Professional Documents

Culture Documents

PQR 1070 Certified Supplier Program

Uploaded by

Mohammad AzamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQR 1070 Certified Supplier Program

Uploaded by

Mohammad AzamCopyright:

Available Formats

PRODUCT QUALITY REQUIREMENTS/ QUALITY EQUIPMENT OPERATING PROCEDURE FEDERAL MANUFACTURING & TECHNOLOGIES (PQR 1070.

doc)

PQR 1070 PAGE 1 OF 6

CERTIFIED SUPPLIER PROGRAM (U)

CHANGE HISTORY

ISSUE A B C D DESCRIPTION OF CHANGE CUSTODIAN DATE 2/10/03 6/26/03 7/27/06 8/18/2006 INITIAL RELEASE OF NEW PQR GEORGE LICHTENAUER TO CERTIFY BY P/N AND TO INCLUDE GEORGE LICHTENAUER DISTRIBUTORS TO MODIFY THE CERTIFIED SUPPLIER STEVE HALTER PROCESS STEVE HALTER TO ADD BUY-ON-LABEL PRODUCT REQUIREMENTS

Distribution: D. R. R. S. R. A. L. K. L. G. Carey Vanhoose Bornkessel Halter Parkinson D/800 D/600 D/891 D/892 D/893 2B37 2C36 BW31 2B37 FJ42 J. S. C. E. J. E. James R. Mandl C. Mears W. Beniac Shoulta D/894 D/400 D/620 D/620 NNSA 2B37 2C36 OC44 OC44 1D49

PQR 1070 ISSUE D PAGE 2 OF 6

1.0

PURPOSE

The purpose of this document is to define the quality system level and other conditions that must be met and maintained by each Certified Supplier to Honeywell, Federal Manufacturing and Technologies (FM&T). Direction is also provided for performing surveillance and for terminating or reinstating a Certified Supplier. Product from a Certified Supplier is allowed to proceed to FM&T stores without any Buyer lot inspection or testing.

2.0 3.0

DEFINITIONS

Definitions of terms and abbreviations are collected in Appendix A.

CERTIFICATION REQUIREMENTS

Each supplier certification shall be valid for only a single site as identified by vendor code and only specific product(s) from that site. The site shall be the one that manufactures and/or provides supplier testing of the product. 3.1 Nomination The Purchased Product Team (PPT) will nominate a supplier site and specific product(s) for Certified Supplier status. Each nominated supplier must, as a minimum, be approved at the PQR 1020 level as documented in FM&Ts CASL. Approval to PQR 1050/1060 or capable of such a designation as judged by the PPT is preferred. Third party certification to ISO 9001, to AS9000 or AS9100, to QS9000 or TS16949 or to TL9000 will enhance the possibility of certification and may decrease the surveillance needs. The PPT will collect information supporting the nomination. This information may include a copy of any third party certification, historical statistics of product test data, a supplier assessment, a risk analysis evaluation (e.g. an FMEA), and other available information. 3.1.1 Manufacturers On occasion, all products from a manufacturer may qualify for certified supplier status. The more usual condition will identify only a list of specific product(s) from the manufacturer for Certified Supplier status. 3.1.2 Distributors Certain value-added distributors who provide product testing/material verification results may qualify for Certified Supplier status for specific product(s). Such a distributor will be a Certified Supplier only for specific identified product(s) from certain identified manufacturers which they represent and for which they provide product testing/material verification results to FM&T. 3.2 Supplier History

