Professional Documents

Culture Documents

Faced Duct Wrap Insulation Technical Data Sheet

Uploaded by

hello1230Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Faced Duct Wrap Insulation Technical Data Sheet

Uploaded by

hello1230Copyright:

Available Formats

Affiliate of

Member of

Arabian Fiberglass Insulation Company Ltd. J.V. of Zamil Industrial & Owens Corning Corp.

Faced Duct Wrap Insulation

DESCRIPTION APPLICATION Faced Duct Wrap Insulation is intended for use in commercial, institutional, industrial and residential construction as thermal and acoustical insulation of heating, air conditioning and dual temperature ducts and air handling equipment. The use of AFICO Faced Duct Wrap helps prevent condensation when properly applied to air-condition ductwork. The semi-rigid duct wrap with densities from 24 to 56 kg/m3, (1.5 - 3.5 lb/ft3) are flexible insulation rolls for application over irregularly-shaped surfaces where rigidity properties are desired.

Technical Data Sheet Product Code: FDW

Faced Duct Wrap Insulation is highly efficient, resilient, flexible blanket insulation composed of fine, stable and uniformly textured inorganic glass fibers bonded together by a non-water soluble and fire-retardant thermosetting and heat resistant resin. It is free from coarse fibers and shot due to its mineral composition. FACING Faced Duct Wrap Insulation is manufactured in a roll form and subsequently faced on one side by factory laminators, with a suitable vapor retardant Aluminium Foil Reinforced Kraft Paper Laminate (FRK), All Service Jacket (ASJ) or other specific vapor barrier for installation on the exterior of ductwork. The facings have UL fire resistant ratings. STANDARD AVAILABLE PRODUCTS

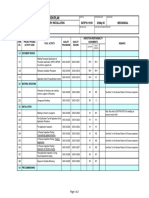

Nominal Manufacturing Specifications. Check for availability of other dimensions and densities. Product Type BD Density

