Professional Documents

Culture Documents

B A S Ket Strainer Pressure Drop-Liquids

Uploaded by

guillemaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B A S Ket Strainer Pressure Drop-Liquids

Uploaded by

guillemaraCopyright:

Available Formats

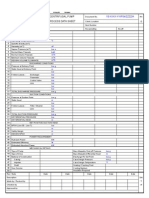

Engineering Data Screen Openings for Basket Strainers

Factors To Consider

Purpose

If the basket strainer is being used for protection rather than direct filtration,IFCs standard screens will suffice in most applications.

Filtration Level

Service

With services that require extremely sturdy screens, such as high pressure/ temperature applications or services with high viscosities, IFC recommends that perforated screens without mesh liners be used. If mesh is required to obtain a certain level of filtration, then IFC recommends a trapped perf./mesh/perf. combination.

When choosing a perf. or a mesh/perf. combination attention should be given to ensure overstraining does not occur.As a general rule the specified level of filtration should be no smaller than half the size of the particle to be removed. If too fine a filtration is specified the pressure drop through the strainer will increase very rapidly, possibly causing damage to the basket.

Screen Types/Dimensions

0.027 Dia. - 23% O.A.

3/ 16

5/ 32

3/ 32

1/ 16

1/ 4

1/ 8

3/ 64

Notes: 1. Screen openings other than those shown above are readily available. IFC inventories various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2 Dia. 2. Screens are available in a wide range of materials. IFC inventories various screen material in carbon steel, stainless steel (304, 316), alloy 20, monel 400, hastalloy C and titanium grade 2. 3. Custom manufactured screens are available upon request. Please consult factory.

1/ 4

Tel. 905-335-8777

Fax. 905-335-0977

Toll Free Tel. 1-866-872-0072

Toll Free Fax. 1-866-872-0073

100 Mesh - 30% O.A. 0.006 Openings

Dia. - 50% O.A.

Dia. - 37% O.A.

Dia. - 36% O.A.

20 Mesh - 49% O.A. 0.035 Openings

30 Mesh - 45% O.A. 0.022 Openings

40 Mesh - 41% O.A. 0.016 Openings

60 Mesh - 38% O.A. 0.010 Openings

80 Mesh - 36% O.A. 0.008 Openings

Dia. - 58% O.A

Dia. - 40% O.A.

Dia. - 40% O.A.

Dia. - 39% O.A

Dia. - 40% O.A.

14

Engineering Data Basket Strainer Pressure Drop-Liquids

Threaded Basket Strainer Pressure Drop - Liquids (Sizes

10

1/

- 1

1/

) FIGURE 1

PRESSURE DROP (PSID)

1/ 2

1/ 4

3/ 4

1/ 2

0.1 1 10 100

FLOW RATE (GPM)

Flanged Basket Strainer Pressure Drop - Liquids (Sizes 2 - 24 )

10

FIGURE 2

PRESSURE DROP (PSID)

10

0.1 10 100 1000 10000

FLOW RATE (GPM)

Notes: 1. Pressure drop curves are based on water flow with standard screens. See page 16 for correction factors to be used with other fluids and/or screen openings. 2. For Style 1 basket strainers multiply value obtained in figure 2 by 1.15 to obtain clean pressure drop.

15

Tel. 905-335-8777

Fax. 905-335-0977

Toll Free Tel. 1-866-872-0072

Toll Free Fax. 1-866-872-0073

24

12 14 16 18 20

Engineering Data Screen Correction Factor Chart

For Non-Standard and Mesh Lined Screens *Multiply values obtained from figure 1 thru 2 by the appropriate values shown below Chart #1 SCREEN OPENINGS Size R ange

1/ 4

60%

0.45 0.65

Perforated Plate % Screen Material Open Area 50% 40% 30%

0.55 0.8 0.7 1 1 1.4

20%

1.15 2.15

Mesh lined standard screens % Screen Material Open Area 50% 40% 30%

1.05 1.05 1.05 1.05 1.2 1.2

- 11/2

2 - 16

Notes: 1. See page 14 for % Open Areas of IFC inventoried perforated plate. 2. Standard screens for sizes 1/4 to 1-1/2 is approximately a 30% open area screen media. 3. Standard screens for sizes 2 and larger is approximately a 40% open area screen media.

