Professional Documents

Culture Documents

Project Manager

Uploaded by

api-121654429Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Manager

Uploaded by

api-121654429Copyright:

Available Formats

P.O. Box 626 Wheatland, Ok 73097 405-406-4499 ac15d01ca@westpost.

net Objective: I am seeking an opportunity to use my 30 years of construction, opera tions and maintenance knowledge to work safely and effectively, with a strong, p rofessional and profitable company. Experience: 2010 - Present Westcon Industries Bismarck, ND Project Manager * Responsible for management of Safety, Quality Control, projects costs and sche dules. * Assurance of records and documentation related to construction projects cost a nd code compliances. * Monitor manpower and equipment needs for each project. * Work with Construction managers, engineers, and contractors to ensure a safe a nd successful implementation of projects within the time frame and budget assign ed. 2008-2010 Koch Nitrogen Enid, Ok Rotating Equipment Manager * Drive profitable change, for the success of EH&S, Reliability, operations and process excellence. * Responsible for the success of Mechanical Reliability Group. * Convert from Reactive maintenance program to Pro- active Reliability program. * Work is planned developed, and prioritized in advance to minimize surprise fin ds. * Coordinate between Operations, and Maintenance to optimize minimum downtime. * Maintain mechanical integrity of all rotating equipment reciprocating and cent rifugal pumps, turbines, and compressors. 2007-2008 Jacobs Engineering Exxon Mobil ESP Project Torrance, CA Construction Manager * Responsible for onsite construction management, Safety, quality control and co de compliance. * Maintain records and documentation related to construction projects and cost. * Responsible for the successful completion of Mechanical, electrical, civil, an d instrumentation of each project. * Work with Projects managers, engineers, contractors, and field staff to ensure successful implementation of projects within the time frame and budget assigned . 2006-2007 Jacobs Engineering BP Refinery EPA Upgrade Carson, CA Field Engineer/Construction Coordinator * Engineering, Interface, and constructability to support field staff for drawin gs, specifications, procedures, and vendor instruction interpretation. * Systems definition, developing subcontract scope of work RFI/Field change orde rs, Assurance of project specifications, Document control, Care, custody and con trol. Monitor compliance with project policies procedures, performance standards , with emphasis on SAFETY. * Oversee the activities of the field subcontract manager, field procurement, si te logics, and the field QA/QC department to ensure compliance to alliance proce sses. 2006-2006 Jacobs Engineering Valero Refinery emphis, TN Turnover Manager Built and turned over packages containing: * System acceptance color coded P&IDs M

* Hydro Test Acceptance sign off with punch list * Electrical and instrumental loop sign offs * Equipment folder(fin fans, pumps, compressors, absorber towers, drums, exchan gers, filters) * Heat tracing 2003-2006 C&C Construction Stigler, OK Field Engineer/Construction Coordinator * Supervised the setting of natural gas compressors, dehydrators, separators, ev aporators, metering stations, and pipelines going to gas gathering stations. * Tracked progress and completion of systems. * Tracked cost of construction and gave daily updates in management meetings * Supervised the fabrication, installation, and pigging of pipelines. 2001-2003 Redbud Energy Power Plant Luther, OK Plant Mechanic * Maintained four 7FA turbines, four Foster Wheeler HRSG boilers, rotating equip ment, water treatment R/O's, E- Cells, and all associated water treatment equipm ent. * Installed Vibrating analysis targets on rotating equipment * Operated 22- ton crane and 10- ton forklift * Taught rigging classes to maintenance team 2000-2001 Duke Energy McClain Energy Power Plant Newcastle, OK Plant Operator / Mechanic maintained and operated: * (2) GE/ ms-7001FA enhanced gas turbines and (2) ABB/ALSTROM heat recovery stea m boilers * Three pressure single reheat dual flow steam turbines and a Clever Brooks Auxi liary boiler * Glegg R/O and all associated equipment including a state of art water treatmen t plant * Other duties include start and stop of equipment, kept logs and records, handl ed bulk chemicals, operate forklifts and man lifts, analyzed water, condensate, and steam chemistry 1999-2000 Duke/Flour Daniel McClain Energy Power Plant Newcastle, OK Project Superintendent * Setting daily schedules and planning work * Supervising the installation of two boilers, two 7-FA turbines, an auxiliary b oiler, a water treatment plant and all associated equipment, including 2.8 miles of 18" concrete lined pipeline * Ordered materials, kept inventory, and checked materials for damages before ac cepting them * Tracked cost of construction and gave daily updates in management meetings 1991-1999 Pacific Technical Services API 510 Pressure Vessel Inspector and Coordinator * Inspected and supervised the recommended repairs of pressure vessels, heat exc hangers, reactors, and pipe used to make petroleum products * Coordinated and inspected the work of all third party contractors responsible for installation of vessels, pipe, tubes, tube sheets, pumps, and catalyst chang es in the reactors 1980-1991 Wholford &Jenkins Gas Consultants FT. Smith Ark. Field Engineer/Construction Coordinator * Supervised the safe setting of natural gas compressors, dehydrators, separator Torrance, CA

s, evaporators, metering stations, and pipelines going to gas gathering stations . Professional Memberships * Nationally Certified API-510 Pressure Vessel Inspector ( 1993 - 2006) * Polypropylene Certified Fusion Welder * Oklahoma Plumbing Code Certification * Alstom HRSG Certified * Siemens Westinghouse Turbine Certified * Oklahoma Mechanical Journeyman License * Trained In Maximo Warehousing and spare parts Inventory

