Professional Documents

Culture Documents

107042hhbs Inch

Uploaded by

Victor ParvanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

107042hhbs Inch

Uploaded by

Victor ParvanCopyright:

Available Formats

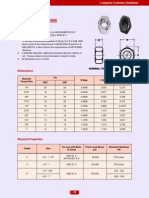

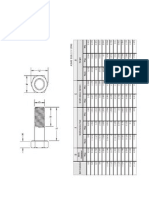

Hexagon Head Bolts/Screws

Inch Series, UNC/UNF-Dimensions

Note :

1. The bolts and screws will generally conform to ANSI B 18.2.1 (Bolts/Screws

made to ANSI B.18.2.1 will also generally conform to B.S.1768).

2. Threads will conform to class 2A of ANSI B1.1 or BS 1580 for Unified threads

(Coarse Fine).

3. Material : "UNILOK" High grade carbon/alloy steel.

4. Heat Treatment : As per SAE grade 5 or 8 (Bolts/Screws made to SAE grade 5 and 8

will also generally conform to requirements of grade 'S' & 'V of BS 1768 respectively.

5. Thread Length LT:

LT1 for L 6

LT2 for L > 6

6. Screw lengths equal to or shorter than those listed in row 'LFT will

be threaded to head.

7. All dimensions are in inches.

Thread

Size

Pitch

W

Max.

Min.

B

Max.

H

Nom.

R

Min.

Q

Min

Length of Thread

Length

Range

LT1

LT2

LFT

0.411

3/4

1/2-2.1/4

0.015

0.473

7/8

1.1/8

1/2-4

0.238

0.015

0.535

1.1/4

1/2-4

0.4375

0.286

0.015

0.595

1.1/8

1.3/8

3/4-3.1/2

0.866

0.5000

0.318

0.015

0.720

1.1/4

1.1/2

1.1/2

3/4-3.1/2

0.9375

1.083

0.6250

0.398

0.020

0.908

1.1/2

1.3/4

1.7/8

1-8

16

1.1250

1.300

0.7500

0.473

0.020

1.090

1.3/4

2.1/8

1.1/2-8

14

1.3125

1.515

0.8750

0.553

0.040

1.275

2.1/4

2.3/8

1.1/2-8

12

1 .5000

1.732

1 .0000

0.617

0.060

1.463

2.1/4

2.1/2

2.5/8

1.1/2-8

UNC

UNF

1/4"

20

28

0.4375

0.505

0.2500

0.158

0.015

5/16"

18

24

0.5000

0.577

0.3125

0.206

3/8"

16

24

0.5625

0.650

0.3750

7/16"

14

20

0.6250

0.722

1/2"

13

20

0.7500

5/8"

11

18

3/4"

10

7/8"

1"

Hexagon Head Bolts/Screws

Inch Series, UNC/UNF-Physical Properties-Tightening Torques:

Grade

Tensile Strength(Min)

Proof Load Stress

Grade 5

120000 Ibs/in

150000 Ibs/in

Recommended Tightening

Torques and Induced

Loads UNC Thread

Recommended Tightening

Torques and Induced

Loads UNF Thread

105.4 Kgf/mm

120000 Ibs/in

84.5 Kgf/mm

84.5Kgf/mm

85000 Ibs/in

59.9Kgf/mm

Elongation % on GL= 4 x Gauge Dia

Rockwell Hardness

Grade 8

2

14%

12%

RC 25-34

Thread

Size

Stress

Area

Sq. Inch

Grade 8

Torque

(lbs-in)

Induced Load

(lbs)

Torque

(lbs-in)

Induced Load

(lbs)

1/4"

0.0324

99.1

2086

140.

2948

5/16"

0.0532

203.4

3426

287.4

4841

3/8"

0.0786

360.5

5061

509.7

7152

7/16"

0.1078

577.1

6942

815.4

9809

1/2"

0.1438

879.6

9260

1243.2

13085

5/8"

0.2290

1705.2

14748

2409.5

20839

3/4"

0.3380

3020.0

21767

4267.6

30758

7/8"

0.4670

4868.5

30075

6878.7

42497

1"

0.6120

7291

39412

10302.9

55692

Thread

Size

Note :

The tightening torques calculated to induce stress

equal to approximately 70% of Yield Stress.