PQR 1070 ISSUE D PAGE 3 OF 6 To be eligible for nomination, a supplier must have delivered at least 3 lots of material 100% trouble free in the past 12 months. They must have an on-time delivery performance of 90% or better and a PATF of 95% or better for a period of at least the previous 12 months. They must not have any outstanding SCARs from any supplier surveys or product defects per the current CATS system records. 3.3 Supplier Responsibility In addition to the requirements of the PQR level for the Certified Supplier, they must notify FM&T in writing of all significant changes to the suppliers production and/or inspection systems, i.e., change in senior quality management, change of facilities, etc. 3.4 Supplier Approval A meeting with the candidate supplier will present the full plan for certification including the quality level and history for nomination, the supplier responsibility and the periodic surveillance. If the supplier agrees, they shall be recommended to the Review Board. The Review Board shall evaluate documentation provided and make the final decision for approval as a Certified Supplier. Certified Suppliers shall be monitored in CASL. 3.5 Buy On Label product Suppliers (manufacturers or distributors) of Buy On Label product may be nominated for PQR 1070 status even if they were only previously at PQR 1000 or PQR 1010 level. The PPT will still collect information supporting the nomination which may include a copy of any third party certification, historical statistics of product test data, a supplier assessment, a risk analysis evaluation (e.g. an FMEA), and other available information. The supplier history shall be per Paragraph 3.2. Paragraphs 3.1, 3.3 and 3.4 shall not apply. Supplier approval shall be by the Review Board and status shall be monitored in CASL.

4.0

SURVEILLANCE OF SUPPLIERS

4.1 Process Profile The Purchased Product Team (PPT) for each certified supplier shall establish a process profile for each supplier inspection or test to be performed on product purchased from that certified supplier. In most cases, the inspection or test profile definition is included in the product specification and/or any referenced Military Standard or public domain (ASTM, JEDEC, etc.) test standard. 4.2 On-Site Audit Certified supplier audits will be performed in conjunction with quality system audits. Each surveillance audit shall be led by a Vendor Contact Field Representative (VCFR) from the Purchased Material Field Office (PMFO) of FM&T who is qualified in performing supplier surveys. An engineering member of the PPT for the supplier being evaluated may also be included. In preparing each new audit plan, previous audits at the certified supplier shall be reviewed. Not all products or all inspections or tests are expected to be covered at a single audit. Each audit shall evaluate 1-3 supplier inspections or tests chosen from the available

PQR 1070 ISSUE D PAGE 4 OF 6 process profile of supplier inspections or tests for that supplier. The overview shall be performed on 1-2 parts or families of product supplied to FM&T. It is preferable to schedule the audit when FM&T product is to be tested. Representative items for audit evaluation include the current calibration of equipment, that the supplier work instructions accurately reflect the requirements in the FM&T specification, that the inspector follows the supplier work instructions, accurate and complete recording of data, adequate supervision of the inspector, and the training and competence of the inspector. Occasionally the packaging and shipping process shall be evaluated for accuracy and completeness of part information and paperwork sent to FM&T. Any problem or improvement areas identified during the audit shall be discussed with supplier management before leaving the site. 4.3 Audit Report Each audit shall result in a report which includes the supplier identification, the report date, the audit team names, the tests and product covered and a discussion of the results with any corrective action or recommendations. The report shall be filed at FM&T with other information for that supplier and shall be readily retrievable. 4.4 Monitor Data Trends Purchased Product Engineering management will monitor the suppliers quality trends by reviewing data provided through the SQES database each quarter. This includes any available product recall information, failure analysis data or next assembly corrective actions. If needed, additional surveillance audits or random engineering evaluations (which may require pulling parts from FM&T stores and testing them) can be requested. 4.5 Product Qualification If a new product line is introduced and requires a Qualification Evaluation (QE), or if an existing product requires reevaluation, the responsible PPT will prepare the appropriate MES routing. The Review Board will be notified of the event and of the outcome. No new product can be added to the certified product listing for that supplier site until all product qualification is complete. 4.6 Buy On Label Product Paragraphs 4.1, 4.2 and 4.3 do not apply.

