Professional Documents

Culture Documents

Lanza: Leading The Way in Carbon Re-Use Technology

Uploaded by

3161758Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lanza: Leading The Way in Carbon Re-Use Technology

Uploaded by

3161758Copyright:

Available Formats

LanzaTech

Leading the way in carbon re-use technology

Spearheading NEW IDEAS in Bio-commodity Technology

With global energy demand expected to double over the next 40 years amid ever-increasing concerns over greenhouse gas-mediated climate change, there is a growing need to explore all available energy resources and technologies to enable sustainable industrial growth. The challenges are clear: How do we expand our manufacturing and processing base without increasing our carbon footprint? Where do we find resources to meet the rapid growth in global demand for transport fuels without compromising global food or farmed resources? How do nations achieve greater energy security and energy efficiency? How do we manage industrial waste in ways that respond to our global energy and environmental challenges? World primary energy demand

12 10 Mtoe, K 8 6 4 2 0 1980 1990

Fossil fuels Zero-carbon fuels Zero-Share of zero-carbon fuels (right axis)

12 10 Mtoe, K 8 6 4 2 0 1990 2000 2010 2020

36% 30% 24% 18% 12% 6% 0 2030

2000

2010

2020

2030

China and India Rest of non-OECD OECD

Source: IEA, World Energy Outlook 2009

Fossil fuels Zero-carbon fuels Share of zero-carbon fuels (right axis)

Global energy demand will double over the next 40 years largely driven by growth in China and India. Containing CO2 growth to a 450 ppm scenario will require that zero carbon fuels make up more than 30% of the fuel pool.

Fueling the future through carbon cycling

To meet increasing global demand for affordable, low-carbon transport fuels, LanzaTech has developed a gas fermentation process that produces ethanol and high-value chemicals from renewable resources that feed on industrial flue gases and waste. Carbon monoxide is generated in large volumes

as a manufacturing by-product in industries ranging from steel production to oil refining. Rather than allowing the CO gas to be emitted into the atmosphere as CO2, LanzaTech captures it and uses it as a resource. This costeffective carbon capture and beneficial re-use greatly improves the facilitys overall energy efficiency and profitability while reducing its carbon footprint.

The LanzaTech Process

Gas feed stream

Gas reception

Compression Fermentation

Recovery

Product tank

Clean industrial growth requires new ideas

At the heart of the LanzaTech process is our patented, wholly-owned microbe that uses gas as its sole source of carbon and energy for fuel and chemical production. Alternative technologies often require the use of food or farmed resources for renewable fuel production. Because our microbe is nutrient agnostic and completely tolerant to the extreme levels of contaminants found in steel mill and other industrial off gases, our process can use the lowest cost, most readily-available resources, including hydrogen-free gases. These include: Industrial flue gas from steel mills and other processing plants. These gases are rich in carbon monoxide and poor in hydrogen. Syngas generated from any biomass resource (e.g., municipal waste, agricultural or forestry waste, organic industrial waste such as tires and waste wood). Syngas contains both carbon monoxide and hydrogen. Coal-derived syngas rich in carbon monoxide and hydrogen. Steam reformed methane (e.g., biogas) that is rich in hydrogen. Through the utilization of these widely available resources, our process provides a strategically important route to renewable fuels without impacting food resources.

New Zealand having achieved an annual production capacity of 15,000 gallons using real waste gas to grow our microbes. This successful pilot program has proven the LanzaTech fermentation process works, clearly demonstrating: Commercial ethanol productivities Tolerance to contaminants in raw gas streams from the steel making process without gas scrubbing Scalability of reactor design LanzaTech now has a rapid commercialization plan in place, with the worlds first steel waste to ethanol production plant scheduled to be fully operational and profitable by 2013.

Resolving the hydrogen puzzle

Synthetic biology for high-value chemicals

LanzaTech is the first company to develop a genetic modification system for a gas fermentation microbe. Through this robust genetic tool box, we have been able to: Secure multiple proprietary genomes Construct a detailed gene expression database Establish our proprietary synthetic biology platform Develop a plug-and-play gene expression/gene regulation system These advancements will allow us to move beyond ethanol production to other fuels and chemicals (e.g., 2,3-BD, isoprene, MEK, isopropanol, etc.), which serve as the building blocks for products such as diesel, jet fuel, olefins, and plastics. Only LanzaTech can use hydrogen-free gases for the production of ethanol. This is because our proprietary microbe can actually produce hydrogen from carbon and water as required. Allows any CO:H2 ratio to be used Reduces the need for thermochemical Water Gas Shift, improving overall C balance Enables a highly efficient, low-energy route to carbon capture and sequestration/reuse