kg/m3 lb/ft3

NOMINAL THERMAL CONDUCTIVITY

W/m.C-Btu.in./ft2.hrF (ASTM C 518) (BS 874) K or value at mean temperatures

Thickness

mm

25 38 50 25 38 50 25 38 50 25 38 50 25 38 50 25 38 50 25 38 50 25 38 50

Width

m ft

Length

m

30 25 20 30 25 20 30 25 20 30 25 20 30 25 20 20 15 10 20 15 10 20 15 10

inch

1 1 2 1 1 2 1 1 2 1 1 2 1 1 2 1 1 2 1 1 2 1 1 2

ft

100 80 65 100 80 65 100 80 65 100 80 65 100 80 65 65 50 33 65 50 33 65 50 33

0C

32F

10C

50F

24C

75F

50C

122F

75C

167F

100C

212F

120*

12

0.75

1.2

0.036

0.25

0.038

0.27

0.040

0.28

0.048

0.34

0.059

0.41

0.065

0.45

140

14

0.875

1.2

0.036

0.24

0.037

0.26

0.039

0.27

0.046

0.32

0.055

0.38

0.061

0.42

160*

16

1.0

1.2

0.034

0.23

0.036

0.25

0.039

0.27

0.044

0.31

0.051

0.35

0.057

0.40

200

20

1.25

1.2

0.032

0.22

0.034

0.23

0.036

0.25

0.041

0.28

0.046

0.32

0.051

0.36

OHSAS

18 001

240* 24 1.5

HEALT H & S A F E T Y STA N D A R D

1.2

0.031

0.21

0.032

0.22

0.035

0.24

0.039

0.27

0.043

0.30

0.047

0.33

320

32

2.0

1.2

0.030

0.20

0.031

0.22

0.033

0.23

0.037

0.25

0.040

0.27

0.044

0.30

480

48

3.0

1.2

0.029

0.20

0.030

0.21

0.031

0.22

0.035

0.24

0.037

0.26

0.041

0.29

560

56

3.5

1.2

0.030

0.21

0.031

0.21

0.032

0.23

0.036

0.24

0.038

0.26

0.042

0.29

* Standard Products and Sizes

Faced Duct Wrap Insulation

Technical Data Sheet Product Code: FDW

Performance & Physical Characteristics

Working Temperature Limitations (ASTM C 411) -4C to +350C. At excessive temperatures a limited migration of binder may occur in the insulation in contact with the hot surface. This in no way impairs the performance of the insulation. Alkalinity pH 9 Corrosiveness (ASTM C 665) Chemically inert. Will not cause or accelerate corrosion of steel, stainless steel, copper or aluminum, due to its particular inorganic and mineral composition. Mold Growth (ASTM D 2020, UL 181) Does not breed or sustain mold, fungus, bacteria or rodents. Moisture Absorption (ASTM D-07 B, ASTM C 553) In conditions of 95% relative humidity at 49C for 96 hours, moisture absorption is less than 0.2% by volume, when tested in accordance with ASTM C 533. fiberglass products do not absorb moisture from the ambient air nor water by capillary attraction, only water under pressure can enter the insulation products but that will quickly dry out owing to the materials open cell structure. Vapor Permeability (ASTM E 96 A) FRK 0.02 PERM (U.S. Federal Specification HH-B-100 B TYPE I) ASJ 0.02 PERM Surface Burning Characteristics (UL 723, ASTM E 84, ASTM E 136) Base glass fiber is non-combustible when tested to ASTM E 84.

Flame Spread

0 5

Specification Compliance Faced Duct Wrap Insulation complies with the property requirements of the following specifications: U.S. Federal Specification HH-I-558 B, Form B, Type 1, Class 6,

ASTM C 553 DCL ASTM - C 533 - C 547 - C 612 - C 665 CE-EN 13162

Fire Properties B.S. 476 PART 4 Non Combustible B.S. 476 PART 5 Ignitability B.S. 476 PART 6 Fire Propagation B.S. 476 PART 7 Surface Spread of Flame Class O fire rating to the building regulations sections E15 Thermal Resistance R Value (Excluding Facings) (ASTM C 167) R is a measure of the resistance to heat flow of a material of any given thickness. (R = m2. C/W or hr. ft2. F/Btu.) T R = where T = thickness K and K or = thermal conductivity Condensation Control How to select appropriate thickness for condensation control: to determine thickness to prevent condensation at various ambient temperature and humidity levels based on installed thickness 75% of nominal (out-of-package) thickness, 55F air duct internal temperature: 1. Select maximum expected relative humidity (RH) on the lower scale. 2. Move up vertically until that line intersects the expected maximum ambient air temperature. 3. Select the thickness indicated by the intersection point

120

Ambient Temperature, oF

3" Req'd.

110 100 90 80 70

Under 1 " Req'd.

2" Req'd. 1 " Req'd.

More that 3" Req'd.

Facing

Smoke Developed

0 10

Fuel Contributed

0 0

FRK ASJ

40

50

60

70

80

90

Relative Humidity, %

The above chart is based on indoor conditions so far as wind and other factors are concerned.

Arabian Fiberglass Insulation Company Ltd. J.V. of Zamil Industrial & Owens Corning Corp.

Performance & Physical Characteristics

Compressive Strength

Type

PSF at 10% Deformation PSF at 25% Deformation

120

5 10

140

5 10

160

5 10

200

10 15

240

12 20

320

16 60

480

25 90

560

30 110

Wire Banding Duct Wrap Metal Ducts

Puncture Resistance (ASTM D 781) FRK ASJ 25 50 Units Units

Self Adhesive Joint Tape Underside of duct to be fully coated with adhesive or fix insulation fixing pins to prevent sag Angle Reinforcement Adhesive Strips 15cm wide

Sound Absorption Coefficients

Insulation

Sound Absorption Coefficient at Frequencies (Hz)

Duct Wrap Fixing pins

Thickness Flexible 25mm ( 1in ) 50mm ( 2in ) Semi-Rigid 25mm ( 1in ) 50mm ( 2in )