Example:

Strainer Size: Flow rate: Service: 2 Style 2 70 GPM Water Filtration: 100 Mesh lined 1/8 perf.

A) Using figure 1 the pressure drop is determined to be 0.9 psig with IFCs standard screen. B) Looking at page 14 we find that the % Open area of 100 mesh is 30%. C) Using chart 1 we read the correction factor to be 1.2 for 100 mesh lined 1/8 perf. D) Total pressure drop equals 0.9 x 1.2 = 1.08 psig clean.

Viscosity and Density Correction Factor Chart * For use see instructions below. Chart #2 Size Component R ange factor (CF)

1/ 4

Viscosity Body Loss Cp Factor Perf alone (BF) (PF)

10 25 100 200 500 1000 2000 1 1.2 1.6 2.2 4.4 8 15.2 1.15 1.25 1.4 1.5 1.6 1.7 1.9

Chart #3 Screen Loss Factor 20 mesh 30 & 40 mesh 60 to 300 mesh lined (MF) lined (MF) lined (MF)

1.3 2 3 4.5 10 15 30 1.4 2.2 4 7 15 30 60 1.5 2.5 6.5 11.5 25 50 100

- 11/2

0.25 0.35

2 - 16

How to Use: 1) Using figures 1 or 2 determine the pressure drop (P1) through the strainer with water flow and standard screens. 2) If non-standard screens (i.e. 40 mesh, etc.) are being used apply factors in chart #1 to determine corrected pressure drop (P2). 3) Multiply P1 or P2 (is used) by the specific gravity of the fluid actually flowing through the strainer to get P3. 4) Using chart #2 multiply P3 by the appropriate Component Factor (CF) to get P4. 5) Let P5 = P3 - P4. 6) Multiply P4 by the appropriate Body Loss Factor (BF) in chart #3 to get P6. 7) Multiply P5 by the appropriate Screen Loss factor (PF or MF) in chart #3 to get P7. 8) Total pressure drop P8 = P6 + P7.

Example:

Strainer Size: Flow rate: Specific Gravity: Viscosity: 2 Style 2 70 GPM 1 100 cP Filtration: 100 mesh lined 1/8 perf.

A) As shown in the above example, the corrected pressure drop (P2) = 1.08 psig B) Since S.G. = 1, P3 = P2 = 1.08 psig C) Using chart #2 P4 = 0.35 x P3 = 0.38 psig D) P5 = 1.08 - 0.38 = 0.70 psig E) Using chart #3 P6 = 0.38 x 1.6 = 0.61 psig F) Again using chart #3 P7 = 0.70 x 6.5 = 4.55 psig G) Total pressure drop P8 = 0.61 + 4.55 = 5.16 psig

Tel. 905-335-8777

Fax. 905-335-0977

Toll Free Tel. 1-866-872-0072

Toll Free Fax. 1-866-872-0073

16

Engineering Data Correction Factors For Clogged Screens

* Multiply values obtained from figures 1 thru 2 and charts #1, #2 and #3 (if used) by the appropriate values shown below % Clogged

10% 20% 30% 40% 50% 60% 70% 80% 90%

10:1

2.3

8:1

1.1 3.45

R atio of Free Screen Area to Pipe Area 6:1 4:1 3:1

1.75 6 1.15 1.75 3.6 13.5 1.25 1.8 2.95 6.25 24

Chart # 4 2:1

1.15 1.4 1.8 2.5 3.7 6.4 14 55

1:1

3.15 3.9 5 6.65 9.45 14.5 26 58 -

Notes: 1. See page 14 for the ratio of free area to pipe area for IFC Basket Strainers equipped with standard screens. 2. For screens other than IFCs standard use the following formula to calculate the ratio free area to pipe area:

R = Ag x OA 100Ap

Example #1

Strainer Size: 10 IFC Series: B150F(Style 2) 1/ perf. Filtration: 8 Flow rate: 3000 GPM Service: Water % Clogged: 60%

where; R

= Ratio free area to pipe area

Ag = Gross screen area, sq. in. (See page 19) OA = Open area of screen media, % (See page 14, i.e. 1/16 perf. = 37%) Ap = Nominal area of pipe fitting, sq. in. (See page 19)

A) Using figure #1 the pressure drop is determined to be 2.0 psig with IFCs standard screen. B) Looking at page 19 the ratio of free area to pipe area for a 10 IFC series B150F (Style 1) strainer is equal to 2.1:1 (2:1 approx.). C) Using chart #4 we read the correction factor to be 3.7 at 60% clogged. D) Total pressure drop equals 2.0 x 3.7 = 7.4 psig when 60% clogged.

Example #2

Strainer Size: 12 IFC Series: B150F(Style 2) 3/ perf. Filtration: 16 Flow rate: 3000 GPM Service: Water % Clogged: 70%

A) Using figure #1 the pressure drop is determined to be 1.0 psig with IFCs standard screen. B) Looking at page 14 we find that the % Open area (OA) of 3/16 perf. is 50%. C) Using chart #1 we read the correction factor to be 0.8 for 3/16 perf. D) Total clean pressure drop equals 1.0 x 0.8 = 0.8 psig. E) Since a non-standard screen is being used we must calculate the ratio free area to pipe area using the above formula. F) Looking at page 27 we find AG = 693.85 in2,Ap = 113.10 in2. G) The ratio free area to pipe area is calculated as 3.07:1. (3:1 approx.) H) Using chart #4 we read the correction factor to be 2.95 at 70% clogged. I) Total pressure drop equals 0.8 x 2.95 = 2.36 psig when 70% clogged.

17

Tel. 905-335-8777

Fax. 905-335-0977

Toll Free Tel. 1-866-872-0072

Toll Free Fax. 1-866-872-0073

You might also like

- Astm A6 PDFDocument59 pagesAstm A6 PDFAlexi SanjinésNo ratings yet

- Sae Ams 5513J-2009Document5 pagesSae Ams 5513J-2009Kashan KhanNo ratings yet

- Sizing SF 6 Inch Y-Strainer-1Document11 pagesSizing SF 6 Inch Y-Strainer-1BIDDU GHOSHNo ratings yet

- Design Data: 2" Threadolet CalculationDocument2 pagesDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- CFD Methodology For Liquid Pressure Recovery PredictionsDocument9 pagesCFD Methodology For Liquid Pressure Recovery PredictionsAshok SureshNo ratings yet

- Strainer SizingDocument20 pagesStrainer Sizingaliscribd46No ratings yet

- Dense Medium Cyclone Selection - It All Adds UpDocument18 pagesDense Medium Cyclone Selection - It All Adds UpLuis VelasquezNo ratings yet

- Strainer Drop PressureDocument2 pagesStrainer Drop PressureJose Manuel Cervantes0% (1)

- Fabrication Strainers Mesh SizingDocument6 pagesFabrication Strainers Mesh SizingArun GuptaNo ratings yet

- Crosby SizingDocument89 pagesCrosby SizingNattapong Pongboot100% (1)

- 25nb y StrainerDocument1 page25nb y StrainerKailas NimbalkarNo ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- Orifice Plate Sizing CalculatorDocument11 pagesOrifice Plate Sizing Calculatormyself_riteshNo ratings yet

- Liquid Line SizingDocument8 pagesLiquid Line Sizingsamuad59No ratings yet

- Is 600 MM Sufficient To Keep BDV FunctionalDocument0 pagesIs 600 MM Sufficient To Keep BDV Functionalsachin2010No ratings yet