5.0

TERMINATION OF CERTIFICATION

Moving a supplier to conditional status will occur for any of the following conditions. 5.1 Audit/SCAR

PQR 1070 ISSUE D PAGE 5 OF 6 An unapproved supplier survey, a surveillance audit significant finding result or nonresponse to SCARs. 5.2 Product Quality Unacceptable quality performance (i.e., trend of declining PATF, high incidence of returned material.). 5.3 5.4 Supply Break Supplier Change A break in continuous product supply of 1 year or more. Suppliers change in ownership of the company or of senior quality management or the location of manufacturing facilities.

6.0

REINSTATEMENT OF CERTIFICATION

If the supplier has been terminated from participation in the Certified Supplier program and reinstatement is desired by and agreed to by the supplier and they meet the requirements of Paragraph 3.2, then the certification requirements of Paragraph 3.4 (or 3.5 for Buy On Label product) shall be followed.

7.0

APPENDIX A

Definitions of terms and abbreviations. ASTM: American Society for Testing and Materials. An independent developer of standards used by all segments of industry. CASL: Consolidated Approved Supplier List. A listing of suppliers currently approved to supply product to FM&T. CATS: Corrective Action Tracking System. A database used to track SCARs and their completion. Certified Supplier: A Certified Supplier to FM&T is one who has been nominated and approved per this document. FM&T: Federal Manufacturing and Technologies. The Honeywell site which is the buyer of product from Certified Suppliers per this document. FMEA: Failure Mode and Effects Analysis. A formal structured method for identifying and evaluating the comparative severity of the possible failure modes of a process. JEDEC: Joint Electron Device Engineering Council. The body of the Electronic Industries Alliance which develops semiconductor engineering standards for industry use. MES: Manufacturing Execution System. A computerized system which provides the latest version of manufacturing and inspection instructions in the FM&T plant.

PQR 1070 ISSUE D PAGE 6 OF 6 PATF: Percent Accepted Trouble Free. A measure of quality performance as determined by the disposition of accepted/rejected parts received at FM&T. PMFO: Purchased Material Field Office. The department at FM&T which performs supplier surveys and surveillance audits. PPT: Purchased Product Team. A team comprised of the FM&T buyer, quality engineer and product engineer. PQR: Product Quality Requirement. A document collecting the requirements for a specific level of product quality. QE: Quality Evaluation. Testing done to qualify a part for use in a particular assembly at FM&T. Review Board: A group of FM&T personnel designated to approve Certified Suppliers and to administer the process. SCAR: Supplier Corrective Action Request. This form documents any discrepancies found during a supplier survey or surveillance audit. The data and completion dates are tracked in the CATS database at FM&T. product inspection at FM&T by supplier and part number.

SQES: Supplier Quality Evaluation System. A database that collects the results of VCFR: Vendor Contact Field Representative. An FM&T employee trained in

evaluation of the adequacy and completeness of product inspection and testing at suppliers.

You might also like

- Production Part Approval Process PPAPDocument4 pagesProduction Part Approval Process PPAPtintucinNo ratings yet

- Quality Assurance Manual: MIL-STD-45208ADocument37 pagesQuality Assurance Manual: MIL-STD-45208AJessica JamesNo ratings yet

- Supplier Approval, Qualification and CertificationDocument1 pageSupplier Approval, Qualification and Certificationqmdocs60% (5)

- Sop 7 4 1 B Qualifying New and Existing VendorsDocument7 pagesSop 7 4 1 B Qualifying New and Existing Vendorsיוליה רחמילובNo ratings yet

- Supplier Quality Requirements PDFDocument8 pagesSupplier Quality Requirements PDFabedo danklawyNo ratings yet

- Ford SpecificDocument7 pagesFord SpecificJulio ChagoyaNo ratings yet

- Sodium Borate: What Is Boron?Document2 pagesSodium Borate: What Is Boron?Gary WhiteNo ratings yet

- Drugs and Health Products: Validation Guidelines For Pharmaceutical Dosage Forms (GUIDE-0029)Document12 pagesDrugs and Health Products: Validation Guidelines For Pharmaceutical Dosage Forms (GUIDE-0029)upadhyayparag01No ratings yet