Tested in the lab, Proven in the field

The LanzaTech process has been demonstrated extensively at lab scale, and since November 2008 at our pilot plant at BlueScope Steel in Glenbrook,

LanzaTech: Spearheading New Ideas in Bio-commodity Technology

LanzaTech was founded in early 2005 with a vision to be a dominant technology provider in the industrial bio-commodities arena. Our goal was simple: to develop and commercialize proprietary technologies for the production of low-carbon fuels that do not compromise food, water or land resources. Throughout 2005 and 2006, the company raised funding through New Zealand-based Angel investors and secured grants. These funds provided the resources to establish LanzaTech as a technology leader. Soon thereafter, the company attracted Series A investment from an investor consortium led by Khosla Ventures; the Series B financing was led by Qiming Ventures. Today, LanzaTech is led by a multinational Board of Directors and Management Team with offices in China New Zealand, and the United States. Our rapidly growing team of biologists, process design engineers, expanding patent portfolio and state-of-the-art lab facility are resulting in a list of capabilities unmatched in the industry. Gas Fermentation: our lab was specifically designed to allow quick and efficient investigation and research of every aspect of a commercial gas fermentation process. Synthetic Biology: we are now capable of defining and directing fuel and chemical production at the DNA-level. Our microbe has a WHO Category 1 safety rating (the same as Bakers yeast). Microbiology: we have one of the worlds largest collections of industrial fuel and chemical production microbes. To date, we have developed two new proprietary strains of gas fermentation microbe. Analytical Chemistry: we have in-house access to full, on-line, high-throughput gas and liquid analysis facilities. Fermentation: our fermentation suite comprises more than 20 bench-top gas fermentation reactors and a test-bay allowing the development and demonstration of several prototype reactor designs in parallel and at scale.

Advanced Engineering and Rapid Scale-up

The engineering team is drawn from a diverse range of backgrounds including process, mechanical, electrical and software engineering, as well as experience in industrial fermentation, gas handling and pressure vessel design. This process engineering expertise has been the driving force behind our rapid scale-up and commercialization plan. Operating since November 2008, our pilot plant located at the BlueScope Steel Mill in New Zealand comprises two 500 liter gas fermentation reactors linked directly to the mills off-gas exhaust. The pilot plant is fully automated and has successfully demonstrated the operation of the LanzaTech process at scale with real-world gas resources. Following on the heels of this success, our first demonstration facility, producing over 100,000 gallons of ethanol per year, will be operational in 2011 with a full scale commercial facility planned for 2012. The worlds first steel waste gas to ethanol plant will be operational and profitable by 2013.

LanzaTech

capturing carbon. fueling growth.

LanzaTech Ltd. China 781 Cailun Road Room 215 Zhangjiang HiTech Park Pudong Shanghai China 201203 Phone: +86 21 50116322 Fax: +86 21 50116323 New Zealand 24 Balfour Road Parnell Auckland NZ Phone: +64 9 304 2110 Fax: +64 9 929 3038 USA 725 E. Irving Park Road Roselle, Illinois 60172 Phone: +1 630 337 2769 www.lanzatech.com

2010 LanzaTech Ltd. All rights reserved.

You might also like

- Global Bioethanol: Evolution, Risks, and UncertaintiesFrom EverandGlobal Bioethanol: Evolution, Risks, and UncertaintiesSergio Luiz Monteiro Salles-FilhoNo ratings yet

- Background On LanzaTech 2-Pager-2015Document4 pagesBackground On LanzaTech 2-Pager-2015stavros7100% (1)

- Carbon Capture and Green TechDocument10 pagesCarbon Capture and Green TechSk SahuNo ratings yet

- Winning The Race Chinas Auto Market Shifts GearsDocument208 pagesWinning The Race Chinas Auto Market Shifts GearsEslam YehiaNo ratings yet

- GasifikasiDocument29 pagesGasifikasiMartha GamalNo ratings yet

- White Paper Blue Ammonia Fueling The Future Today 1705324080Document18 pagesWhite Paper Blue Ammonia Fueling The Future Today 1705324080Muhammad IlyasNo ratings yet

- Project Funded by NH Industrial Research Center January 2002-PresentDocument21 pagesProject Funded by NH Industrial Research Center January 2002-PresentAlen WangNo ratings yet