125

250

500

1000

2000

4000

NRC

0.38 0.44

0.34 0.66

0.68 1.07

0.82 1.06

0.87 0.99

0.96 1.06

0.70 0.95

0.33 0.38

0.28 0.68

0.62 1.10

0.88 1.07

0.96 1.05

1.04 1.05

0.70 0.95

Self adhesive aluminium tape

Mounting F405: Insulation placed against 24 gauge metal over a 16 inch air space. This mounting configuration is typical of a sheet metal enclosure with insulation on one side. Installation Recommendation Faced Duct Wrap Insulation products are available in rolls. The desired application length can be easily measured and cut from the full roll. AFICO Faced Duct Wrap can be impaled on pins and adhered with recommended adhesive. When using aluminium alloys pins, pin spacing along a duct should be no greater than 300mm on centers. Fasteners should be located no less than 75mm from each edge or corner. Apply vapor-seal pressure-sensitive aluminium joint sealing tape to joints and protrusions. 75mm wide tape should be used. Note: Outdoor applications require additional weather protection.

Wire tie or strapping on large ducts Duct Wrap

Adhesive, 15cm wide strips at 30-40 cm on centers

Self adhesive aluminum tape at joints.

Faced Duct Wrap Insulation

Technical Data Sheet Product Code: FDW

MAINTENANCE No maintenance is required. Faced Duct Wrap Insulation have a high resistance to accidental damage from knocks and handling during installation and maintenance. Dimensionally stable under varying conditions of temperature and humidity, rot-proof, odourless, non-hygroscopic and will not sustain vermin or fungus due to its inorganic and mineral compositions. The product will maintain its thermal properties throughout the lifetime of the construction and will not age. fibreglass is non toxic and not hazardous to health. STORAGE To avoid moisture in the building construction, insulation products stored outside must be kept dry. We recommend products to be always stored in covered and dry areas. is not liable for the damage resulting from inadequate utilization, loading and off loading and mishandling of its products. WARRANTY See manufacturers General Terms and Conditions of Sale. As and/or OC has no control over installation design, installation workmanship, accessory materials, or conditions of application, and/or OC does not warrant the performance or results of any installation containing their products. This warranty disclaimer includes all implied warranties, including the warranties or merchantability and fitness for a particular purpose. Arabian Fiberglass Insulation Company reserves the right to alter product specifications without prior notice, as part of its policy of continued development and improvement. The installation methods described in this leaflet are not compulsory. The choice of materials and methods of fixing are the decision of the specifier, consultant or contractor. For further information or advice on specification of products, contact your local sales office. AVAILABILITY Manufactured by Arabian Fiberglass Insulation Company, Ltd. (AFICO), member of Zamil Industrial, with headquarters and production facilities located in Dammam, Saudi Arabia, under license from and utilizing the manufacturing specifications and technology of Owens-Corning Corporation (OC), Toledo, Ohio, U.S.A. Marketed throughout Saudi Arabia, the G.C.C. countries, the Middle East and the Far East. products are available directly from as well as through a vast and reliable network of local distributors. Special products are manufactured on request.

PRODUCTS Acoustical Ceiling Panels Blanket Insulation HD Series Blanket Insulation Board Insulation Roof Insulation Roof Deck Board Insulation Cavity Wall Insulation Pre-engineered Metal Building Insulation Faced Duct Wrap Duct Liner Duct Liner Board Mechanical Board Insulation Heavy Density Pipe Insulation Pipe Wrap Insulation Thermal Insulating Wool Quiet Liner Woven Facing Prefabricated Duct Board

PRODUCTS CODE ACP BKT HDB BD RI RD CWI MBI FDW DL DLB MBD PI PWI TIW AQL AWF PDB

For more information call the insulation professionals:

H.O. & Factory: Tel: Fax: E-mail: Riyadh Office: Tel: Fax: E-mail: Jeddah office: Tel: Fax: E-mail:

P.O. Box 1289, Dammam 31431, Saudi Arabia +966 3 847 2901 / 847 1519 +966 3 847 3605 wajdei@afico.com.sa P.O. Box 50281, Riyadh 11523, Saudi Arabia +966 1 472 5555 ext. 283 +966 1 291 0162 kathunaiyan@afico.com.sa P.O. Box 2140, Jeddah 21451, Saudi Arabia +966 2 670 0020 ext. 133 +966 2 287 2283

