Professional Documents

Culture Documents

Transmission Removal and Installation at

Uploaded by

cb950Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transmission Removal and Installation at

Uploaded by

cb950Copyright:

Available Formats

TRANSMISSION REMOVAL & INSTALLATION - A/T

1994 Toyota Celica

1994 TRANSMISSION SERVICING Toyota Automatic Transmission Removal & Installation Celica

AUTOMATIC

WARNING: On models equipped with a Supplemental Restraint System (SRS), SRS must be disabled before repairs are started. Turn ignition switch to LOCK position and disconnect negative battery cable and wait at least 90 seconds. Back-up power supply maintains SRS activation voltage for about 90 seconds after battery is disconnected. See AIR BAG RESTRAINT SYSTEM under ACCESSORIES & EQUIPMENT. Removal (Celica A140E) 1) Disconnect negative battery cable and remove battery. Wait at least 90 seconds before starting work to prevent air bag deployment. Disconnect throttle cable. Remove cruise control actuator (if equipped). Disconnect airflow meter connector and remove air cleaner assembly. Remove ground strap. 2) Remove engine upper left mounting bolt. Remove starter. Disconnect vehicle speed sensor, park/neutral position switch and both solenoid connectors. Remove 3 transaxle mounting bolts. Disconnect transaxle fluid cooling hoses. Install engine support and raise vehicle. Remove engine undercovers and drain transaxle fluid. 3) Remove front wheels. Remove drive axle lock nut. Disconnect stabilizer bar links from lower arms. Disconnect tie rod ends and ball joints from steering knuckle. Remove left side drive shaft. Remove 2 center bearing bracket bolts and remove right side drive shaft and center bearing case. 4) Support transaxle with jack. Disconnect shift control cable. Remove rear engine mounting bolt. Remove front exhaust pipe. Disconnect intermediate steering shaft at rack. Disconnect power steering lines at rack. Remove 2 shift cable mounting bolts. Disconnect air conditioner line bracket. 5) Remove 3 grommets from subframe crossmember and lower center member. Remove 13 bolts and 2 nuts and remove lower center member and subframe crossmember with steering rack attached. Remove No. 1 manifold support and transaxle support plate. Remove 6 torque converter bolts. Remove 3 transaxle bolts and using jack, remove transaxle. Installation 1) Check torque converter fluid level. Measure distance from torque converter drive lug to engine mating surface of transaxle. Distance should be at least .90" (22.8 mm). See Fig. 1. 2) Reverse removal procedure to complete installation of transaxle. Tighten bolts and nuts to specification. Subframe crossmember and lower center member bolts and nuts have different tightening specifications. See Fig. 2. See TORQUE SPECIFICATIONS. 3) Fill transaxle to proper capacity. Check and adjust throttle cable and control cable.

Fig. 1: Measuring Torque Converter Depth (Typical) Courtesy of Toyota Motor Sales, U.S.A., Inc.

Fig. 2: Locating Suspension Members Mounting Bolts & Nuts (Celica - A140E Shown; Celica - A246E Is Similar) Courtesy of Toyota Motor Sales, U.S.A., Inc. Removal (Celica A246E)

1) Disconnect negative battery cable. Wait at least 90 seconds before starting work to prevent air bag deployment. Remove dipstick. Disconnect throttle cable. Remove air cleaner assembly. Remove battery. Remove left engine upper mounting bolt. Disconnect throttle cable mounting bolt. Disconnect ground strap. Disconnect harness clamp mounting bolt from transaxle. 2) Remove starter upper mounting bolt and 2 transaxle mounting bolts. Remove filler tube. Disconnect transaxle fluid cooler hoses. Disconnect intermediate steering shaft at rack. Disconnect power steering lines at steering rack. 3) Install engine support and raise vehicle. Remove engine undercovers and drain transaxle fluid. Remove drive axle lock nut. Disconnect stabilizer bar links from lower arms. Disconnect tie rod ends and ball joints from steering knuckle. Remove drive axles. Support transaxle using a jack. Remove engine rear mounting bolt. Remove front exhaust pipe supports from suspension crossmembers. Remove front exhaust pipe. 4) Disconnect air conditioning pipe from crossmember. Disconnect power steering lines bracket. Remove lower suspension crossmember. Remove starter. Disconnect vehicle speed sensor connector and shift control cable. Disconnect solenoid and park/neutral position switch connectors. 5) Remove torque converter cover and remove 6 torque converter-to-drive plate bolts. Remove 2 lower left engine mounting bolts. Remove 5 transaxle-to-engine mounting bolts. Using jack, remove transaxle. Installation 1) Check torque converter fluid level. Measure distance from torque converter drive lug to engine mating surface of transaxle. Distance should be at least .90" (22.8 mm). See Fig. 1. 2) Reverse removal procedure to complete installation of transaxle. Tighten bolts and nuts to specification. Subframe crossmember bolts and nuts have different tightening specifications. See Fig. 2. See TORQUE SPECIFICATIONS. 3) Fill transaxle to proper capacity. Check and adjust throttle cable and control cable.

