

Course Objectives: To develop the English communication skills in terms of reading, writing and understanding of engineering terms with the improved technical English and to be able to express the technical ideas. Prerequisite(s): nil COURSE OF CONTENTS Unit-I Basic of Technical Communication: Concept and Process of Communication; Forms of Communication: Verbal and Non-Verbal; Technology-Enabled Communication; Barriers to Communication; Essentials of Effective Communication; Nature and Dimensions of Technical Communication; Identifying & Defining Audiences for Technical Communication; Types of Communication ranked by importance to Engineering Practice; Language tasks performed by Technical Professionals. Unit-II Professional Correspondence: Qualities of Professionals Correspondence: Goodwill Techniques; Types of Correspondence: Letters, Memos, Transmittal Correspondence, E-Mail. Letters: Elements of a Letter: Essential and Optional; Basic Letter Formats; Planning, Organizing, and Writing Business Letters; Types of Business Letters: Positive Letters/Good-News and Goodwill Messages, Negative Letters/Bad-News Messages, Direct Requests, Letters of Inquiry, Sales Letters, Complaint Letters, Letters of Transmittal. Memos: Components of a Memo; Organization, Development, Language and Tone of a Memo; Memo Formats; Types of Memos: Status Memos, Negative Memos, Personal Memos, Memos of Transmittal. Employment Communication: Writing Job Application Letters; Designing Resumes; Organization Approaches to Letters of Application and Resumes; Follow-Up Correspondence. Unit-III Technical Writing: Purpose and Characteristics of Technical Writing; Technical Writing Process; Technical Writing Style; Formatting Technical Documents for Function and Effectiveness; Some Forms of Technical Writing: Technical Descriptions, Summaries, Instructions, Technical Proposals, User Manuals. Communicating Through Reports: Essentials of Good Report Writing; Classification of Reports; Planning, Organizing, and Writing the Report: Report Formats: Formal and Informal (Short and Long); Structure and Formatting of Short Informal Reports and Memo Reports. Technical Reports: Structures of a Technical Report; Techniques that help the Process of Writing Technical Reports; Editing and Revising Technical Reports for Style and Usage, for Grammar and Punctuation; Some Common Informal Technical Reports: Progress Reports, Lab Reports, Feasibility Reports, Incident Reports, Problem-Solving Reports, Reports Identifying Cause-and-Effect Relationship. Unit-IV Reading Comprehension: Reading Styles for Technical Professionals; Skimming a Passage to abstract relevant ideas and information; Skimming Memos. Letters and Reports, Rewriting a Receptive Passage as a Skim Passage; Scanning a Passage for specific information; INFERENTIAL COMPREHENSION: Understanding Logical Relationships (Cause-Effect, Rule-Illustration, Data-Conclusion.); Inferring meanings of words, Phrases; and sentences in context; Judging the Tone of the Passage and Identifying the Attitude of the Writer; Prcis Writing/Reformulating/Summarizing: Restating in a shortened form the main ideas of a given Passage; Summarizing a Passage for various purposes and for particulars audiences; Reducing or Selectively Rewriting a Passage for a specific purpose.

Scheme for B.E. All Semester Examination effective from July 2006

Unit-V English for Technical Communication: Vocabulary Extension: Word Usage; Related Forms; Foreign Roots, Prefixes and Suffixes that form Technical Words; Conversational Expressions, Formal And Informal Expressions for Scientific and Technical Communication; Antonyms and Synonyms; Frequently Confused, Misused and Misspelled Words; Transitional Words and Phrases; Choosing Appropriate Words that Communicate. The Most Commonly Used Grammatical Items in Technical: Major Tense Distinctions; Articles; Modal Verbs: Connectives; Relative Clauses; Noun/Nominal Compounds. Mechanics and Punctuation: Abbreviations; Capitalisation; Number Usage; Sentence Punctuation; Word and Phrase Punctuation. Common Grammatical and Stylistic Errors In Professional Communication: Structural Ambiguity: Agreement between Subject and Verb: Agreement between Pronoun and Antecedent; Faulty or Vague Pronoun Reference: Sentence Fragments; Fused Sentences and Comma Splices; Misplaced/Dangling Modifiers; Parallelism; Embedding sentences within sentences; Wordiness; Inappropriate Jargon. BOOKS RECOMMENDED: [1] T N Huckin & L A Olsen, Technical Writing and Professional Communication, McGraw-Hill, Inc. [2] S J Gerson & S M Gerson, Technical Writing, 3/e, Pearson Education Asia, 2002. [3] A Esenberg, A Begineers Guide to Technical Communication, McGraw-Hill, [4] S E Pauley and D G Riordan, Technical Report Writing Today, Houghton Miffin Company [5] A J Rutherford, Basic Communication Skills for Technology, Pearson Education Asia [6] R V Lesikar, J D Perrit, Jr., & ME Flately, Lesikars Basic Business Communication [7] C L Bovee, J V Thill & B Schatzman, Business Communication Today, 7/e, Pearson Education, 2002 [8] S Ober, Contemporary Business Communication, Houghton Mifflin Company, 5/e, Wiley-Dreamtech, 2005. [9] R C Sharma and K Mohan, Business Correspondence and Report Writing, Tata McGraw-Hill, 2002 [10] G Leech & J Svartvik, A Communicative Grammar of English, Longman Group UK Ltd, Pearson Education 2002

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 1ME056 Workshop Practice 4 Duration of Theory Paper: Only practical examination.