Gulf Regional Office: P.O. Box 44493, Deira, Dubai, U.A.E. Tel: +971 4 294 1211 Fax: +971 4 294 1168 E-mail: aficogcc@emirates.net.ae Export Office: Tel: Fax: E-mail: P.O. Box 90-284, Jdeidet El Metn Beirut Lebanon +961 1 900962 +961 1 900963 AFICO@cyberia.net.lb www.afico.com.sa Authorized Distributor

info@afico.com.sa

Our GREEN promise the healthy solut on

ENERGY SAVING ENVIRONMENTALLY FRIENDLY RECYCLED MATERIALS SOLUTION FOR GLOBAL WARMING

AFICO is committed to a greener, cleaner environment. AFICO have responded to this call for conservation by increasing the amounts of recycled materials in our products.

Pub No. 05-TDS-CWI Printed November 2007

You might also like

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65No ratings yet

- HVAC Specification Detail Guide: A Guide To Specifying ROCKWOOL Insulations For HVAC ApplicationsDocument40 pagesHVAC Specification Detail Guide: A Guide To Specifying ROCKWOOL Insulations For HVAC ApplicationsjgonzaloNo ratings yet

- AFICO HD Series Blanket Insulation Technical Data SheetDocument4 pagesAFICO HD Series Blanket Insulation Technical Data SheetSummer KingNo ratings yet

- FTI Tech AdvancedCladdingPreInsulationSystemsDocument5 pagesFTI Tech AdvancedCladdingPreInsulationSystemseoseos12No ratings yet

- 131 - 1.9.1.2-85T - 316 Stainless SteelDocument4 pages131 - 1.9.1.2-85T - 316 Stainless SteelFtg WwfdfNo ratings yet

- SRW HVAC Insulation GuideDocument12 pagesSRW HVAC Insulation GuidejengandxbNo ratings yet

- Complete Range of Quality HVAC ProductsDocument6 pagesComplete Range of Quality HVAC ProductsMurali EthirajNo ratings yet

- PAL - Construction GuidelinesDocument28 pagesPAL - Construction GuidelinesCarew Mohammed AbayomiNo ratings yet

- Pip Inih1000 TocDocument1 pagePip Inih1000 Toc최우혁No ratings yet

- Trane Decorative Split / Hi Wall Split UnitDocument31 pagesTrane Decorative Split / Hi Wall Split UnitdreamagiczNo ratings yet

- Duct Installation LiningDocument5 pagesDuct Installation Liningم.وليد شكرNo ratings yet

- Nitoflor TF5000: Constructive SolutionsDocument3 pagesNitoflor TF5000: Constructive SolutionstalatzahoorNo ratings yet

- Kaowool Paper 1260Document2 pagesKaowool Paper 1260praveentienNo ratings yet

- National Cyber Security Center Qatar Project DetailsDocument1 pageNational Cyber Security Center Qatar Project Detailsmohamed haniNo ratings yet

- 1 SATIP-N-110-01 Castable Refractory InstallationDocument2 pages1 SATIP-N-110-01 Castable Refractory Installationsonalisabir100% (1)

- Method Statement of Hvac Duct System: Class 1Document20 pagesMethod Statement of Hvac Duct System: Class 1EntegharNo ratings yet

- Neolon Profile - Duct & PIPE Insulation (Updated)Document15 pagesNeolon Profile - Duct & PIPE Insulation (Updated)ntt_121987100% (1)

- Versatile Dry Chemical Fire ExtinguishersDocument2 pagesVersatile Dry Chemical Fire ExtinguishersTransgulf2013No ratings yet

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- Afico BrochureDocument6 pagesAfico BrochureAbdul Tawwab100% (1)

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 pagesElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- Method Statement Ducts, Attenuator Done 7Document5 pagesMethod Statement Ducts, Attenuator Done 7sarmad009No ratings yet

- 25 Important Design Considerations For A BlastroomDocument28 pages25 Important Design Considerations For A BlastroomVinay KUMAR N100% (1)

- C892Document5 pagesC892dinhtung2210No ratings yet

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFSohail Tisekar100% (1)

