Professional Documents

Culture Documents

Mike Smyth's Compressed Air Engines: Got A Question? Check Out The FAQ Page

Uploaded by

Miklós Akira ÁrpádOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mike Smyth's Compressed Air Engines: Got A Question? Check Out The FAQ Page

Uploaded by

Miklós Akira ÁrpádCopyright:

Available Formats

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

Mike Smyth's Compressed Air Engines

Welcome to my compressed air engine page! Below you'll find information about the V-twin and radial air engines that I designed and constructed.

Got a question? Check out the FAQ page: Air Engine FAQ SF376

Configuration: 5 cylinder radial Bore: 0.4375 in (7/16") Stroke: 0.500 in Displacement: 0.376 cu in Intake Valves: Rotary Intake Dia.: 0.0938 in Intake Duration: 44 deg Exhaust Valves: Rotary Exhaust Dia.: 0.125 in Exhaust Duration: 60 deg Weight: 6 oz.

1 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

2 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

This is a 5 cylinder radial engine that has the same displacement as the V-twin below. The radial cylinder configuration has the advantage that at least one cylinder is on a power stroke at all times. This allows the engine to self start from any position and it also allows the engine to run at very low RPM without a flywheel. The valve design is similar to the V-twin except the valves are integrated with the crankshaft. This eliminates the need for the external timing gears. The intake and exhaust timing are independently adjustable. The construction of the SF376 is very similar to the V-twin. All of the metal parts are made from brass tubing and sheet from a local hardware store. The white parts are made from a plastic cutting board. All of the parts were made with basic tools - drill press, belt sander, bench grinder, hacksaw, dremel tool and a vise. The brass parts were soldered together using a small butane torch and plumbing solder. The videos below show how the engine performs under different conditions. All the videos except the first one include sound. The first video shows engine with one side of the crankcase removed. The crankshaft is slowly rotated through a full rotation to show the connecting rod configuration. If the video player is put on continuous repeat it will look like the engine is turning continuously. In the second video, the engine is idling at only a couple hundred RPM on about 1-2psi. without a flywheel. The third video shows the engine revving with no load, and the fourth shows the engine spinning an 18" 3-blade propeller. Even with the fairly heavy load, the engine accelerates rapidly. The maximum pressure in this

3 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

video was about 45psi. The engine would easily generate enough thrust to lift it's own weight vertically. Video 1 (340Kb) Cutaway view showing the internal movement Video 2 (1.8Mb) Engine idling slowly with no flywheel Video 3 (2.0Mb) Engine revving with no load and no flywheel Video 4 (2.6Mb) Engine powering an 18" 3-blade propeller I am working on a set of plans with step by step instructions for the SF376. These will be available from this web site for a small fee.

V-Twin

Configuration: 70deg V-Twin Bore: 0.563 in Stroke: 0.750 in Displacement: 0.373 cu in Intake Valves: Rotary Intake Duration: 167 deg Exhaust Valves: 0.125 in dia. port at bottom of stroke Exhaust Duration: 122 deg Timing Shaft: Gear drive

4 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

5 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

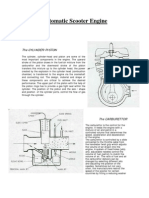

The bottom end of the engine (pistons, connecting rods, crankshaft) is very similar to engines found in everyday automobiles. However, the top end normally consisting of multiple poppet valves, springs, at least one camshaft, rocker arms and push rods (unless it's an overhead cam design) is replaced by a rotary valve that controls the timing of airflow into the cylinders. All of the above mentioned components are replaced by a single hallow shaft with cutouts in strategic locations. The picture below shows the timing shaft, timing gear and the intake manifold.