BE I Year (Common to all branches) Semester Marks TH Max Min CW SW 75 38 PR 75 38 Total 150 76

Course Objectives: To develop the basic working skills with engineering tools & machines along with the practical understanding of engineering materials, processes and manufacturing. Prerequisite(s): nil COURSE OF CONTENTS Introduction of and practice work on the following trade shops, processes, tools, material and their application in manufacturing: 1. Smithy 2. Fitting 3. Carpentry 4. Welding 5. Foundry 6. Machine shop 7. Plumbing Shop BOOKS RECOMMENDED: [1] W A J Chapman, Workshop Technology, Vol-I/II, Elsevier Butterworth Heinenman, 5/e, [2] S.K.Hajra Choudhury, Elements of Workshop Technology, Media Promoters of Publishers

Scheme for B.E. All Semester Examination effective from July 2006

DEVI AHILYA VISHWAVIDYALAYA, INDORE

FACULTY OF ENGINEERING

SCHEME OF EXAMINATION & COURSE OF CONTENTS

BE II Year Programme (Mechanical Engineering)

INSTITUTE OF ENGINEERING & TECHNOLOGY (www.iet.dauniv.ac.in)

Scheme for B.E. All Semester Examination effective from July 2006

DEVI AHILYA VISHWAVIDYALAYA, INDORE INSTITUTE OF ENGINEERING & TECHNOLOGY

SCHEMES OF EXAMINATION FOR BE II PROGRAMME (Subject to Revision)

B. E. II YEAR MECHANICAL ENGINEERING

Th- Theory, CW Class Work, SW Sessional Work, Pr Practical

Semester III S. No 1. 2. 3. 4. 5. 6. Sub Code 2AM101 2ME102 2ME103 2ME104 2ME105 2SS106 TOTAL Subject Applied Mathematics-III Strength of Materials Material Science Manufacturing Processes Applied Thermodynamics Effective Communication Skills Maximum Marks L P Th 4 100 4 2 100 4 2 100 4 2 100 4 2 100 2 22 8 500 CW 50 50 50 50 50 50 300 SW 50 50 50 50 200 Pr 50 50 50 50 200 TOTAL 150 250 250 250 250 50 1200

Semester IV S. No 1. 2. 3. 4. 5. 6. Sub Code 2ME151 2ME152 2ME153 2ME154 2ME155 2SS156 TOTAL Subject Industrial Engineering and Management Theory of Machines Machine Design and Drawing Mechatronics Fluid Mechanics Engineering Economics L 4 4 4 4 4 2 22 P 2 4 2 2 10 Th 100 100 100 100 100 500 CW 50 50 50 50 50 250 SW 50 50 50 50 50 250 Pr 50 50 50 50 200 TOTAL 150 250 250 250 250 50 1200

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2AM101 APPLIED 4 0 0 MATHEMATICS-III Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25

TH Max Min 100 35

PR

Total 150 60

Objective of the subject:

The course aims at developing the Laplace Transform methods, useful in problems where mechanical/electrical driving force has discontinuities, is impulsive or is a complicated periodic function, fundamentals of Complex Analysis, applicable to potential theory useful in steady state conduction, electrostatic and gravitational fields, and the most basic Numerical Methods and concepts like error estimation, order of convergence, stability etc. Software like Matlab, MathCAD, Mathematica etc. can be used to simulate the results of various numerical methods. Prerequisite(s): Basic knowledge of determinants, matrices, differentiation and integration of functions and complex numbers. COURSE OF CONTENTS UNIT 1: Laplace transform: Definition and properties of Laplace transform, Inverse Laplace Transforms. Convolution theorem. Application of Laplace transform in solution of ordinary differential equations: Solution of ordinary differential equations with constant and variable coefficients. Simultaneous differential equations with constant coefficients. UNIT-2 : Function of Complex variables: Analytic functions, Cauchy-Riemann conditions, Harmonic functions, Conjugate functions and their applications. Complex integral: Integration of complex functions, simply and multiply connected regions, Cauchys integral theorem, Cauchys integral formula, Singularities, Zeroes, Residues and Residue theorem. UNIT-3 Numerical solutions of algebraic and transcendental equations: Bisection method, Regula-Falsi method, Newton-Raphsom method, Direct iterative method, Graffes root squaring method. Solution of system of linear algebraic equation: Matrix inversion method, Gauss- elimination Method, Jordans method, Crouts method. Gauss-Seidel iterative method UNIT-4 Interpolation: Finite difference operator, Interpolation formula with equal and unequal intervals. Divided differences and central differences. Numerical differentiation and integration: Differentiation using forward, backward and divided difference General quadrature formula, Trapezoidal rule, Simpsons 1/3rd rule, Simpsons 3/8th rule, Weddles rule. UNIT-5 Numerical solution of ordinary differential equation: - solution by Eulers,method Euler Modified method Taylors series. Picards successive approximation method. Runga-kutta method. Milnes Predictors and Correctors method. Numerovs methods Numerical solution of partial differential equation:. Classification of second order Partial differential equation. Integration of elliptic, parabolic and hyperbolic equations by Iteration method. Method of Crank-Nicolson for space time problems. RECOMMENDED BOOKS: [1] Francis J. Scheid, Schaums Outline of Numerical Analysis, McGraw-Hill, New York, 1989. [2] Gupta P.P.& Malik G.S., Calculus of Finite Differences and Numerical Analysis, Krishna Prakashan Mandir, Meerut, 21/e, 2006. [3] B.S.Grewal, Engineering Mathematics, Khanna Publishers, 12/e, 2006. [4] S. S. Sastry, Engineering Mathematics, Vol I,II Prentice Hall Publication, 3/e, 2004. [5] Murray R. Spiegel, Schaums Outline of Complex Variables, McGraw-Hill, NewYork, 1968.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME102 STRENGTH OF 4 0 2 MATERIALS Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