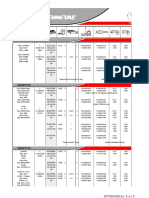

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE Application

Drain Plug ....................................... 25 (34) Drive Shaft Bolts Center Bearing Support .......................... 36 (49) Transaxle Side .................................. 41 (56) Differential Side ............................... 58 (79) Engine Side Mounting Bolts Left Lower ...................................... 38 (52) Left Upper ...................................... 47 (64) Front Exhaust Pipe ............................... 46 (62) Intermediate Steering Shaft Pinch Bolt ........... 26 (35) Rear Exhaust Pipe ................................ 31 (42) Rear Engine Mount ................................ 64 (87) Oil Cooler Tubes ................................. 25 (34) Starter Bolt ..................................... 29 (39) Suspension Members (1) "A" Bolt ........................................ 26 (35) "B" Bolt ........................................ 59 (80) "C" Bolt ...................................... 130 (176)

Ft. Lbs. (N.m)

"D" Bolt ....................................... 94 (127) "E" Bolt ...................................... 123 (167) Nut ............................................. 59 (80) Torque Converter Clutch Bolts .................... 25 (33) Transaxle Support Plate 12 mm Bolts ..................................... 17 (23) 14 mm Bolts ..................................... 34 (46) Transaxle-To-Engine Bolts 14-mm ........................................... 27 (37) 17-mm ........................................... 53 (72) (1) - See Fig. 2.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Autokoi Pricelist - 00021Document2 pagesAutokoi Pricelist - 00021amitNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Kentucky Designated Roadways For Truck DriversDocument1 pageKentucky Designated Roadways For Truck DriversWBKONo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- TGS 6x2 DrawbarDocument4 pagesTGS 6x2 DrawbarAbrar HussainNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CP201W (40658) Y3394hrDocument4 pagesCP201W (40658) Y3394hrمحمد بن علي الصياديNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 1908-1927 Ford Model T - Hemmings Motor NewsDocument14 pages1908-1927 Ford Model T - Hemmings Motor NewsTheodor Eike0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Rodamientos GAUSS 2019Document8 pagesRodamientos GAUSS 2019YeriselMamaniAlarconNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- User-Guide 7 Wheeled-Board 00 en z15001Document3 pagesUser-Guide 7 Wheeled-Board 00 en z15001007003sNo ratings yet

- UAZ Hunter Comprehensive Brochure For Philippine MarketDocument22 pagesUAZ Hunter Comprehensive Brochure For Philippine MarketMijur Juris100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 722.9 ManualDocument60 pages722.9 ManualDenis Konovalov100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- HSL650 7aDocument4 pagesHSL650 7ahamdi galipNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Fascino125fi NewDocument2 pagesFascino125fi Newchenthil89No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Toyota Electric Forklift PDFDocument8 pagesToyota Electric Forklift PDFlesantiago100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Mio Amore - Engine Oil Filter ElementDocument1 pageMio Amore - Engine Oil Filter Elementmotley crewzNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- More Efficiency With The Dry Seven-Speed Dual-Clutch Transmission by HyundaiDocument4 pagesMore Efficiency With The Dry Seven-Speed Dual-Clutch Transmission by HyundaiSlV100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hyun DayVBDocument8 pagesHyun DayVBIsrael Moller WildcatNo ratings yet

- Modelos 550FDocument5 pagesModelos 550FItacimar BrasilNo ratings yet

- Detailed Outline Foreign Cars - DanielDocument3 pagesDetailed Outline Foreign Cars - DanielDanielGalassoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- TRUNK, TAILGATE, FUEL DOOR - Honda Civic LX 2014 - SYSTEM WIRING DIAGRAMSDocument2 pagesTRUNK, TAILGATE, FUEL DOOR - Honda Civic LX 2014 - SYSTEM WIRING DIAGRAMSLucas Matheus KohlerNo ratings yet

- History: Fortune MagazineDocument17 pagesHistory: Fortune MagazineSunena SahuNo ratings yet

- Ducati Desmodici Manual D16RR-08 - enDocument117 pagesDucati Desmodici Manual D16RR-08 - entradetodeathNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Usaa Documentbfa73e53 Cab0 4866 9d74 Fbab0b317b6eDocument3 pagesUsaa Documentbfa73e53 Cab0 4866 9d74 Fbab0b317b6eRobin JamesNo ratings yet

- Catalogo Max LifeDocument7 pagesCatalogo Max Liferamsi17No ratings yet

- AT2353 - Auque 21 PDFDocument6 pagesAT2353 - Auque 21 PDFShriHemaRajaNo ratings yet

- Audio NAV b9017Document11 pagesAudio NAV b9017Natalia Boyco100% (1)

- Daily Pre-Operationla Check List (Wheel Loader)Document1 pageDaily Pre-Operationla Check List (Wheel Loader)Soufian BahmadNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Jeep KJ 2002 Liberty Cherokee Parts CatalogDocument15 pagesJeep KJ 2002 Liberty Cherokee Parts Catalogaleks marinov100% (1)

- Tata Motors Limited - India, December 2020Document65 pagesTata Motors Limited - India, December 2020acc walaNo ratings yet

- Catalogo Bobinas 2018Document85 pagesCatalogo Bobinas 2018Rolman Hernández0% (1)

- ch16Document26 pagesch16Chandan S GanigNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)