- Isoking Yellow Package Fiberglass Wool Insulation BlanketDocument6 pagesIsoking Yellow Package Fiberglass Wool Insulation Blanketviethung_01No ratings yet

- m4 U10Document15 pagesm4 U10Lasandu WanniarachchiNo ratings yet

- Over Smooth or Granulated Bur/Modbit SPF: Spray Polurethane Foam & CoatingDocument9 pagesOver Smooth or Granulated Bur/Modbit SPF: Spray Polurethane Foam & CoatinghemantrulzNo ratings yet

- Easy Duct PDFDocument8 pagesEasy Duct PDFSameera Sri VidurangaNo ratings yet

- Ingress Protection (IP)Document2 pagesIngress Protection (IP)nileshb1985No ratings yet

- Armacell Armaflex Sheet Roll Data SheetDocument4 pagesArmacell Armaflex Sheet Roll Data SheetDoniNo ratings yet

- 052876-005 Patio Awning Installation ManualDocument8 pages052876-005 Patio Awning Installation ManualStacy OneillNo ratings yet

- Aluco21spec PDFDocument12 pagesAluco21spec PDFRené Galbraith BerraNo ratings yet

- uPVC Fittings: For Drainage ApplicationsDocument24 pagesuPVC Fittings: For Drainage ApplicationsMiguel GualdaNo ratings yet

- Gypwall 3.2: General Purpose Metal Stud Partition SystemDocument20 pagesGypwall 3.2: General Purpose Metal Stud Partition SystemA CNo ratings yet

- Vikings-Halar Coated Deluge ValveDocument12 pagesVikings-Halar Coated Deluge ValveHenry WuNo ratings yet

- HVAC Ductwork SpecificationDocument4 pagesHVAC Ductwork SpecificationhvacwallyNo ratings yet

- GST C-9404 (Ex) SounderDocument2 pagesGST C-9404 (Ex) SounderReinaldo SouzaNo ratings yet

- Aeroflex InsulationDocument6 pagesAeroflex InsulationorganicspolybondNo ratings yet

- VCD - Comparison SheetDocument6 pagesVCD - Comparison SheetSavad AlwyeNo ratings yet

- SDS Nitoflor FC150 SeaDocument34 pagesSDS Nitoflor FC150 SeaAzmi NordinNo ratings yet

- Thermobreak AcoustiplusDocument4 pagesThermobreak Acoustiplusdody andiNo ratings yet

- Armaflex Class 1: Engineered To Prevent CondensationDocument6 pagesArmaflex Class 1: Engineered To Prevent CondensationTeoxNo ratings yet

- STING - Technical Catalogue 8210GB 200902Document52 pagesSTING - Technical Catalogue 8210GB 200902hungdinhthanhNo ratings yet

- Electrical trunking system installation guideDocument7 pagesElectrical trunking system installation guidechandraNo ratings yet

- Al-Jazeera Firedamp 263Document2 pagesAl-Jazeera Firedamp 263EngTamer100% (1)

- Signage Manual Eng O200703Document54 pagesSignage Manual Eng O200703Nguyễn Thành LongNo ratings yet

- Ids Blast Room GuideDocument19 pagesIds Blast Room GuideMungNguyenDinh100% (2)

- Learn How Backdraft Dampers Work and Their ApplicationsDocument13 pagesLearn How Backdraft Dampers Work and Their ApplicationsJay SuguitanNo ratings yet

- Fire Fighting EquipmentsDocument67 pagesFire Fighting EquipmentsaliiiiiiiiiiNo ratings yet

- Cabinet Features and Specs for Fire Hose Reel and Layflat ModelsDocument4 pagesCabinet Features and Specs for Fire Hose Reel and Layflat Modelsmain mydriveNo ratings yet

- Sikagard - 62Document4 pagesSikagard - 62bassem kooliNo ratings yet

- Leaflet UL 555Document2 pagesLeaflet UL 555ahmedomar_953724702No ratings yet

- Weld Tech FolderDocument42 pagesWeld Tech FolderIlija RunjajicNo ratings yet

- AFICO Heavy Density Pipe Insulation - NewDocument4 pagesAFICO Heavy Density Pipe Insulation - NewNickolas HeadNo ratings yet