With this subject the beginning of a Mechanical engineering starts for the II year Mechanical Engineering students. The subjects introduce the students about the mechanics of a material by introducing the terms stress and strain. It gives an idea of behavior of a material comes under the different loading like tensile, compression , shear and torsion. The subject also covers the theory used in designing of column and struts. COURSE OF CONTENTS UNIT-1 Stress and strain Tensile, compressive and shear stresses, complimentary shear stresses with varying cross section, Temperature stresses, Modulus of Elasticity. Modulus of rigidity, Bulk modulus, Poissons ratio, Relations between the three moduli, Stress on oblique Section of a bar subjected to axial stress, Compound stresses, Principle stresses & strain, Mohrs circle of stresses and strain. Elastic strain energy, Different type of loading, Resilience, Proof resilience, Strain energy in Tensile, Static, Sudden falling, Gradually applied and Impact loading. Strain energy due to shear stresses. UNIT-2 Shear force and Bending moment of Beams Beams, Classification of beams, Types of loading, span, Shear force and Bending moment, Relation between load, shear force and bending moment, shear force and bending moment diagram for cantilever and simply supported beam with concentrated load, Point load, uniformly distributed load, gradually varying load, Eccentric point load. UNIT-3 Bending stresses & Deflection of Beams Introduction, Pure Bending ,Simple Bending theory, Expression for Bending Stress, Moment of inertia of section, Bending Stresses in Symmetrical Section, Shearing stresses in Beams, Distribution of shearing stress in different sections.. Slope & Deflection of Beam subjected to Uniform Bending Moment, Relation between Slope, Deflection and Radius of Curvature, Deflection of simply supported beam carrying a point load and uniform distributed load, Macaulays Method and Moment Area Method for finding out deflection of beam. UNIT-4 Torsion of Circular shaft Introduction, Pure Torsion, Torsional stress & strain in circular shafts, Polar moment of Inertia, Torsional moment of resistance, Torsion equation of circular shaft, Power transmitted by shaft, composite shaft, Strength of shaft, Torsional shear stress in shaft, Shaft of varying section. UNIT-5 Columns & Struts Introduction, Classification of column, Failure of column Eulers theory for column, End conditions of column and struts, Equivalent length of column, Calculation of equivalent length for different end conditions of column, Slenderness ratio, limitations of Eulers formula, Rankins formula for long column and eccentric loading. Formula for Indian standard code of practice.

BOOKS RECOMMENDED [1] Warnock Ramamurtham, Strength of Materials,Dhanpat Rai Publications,1998 [2] Bansal R K, Strength of Materials,4/e,Laxmi Publications(P) Ltd,2007 [3] Popov Mechanics of Solids,2/e, Pearson Education (India), [4] Timoshenko, Elements of Strength of Materials, 5/e,Wadsworth Publishing;1968

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Performance of Tensile test to obtained Tensile properties of the material Performance of Tensile test to obtained Stress-Strain curve Performance of Compressive test to obtained Compressive properties of the material. Performance of Shear test to obtained Shear properties of the material Performance of Bending test to obtained Bending properties of the material. Performance of Brinell Hardness Test. Performance of Vickers Hardness Test. Performance of Torsion test to obtained torsional properties of the material. Performance of Torsion test to obtained T- Curve Performance of Impact test to obtained Impact Strength of the materials.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME103 MATERIAL SCIENCE 4 0 2 Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

COURSE OF CONTENTS

Objective of the subject:

The objective of the subject to introduce the students about the different materials used in the engineering applications and study of different mechanical properties and performance of the materials. The pre requisites is Engineering Chemistry. UNIT-1 Ferrous and Non-Ferrous Metals and Alloys: Properties and application of various steels and cast iron. Effect of impurities, in ferrous metals. Effect of common alloying elements on the steels, High speed steels, Stainless steel, Other steel. Corrosion and its prevention. Composition, microstructure, properties and applications of Aluminium and its principle alloys, Copper and its principle alloys, Nickel and its principle alloys. UNIT-2 Mechanical Properties & Equilibrium Diagram: Various mechanical properties like strength, stiffness, elasticity, plasticity, ductility, hardness, impact strength, malleability, brittleness, toughness, resilience, etc Allotropy structure of alloys, lever rule, phase rule, Various types of phase diagrams. Cooling curves, Iron carbon equilibrium diagram . TTT diagrams. UNIT-3 Heat Treatment of Metals and Alloys and Powder metallurgy: Heat treatment procedure for steel hardening, harden ability, Surface hardening of steel, Defects in heat treated parts. Strengthening mechanisms. Manufacturing of metal powders. Sintering and secondary operations. Projects of finished parts. Design considerations and applications. Composite materials. UNIT-4 Destructive and Non-Destructive Testings: Tensile, compression, shear, torsion fatigue, impact, hardness tests. Ultrasonic, magnetic, eddy current, radiography tests etc. Metallography. Introduction to instrumental methods of analysis. UNIT-5 Discription of Crystal Structure and Dislocation: Seven Crystal System. Bravais lattice. Symmetry and properties of simple crystal structure Millers indices. Direction and planes indices.Edge Dislocation, Screw dislocations slip planes. Stress fields of dislocation. Grain Boundaries. Dislocation Densities. Strength of alloys. Dislocations and crystal growth.

BOOKS RECOMMENDED [1] Khanna, O.,P., Material Science and Metallurgy, Dhanpat Rai Publications,2005 [2] Nayak, S.,P., Engineering Metallurgy & Material Science, Charotara Publications,2000 [3]Narang., Material Science, Khanna Publisher-2000 [4] Singh,I. P., Material Science and Engineering , Jain Brothers-2003

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS 1. 2. 3. 4. 5. 6. 7. 8. 9. Performance of hardness test of ferrous materials using Rock Well hardness testing machine Performance of magnetic particle crack detection to detect the cracks Performance of impact test on a plastic test sample to detect impact strength of materials. Study of construction and function of metallurgical microscope Study of steps involved in sample preparation for observing the microstructure under metallurgical microscope Study of microstructures of ferrous metal alloys Study of iron carbon diagram Study the working of ultrasonic crack detector Study of T.T.T. diagram and various heat treatment process

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME104 Manufacturing Processes 4 0 2 Duration of Theory Paper: 3 Hours