- Autocar Ppap Requirements Rev 5Document17 pagesAutocar Ppap Requirements Rev 5man hoNo ratings yet

- Fire Art Case StudyDocument15 pagesFire Art Case StudyKimberlyHerring100% (1)

- Trudy Scott Amino-AcidsDocument35 pagesTrudy Scott Amino-AcidsPreeti100% (5)

- Global Supplier Quality Manual: Revision 5Document14 pagesGlobal Supplier Quality Manual: Revision 5Avinash SilimkarNo ratings yet

- Supplier Quality ManualDocument29 pagesSupplier Quality Manualppanambo100% (2)

- WFRP - White Dwarf 99 - The Ritual (The Enemy Within)Document10 pagesWFRP - White Dwarf 99 - The Ritual (The Enemy Within)Luife Lopez100% (2)

- Quality Assurance Requirements For Licensees-07162010Document4 pagesQuality Assurance Requirements For Licensees-07162010Norma GarciaNo ratings yet

- Supplier Quality System AssessmentDocument47 pagesSupplier Quality System Assessmentmehdi810No ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- Qualification of Equipment - A Risk-Based ApproachDocument6 pagesQualification of Equipment - A Risk-Based ApproachJorge Humberto Herrera100% (9)

- 1 Objective: Packaging Validation Packaging Line/packaging RoomDocument13 pages1 Objective: Packaging Validation Packaging Line/packaging RoomAngel CvetanovNo ratings yet

- Pe 008 4 Site Master File Copy1 PDFDocument8 pagesPe 008 4 Site Master File Copy1 PDFCamilo SuárezNo ratings yet

- Annexure - 31 Calibration ProcedureDocument5 pagesAnnexure - 31 Calibration Proceduresrikanta ksNo ratings yet

- Pharmaguidesop Com 2021 03 Sop On Supplier Qualification VenDocument14 pagesPharmaguidesop Com 2021 03 Sop On Supplier Qualification VenTuriyo AnthonyNo ratings yet

- AC 21-20B - Supplier Surveillance ProceduresDocument10 pagesAC 21-20B - Supplier Surveillance Procedurestwj84No ratings yet

- ASEAN Guideline Process OnDocument7 pagesASEAN Guideline Process OnVipin GuptaNo ratings yet

- Validation and Validation ProtocolDocument18 pagesValidation and Validation ProtocolLalit Lata JhaNo ratings yet

- Cooper Industries PPAP Manual PDFDocument51 pagesCooper Industries PPAP Manual PDFmuselhakNo ratings yet

- QP11-100 E - Calibration - Control of Monitoring and Measuring Equipment PDFDocument12 pagesQP11-100 E - Calibration - Control of Monitoring and Measuring Equipment PDFgranburyjohnstevensNo ratings yet

- ACCA Advanced Corporate Reporting 2005Document763 pagesACCA Advanced Corporate Reporting 2005Platonic100% (2)

- ValidationDocument49 pagesValidationAshokPokiriNo ratings yet

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- Process Audit Check ListDocument24 pagesProcess Audit Check ListSorin FrentoniNo ratings yet

- QMS 050 SampleDocument2 pagesQMS 050 SampleMostafa FawzyNo ratings yet

- Validation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyDocument26 pagesValidation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyAfdal Naim100% (1)

- (Dan Stone) The Historiography of The HolocaustDocument586 pages(Dan Stone) The Historiography of The HolocaustPop Catalin100% (1)

- VAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleDocument3 pagesVAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleMarwa Ahmed100% (2)

- Supplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017Document21 pagesSupplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017ilayaraja MKNo ratings yet

- Friability Tester IQ ProtocolDocument25 pagesFriability Tester IQ ProtocolJames Huang75% (4)