RC 33-39

Stress

Area

Sq. Inch

Grade 5

Grade 8

Torque

(lbs-in)

Induced Load

(lbs)

Torque

(lbs-in)

Induced Load

(lbs)

1/4"

0.0368

112.5

2370

159.1

3349

5/16"

0.0587

224.4

3780

317.2

5341

3/8"

0.0887

406.6

5706

574.5

8063

7/16"

0.1198

641.3

7715

906.2

10902

1/2"

0.1612

986.2

10381

1393.5

14669

5/8"

0.2580

1921.1

16615

2715.0

23478

3/4"

0.375

3351.0

24150

4735.0

34125

7/8"

0.513

5326.5

33037

7557

46683

1"

0.667

7946.2

42955

11229

60697

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Stainless Steel Pipe and Fittings SpecificationDocument10 pagesStainless Steel Pipe and Fittings SpecificationCassy AbulenciaNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- Sigma FastenersDocument5 pagesSigma Fastenerskhafif01No ratings yet

- 02-Pipe Fittings PDFDocument12 pages02-Pipe Fittings PDFSaid Ahmed SalemNo ratings yet

- Specification For Fire Pump - Part 9Document5 pagesSpecification For Fire Pump - Part 9Melisa MackNo ratings yet

- Thermocouples and SensorsDocument40 pagesThermocouples and SensorsEliasNo ratings yet

- Amscrew Part Numbering - Rev18 (11-2020) - SAPDocument43 pagesAmscrew Part Numbering - Rev18 (11-2020) - SAPValentina RojasNo ratings yet

- RITZ Screw SpecificationDocument12 pagesRITZ Screw Specificationmx100sanookNo ratings yet

- British Standards Institution - Bsi: BSI - Engineering Components and Equipment CollectionDocument163 pagesBritish Standards Institution - Bsi: BSI - Engineering Components and Equipment CollectionCode ValmirNo ratings yet

- Pipe Threads (R) - 50Document2 pagesPipe Threads (R) - 50Karthik RajanNo ratings yet

- Bolts For FlangeDocument7 pagesBolts For FlangeMaysaraNo ratings yet

- B3000 & Eb3000Document1 pageB3000 & Eb3000husamNo ratings yet

- Section 2 PDFDocument5 pagesSection 2 PDFimanNo ratings yet

- 05-Pipe Fittings PDFDocument1 page05-Pipe Fittings PDFsopan kharcheNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Nipple Outlet: Welding Onto Header PipeDocument1 pageNipple Outlet: Welding Onto Header PipejensdcvNo ratings yet

- Catalogo Tecnico Stud WeldingDocument68 pagesCatalogo Tecnico Stud Weldingalexfc81No ratings yet

- Asme B16.5-2009Document4 pagesAsme B16.5-2009Mohamed FayedNo ratings yet

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- All Fastenal Bolt Torque Chart-2Document9 pagesAll Fastenal Bolt Torque Chart-2rizman123786No ratings yet

- 02 Precision Pipe FittingsDocument28 pages02 Precision Pipe FittingsNilesh MistryNo ratings yet

- 15 Threaded Fittings and Weld FittingsDocument12 pages15 Threaded Fittings and Weld FittingsAsmaa MohamedNo ratings yet

- Ball Valves Jis10k Flanged End 0Document5 pagesBall Valves Jis10k Flanged End 0Royal BoardNo ratings yet

- 3 Way Valve - BallDocument2 pages3 Way Valve - BallchintanNo ratings yet

- BSIDocument163 pagesBSIhemant1886100% (1)

- NPT (Asme B1.20.1)Document5 pagesNPT (Asme B1.20.1)Afronie Cepoz D'nextNo ratings yet