Compressed air is injected at the left end of the intake manifold tube. When the timing shaft is turned so the ports do not line up with the cylinder ports (the two tubes on the side of the main tube) the intake valves are closed and no air flows because there is nowhere for the air to escape (the end of the timing shaft by the gear is plugged). When the timing shaft is turned so that either of the ports is lined up with the cylinder ports, the intake valves are open and compressed air flows into the respective cylinders. By changing the location of the ports in the timing shaft, the firing order and relative timing can be adjusted. Changing the mesh of the timing gear and the crankshaft gear allow intake timing adjustment relative to the crankshaft position. Fine adjustments to intake timing can be made by rotating the intake manifold in the plastic friction mounts in either end of the

6 / 11 2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

block. This can be done while the engine is running. The exhaust ports are simply tubes at the bottom of the piston stroke that open to the atmosphere to relieve the pressure in the cylinder. This is very similar to a 2-stroke engine. With this design, the exhaust timing is dependent on the location of the port in the cylinder and the duration is a function of the diameter of the port (a larger diameter port will have a longer duration). This engine design worked (barely) the first time, but is very sensitive to the air pressure used. There is plenty of torque on the compression stroke even with very low air pressure, but because there is only an exhaust port at the bottom of the stroke much of the power is wasted as the pistons are traveling up. The high cylinder pressure from the power stroke is relieved once the exhaust port is opened, but when it closes off as the piston travels up, the remaining air in the cyclinder is compressed - robbing energy. This problem is made worse by the small amount of air that leaks into the cylinders around the rotary intake valve. Not only is the air in the cyclinder being compressed, the leaking air also exerts downward force on the cylinder robbing more power. The main drawback to this design is the power loss on the upward stroke of the piston caused by the exhaust valving. On a 2-stroke engine, the upward stroke is the compression stroke. In this case, it's necessary to compress the fuel/air mixture and the compression is a good thing. The energy lost compressing the fuel/air is more than compensated for by the additional energy gained by igniting the fuel under pressure rather than at atmospheric pressure. However, in a compressed air engine, no additional energy is gained if the air in the cylinder is compressed on the upward stroke of the piston. Any additional energy gain due to the higher pressure on the power stroke can't be greater than the energy required to compress the air in the first place. Because of this major drawback, I redesigned the valve system to relieve the pressure in the cylinders on the upstroke of the pistons. One way to alieviate this drawback would be to increase the exhaust duration by using a bigger exhaust port. This would allow the piston to travel up farther before the port is closed thereby reducing the power loss. However, this would also reduce the effective length of the power stroke because once the exhaust valve opens, there is no longer cylinder pressure to force the cylinder down. Because I did not want the power loss caused by simply increasing the exhaust duration, I added exhaust valves to the

7 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

timing shaft in addition to the intake valves. The picture below shows the redesigned valve. This configuration allows the exhaust valves to be closed during the entire power stroke and also allows them to be open through the entire upstroke.

The new timing shaft is plugged in the center between the intake and exhaust valves and is open at both ends. Air flows in the left side of the timing shaft and is distributed to the cylinders as before through the two left intake ports. Air is exhausted through the two ports on the right and out the gear-end of the timing shaft. There is also now a second port in the top of each cylinder that connects to the new exhaust ports on the manifold. On the upward piston strokes, the exhaust valves are open until the piston is nearly at TDC (top dead center). This corrects the drawback described above and allows wider adjustment of the exhaust timing and duration. With the redesigned valves, the engine is not sensitive to air pressure and will easily run just by blowing into the intake manifold. I may make a small dyno with a DC motor to measure the actual power output of the engine at various intake air pressures. Below are revised engine specifications and pictures with the new valves.

V-Twin with Improved Valves

Configuration: 70deg V-Twin Bore: 0.563 in Stroke: 0.750 in Displacement: 0.373 cu in Intake Valves: Rotary Intake Duration: 175 deg

8 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

Exhaust Valves: Rotary Exhaust Duration: 175 deg Timing Shaft: Gear drive

9 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

Not shown in the pictures above is the flywheel. The flywheel I've been using is simply a bar with a bolt in each end for weight. It serves the purpose, but is pretty ugly so I didn't include it in the pictures. Once I turn down a nice steel flywheel on the lathe I'll post some pictures with the flywheel. With the improved valve design, the engine will actually run without the flywheel, but it will need one if I do any dyno testing. The engine could also use some crankshaft counterbalance to make it run smoother. I may try to add some weight to the crankshaft and maybe offset the flywheel weight a little. Here is a video of the V-twin engine running with a simple flywheel. It is simply a piece of plastic with a large nut and bolt at each end. It's a little crude, but it offers a significant load as the engine accelerates. The picture below shows the flywheel. Video 1 (1.4M) Engine accelerating with flywheel.