- Uhde Biomass and Coal Gasification: Fluidized Bed Entrained FlowDocument24 pagesUhde Biomass and Coal Gasification: Fluidized Bed Entrained Flowanshuman432No ratings yet

- Oil & Gas, Petrochemicals and Infrastructure Solutions OverviewDocument58 pagesOil & Gas, Petrochemicals and Infrastructure Solutions Overviewraj_shekhar72No ratings yet

- STAMICARBON Brochure Green AmmoniaDocument16 pagesSTAMICARBON Brochure Green AmmoniaMarilia Da SilvaNo ratings yet

- TTCL Vietnam Corporation Limited - Leading EPC ContractorDocument4 pagesTTCL Vietnam Corporation Limited - Leading EPC ContractorLinh GiangNo ratings yet

- 2021.08.19 - FGD Ammonia Co-Combustion Into Coal Power Plant R8Document18 pages2021.08.19 - FGD Ammonia Co-Combustion Into Coal Power Plant R8Miftahul HudaNo ratings yet

- Summary of process equipment for annual distillation unitDocument5 pagesSummary of process equipment for annual distillation unitidilfitriNo ratings yet

- Sunfire Factsheet HyLink SOEC 20210303Document2 pagesSunfire Factsheet HyLink SOEC 20210303Amin AhmadiNo ratings yet

- POSCO Reference Environment Business (수자원소개용)Document34 pagesPOSCO Reference Environment Business (수자원소개용)German Jaramillo VillarNo ratings yet

- RWPR 900 Pellet Mill BrochureDocument4 pagesRWPR 900 Pellet Mill Brochuregrupa2904No ratings yet

- EPD H2O2-Eka ChemicalsDocument4 pagesEPD H2O2-Eka ChemicalsnhangocNo ratings yet

- Modular UFC MiniDocument3 pagesModular UFC MiniVinh Do ThanhNo ratings yet

- New Technologies & Projects Based On Topsøe's Knowledge of Downstream Topsøe S Knowledge of Downstream Gasification TechnologiesDocument16 pagesNew Technologies & Projects Based On Topsøe's Knowledge of Downstream Topsøe S Knowledge of Downstream Gasification TechnologiesRamakrisnanMeenakshiSundaramRamaNo ratings yet

- Turboden - ORC in Biomass Plants OverviewDocument9 pagesTurboden - ORC in Biomass Plants OverviewRatnin PanityingNo ratings yet

- Pbrief Cbam SL 21.4.21Document16 pagesPbrief Cbam SL 21.4.21吴善统No ratings yet

- Augmenting Use of Non-Coking Coal in Steel Industry:: 4 Coal Summit 19-20 November Hotel The Ashok, New DelhiDocument31 pagesAugmenting Use of Non-Coking Coal in Steel Industry:: 4 Coal Summit 19-20 November Hotel The Ashok, New DelhiakshukNo ratings yet

- AFF Brochure 2014Document10 pagesAFF Brochure 2014KatlinKitchensNo ratings yet

- Critical P&ID Reviews Using HAZOP/LOPA Methodology - Overkill or Underrated?Document16 pagesCritical P&ID Reviews Using HAZOP/LOPA Methodology - Overkill or Underrated?kirandevi1981No ratings yet

- Technology of RDF Manufacturing Facilities at Sudokwon LandfillDocument7 pagesTechnology of RDF Manufacturing Facilities at Sudokwon LandfillNghi VoNo ratings yet

- CFN Briquette Press Solutions EnglishDocument2 pagesCFN Briquette Press Solutions EnglishBorko CicovicNo ratings yet

- Annual Plan 2011 Gantt ChartDocument2 pagesAnnual Plan 2011 Gantt ChartdebbycleyNo ratings yet

- Real Gantt Chart - ImahDocument2 pagesReal Gantt Chart - Imahima87_daisyNo ratings yet

- Shenhua Coal Conversion DevelopmentDocument51 pagesShenhua Coal Conversion Developmentstavros7No ratings yet

- 2020 w1 d2 m1 JD SynCORDocument11 pages2020 w1 d2 m1 JD SynCORNhân Trương VănNo ratings yet

- CCUS in Southeast Asian ContextDocument14 pagesCCUS in Southeast Asian ContextIndra Fatah100% (1)

- Urea 6Document28 pagesUrea 6Pragati Kshatriya100% (1)

- BICHLOR™ Electrolyser: Designed by Operators For OperatorsDocument30 pagesBICHLOR™ Electrolyser: Designed by Operators For Operatorsعلي الزغلNo ratings yet