II BE (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

To provide understanding about different manufacturing operations along with practical exposure of manufacturing processes. COURSE OF CONTENTS Unit-1 Production of Axisymmetric Parts Introduction to Turning and related processes, turning parameters, constructional features and operation of turning and related machine tools: Lathes, Capstan-Turret lathes, Automats, CNC lathes, Machining centers and Turning centers. Single point cutting tools: types and geometry. Unit-2 Production of Prismatic Parts Fundamentals of Shaping, Planning and Milling processes, constructional features and operation of Shaper, Planner, Slotter and Milling machines, tool holding, work holding and indexing methods. Types of milling cutters. Unit-3 Drilling, Broaching, Screw Thread and Gear cutting Introduction to operations likeDrilling, Boring, Reaming, Counter Boring and Counter Sinking. Cutting tools, tool holding and work holding devices. Machine Tools for drilling and related hole making processes, accuracy and finish of drilled holes, Broaching process and Broaching machines, power calculations. Geometry of multipoint cutting tools like drill, reamer, broach and taps. Types of Threads, External and Internal thread cutting processes. Gear: Types and Methods of Gear manufacturing. Unit-4 Abrasive Machining Introduction, types of abrasives and bonds, marking system for grinding wheels and their selection criteria, mechanics of grinding, truing and dressing of grinding wheels, grinding machines for cylindrical and surface grinding, tool & cutter grinders. Safety in grinding, other abrasive processes: Honing, Lapping, Super finishing, Polishing and Buffing. Unit-5 Metrology Limits, tolerances and fits: Need for limit systems, interchangeability, statistical assembly, selective assembly, limit system. Taylors principles of gauge design, gauge tolerance and wear allowances, types of limit gauges, thread or screw gauges, advantages & limitation of limit gauges. Measurement and inspection of external screw threads and gears. BOOKS RECOMMENDED [1] DeGarmo E.Paul, Materials and Processes in Manufacturing, Pearson Education. [2] Sharma P. C., Production Technology, Production Engineering, S.Chand and Co. [3] HMT Production Technology , Tata McGraw-Hill Publishing Company Ltd. [4] Chapman W.A.J., WorkshopTechnology Part1,2 and,3, 4ed, Viva Books Private Ltd.

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS 1. Study of geometry of single point cutting tools. 2. Study of geometry of milling cutters. 3. Study of geometry of double fluted twist drill. 4. Study of geometry of Taps and Reamer. 5. Study of constructional features of the Lathe and to machine a job as per given dimensions on it. 6. Study of constructional features of the Shaper and to machine a job as per given dimensions on it. 7. Study of constructional features of the Milling m/c and to machine a job as per given dimensions on it. 8. Study of constructional features of the CNC lathe. 9. Study of comparators. 10. Measurement and inspection of screw threads and cutting tools using a Tool Makers Microscope and Profile Projector.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME105 APPLIED 4 0 2 THERMODYNAMICS Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

To make a fundamentally strong base to design Thermal System. Pre requisites is Elements of Mechanical Engineering COURSE OF CONTENTS UNIT-1: Second Law of Thermodynamics: Qualitative difference between Heat and Work, Cyclic Heat Engine, Kelvin-Planck statement, Clausius statement, Refrigerator and Heat pump, Equivalence of Kelvin-Planck and Clausius statement, Reversibility and Irreversibility, Carnots Theorem, Corollary of Carnots theorem, Absolute thermodynamic temperature scale. UNIT-2: Entropy: Introduction, Clausius theorem, Property of Entropy, Entropy principle and applications, Entropy generation in Closed system, Entropy transfer with heat flow, Entropy and disorder, Absolute entropy, Postulatory thermodynamics. UNIT-3: Exergy: Introduction, Available energy, Quality of energy, Maximum work in a reversible process, Rreversible work by an open system exchanging heat with the surroundings, useful work, Dead state, Availability. UNIT-4: ThermodynamiC Relations: Mathematical theorems, Maxwells equations, TdS Equations, Difference in heat capacities, Ratio of heat capacities, Energy equation, Joule-Kelvin effect, Evaluation of thermodynamic properties, General thermodynamic considerations. UNIT-5: Compressors: Introduction, Types of compressors, Compression Processes, Work done in compression, Single stage Reciprocating air compressor, Volumetric efficiency, Multi-stage compression, Advantages of Multi-staging, Air motors, Introduction to Rotary compressors. REOMMENDED BOOKS [1] P.K. Nag, Engineering Thermodynamics, Tata McGraw-Hill Co, 2005 [2] Y.A. Centgel, Thermodynamics- An Engineering Approach, Tata McGraw-Hill Co, 2003. [3] R. Yadav, Thermodynamics and Heat Engines, Central Publishing House, 2002. [4] G. E. Myers, Engineering Thermodynamics, Prentice Hall Englewood Ciffs, 1989.

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS: 1. 2. 3. 4. 5. 6. 7. Finding out the Coefficient of Performance of a refrigerator. Finding out Energy Performance Ratio of a refrigerating plant used as a heat pump. Establishing the relation between EPR and COP. Carrying out the Exergy analysis of any component of thermal power plant. Verifying the entropy principles in generalized fluid flow. Finding out the Isothermal, Volumetric Efficiency of the Reciprocating Air Compressor. Finding out the effectiveness of the intercooler in two stage compressor.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2SS007 EFFECTIVE 2 0 0 COMMUNICATION SKILLS Duration of Theory Paper: 3 Hours

BE II Year (Common to All Branches.) TH Max Min Marks CW SW 50 25 PR Total 50 25

Objective of the subject: To develop effective communication skills in engineers for expressing the technical ideas and for discussing the technical issues with confidence. COURSE CONTENTS UNIT-1 Fundamentals of Communication: The importance of communication; the basic forms of communication; the process of communication; why communication is necessary? ; art of communication. UNIT-2 Inter Personal Skills: Building positive relationships; giving praise; dealing with criticism; managing conflicts; telephone speaking skills and cross cultural communication skills. UNIT-3 Listening: The importance of listening; barriers to effective listening; approaches to listening; how to be better listener; what speakers can do to ensure better listening. UNIT-4 Interviews: Points to be remembered as an interviewer or an interviewee; commonly asked questions; types of interview; dos and donts. UNIT-5 Making Presentations: Speech purpose general and specific; methods of speaking; analyzing the audience; non-verbal dimension of presentation, group discussion; importance; process; points to be kept in mind while participating; dos and donts.

Note: There shall be seminars and practice sessions by students.