- SCFM To AcfmDocument6 pagesSCFM To AcfmFaizanNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainNo ratings yet

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different StandardsAMRUTA PATILNo ratings yet

- Basket Strainer PDC 350NBDocument1 pageBasket Strainer PDC 350NBKailas Nimbalkar0% (1)

- Cuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingDocument9 pagesCuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingVăn HoàngNo ratings yet

- CVC AlcsDocument10 pagesCVC Alcsmanoj_amritkarNo ratings yet

- 9.line Size & Wall ThicknessDocument48 pages9.line Size & Wall ThicknessClark PlúaNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Nozzle CriteriaDocument2 pagesNozzle CriteriaKhalil LasferNo ratings yet

- Float Board Level GaugeDocument6 pagesFloat Board Level GaugeanaismariaNo ratings yet

- Restriction OrificeDocument4 pagesRestriction OrificeRaghulal SethumadhavanNo ratings yet

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- Separator Sizing Example CalculationDocument2 pagesSeparator Sizing Example CalculationJosé Juan MontejoNo ratings yet

- Steam-Water Two-Phase Flow in Large Diameter Vertical PipingDocument11 pagesSteam-Water Two-Phase Flow in Large Diameter Vertical Pipingfujiman35No ratings yet

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- Orifice Plate BrochureDocument39 pagesOrifice Plate Brochureronzies100% (1)

- 00000-Jds-003 (Level Trans DS) Rev 0Document4 pages00000-Jds-003 (Level Trans DS) Rev 0sithulibraNo ratings yet

- Calculate Pressure Drop in Basket & Tee Strainers ReferenceDocument5 pagesCalculate Pressure Drop in Basket & Tee Strainers Referencebrock100% (1)

- 03 Ernstsen Jensen Slug Force PresentationDocument26 pages03 Ernstsen Jensen Slug Force Presentationsam_kamali85No ratings yet

- 8-0241-4503-Flare System Design PDFDocument8 pages8-0241-4503-Flare System Design PDFVinothrajaNo ratings yet

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 pagesOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulNo ratings yet

- Hannibal Slug CatcherDocument2 pagesHannibal Slug CatcherBigBall PaNuNo ratings yet

- Volume and Wetted Area of Partially Filled Horizontal VesselsDocument11 pagesVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaNo ratings yet

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDocument6 pagesDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTORONo ratings yet

- SeparatorDocument23 pagesSeparatorLeonardo Ramirez GuzmanNo ratings yet

- Faculty of Engineering & Technology Mechanical Engineering Lab Report Fluid MechanicsDocument11 pagesFaculty of Engineering & Technology Mechanical Engineering Lab Report Fluid MechanicsTan YikcongNo ratings yet

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- Filter CalculationDocument4 pagesFilter CalculationRashmi RanjanNo ratings yet

- Savvy Separator: The Ghosts of Separators Past, Present, and FutureDocument7 pagesSavvy Separator: The Ghosts of Separators Past, Present, and FutureDeepblue09100% (1)

- 521 TiDocument4 pages521 Tisa.somaNo ratings yet

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Flare System DesignDocument2 pagesFlare System Designomar alnasserNo ratings yet

- Rupturedisk CheresourcesDocument9 pagesRupturedisk Cheresourcessammar_10100% (1)

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINo ratings yet

- Data SheetDocument6 pagesData Sheetnalawade_pradeepNo ratings yet

- Rotary Lobe Pump Application Datasheet2Document1 pageRotary Lobe Pump Application Datasheet2paldopalNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Vane Separator (Brochure PEERLESSMFG)Document6 pagesVane Separator (Brochure PEERLESSMFG)Julio OrtegaNo ratings yet

- Screen Openings For Y-StrainersDocument6 pagesScreen Openings For Y-Strainersboom10No ratings yet