- 1stQ Week5Document3 pages1stQ Week5Jesse QuingaNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Asean Process Validation GuidelineDocument6 pagesAsean Process Validation GuidelineWilliam Chandra100% (1)

- Guidance For Industry: Process ValidationDocument18 pagesGuidance For Industry: Process ValidationBruno DebonnetNo ratings yet

- Sop 1 Recommended Standard Operating Procedure For Calibration Certificate PreparationDocument10 pagesSop 1 Recommended Standard Operating Procedure For Calibration Certificate PreparationEileen OngNo ratings yet

- Supplier Parts Quality ManualDocument41 pagesSupplier Parts Quality Manualkyu999950% (2)

- Production Process and Product Release Procedure: 1 PurposeDocument7 pagesProduction Process and Product Release Procedure: 1 PurposeOmprakash ThakurNo ratings yet

- ISPE ArticleDocument12 pagesISPE Articledrs_mdu48No ratings yet

- GUIDE-MQA-006-008 (Installation and Operational Qualification)Document9 pagesGUIDE-MQA-006-008 (Installation and Operational Qualification)William ChandraNo ratings yet

- IVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20Document3 pagesIVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20huykhiemNo ratings yet

- Annex10c Asean Process Validation Guideline 2 July-AdoptedDocument4 pagesAnnex10c Asean Process Validation Guideline 2 July-AdoptedBrian WilliamsNo ratings yet

- SOP For New Product IntroductionDocument12 pagesSOP For New Product Introduction王仁宏No ratings yet

- AC10 (January 2019) .PDFDocument10 pagesAC10 (January 2019) .PDFGolden RosesNo ratings yet

- Supplier Selection by KetanDocument37 pagesSupplier Selection by KetanKetan PatelNo ratings yet

- Lyondellbasell Commercial Grade Survey ChecklistDocument11 pagesLyondellbasell Commercial Grade Survey ChecklistJuan Carlos CampilloNo ratings yet

- The Addendum 2 Brings Changes To The Following Sections of API Spec Q1Document4 pagesThe Addendum 2 Brings Changes To The Following Sections of API Spec Q1Shahnawaz PathanNo ratings yet

- Quality Control Manual: Company Name Address City, State, ZipDocument10 pagesQuality Control Manual: Company Name Address City, State, ZipMarco CandoNo ratings yet

- Global Supplier Quality Manual 02-18-2020Document13 pagesGlobal Supplier Quality Manual 02-18-2020Emre TekinNo ratings yet

- P112 - Policy On Flexible Scopes-5648-4Document6 pagesP112 - Policy On Flexible Scopes-5648-4Volca CmmNo ratings yet

- FMRC 1046 Fire Pump Flowmeter Systems PDFDocument18 pagesFMRC 1046 Fire Pump Flowmeter Systems PDFdyıldırım_4No ratings yet

- Guide Mqa 024 002 WebDocument9 pagesGuide Mqa 024 002 WebDanina_1981No ratings yet

- WI-H-003 Inspection and Acceptance Work Instruction Rev ADocument8 pagesWI-H-003 Inspection and Acceptance Work Instruction Rev AAnil Chowadary Anil ChowadaryNo ratings yet

- IAPMO Quality Management System Review Procedures For Certified Manufacture's Quality Manual ES-010Document5 pagesIAPMO Quality Management System Review Procedures For Certified Manufacture's Quality Manual ES-010Jasneil SidhuNo ratings yet

- Nbog-2010-1 (Auditing Suppliers)Document7 pagesNbog-2010-1 (Auditing Suppliers)DO KHNo ratings yet

- GMP Standard Operating ProceduresDocument13 pagesGMP Standard Operating Proceduresfagbemi.maNo ratings yet

- Guidance For Industry and FDA Staff Assayed and Unassayed Quality Control MaterialDocument13 pagesGuidance For Industry and FDA Staff Assayed and Unassayed Quality Control Materialsyparab1977No ratings yet