10 / 11

2009-01-20 19:51

air_engines

http://home.ctlnet.com/~robotguy67/classic_cars/ai...

Got a question? Check out the FAQ page: Air Engine FAQ

Home Mechadon Hexapod MiniMechadon LEGO Bots Classic Cars Air Engines

EasyCounter

11 / 11

2009-01-20 19:51

You might also like

- Cylinder Head PortingDocument10 pagesCylinder Head Portingdebugevdo75% (8)

- F4a41, F4a51, F5a51Document4 pagesF4a41, F4a51, F5a51Vadim Urupa67% (3)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Diesel Engine ImprovementDocument12 pagesDiesel Engine Improvementkumail raza100% (1)

- Advantages of 4 Stroke EngineDocument6 pagesAdvantages of 4 Stroke EngineJILLIEN KAITH ARELLANONo ratings yet

- Triumph TR Tuning - MclayDocument65 pagesTriumph TR Tuning - Mclaytriumph_friend100% (1)

- Keihin CV Images and Diagrams - Tune UPDocument5 pagesKeihin CV Images and Diagrams - Tune UPНикола Карагьозов100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 3.1 - ScavengingDocument6 pages3.1 - ScavengingPrafull TripathiNo ratings yet

- Scooter Tuning GuideDocument22 pagesScooter Tuning GuideCarlos Simões100% (5)

- Training ManualDocument135 pagesTraining ManualVinithra Rajesh100% (1)

- 233 2.0-Litre Engine PDFDocument41 pages233 2.0-Litre Engine PDFAllan Cancino100% (1)

- Engine DesignDocument60 pagesEngine DesignGuri DhindsaNo ratings yet

- Engine Part IDocument39 pagesEngine Part Iaashish koiralaNo ratings yet

- T100 Carb Jetting InfoDocument14 pagesT100 Carb Jetting InfoPaul JenkinsNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Engine Design & Basic TheoryDocument16 pagesEngine Design & Basic Theoryİsmet Sezer100% (2)

- Tech110 PDFDocument4 pagesTech110 PDFPrasetyo AdiNo ratings yet

- 2 Stroke Petrol EngineDocument4 pages2 Stroke Petrol Enginebinoy_sarkar_123100% (2)

- 6802988C45 ADocument26 pages6802988C45 AJose Luis Pardo FigueroaNo ratings yet

- Fallout New OrleansDocument44 pagesFallout New Orleansender000No ratings yet

- Same Tractor Titan 145 150 160 165 190 Parts CatalogDocument22 pagesSame Tractor Titan 145 150 160 165 190 Parts Catalogkimberlywhitney150688bmd100% (119)

- Miller Nitro 4000 Series Sprayer Maintenance Repair Manual 21 47116Document22 pagesMiller Nitro 4000 Series Sprayer Maintenance Repair Manual 21 47116teresataylor130203xqo100% (25)

- Scavenging in 2 Stroke Engine FinalDocument35 pagesScavenging in 2 Stroke Engine Finalnitin_parwaniNo ratings yet

- Propulsion LabDocument39 pagesPropulsion LabKalpit KauraseNo ratings yet

- Ic Engines: Four Stroke Cycle Diesel EnginesDocument11 pagesIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meNo ratings yet

- Exp No - Docx Gaurav Kr.Document13 pagesExp No - Docx Gaurav Kr.Prashant KashyapNo ratings yet

- Pusa Institute of TechnologyDocument13 pagesPusa Institute of TechnologyAbhishek SinghNo ratings yet

- The Z Engine, A New Type of Car Diesel Engine Having Low Emissions, High Part Load Efficiency and Power Density and Low Manufacturing CostsDocument9 pagesThe Z Engine, A New Type of Car Diesel Engine Having Low Emissions, High Part Load Efficiency and Power Density and Low Manufacturing Costsslv_prasaadNo ratings yet