- FB Biomass Pelleting en DataDocument8 pagesFB Biomass Pelleting en Datasarah ahmedNo ratings yet

- WG 2013 12 01 PDFDocument104 pagesWG 2013 12 01 PDFcabekiladNo ratings yet

- TIGAS Haldor TopsoeDocument25 pagesTIGAS Haldor TopsoeGabriele CentiNo ratings yet

- Aspek Keselamatan Pada Aplikasi Reaktor Nuklir Suhu Tinggi Untuk Proses Steam Reforming Gas AlamDocument9 pagesAspek Keselamatan Pada Aplikasi Reaktor Nuklir Suhu Tinggi Untuk Proses Steam Reforming Gas AlamhasmiatiNo ratings yet

- Conceptos de NOxDocument48 pagesConceptos de NOxJESS100% (1)

- Petronet LNG - A ProfileDocument30 pagesPetronet LNG - A ProfileWaghela ManishNo ratings yet

- Biogas As Vehicle FuelDocument51 pagesBiogas As Vehicle FuelSuzana KrstanovićNo ratings yet

- Putting Carbon Back Into The GroundDocument32 pagesPutting Carbon Back Into The GroundmanuciaNo ratings yet

- Hybrid Fuel Cell Gas Turbine SystemsDocument32 pagesHybrid Fuel Cell Gas Turbine Systemsİsmail Cem OktayNo ratings yet

- Cement Industry Environmental Consortium: Carbon Capture and Reuse ProjectDocument27 pagesCement Industry Environmental Consortium: Carbon Capture and Reuse ProjectHala RiadNo ratings yet

- ENSYN RTP Description (2011)Document25 pagesENSYN RTP Description (2011)iboukis100% (1)

- Gaga 2006 MKZM Drum SieveDocument6 pagesGaga 2006 MKZM Drum SievelrbolNo ratings yet

- 30 Full Turnkey CapabilitiesDocument12 pages30 Full Turnkey CapabilitiesMahazan Ab. GhaniNo ratings yet

- RDF CompositionDocument2 pagesRDF Compositionmaz zlsNo ratings yet

- IHS Markit Chemical Process Economics Program PEP BrochureDocument4 pagesIHS Markit Chemical Process Economics Program PEP BrochureMohammad MohseniNo ratings yet

- GLOBAL PELLET MARKETS & BIOMASS CO-FIRING GROWTHDocument28 pagesGLOBAL PELLET MARKETS & BIOMASS CO-FIRING GROWTHNorzuriani Mohamed SeberiNo ratings yet

- Blue Hydrogen 1644367839Document45 pagesBlue Hydrogen 1644367839Muhammad Husein MahfudzNo ratings yet

- Topsoe EFUELS Technology For Converting CO2 To Renewable Synthetic FuelDocument19 pagesTopsoe EFUELS Technology For Converting CO2 To Renewable Synthetic FuelBen PowersNo ratings yet

- Wood Pellets For Biopower in TheusandintheeuDocument30 pagesWood Pellets For Biopower in TheusandintheeuKevin C. BondNo ratings yet

- Converting Biogas To CNG For Vehicle Fuel: September 30, 2013 Chris Voell, Eastern Sales ManagerDocument51 pagesConverting Biogas To CNG For Vehicle Fuel: September 30, 2013 Chris Voell, Eastern Sales ManagerStalinraja DNo ratings yet

- Smart Solutions Delivers Cutting-Edge Precast Concrete and Building ProductsDocument29 pagesSmart Solutions Delivers Cutting-Edge Precast Concrete and Building Productssurya0588No ratings yet

- CO2 Capture Technologies OverviewDocument11 pagesCO2 Capture Technologies OverviewOanaNo ratings yet

- Steel From Solar Energy ReportDocument90 pagesSteel From Solar Energy ReportPedramNo ratings yet

- RusBBTC2015 HALDOR TOPSOE ALEXANDRA KARYAGINA Eng PDFDocument28 pagesRusBBTC2015 HALDOR TOPSOE ALEXANDRA KARYAGINA Eng PDFlaquetengoNo ratings yet

- SJG06 017 (11) GRACE01 by MengdeDocument24 pagesSJG06 017 (11) GRACE01 by MengdeБахтияр АбдуразаковNo ratings yet

- National Grade Six Assessment ScienceDocument11 pagesNational Grade Six Assessment ScienceGrace EtwaruNo ratings yet

- Margaret Hamilton Takes Software Engineering To The Moon and BeyondDocument5 pagesMargaret Hamilton Takes Software Engineering To The Moon and BeyondAntonio TorizNo ratings yet