- Quality Test Specification QCS-83-4 FOR First Article Inspection (F.A.I.)Document10 pagesQuality Test Specification QCS-83-4 FOR First Article Inspection (F.A.I.)Amit GauravNo ratings yet

- Plantwide Control: Recent Developments and ApplicationsFrom EverandPlantwide Control: Recent Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Practice Test 4 For Grade 12Document5 pagesPractice Test 4 For Grade 12MAx IMp BayuNo ratings yet

- FJ&GJ SMDocument30 pagesFJ&GJ SMSAJAHAN MOLLANo ratings yet

- Final PS-37 Election Duties 06-02-24 1125pm)Document183 pagesFinal PS-37 Election Duties 06-02-24 1125pm)Muhammad InamNo ratings yet

- 9m.2-L.5@i Have A Dream & Literary DevicesDocument2 pages9m.2-L.5@i Have A Dream & Literary DevicesMaria BuizonNo ratings yet

- Signalling in Telecom Network &SSTPDocument39 pagesSignalling in Telecom Network &SSTPDilan TuderNo ratings yet

- Islamic Meditation (Full) PDFDocument10 pagesIslamic Meditation (Full) PDFIslamicfaith Introspection0% (1)

- 1.quetta Master Plan RFP Draft1Document99 pages1.quetta Master Plan RFP Draft1Munir HussainNo ratings yet

- How To Export: 1) Establishing An OrganisationDocument5 pagesHow To Export: 1) Establishing An Organisationarpit85No ratings yet

- The Hawthorne Studies RevisitedDocument25 pagesThe Hawthorne Studies Revisitedsuhana satijaNo ratings yet

- Introduction To Instrumented IndentationDocument7 pagesIntroduction To Instrumented Indentationopvsj42No ratings yet

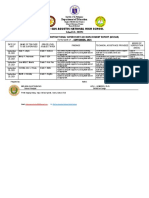

- Old San Agustin NHS MSISAR Sept 2021Document2 pagesOld San Agustin NHS MSISAR Sept 2021ERICSON SABANGANNo ratings yet

- List de VerbosDocument2 pagesList de VerbosmarcoNo ratings yet

- Kurukku PadaiDocument4 pagesKurukku PadaisimranNo ratings yet

- Balezi - Annale Générale Vol 4 - 1 - 2 Fin OkDocument53 pagesBalezi - Annale Générale Vol 4 - 1 - 2 Fin OkNcangu BenjaminNo ratings yet

- BedDocument17 pagesBedprasadum2321No ratings yet

- Digital TransmissionDIGITAL TRANSMISSIONDocument2 pagesDigital TransmissionDIGITAL TRANSMISSIONEla DerarajNo ratings yet

- Enunciado de La Pregunta: Finalizado Se Puntúa 1.00 Sobre 1.00Document9 pagesEnunciado de La Pregunta: Finalizado Se Puntúa 1.00 Sobre 1.00Samuel MojicaNo ratings yet

- In Mein KampfDocument3 pagesIn Mein KampfAnonymous t5XUqBNo ratings yet

- AASW Code of Ethics-2004Document36 pagesAASW Code of Ethics-2004Steven TanNo ratings yet

- A2B1 Unit 11bDocument2 pagesA2B1 Unit 11bTheToan.No ratings yet

- A Quality Improvement Initiative To Engage Older Adults in The DiDocument128 pagesA Quality Improvement Initiative To Engage Older Adults in The Disara mohamedNo ratings yet

- Reported Speech StatementsDocument1 pageReported Speech StatementsEmilijus Bartasevic100% (1)

- Creative Nonfiction 2 For Humss 12 Creative Nonfiction 2 For Humss 12Document55 pagesCreative Nonfiction 2 For Humss 12 Creative Nonfiction 2 For Humss 12QUINTOS, JOVINCE U. G-12 HUMSS A GROUP 8No ratings yet