- Rockwool 3Document28 pagesRockwool 3deerajksNo ratings yet

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesDocument4 pagesSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanNo ratings yet

- EG Tech Bulletin ASTM C1695Document3 pagesEG Tech Bulletin ASTM C1695AuburnMfgNo ratings yet

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Trillium Seismometer: User GuideDocument34 pagesTrillium Seismometer: User GuideDjibril Idé AlphaNo ratings yet

- Day 4 Quiz - Attempt ReviewDocument8 pagesDay 4 Quiz - Attempt ReviewĐỗ Đức AnhNo ratings yet

- Bula Defense M14 Operator's ManualDocument32 pagesBula Defense M14 Operator's ManualmeNo ratings yet

- Master SEODocument8 pagesMaster SEOOkane MochiNo ratings yet

- THE DOSE, Issue 1 (Tokyo)Document142 pagesTHE DOSE, Issue 1 (Tokyo)Damage85% (20)

- Eye Bags ReliefDocument27 pagesEye Bags ReliefNatsu DragneelNo ratings yet

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionDocument29 pagesAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramNo ratings yet

- BenchmarkDocument4 pagesBenchmarkKiran KumarNo ratings yet

- Easa Management System Assessment ToolDocument40 pagesEasa Management System Assessment ToolAdam Tudor-danielNo ratings yet

- Meet Joe Black (1998) : A Metaphor of LifeDocument10 pagesMeet Joe Black (1998) : A Metaphor of LifeSara OrsenoNo ratings yet

- Jesd8 15aDocument22 pagesJesd8 15aSridhar PonnurangamNo ratings yet

- Oxgen Sensor Cat WEBDocument184 pagesOxgen Sensor Cat WEBBuddy Davis100% (2)

- United States Bankruptcy Court Southern District of New YorkDocument21 pagesUnited States Bankruptcy Court Southern District of New YorkChapter 11 DocketsNo ratings yet

- Cot 2Document3 pagesCot 2Kathjoy ParochaNo ratings yet

- Shopping Mall: Computer Application - IiiDocument15 pagesShopping Mall: Computer Application - IiiShadowdare VirkNo ratings yet

- Arta Kelmendi's resume highlighting education and work experienceDocument2 pagesArta Kelmendi's resume highlighting education and work experienceArta KelmendiNo ratings yet

- Hi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!Document8 pagesHi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!BS Central, Inc. "The Buzz"No ratings yet

- Srimanta Sankaradeva Universityof Health SciencesDocument3 pagesSrimanta Sankaradeva Universityof Health SciencesTemple RunNo ratings yet

- Evil Days of Luckless JohnDocument5 pagesEvil Days of Luckless JohnadikressNo ratings yet

- Form 4 Additional Mathematics Revision PatDocument7 pagesForm 4 Additional Mathematics Revision PatJiajia LauNo ratings yet

- Busbar sizing recommendations for Masterpact circuit breakersDocument1 pageBusbar sizing recommendations for Masterpact circuit breakersVikram SinghNo ratings yet

- Cover Letter PDFDocument1 pageCover Letter PDFAli EjazNo ratings yet

- Price List PPM TerbaruDocument7 pagesPrice List PPM TerbaruAvip HidayatNo ratings yet

- TJUSAMO 2013-2014 Modular ArithmeticDocument4 pagesTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNo ratings yet

- SDS OU1060 IPeptideDocument6 pagesSDS OU1060 IPeptideSaowalak PhonseeNo ratings yet

- Ofper 1 Application For Seagoing AppointmentDocument4 pagesOfper 1 Application For Seagoing AppointmentNarayana ReddyNo ratings yet

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDocument3 pagesCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikNo ratings yet

- Efaverenz p1Document4 pagesEfaverenz p1Pragat KumarNo ratings yet

- Special Power of Attorney: Benedict Joseph M. CruzDocument1 pageSpecial Power of Attorney: Benedict Joseph M. CruzJson GalvezNo ratings yet

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDocument18 pagesTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (47)