- Thermo NotesDocument18 pagesThermo NotesPavan SharmaNo ratings yet

- Ic Engines: Four Stroke Cycle Diesel EnginesDocument10 pagesIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meNo ratings yet

- Mec 4Document1 pageMec 4api-3761679No ratings yet

- An Innovation in Automotive IndustryDocument10 pagesAn Innovation in Automotive IndustryVanam VenkateshNo ratings yet

- Technical: Engine Blueprinting 101 - Part OneDocument4 pagesTechnical: Engine Blueprinting 101 - Part OneJimmy ChaffaNo ratings yet

- Braking ReferenceDocument38 pagesBraking ReferenceNavid HassanabadyNo ratings yet

- Engine Troubleshooting VespaDocument67 pagesEngine Troubleshooting VespaMuch Abdulah NurhidayatNo ratings yet

- Honda: Four-Stroke Internal Combustion EngineDocument10 pagesHonda: Four-Stroke Internal Combustion EnginetumimurNo ratings yet

- Fuel Is Any Material That Can Be Made ToDocument13 pagesFuel Is Any Material That Can Be Made TojhanelleNo ratings yet

- Theory of Engine OperationDocument19 pagesTheory of Engine OperationGabriel Dela Cruz LagmanNo ratings yet

- Assignment 1Document15 pagesAssignment 1Ikhwan TeeNo ratings yet

- EME Notes Unit 1Document11 pagesEME Notes Unit 1SumanranuNo ratings yet

- Report On Ball Piston EngineDocument10 pagesReport On Ball Piston EngineINFINITE DIRECTIONNo ratings yet

- Increasing The Efficiency of A Two-Stroke Car Diesel EngineDocument4 pagesIncreasing The Efficiency of A Two-Stroke Car Diesel Enginebionda_otrovNo ratings yet

- Automotive Transmissions - Efficiently Transferring Power From Engine To WheelsDocument26 pagesAutomotive Transmissions - Efficiently Transferring Power From Engine To WheelsAja YlNo ratings yet

- What Is The Difference Between A Two Stroke and Four Stroke EngineDocument7 pagesWhat Is The Difference Between A Two Stroke and Four Stroke EngineAllen NopreNo ratings yet

- Shubhradip Roy - PE-ME601ADocument5 pagesShubhradip Roy - PE-ME601Ashubhradiproy2003No ratings yet

- Pocket Guide Air Motors: Omsl - 9067 - 01.indd 1Document28 pagesPocket Guide Air Motors: Omsl - 9067 - 01.indd 1zranothmanNo ratings yet

- Scms College of Polytechnics, Vaikkara Shim Underbucket TechnologyDocument29 pagesScms College of Polytechnics, Vaikkara Shim Underbucket TechnologyÅBin PÅulNo ratings yet

- Types of Scavenging: Loop or Cross Scavenge UniflowDocument22 pagesTypes of Scavenging: Loop or Cross Scavenge UniflowBharatiyulamNo ratings yet

- Aero Engines - Diesel - The Guiberson EngineDocument7 pagesAero Engines - Diesel - The Guiberson EngineAislan Souza100% (1)

- Diesel Fuel Injector Pump: Factsheet Updated 3 October 2008Document8 pagesDiesel Fuel Injector Pump: Factsheet Updated 3 October 2008anshel100% (1)

- Ice PPT 2021 30.09.2021Document123 pagesIce PPT 2021 30.09.2021yoleber398No ratings yet

- Final-Advance Breaking System For Hill Drive VehiclesDocument59 pagesFinal-Advance Breaking System For Hill Drive VehiclesMurali VannappanNo ratings yet

- Mekm November 2022Document18 pagesMekm November 2022Chirag GuptaNo ratings yet

- Ariel Portugal and Vince RiveraDocument81 pagesAriel Portugal and Vince RiveraAriel PortugalNo ratings yet

- Seminar Powerpoint Presentation On 6 Stroke EnginesDocument31 pagesSeminar Powerpoint Presentation On 6 Stroke EnginesVijay ChauhanNo ratings yet