BOOKS RECOMMENDED [1] P D Chaturvedi, P.D. & M Chaturvedi, Business Communication: Concepts, Cases and Applications, Pearson Education, Singapore Pvt. Ltd, 2004. [2] ICMR, Business Communication, Feb 2001. [3] J Davies, Communication Skills: A Guide for Engineering and Applied Science Students, 2/e Pearson Education. [4] Lecture material given by the course teacher.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME151 INDUSTRIAL ENGG & 4 0 2 MANAGEMENT Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25 -

TH Max Min 100 35

PR -

Total 150 60

Objective of the subject:

To provide understanding about industrial management practices along with their linkages to organizational efficiency and effectiveness. COURSE OF CONTENTS UNIT-1 Methods Engineering: Introduction to Methods Engineering and Productivity, Methods study, Recording techniques, Work Measurement tool and techniques. Work place Design - Fundamental of Work place Design. Introduction to job Evaluation and Wage Incentive Schemes UNIT-2 Operations Management: Introduction to Operations management, manufacturing v/s service, Tools and Techniques. Types of Production system. Facilities planning, Introduction to plant Layout . UNIT-3 Organization and Management: Principles of Management and Management functions. Organization, Principles, Structures, Span of Control, Delegation, Centralization and Decentralization, Formal and Informal Organizations. Personal Management, Introduction, Communication, Motivation and Leadership. UNIT-4 Quantitative Techniques for Decision Making: Introduction to operation Research, Basic Transportation and Assignment Models and Their Applications, Network Techniques and its Application

UNIT-5 Quality Control: Quality planning and quality control Programme. Economics of Quality control. and control chart for variables and attributes. Introduction to TQM.

REOMMENDED BOOKS: 1. I.L.O., Work study. 2. Monks, J.E. Operations Management, Mc. Graw Hills 3. Hira and Gupta, Operation Research, S. Chand and Co, New Delhi 4. Mahajan, Statical Quality Control, Dhanpat Rai, New Delhi

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME152 THEORY OF MACHINES 4 0 2 Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

To provide knowledge about the different kinematic pairs and the relationship between the different mechanical linkages. The subject provide enough knowledge about the analysis of mechanical forces, velocity and acceleration analysis on different mechanical pairs and link. COURSE OF CONTENTS UNIT-1 Basics of theory of machines: Degree of Freedom (Grublers criterion) ,Inversions of Quadric cycle chain, single and double slider crank mechanism. Grashofs criterion, Types of kinematic synthesis, Chebychev spacing method for 3- positions, Synthesis of four bar function generator , Study Pantograph, Straight line mechanisms, Steering Mechanisms (Ackermans mechanism, Delays Steering Gear mechanism). Hookes joint and engine indicators. . Determination of velocity and acceleration by analytical and/or graphical methods. UNIT-2 Velocity and acceleration diagrams: Determination of velocity and acceleration by analytical and/or graphical methods of various mechanisms. , Coriolis components ,Kliens construction. UNIT-3 Cams: Types of Cams and followers, Cam profiles with specified follower motion e.g. simple harmonic, constant velocity and acceleration types, Cams with specified contours. Tangent Cams, Displacement, Velocity and Acceleration of followers. UNIT-4 Toothed Gearing : Types of gears, Terminologies of various gears (Spur. Bevel gear, Helical gear, Worm and Worm wheel), Condition for correct gearing. Tooth profiles (cycloidal and involute). Gear trains, Epicyclic gear trains and their applications. UNIT-5 Gyroscopes : Product of inertia, Principle axis, Gyroscopic motion, Gyroscopic torque, Gyrostabilizer, Gyrocompass. Application to ships and aeroplanes. Stability of two & four wheelers. REOMMENDED BOOKS : [1] T. Bevan, Theory of Machines, CBS Publications & Distributions,2000 [2] J. Shigley, Theory of Machines and mechanisms, Oxford University,2006. [3] Ambekar, A.G.,Mechanism and Machine Theory, Jain Brothers-2005 [4] Singh Sadhu, Theory of Machines, Pearsons Education -2006.

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS 1. Study of cam and follower and finding velocity and acceleration of follower 2. Study of slider crank mechanism 3. Study of diffrent kinematic pairs 4. Generation of involute teeth profile for diffrent gears 5. Performance of interference and undercutting of tooth (by ploting) 6. Study of gyroscopic effect using gyroscope 7. Reducing and enlarging drawings using pantograph 8. Study of Double Hooks joint 9. Study of Oldhams coupling 10. Verification of Grashofs law 11. Study of automobile steering gears

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME153 MACHINE DESIGN & DRAWING 4 0 4 Duration of Theory Paper: 3 Hours

BE II Year(Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

Objective of the subject is to familiar the students with the design concepts and to provide the application of drawing in the design of different mechanical parts. Pre requisites is Engineering Drawing.

COURSE OF CONTENTS UNIT-1 1. Engineering Materials: General selection of materials. 2. Manufacturing Considerations in Design: Tolerances, Fits and Surface Roughness. 3. Design and Drawing of Machine parts subjected to Tensile, Compressive and Shear Stresses such as Levers, Pins, Keys and Cotters. UNIT-2 1. Riveted Joints: Design and Drawing of Boilers, Structures and Eccentrically Loaded joints. 2. Welded Joints: Design and Drawings, Strength calculation for direct and eccentric loading. UNIT-3 1. Screwed Fastenings: Design of bolts, Eccentric loading and Turnbuckle. 2. Power Transmission Elements: Design of shafts and Couplings. UNIT-4 Machine Parts Drawings: Free Hand Sketches and fully dimensioned drawings of IC Engine Pats-Piston, Piston Rod, Connecting Rod, Crank Shaft and Flywheel using conventions and standard practices. UNIT-5 Boiler Mountings: Free Hand Sketches and fully dimensioned drawings of Stop Valve, Feed Check Valve, Safety Valve and Blow off Cock using conventions and standard practices. REOMMENDED BOOKS: [1]. Abdulla Sharif, Design of Machine Elements, Dhanpat Rai Publications (P) Ltd, New Delhi, 1995 [2]. P. C. Sharma, D. K. Agrawal, Machine Design, S. K. Kataria & Sons, New Delhi, 2007 [3]. K. Mahadevan, K. Balaveera Reddy, Design Data Hand Book, CBS Publishers & Distributors, New Delhi, 2007 [4]. P. S. Gill, Machine Drawing, S. K. Kataria & Sons, New Delhi 2007