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PETRO GRACO 4 WAY Evacuation Valve BrochureDocument2 pagesPETRO GRACO 4 WAY Evacuation Valve Brochurepaulm3565No ratings yet

- Handbook of Ship SurveyingDocument776 pagesHandbook of Ship SurveyingAbdul Anis100% (6)

- Karakteristik Turbin dan Boiler PLTUDocument2 pagesKarakteristik Turbin dan Boiler PLTUWahyu Ginanjar ArgianNo ratings yet

- WM Porsche 944 Vol 1a Engine 16vDocument150 pagesWM Porsche 944 Vol 1a Engine 16v9TECHNIKNo ratings yet

- 4-Medical Gases Systems. The Fourth Lecture.Document23 pages4-Medical Gases Systems. The Fourth Lecture.Fireproof Sistemas ElectromecánicosNo ratings yet

- ManualsLib - Makes It Easy To Find Manuals Online! PDFDocument438 pagesManualsLib - Makes It Easy To Find Manuals Online! PDFAaron Rivas100% (1)

- 3,5 DimethylpyrazoleDocument2 pages3,5 DimethylpyrazoleKarla VT0% (1)

- Manual Powerflame C PDFDocument56 pagesManual Powerflame C PDFRoberto MnedezNo ratings yet

- "Owner'S Manual": DuraheatDocument16 pages"Owner'S Manual": DuraheatMichael PotterNo ratings yet

- Dacia Sandero BrochureDocument8 pagesDacia Sandero BrochurechechumenendezNo ratings yet

- ORAP Data Entry PresentationDocument18 pagesORAP Data Entry PresentationcastilvNo ratings yet

- Status Report 2009Document16 pagesStatus Report 2009Aman VermaNo ratings yet

- 45 Series E Frame Repair Manual (520L0609 Rev A-1 August 2006)Document28 pages45 Series E Frame Repair Manual (520L0609 Rev A-1 August 2006)Sasko Dimitrov100% (2)

- Watch Cleaning Machine Operating InstructionsDocument4 pagesWatch Cleaning Machine Operating InstructionsKaj Lydestad67% (3)

- Off The Grid Independent Energy ProductionDocument31 pagesOff The Grid Independent Energy ProductionMoreMoseySpeedNo ratings yet

- Chemical reactions that release energy quicklyDocument35 pagesChemical reactions that release energy quicklyChetan SuranaNo ratings yet

- 80ZV 2Document12 pages80ZV 2mhmd_saad100% (2)

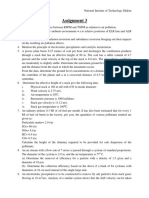

- Assignment 3Document3 pagesAssignment 3HARINo ratings yet

- Fire Pump Design Considerations: Water Supply, Sizing, SelectionDocument5 pagesFire Pump Design Considerations: Water Supply, Sizing, SelectionNikhil NambiarNo ratings yet

- Raptor 44 ReseminDocument6 pagesRaptor 44 ReseminlucasmaltaNo ratings yet

- Dry Dock TermsDocument15 pagesDry Dock TermswaleedyehiaNo ratings yet

- Scooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityDocument8 pagesScooptram ST14 Battery: Fully Battery Electric Loader With 14-Tonne CapacityAnonymous Mdw6y7Q1No ratings yet

- RXYQ-P9W1B DatabookDocument153 pagesRXYQ-P9W1B DatabookTércio MoreiraNo ratings yet

- HOW TO CHANGE CAR OIL IN 5 STEPSDocument6 pagesHOW TO CHANGE CAR OIL IN 5 STEPSPhilip McdonaldNo ratings yet

- Proceedings of International Conference on Heat Exchanger Fouling and Cleaning - 2011 (Peer-reviewedDocument8 pagesProceedings of International Conference on Heat Exchanger Fouling and Cleaning - 2011 (Peer-reviewedFranklin Santiago Suclla Podesta100% (2)

- Multiphase Method For Converting WHP To BHPDocument7 pagesMultiphase Method For Converting WHP To BHPHichem FakhfekhNo ratings yet

- Sulphur Market Outlook: Is the 2017 Price Rally Here to StayDocument23 pagesSulphur Market Outlook: Is the 2017 Price Rally Here to StaysaeidNo ratings yet

- Public Transportation Benefits: Safety, Savings, Traffic ReliefDocument1 pagePublic Transportation Benefits: Safety, Savings, Traffic ReliefHaritharan ManiamNo ratings yet

- Pump DataDocument2 pagesPump DataHector CachoNo ratings yet

- MEM554 - Thermalfluids Lab Computer Linked RefrigerationDocument25 pagesMEM554 - Thermalfluids Lab Computer Linked Refrigerationsayabudakcomey75% (12)