- 27.4 MATHS Number-and-Place-Value-Workbook PDFDocument34 pages27.4 MATHS Number-and-Place-Value-Workbook PDFdddenisadNo ratings yet

- Numerical Differentiation and Integration: Lecture Series On " Numerical Techniques and Programming in Matlab"Document55 pagesNumerical Differentiation and Integration: Lecture Series On " Numerical Techniques and Programming in Matlab"ahmedNo ratings yet

- Self Evaluation Rubric ShadowingDocument1 pageSelf Evaluation Rubric ShadowingJoaquín LaraNo ratings yet

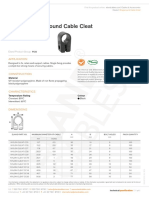

- Wraparound Cable CleatDocument1 pageWraparound Cable Cleatsaghaee.rezaNo ratings yet

- The Ohsol PresentationDocument53 pagesThe Ohsol PresentationArsalan QadirNo ratings yet

- Feeding The Positive WolfDocument4 pagesFeeding The Positive WolfJenelle FerrerNo ratings yet

- Positive Effects of Technology Reading Comprehension Exercises - 93071Document2 pagesPositive Effects of Technology Reading Comprehension Exercises - 93071andreiNo ratings yet

- Chan Paton Generalized Veneziano Model With Isospin PDFDocument5 pagesChan Paton Generalized Veneziano Model With Isospin PDFitt shNo ratings yet

- ECOMATH - Problem Set 1-2Document4 pagesECOMATH - Problem Set 1-2Rodje Marcus MartinezNo ratings yet

- 201 EE1029 Midterm - Group1Document4 pages201 EE1029 Midterm - Group1Thao Vo VanNo ratings yet

- Corrigendum For Advt 02 2023Document1 pageCorrigendum For Advt 02 2023Amerjit KumarNo ratings yet

- PH102 LabDocument10 pagesPH102 LabPeggy CockerNo ratings yet

- Test 1 CHM256 - Question Paper - 231105 - 121107Document7 pagesTest 1 CHM256 - Question Paper - 231105 - 121107Aqilah NajwaNo ratings yet

- Final Draft of Academic WritingDocument4 pagesFinal Draft of Academic Writingvwandah0No ratings yet

- Chapter 5 Geological and Geophysical Investigations in Civil EngineeringDocument28 pagesChapter 5 Geological and Geophysical Investigations in Civil EngineeringnojikoooooooooNo ratings yet

- Slope & Y-Intercept InterpretationDocument6 pagesSlope & Y-Intercept InterpretationNeal SinhaNo ratings yet

- Checkpoint April 2016 Mathematics Paper 2Document16 pagesCheckpoint April 2016 Mathematics Paper 2Aditya Senthil100% (1)

- Age and Gender With Mask ReportDocument15 pagesAge and Gender With Mask Reportsuryavamsi kakaraNo ratings yet

- Branching Stochastic Processes History, Theory, Applications - Mitov 2011Document9 pagesBranching Stochastic Processes History, Theory, Applications - Mitov 2011Manelisi LuthuliNo ratings yet

- General Academic Vacancy PositionDocument282 pagesGeneral Academic Vacancy PositionkaranNo ratings yet

- Parameter Settings: T 9510-9 EN Media 7 Differential Pressure MeterDocument2 pagesParameter Settings: T 9510-9 EN Media 7 Differential Pressure Metermauri flixNo ratings yet

- Grade 7 Quarter 4 Unit Test 1Document2 pagesGrade 7 Quarter 4 Unit Test 1Vener ManlapatNo ratings yet

- Inked Lives - Tattoos Identity and PowerDocument88 pagesInked Lives - Tattoos Identity and Powerךו ני אלNo ratings yet

- Population Growth: SC.912.L.17.5 Analyze How Population Size Is Determined by Births, Deaths, ImmigrationDocument14 pagesPopulation Growth: SC.912.L.17.5 Analyze How Population Size Is Determined by Births, Deaths, ImmigrationBrianna DominguezNo ratings yet

- Danpal Compact BrochureDocument8 pagesDanpal Compact BrochureErik FerrerNo ratings yet

- History Memoir - Anjuli DarjeeDocument10 pagesHistory Memoir - Anjuli DarjeeTshering NamgyalNo ratings yet

- Atmospheric and Liquid Pressure QuizDocument5 pagesAtmospheric and Liquid Pressure QuizNilar LwinNo ratings yet