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS: 1. Application Program for Selection of Materials, Tolerances, Fits, and Surface Roughness using Computer Programming Languages such as C++ etc 2. Manual Design and Design Program for Keys, Pins and Cotters using Computer Programming Languages such as C++ etc 3. Manual Design and Design Program for Riveted Joints using Computer Programming Languages such as C++ etc 4. Manual Design and Design Program for Welded Joints using Computer Programming Languages such as C++ etc 5. Manual Design and Design Program for Bolts using Computer Programming Languages such as C++ etc 6. Manual Design and Design Program for Shaft and Couplings using Computer Programming Languages such as C++ etc 7. Manual Drawing of Piston and Piston Rod on Drawing Sheet 8. Manual Drawing of Connecting Rod on Drawing Sheet 9. Manual Drawing of Crank Shaft and Flywheel on Drawing Sheet 10. Manual Drawing of Stop Valve on Drawing Sheet. 11. Manual Drawing of Feed Check Valve on Drawing Sheet. 12. Manual Drawing of Safety Valves on Drawing Sheet. 13. Manual Drawing of Blow of Cock on Drawing Sheet. 14. Computer Aided Drawing of Any one of the Machine Parts using CAD Packages such as AutoCAD Inventor and IDEAS. 15. Computer Aided Drawing of Any one of the Boiler Mountings using CAD Packages such as AutoCAD Inventor and IDEAS.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME154 MECHATRONICS 4 0 4 Duration of Theory Paper: 3 Hours

BE II Year(Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

The present course is intended for the undergraduate students of mechanical engineering to give an introduction to the development of mechatronic systems by considering the modeling of the dynamics of the components, their interactions and overall behaviour and by describing the components of information processing from sensors through microcomputers/microcontrollers to actuators. Prerequisites is, a basic understanding of the electrical and electronic devices along with the concepts of digital electronics and a basic course in computer science and engineering. COURSE OF CONTENTS Unit-1 Introduction to mechatronics: Elements of a mechatronic system, Mechatronic design process, Application in mechatronics. Introduction to signals & system: Block diagram approach to system modeling, Modeling of electrical, mechanical, translational and rotational, fluid and thermal systems, Measurement of system response, Linearization of non linear systems, Fourier series representation of signals, O/P response of first order systems. Unit-2 Sensors & Transducers: Introduction of sensors and transducers, Performance characteristics of sensors and measurement systems, Sensors for motion & position measurement, Force torque & tactile sensors, Flow sensors, Temperature measuring devices, Ultra sonic sensors, Range sensors, Active vibration control using magnetorestrictive transducers, Semiconductor, Fiber optic & microelectromechanical system(MEMS) devices in mechatronics. Unit-3 Signal conditioning & recording of data: Basic steps of signal conditioning, Devices for signal conditioning & data conversion : Voltage divider & rectifiers , bridge circuits, Operational and instrumentation amplifiers ,comparators & oscillators multiplexers, timers, amplitude modulation & demodulation ,voltage to frequency & frequency to voltage converters, pulse width modulation., Analog to digital conversion & digital to analog conversion ,Data recording & display devices. Unit-4 Actuators: Introduction , Mechanical actuation systems , Electrical actuation systems: solenoids & relays, electric motors: DC motors , AC motors , Stepper motors, Servo motor drive circuits , selecting a motor , Fluid power actuators, Piezoelectric actuators, Power amplifiers & actuators drives. Unit-5 Interfacing & control of mechatronic systems: Elements of a data acquisition & control system, Overview of input / output systems: Interfacing, I/O addressing , Interface requirements , Peripheral interface adapters , serial common interface , Input /Output card & software, open systems, Communication interfaces. Introduction of various control systems, Control modes and control system performance, velocity control & adaptive control. BOOKS RECOMMENDED [1] W.Bolton, Mechatronics, 3rd Ed, Pearson Education. [2] Nitai Gour & P.Mahalik, Mechatronics: Principles, concepts and applications, Tata McGraw-Hill Publishing Company Ltd. [3] Michael B.Histand & David Alciatore, Introduction to mechatronics and measurement systems, McGraw-Hill Publication. [4].Peckwith & Buck, Mechanical Measurement Addison Wesley Publishing company,Inc.Reading [5].D.S.Kumar, Measurment & Control Metropolitan Book Co. Delhi. [6].Narka and Choudhary, Instrumentation, Measurement and analysis Tata Mc Graw Hill,2e,2003

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS 1. Study of electrical resistance strain gauges. 2. Study of linear variable differential transformer(LVDT). 3. Study of capacitive transducer. 4. Study of piezoelectric transducer. 5. A mechatronic approach to the study of the following: Printers, Photocopier machine, Ignition system in automobiles, TV remote control, Washing Machine etc. 6. Calibration of pressure gauge using dead weight pressure gauge tester. 7. Calibration of orifice plate using anemometer. 8. Study and Calibration of Thermocouple. 9. Study on Hydraulic system power pack. 10. Study on Pneumatic system power pack.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2ME155 FLUID MECHANICS 4 0 2 Duration of Theory Paper: 3 Hours

BE II Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective of the subject:

To make a fundamentally strong base to design fluid systems and understand the different fluid properties. Pre requisites of the subject is Engineering Thermodynamics. COURSE OF CONTENTS UNIT-1 Review of Fluid Mechanics Introduction, Fluid Properties, Pressure and its measurement, Hydrostatic forces on submerged surfaces, Buoyancy and Stability. Relative Equilibrium. Fluid Kinematics: Lagrangian and Eulerian Approaches, Fundamentals of Flow visualization, Potential flow, Stream function and Velocity Potential function, Vorticity, Rotationality and Circulation, Flow Nets, Reynolds Transport Theorem. UNIT-2 Fluid Dynamics Introduction, Conservation of mass, Mechanical energy and efficiency, Bernoullis equation, Applications of Bernoullis equation, Correction factors, Newton Law and Conservation of momentum, Linear Momentum equation, Angular Momentum equation. Introduction to boundary layer, Laminar and Turbulent boundary layers, Boundary Layer Thickness, Reynolds, Number, Boundary Layer Separation. UNIT-3 Flow Over Bodies Introduction, Navier-Stokes Equations, Drag and Lift, Friction and Pressure Drag, Drag Coefficients of common geometries, Parallel Flow over Flat Plates, Flow over Cylinders and Spheres, Aerofoils, Lift, VonKarmon Vortex Street, Kutta-Joukowski Equation. UNIT-4 Flow Trough Conduits Flow through Pipes: Introduction to Laminar and Turbulent Flows, Entrance region, Fully Developed flow, Laminar Flow in pipes, Turbulent flow in pipes, Losses in Pipe flow, Hagen-Poiseuilles Equation, Dracys Weisbach Equation, Moodys Chart, Piping Networks. Open Channel flow: Classification, Froude Number and Wave Speed, Specific energy, Continuity and Energy equations, Uniform flow and Gradually Varied flow. UNIT-5 Compressible Flow Stagnation Properties, Speed of Sound and Mach Number, One- Dimensional Isentropic Flow, Isentropic Flow Through Nozzles, Shock Waves and Expansion Waves, Rayleigh and Fanno Flows. Introduction to Computational Fluid Dynamics(CFD)System. REOMMENDED BOOKS[1] D. S Kumar, Fluid Mechanics and Fluid Power Engineering, S.K. Kataria & Sons, 2007 [2] John F.Douglas,Fluid Mechanics,Pearson Education,2005. [3] Y.A. Centgel, Fluid Mechanics: Fundamentals and Applications, McGraw-Hill Co, 2003. [4] V. L Streeter and E. B. Wylie, Fluid Mechanics, McGraw-Hill Co, 2003. [5] C. White, Fundamentals of Fluid mechanics, McGraw-Hill Co, 2003.

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS: 1. 2. 3. 4. 5. 6. 7. 8. 9. To verify Bernoullis Theorem Calibration of Venturi-meter and Orifice-meter. To find the Friction Coefficient of different pipes. To Determine Coefficient of impact for the vanes. Determination of different coefficients of the orifice Calibration of external cylindrical mouth pieces of different diameters/ Different L/D ratios Calibration of internal cylindrical or Bordas mouth piece. To Visualize the Forced/ Free Vortex Phenomenon. To determine loss of head in the fittings at various water flow rates.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 2SS057 Engineering Economics 2 Duration of Theory Paper: Only Internal Tests 0 0

BE II Year (Common to All Branches) Marks CW SW 50 25 -

TH Max Min -

PR -

Total 50 25

Objective of the subject: To make fundamentally strong base for decision making skills by applying the

concepts of economics and accounting to cope up with the current dynamic business environment COURSE OF CONTENTS Unit-1 Engineering Economics Economic Decision: Role of Engineering in Business; Concept, Nature and Scope of Economics & Business Economics; Types of Business Organizations. Cost, Revenue and Profit Analysis: Cost Classifications for Predicting Cost Behavior; Concept of Profit, Gross Profit and Net Profit; Break Even Point (BEP). Unit-2 National Income Meaning and Concept of National Income: GNP/GNI, NNP/NNI, Personal Income and Disposable Income; Methods of Computing National Income -Production Method, Income Method, Expenditure Method. Unit-3 Consumer Demand Consumer Demand Analysis: Meaning, Features and Determinants of demand; Law of Demand and its Exceptions; Reasons for Law of Demand; Importance of Law of Demand; Elasticity of Demand. Unit-4 Production Supply Production Supply Analysis: Meaning, Supply Function, Law of Supply, Determinants of Supply, Fluctuation of supply; Elasticity of supply and its measurement. Unit-5 Liberalization Liberalization, Globalization & Privatization: Concept & Characteristics; Evaluation of New Liberal Economic, Policy of India; Economy through Globalization. BOOKS RECOMMENDED [1]C S Park, Contemporary Engineering Economics, Pearson Education, 2002 [2]J S Chandan, Statistics for Business and Economics, [3]C Dislis, JH Dick, I D Dear & AP Ambler, Test Economics and Design for Testability, [4]S Damodaran, Managerial Economics,

Scheme for B.E. All Semester Examination effective from July 2006

DEVI AHILYA VISHWAVIDYALAYA, INDORE

FACULTY OF ENGINEERING

SCHEME OF EXAMINATION & COURSE OF CONTENTS

BE III Year Programme (Mechanical Engineering)

INSTITUTE OF ENGINEERING & TECHNOLOGY (www.iet.dauniv.ac.in)

Scheme for B.E. All Semester Examination effective from July 2006

DEVI AHILYA VISHWAVIDYALAYA, INDORE INSTITUTE OF ENGINEERING & TECHNOLOGY

SCHEMES OF EXAMINATION FOR BE III PROGRAMME (Subject to Revision)

B. E. III YEAR MECHANICAL ENGINEERING

Th- Theory, CW Class Work, SW Sessional Work, Pr Practical

Semester V SNo 1. 2. 3. 4. 5. 6. Sub Code Subject 3ME101 Dynamics of Machine 3ME102 Machine Design I 3ME103 Production Engineering-I I C Engines and Gas 3ME104 Turbines 3ME105 Heat and Mass Transfer Principles of 3SS106 Management TOTAL L 4 4 4 4 4 2 22 P 2 4 2 2 10 Maximum Marks Th CW SW 100 50 50 100 50 50 100 50 100 100 500 50 50 50 300 50 50 200 Pr 50 50 50 50 200 TOTAL 250 250 150 250 250 50 1200