- 5tech EnginDocument20 pages5tech EngintravelnammamysoreNo ratings yet

- 2 StrokeengineDocument6 pages2 StrokeengineifzaeNo ratings yet

- Two StrokeDocument11 pagesTwo StrokeAfzal Shams100% (1)

- M17-Gas and Diesel Engines - Rev1 (Zadco-AHRT)Document40 pagesM17-Gas and Diesel Engines - Rev1 (Zadco-AHRT)VAN VIET NGONo ratings yet

- Buscar TurboDocument37 pagesBuscar TurboSarah Saida Villanueva GuevaraNo ratings yet

- Mathematical Description of OFDMDocument8 pagesMathematical Description of OFDMthegioiphang_1604No ratings yet

- Mathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringDocument40 pagesMathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringVishal ShasiNo ratings yet

- Sony CR1220 PDFDocument2 pagesSony CR1220 PDFdiego742000No ratings yet

- David Beard Composer CV ShortDocument2 pagesDavid Beard Composer CV ShortEhsan KarimyNo ratings yet

- New Microsoft Office Power Point PresentationDocument21 pagesNew Microsoft Office Power Point PresentationSai DhanushNo ratings yet

- k2601 enDocument12 pagesk2601 enRobert MasaNo ratings yet

- Reviewer NG Water UkinamDocument3 pagesReviewer NG Water UkinamMl KrishaNo ratings yet

- ES1022 y Midterm December 2013 With Final AnswersDocument13 pagesES1022 y Midterm December 2013 With Final AnswersGASR2017No ratings yet

- 8 Candidate Quiz Buzzer Using 8051Document33 pages8 Candidate Quiz Buzzer Using 8051prasadzeal0% (1)

- Corona ConcernsDocument5 pagesCorona ConcernsIvanNo ratings yet

- Ao-90265ba Pci CardDocument46 pagesAo-90265ba Pci CardFrancisco Javier PérezNo ratings yet

- Ric RG90 y RG60Document1 pageRic RG90 y RG60GabrielConsentidoNo ratings yet

- Abbbaileyinfi 90Document17 pagesAbbbaileyinfi 90Vipper80No ratings yet

- Sports Collection CatalogueDocument31 pagesSports Collection CataloguesitarazmiNo ratings yet

- RS232STATUSMONDocument1 pageRS232STATUSMONashish.boradNo ratings yet

- Boomer M-Series Technical Specification tcm835-1533266 PDFDocument8 pagesBoomer M-Series Technical Specification tcm835-1533266 PDFseferinoNo ratings yet

- K60-HSS Install GuideDocument2 pagesK60-HSS Install GuidedakidofdaboomNo ratings yet

- Slide Akuntansi ManahemenDocument10 pagesSlide Akuntansi ManahemenHandaru Edit Sasongko0% (1)

- Heat Loss and Gain CalculationDocument84 pagesHeat Loss and Gain Calculationafraz_xecNo ratings yet

- TCE BE EEE RulesandRegulationsDocument509 pagesTCE BE EEE RulesandRegulationsAplieNo ratings yet

- Quick Start Guide: Digital Camera D7000Document2 pagesQuick Start Guide: Digital Camera D7000foosome12No ratings yet

- Baep 471 Syllabus Spring 2016Document8 pagesBaep 471 Syllabus Spring 2016api-299352148No ratings yet

- Sixthsense: - Sanjana Sukumar 3Rd YearDocument2 pagesSixthsense: - Sanjana Sukumar 3Rd YearSanjana SukumarNo ratings yet

- E85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFDocument8 pagesE85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFLuis TovarNo ratings yet

- Database Upgrade 10g To 11gDocument28 pagesDatabase Upgrade 10g To 11gSubhasis1928No ratings yet

- C3691 - NEC, NPN Transistor, 100v, 7v Base, 5A, High Switching SpeedDocument3 pagesC3691 - NEC, NPN Transistor, 100v, 7v Base, 5A, High Switching SpeedLangllyNo ratings yet

- AOGR MLT Promise For ShalesDocument3 pagesAOGR MLT Promise For ShalesJose Antonio Olvera JimenezNo ratings yet