- Valve Data Sheet - Gate Valve: Colves Fluid Control S.R.LDocument1 pageValve Data Sheet - Gate Valve: Colves Fluid Control S.R.LMohamed gaballa SaidNo ratings yet

- Bolts & Nuts SpecificationDocument7 pagesBolts & Nuts Specificationpattanaik_munaNo ratings yet

- Carbon Steel Strainer Fig 34 HP-Technical InformationDocument3 pagesCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferNo ratings yet

- RTDDocument68 pagesRTDMaria DenetNo ratings yet

- Hexagon Nuts SAE J995: DimensionsDocument1 pageHexagon Nuts SAE J995: DimensionsFederico.IoriNo ratings yet

- British GagesDocument1 pageBritish GagesAnonymous uL3JlWfhNo ratings yet

- ANSI-Piping Fittings StandardDocument8 pagesANSI-Piping Fittings StandardNikola ŠererNo ratings yet

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Document44 pagesPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- f13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdDocument5 pagesf13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdsimanjuntakagusboyNo ratings yet

- Pressure Relief Valve Model: SRV530Document7 pagesPressure Relief Valve Model: SRV530loloNo ratings yet

- Data Sheet For Ball ValveDocument6 pagesData Sheet For Ball ValveTauqueerAhmadNo ratings yet

- Komparasi New MTO Vs Kontrak (Scope Instrument)Document20 pagesKomparasi New MTO Vs Kontrak (Scope Instrument)henryNo ratings yet

- Globe Valve Specification Manuf'S OfferDocument1 pageGlobe Valve Specification Manuf'S OfferAakash KumarNo ratings yet

- Tech Spec of Gas Cutting Set PDFDocument3 pagesTech Spec of Gas Cutting Set PDFVipin SomasekharanNo ratings yet

- Technical Specification For Butt Welded and Socket Welded Fittings 1.1 GeneralDocument4 pagesTechnical Specification For Butt Welded and Socket Welded Fittings 1.1 GeneralRadhakrishnan SreerekhaNo ratings yet

- ASTM A182 F22 Flanges and SA 182 GR F22 Blind - Slip On - SWRF MaterialDocument14 pagesASTM A182 F22 Flanges and SA 182 GR F22 Blind - Slip On - SWRF MaterialMohanasundaram KandasamyNo ratings yet

- Hexagon Head Plug: Length of Thread Screwed Into FittingDocument1 pageHexagon Head Plug: Length of Thread Screwed Into FittingVEERAMANINo ratings yet

- Ball Float Steam Trap 1 PDFDocument3 pagesBall Float Steam Trap 1 PDFmaminzzzNo ratings yet

- Bolts and Compatible Nuts InformationDocument11 pagesBolts and Compatible Nuts InformationBHARATHNo ratings yet

- Kirlosker PM BallValveDocument8 pagesKirlosker PM BallValveSavalia HardikNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Piping Material DetailsDocument12 pagesPiping Material DetailsJay Vinoth100% (2)

- Bayu Undan / Darwin LNG Facilities Technical Delivery TermsDocument6 pagesBayu Undan / Darwin LNG Facilities Technical Delivery TermsWidodo MuisNo ratings yet

- Mil DTL 3922cDocument7 pagesMil DTL 3922cshravan_3393No ratings yet

- Mildsteeltubes, Tubctlars Andother Wroughtsteel Fittings-SpecificationDocument17 pagesMildsteeltubes, Tubctlars Andother Wroughtsteel Fittings-SpecificationRakesh SrivastavaNo ratings yet

- Ansi Flange HandbookDocument76 pagesAnsi Flange HandbookSuperstarVirgo100% (1)

- Piping Joints HandbookDocument161 pagesPiping Joints HandbookKakoDa100% (4)

- Lap Joint Stub End DimensionsDocument2 pagesLap Joint Stub End DimensionsLupul50No ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- TWW Scrapwood Jewelry Box Metric V1Document7 pagesTWW Scrapwood Jewelry Box Metric V1Victor Parvan100% (1)

- Renault Trim RemovalDocument92 pagesRenault Trim Removalalen_tutić100% (2)

- Steel W-Shape Section DataDocument7 pagesSteel W-Shape Section DataNelson MendozaNo ratings yet

- Short Guide Programming Sinumerik 840DDocument101 pagesShort Guide Programming Sinumerik 840DIlija BozovicNo ratings yet

- Detail 2 Detail 1 Detail 3 Detail 4 3 3: Detail 2 Detail 1 Detail 3 Detail 4Document1 pageDetail 2 Detail 1 Detail 3 Detail 4 3 3: Detail 2 Detail 1 Detail 3 Detail 4Victor ParvanNo ratings yet

- 2013 - Lista Preturi 2013Document6 pages2013 - Lista Preturi 2013Victor ParvanNo ratings yet

- 5304.080PL T 304StainlessSteelWireMesh 5x5mesh 0.08DiameterWireDocument3 pages5304.080PL T 304StainlessSteelWireMesh 5x5mesh 0.08DiameterWireVictor ParvanNo ratings yet

- Steel Grades Equivalence Table1 PDFDocument13 pagesSteel Grades Equivalence Table1 PDFVictor ParvanNo ratings yet

- HYTORC Hydraulic Pump Unit JetStream115 - 230 Torque Angle Pump Unit PDFDocument2 pagesHYTORC Hydraulic Pump Unit JetStream115 - 230 Torque Angle Pump Unit PDFVictor ParvanNo ratings yet

- The ABC and XYZ of Bee Culture - 1910 Ed.)Document584 pagesThe ABC and XYZ of Bee Culture - 1910 Ed.)FuneralLily100% (4)

- Iso 4753 PDFDocument1 pageIso 4753 PDFmikhail_vioNo ratings yet

- HYTORC Hydraulic Pump Unit JetStream115 - 230 Torque Angle Pump Unit PDFDocument2 pagesHYTORC Hydraulic Pump Unit JetStream115 - 230 Torque Angle Pump Unit PDFVictor ParvanNo ratings yet

- Design and Analysis of A Spiral Bevel GearDocument72 pagesDesign and Analysis of A Spiral Bevel GearVictor ParvanNo ratings yet

- Grammar Time 11Document43 pagesGrammar Time 11Victor Parvan33% (6)

- 2gd&t - GdandtDocument83 pages2gd&t - GdandtVictor ParvanNo ratings yet

- Materialqualitaeten EDocument26 pagesMaterialqualitaeten EVictor ParvanNo ratings yet

- FANUC GFTE-589-EN - 04 - 101112. Manual Guide I, CNC Turning Made Easy.Document172 pagesFANUC GFTE-589-EN - 04 - 101112. Manual Guide I, CNC Turning Made Easy.JohnPaulSmith100% (6)

- Fits&tolerances Semi 0708Document32 pagesFits&tolerances Semi 0708Ankit KumarNo ratings yet

- Gas Purifying Systems: ContainerDocument4 pagesGas Purifying Systems: ContainerVictor ParvanNo ratings yet

- Engineering Design Representation - Fastener - HandoutDocument32 pagesEngineering Design Representation - Fastener - HandoutVictor ParvanNo ratings yet

- Catalogue Joasa PresiuneDocument354 pagesCatalogue Joasa PresiuneVictor ParvanNo ratings yet

- 302503Document1 page302503Victor ParvanNo ratings yet

- E CatalogueDocument46 pagesE CatalogueLLNo ratings yet

- Massey Ferguson MF 145 TRACTOR Service Parts Catalogue Manual (Part Number 957180)Document15 pagesMassey Ferguson MF 145 TRACTOR Service Parts Catalogue Manual (Part Number 957180)bvk2980022No ratings yet

- Hansa Flex-K1 02 Techinfo eDocument75 pagesHansa Flex-K1 02 Techinfo eMoustafa FahmyNo ratings yet

- VARDEX Main Catalog Supplement 2019 NEW!Document32 pagesVARDEX Main Catalog Supplement 2019 NEW!nevskynaumNo ratings yet

- Uploadfilescatalogues2017salvadori Conveyor-Tools 2017-10-2 Web PDFDocument48 pagesUploadfilescatalogues2017salvadori Conveyor-Tools 2017-10-2 Web PDFaimadjeddaNo ratings yet

- Minimess Katalog PDFDocument39 pagesMinimess Katalog PDFaneesh awasthiNo ratings yet

- Euclid Air Brake Catalog 100asDocument206 pagesEuclid Air Brake Catalog 100asMGS Repuestos PROMOCIONESNo ratings yet

- Unified Screw Threads Threads Per InchDocument15 pagesUnified Screw Threads Threads Per Inchcqh53xn100% (1)

- Threaded Rod, ASTM A193/A193M and ASME SA193/SA193M, B7, PlainDocument2 pagesThreaded Rod, ASTM A193/A193M and ASME SA193/SA193M, B7, PlainRandy ViolaNo ratings yet

- HeliCoil CatalogueDocument34 pagesHeliCoil Cataloguejarv7910No ratings yet

- To-HQ-02-041-00 Philosophy Structures and Foundations OnshoreDocument25 pagesTo-HQ-02-041-00 Philosophy Structures and Foundations Onshoremarin cristianNo ratings yet

- Test Pont and MicroboreDocument4 pagesTest Pont and MicroborePhong DuongNo ratings yet

- Ceramic and Polymer Station Post Insulators CatalogDocument24 pagesCeramic and Polymer Station Post Insulators CatalogCarlos SchulzNo ratings yet

- Unified Thread StandardDocument3 pagesUnified Thread Standardeogus9021No ratings yet

- Двигатель. насосы.Document6 pagesДвигатель. насосы.Павлик МорозNo ratings yet

- Torques LH517iDocument1 pageTorques LH517iJohnatan MezaNo ratings yet

- Standard Hex Jam Nuts: FunctionDocument1 pageStandard Hex Jam Nuts: Functionocy1212No ratings yet

- The Basics of Pressure Relief ValvesDocument4 pagesThe Basics of Pressure Relief ValvesSud GawaliNo ratings yet

- Tap DrillsDocument1 pageTap Drillsdharmesh patelNo ratings yet

- Kioti Daedong DK55 (DK501, DK551) Tractors Service ManualDocument19 pagesKioti Daedong DK55 (DK501, DK551) Tractors Service ManualLisakolyNo ratings yet

- Quick Change Connectors: JK 201 Nipples (Special Mold Plug)Document2 pagesQuick Change Connectors: JK 201 Nipples (Special Mold Plug)Anilabc VermaxyzNo ratings yet

- Recoil Technical Catalogue 2018Document112 pagesRecoil Technical Catalogue 2018Marsal CMNo ratings yet

- MP II - Lecture 3 - Thread and Gear ManufacturingDocument57 pagesMP II - Lecture 3 - Thread and Gear ManufacturingArif Hossain100% (1)

- Rolling Threads DetailsDocument0 pagesRolling Threads DetailsfastenersworldNo ratings yet

- (Ye-Tm) Thread Mills PDFDocument12 pages(Ye-Tm) Thread Mills PDFdavidNo ratings yet

- Model V32 Manual Assembly DisassemblyDocument54 pagesModel V32 Manual Assembly Disassemblysamira1630No ratings yet

- Válvula Anti-Retorno Rexroth - S10A1Document8 pagesVálvula Anti-Retorno Rexroth - S10A1vinícius josé zortéa merinoNo ratings yet

- Tuerca Hex Inox 304 Unc 5.8-11Document1 pageTuerca Hex Inox 304 Unc 5.8-11RENmo123No ratings yet

- SubmarinerDocument30 pagesSubmarinerSuraj SinghNo ratings yet

- 3300 XL NSV Proximity Transducer System Datasheet - 147385Document30 pages3300 XL NSV Proximity Transducer System Datasheet - 147385sidsitdikovNo ratings yet