- Sizing of StrainerDocument20 pagesSizing of StrainerMASOMESE KIKILENo ratings yet

- 33 - STR990-1 - Pressure Drop Data YDocument2 pages33 - STR990-1 - Pressure Drop Data YblindjaxxNo ratings yet

- Using Flange Joint in Duct SiystemDocument23 pagesUsing Flange Joint in Duct Siystematamete100% (1)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- ST7006-Design of Bridges PDFDocument9 pagesST7006-Design of Bridges PDFmiestyNo ratings yet

- Foundation Calculation Format: MEC Piperack Calculation - Presentation Preferable Main ContentDocument13 pagesFoundation Calculation Format: MEC Piperack Calculation - Presentation Preferable Main Contentdinu69inNo ratings yet

- En 10051-2010Document16 pagesEn 10051-2010yousab creator2No ratings yet

- Structural FPD P.sanchezDocument9 pagesStructural FPD P.sanchezHailley DensonNo ratings yet

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDocument5 pagesGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargNo ratings yet

- QCS 2010 Section 16 Part 2 Materials PDFDocument5 pagesQCS 2010 Section 16 Part 2 Materials PDFbryanpastor10650% (2)

- DEXT 067 DIN en 10277 2 Aços para Propósitos Gerais de EngenhariaDocument11 pagesDEXT 067 DIN en 10277 2 Aços para Propósitos Gerais de EngenhariatestesadaNo ratings yet

- Flour Mill Instruction SheetDocument13 pagesFlour Mill Instruction SheetM Indra RahmansyahNo ratings yet

- GRC-ES003 - r2 - Prefabricated Electrical SwitchroomsDocument15 pagesGRC-ES003 - r2 - Prefabricated Electrical SwitchroomsAulinoNo ratings yet

- Steel ConstructionDocument70 pagesSteel Constructionfabhinaya100% (11)

- Tubular Brace MemberDocument8 pagesTubular Brace MemberRegina MillerNo ratings yet

- Compare S235JR, E250BRDocument6 pagesCompare S235JR, E250BRGANESHNo ratings yet

- Technical Specification For 24kV Cable Entry Transformers: Ergon Energy Corporation LimitedDocument38 pagesTechnical Specification For 24kV Cable Entry Transformers: Ergon Energy Corporation Limitedvzimak2355No ratings yet

- Allied Machine & Engineering T-A Drilling System CatalogDocument128 pagesAllied Machine & Engineering T-A Drilling System CatalogdlstoneNo ratings yet

- VA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1Document20 pagesVA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1MungNguyenDinhNo ratings yet

- Steel - Equivalent GradesDocument23 pagesSteel - Equivalent GradesSowmen Chakroborty100% (1)

- Jis 3193Document2 pagesJis 3193Nguyeentt Tnt100% (2)

- Hollow Sections Book WardenierDocument199 pagesHollow Sections Book WardenierANUSSBAUMER100% (3)

- Rajeev Shah & Associates: Structural Design Basis ReportDocument8 pagesRajeev Shah & Associates: Structural Design Basis Reportrajeev shahNo ratings yet

- Technical Stell ResearchDocument141 pagesTechnical Stell Researchscribd_namnNo ratings yet

- Structural Engineer Resume - Sathik - Oct - 2023-1Document3 pagesStructural Engineer Resume - Sathik - Oct - 2023-1sathik sowfarNo ratings yet

- A572gr50 Round BarDocument2 pagesA572gr50 Round BarPeines Tangenciales SA DE CVNo ratings yet

- En 10025Document2 pagesEn 10025Anonymous GE8mQqxNo ratings yet

- Piping Load DataDocument2 pagesPiping Load DatassjunedNo ratings yet

- Main Building Structure ReportDocument65 pagesMain Building Structure ReportRoshan KejariwalNo ratings yet

- Tower Palace-Korea PDFDocument8 pagesTower Palace-Korea PDFjafeelnmNo ratings yet