Semester VI Maximum Marks SNo 1. 2. 3. 4. 5. 6. Sub Code 3ME151 3ME152 3ME153 3ME154 3ME155 3SS156 TOTAL Subject Project - I Machine Design II Production Engineering II Fluid Machines Energy Conversion Systems Entrepreneurship Development & IPR L 4 4 4 4 2 18 P 2 4 2 2 2 12 TH 100 100 100 100 500 CW 50 50 50 50 50 300 SW 100 50 50 50 50 200 PR 50 50 50 50 50 200 TOTAL 150 250 250 250 250 50 1200

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 3ME101 DYNAMICS OF MACHINE 4 2 Duration of Theory Paper: 3 Hours

BE III Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objectives & Pre requisites: To Develop the Understanding of Dynamic Behavior Machine components. Pre requisites are Theory of Machine. COURSE CONTENTS UNIT-1 Friction & Power Transmission Devices: Introduction, classification and types of friction, laws of frictions and screw frictions, journal Bearings, thrust bearings, pivot and collar bearings, ball and roller bearings, single & multi-plate clutch, cone clutch, centrifugal clutch, belt, rope and chain drives. UNIT-2 Brakes & Dynamometer: Introduction, classification and types of brakes, shoe/block brake, band brake, band and block brake, internal expanding shoe brake, disc brake. Introduction, classification and types of dynamometers, propulsion and breaking of vehicles. UNIT-3 Analysis of Dynamic Forces: Inertia force and inertia torque, D.Alemberts principle, gas forces, equivalent masses, piston efforts, crank shaft torque, turning moment diagrams, fly wheels, fluctuation of energy and speed. UNIT-4 Governors: Introduction, types and classifications, centrifugal governors, gravity controlled and spring controlled governors, inertia governors, governor characteristics and effect of friction. UNIT-5 Balancing: Balancing of Rotating Masses: Static and dynamic balancing, balancing a single cylinder engine, balancing multi-cylinder engines Balancing of Reciprocating Masses: Primary and secondary balancing, locomotive balancing, hammer blow, pitching and swaying couples, conditions of balance in V-engine, radial engine and multi-cylinder in line engines.

BOOKS RECOMMENDED [1]. Rattan S.S., Theory of Machines, Tata McGraw Hill Publishing Company Ltd., New Delhi, Second Reprint 2005. [2].Shigley J.E. and Uicker J.J., Theory of Machines and Mechanisms, McGraw Hill, Inc., 1995. [3].Thomas Bevan, Theory of Machines, CBS Publishers and Distributors, 1984. [4].Ghosh A. and Mallick A.K., Theory of Mechanisms and Machines, Affiliated East-West Press Pvt.Ltd., New Delhi, 1988. [5]. Rao J.S. and Dukkipati R.V., Mechanism and Machine Theory, Wiley-Eastern Limited, New Delhi, 1992. [6]. John Hannah and Stephens R.C., Mechanics of Machines, Viva low-Priced Student Edition, 1999.

Scheme for B.E. All Semester Examination effective from July 2006

LABORATORY EXPERIMENTS: 1. To determine the coefficient of friction between the surfaces of different materials by inclined plane method. 2. To determine coefficient of friction between leather belt and CI pulley by differential band brake method. 3. To determination the coefficient of friction between leather belt and wooden pulley by belt and pulley apparatus. 4. To Study different types of bearings. 5. To Determine the pressure distribution in the oil film of the journal bearing for various speeds and a) Plot the Cartesian and polar pressure curves for various speeds. b) Determine the constants n and K in the summer field pressure function from the Cartesian pressure curves. c) Plot the summer field pressure curve for each speed. d) Compare the mean load, due to the mean upward pressure on the projected and developed areas of the bearing with the total applied load. e) With the aid of the values of n and K determined as above for each speed, determine the total load on the journal and compare with total load on the bearing. d) Determination of tract ional torque. 6. To study different types of clutches. 7. To study different types of brakes. 8. To study absorption types of dynamometer. 9. To study transmission types of dynamometers. 10. To determine the torque in shaft by epicyclical gear train and holding torque apparatus 11. To determine the moment of inertia of objects using trifler suspension method. 12. To determine the moment of inertia of connecting rod by compound pendulum method. 13. To determine characteristic curves of (i) sleeve position against controlling force and speed and (ii) radius of rotation for Watt, Porter, Proell and Hartnell type governors. 14. To perform static balancing of given weights by balancing apparatus. 15. To perform dynamic balancing of given weights by balancing apparatus.

Scheme for B.E. All Semester Examination effective from July 2006

Devi Ahilya University, Indore, India Institute of Engineering & Technology Subject Code & Name Instructions Hours per Week L T P 3ME102 MACHINE DESIGN I 4 Duration of Theory Paper: 4 Hours 4

BE III Year (Mechanical Engg.) Marks CW SW 50 25 50 25

TH Max Min 100 35

PR 50 25

Total 250 110

Objective and Pre requisites: The objective of the subject to introduce the students about the design of mechanical components like spring, rotating elements, theory of failures etc. Advance methods of stress analysis will also be covered in the subject. Pre requisites is Dynamics of Machine.

COURSE CONTENTS UNIT-1 Theory of Failures & Applications: Theories of failure, their applications to the design problems. Design of parts subjected to torsional and/ or bending such as spiral, helical and leaf springs. UNIT-2 Pressure Vessels and Cover Plates: Analysis of thick cylindrical and spherical shells, compound cylinders, joint for steam and hydraulic pipes, parts of press fit and shrink fit, design consideration of pressure vessels and cover plates. UNIT-3 Rotating Rings and Disks: Disk of uniform thickness and disk of uniform strength. Effect of drilled hole and extra mass, design of flywheel and pulleys. UNIT-4 Design Analysis of Curved Machine Members: Crane Hook, Chain link, open and closed links, M/c. Frames, Wall brackets, design and selection of hooks and wire ropes. UNIT-5 Experimental Methods in Design: Brief idea about experimental stress analysis techniques and their applications and limitation. Only Mechanical Engineers Handbook, Data-books and Certified notes are allowed in the examination hall.

Note: