Professional Documents

Culture Documents

Gard P I Club News179 A Fatal LPG Tanker Accident

Uploaded by

wojciechkoziolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gard P I Club News179 A Fatal LPG Tanker Accident

Uploaded by

wojciechkoziolCopyright:

Available Formats

G A R D N E W S ISSUE 1 7 9 August/ October 2 0 0 5

A fatal tanker accident

The problems of gas and lack of air on board tankers are a part of the job and there is no shortage of procedures and warnings. Still, accidents do happen. The following accident, which took place in 2004, led to the death of the vessels master.

The incident

An LPG/ethylene tanker insured with Gard was being prepared for dry-docking following a discharge of ethylene. In order to arrive at the yard with breathable air in the cargo tanks, purging and gas-freeing operations were carried out. Due to technical problems there were several stops of the vessels oil-fired inert gas generator, and the final inerting was done by wet inert gas, bypassing the dryer and the compressor. The inert gas was partly of poor quality and observed at times to be quite blackish. Once the inerting process was completed, ventilation of all tanks was started. When the oxygen content of cargo tank No. 3 was measured to 21 per cent, the master and chief officer entered the tank for a five-minute inspection, wearing ELSA sets for safety. Around the sump of the pump suction some water from the wet inert gas was found, and to remove this, three crew members with a portable pump entered the tank. Once the pump was rigged, one AB remained in the tank to monitor the pumping. After about 20 minutes, he began to feel dizzy and started to climb the ladder when he passed out. The last thing he remembered was hooking his foot behind a ladder step to avoid falling down. The two other crew members were higher up in the tank when the AB collapsed, and climbing out they notified the master of the accident. One can not know for sure, but the master, who had just been inside the tank, may have felt over-confident, or perhaps responsible for the AB being in the tank on his orders. Anyhow, he immediately entered the tank and did not take time to don any breathing apparatus. Struggling to rescue the AB, the master managed to put a rope around him before getting into trouble himself and falling to the bottom of the tank, unconscious. After 20 minutes crew

Crew member with air bottle. A number of bottles were used during the rescue attempt.

The AB had to be removed from the ladder first, and a chain block had to be rigged on deck to hoist the master.

members managed to rescue the AB, who regained consciousness once brought to open air on deck. Later he was brought to a hospital and recovered quickly. The master was worse off a heavy man lying in the bottom of the tank. The AB had to be removed from the ladder first, and a chain block had to be rigged on deck to hoist the master. It took 40 minutes to get

him out. It also took considerable time to get him ashore by a launch, while supporting him on the vessels portable oxygen supply, until it eventually ran out. The master was pronounced dead upon arrival ashore, and a post mortem examination concluded that he died of a heart attack.

Lessons learned

The member in question had always focused on safety on board and had up to this incident not had any fatal accident on his vessels. Good procedures were in place, experienced personnel and adequate gas monitoring and safety equipment were on board. Following the accident a thorough investigation was

is highly toxic because it replaces oxygen in the bloodstream. Before entering the tank, the oxygen level was tested, but no test for hydrocarbons or CO was carried out, although testing for toxic gases was called for in the Tank Entry Permit Procedure. Tanker personnel may only think about toxic gases from cargoes in this context, but especially after the problems of the inert gas generator, the possibility of CO being present in the tank should have been verified. The member has now underlined the need to check for CO in the revised entry permit form. Furthermore, the paperwork was not fully completed before entering the tank, and the exact level of oxygen was not recorded. When the AB collapsed, the masters rescue attempt was

2

To get the master out of the tank a chain block was rigged above the tank entrance. A chain block is powerful but slow and it might have been faster to use a simple pulley block with rope and a few crew members to pull. carried out, as well as a review of the safety procedures for tank entry. The case has since been used as an example in the training of personnel and other loss prevention schemes. Gard commends the member for these initiatives, because once tragic accidents have happened, they can be used to prevent others. On the balance of probability, and judging by his symptoms, it was concluded that the ABs collapse inside the tank was due to carbon monoxide (CO) poisoning. CO is a colourless and odourless gas, produced by the incomplete combustion of fuel. In a combustion-based inert gas space there is probably always some amount of CO. The gas

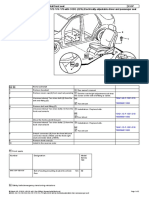

Lay of cargo No. showing of col ollapsed seaman master. Layout of cargo tank No. 3 showing the positions of the collapsed AB seaman and the master.

heroic, but he should not have entered the tank without the available breathing apparatus. It is easy to say that with hindsight and from a shore-based office, but being the captain of the ship he should not have undertaken the rescue task at all, and should have stayed in command. Following the accident, the member has also amended the Entry Permit to include a requirement for all personnel to use ELSA sets for entry into enclosed spaces, and to carry gas monitors. As medical assistance and transportation ashore was difficult to obtain, the member also debated whether a PANPAN or a MAYDAY signal should have been sent out to speed up shore assistance, a decision that would have been easier had the master not been the one to be evacuated.

Ventilation of cargo tank No. 3 through the entrance opening.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TBM Operation For Tunneling Work (Final) PDFDocument117 pagesTBM Operation For Tunneling Work (Final) PDFkiller_pro75% (8)

- AtlesDocument26 pagesAtlesAnonymous CdUZMZJq73No ratings yet

- Airo Part ManualDocument52 pagesAiro Part ManualCemYurtseverNo ratings yet

- Project Report On Pavement DesignDocument50 pagesProject Report On Pavement Designsagar kumar100% (1)

- TransChicago Truck Group Project SummaryDocument17 pagesTransChicago Truck Group Project SummaryTodd FeurerNo ratings yet

- Spare Parts Catalogue: Bajaj Auto LimitedDocument46 pagesSpare Parts Catalogue: Bajaj Auto LimitedGabriel ZamoraNo ratings yet

- FraseologiaDocument52 pagesFraseologiaBruno GanicocheNo ratings yet

- NahDocument3 pagesNahmico de jesusNo ratings yet

- Engineer Estimate ManualDocument24 pagesEngineer Estimate ManualNes-tValdezNo ratings yet

- BS en 45545-5-2013Document20 pagesBS en 45545-5-2013Shiv PandeyNo ratings yet

- Topic 3: Ship's Stresses: MTR 1102 - Ship, Ship Routines and Ship ConstructionDocument25 pagesTopic 3: Ship's Stresses: MTR 1102 - Ship, Ship Routines and Ship ConstructionJuan GonzalesNo ratings yet

- Asu Skysong Map and DirectionsDocument3 pagesAsu Skysong Map and DirectionsCarleone PrimaNo ratings yet

- Indian Biogas Association Biogas Market IndiaDocument36 pagesIndian Biogas Association Biogas Market Indiasj singh100% (1)

- What Does Fedex Deliver?Document17 pagesWhat Does Fedex Deliver?duckythiefNo ratings yet

- HSC Engineering StudiesDocument13 pagesHSC Engineering StudiesRick ThuranNo ratings yet

- Cessna 404Document11 pagesCessna 404AnkkyloFGNo ratings yet

- 5l - FORMDocument7 pages5l - FORMAnthony Steve LomilloNo ratings yet

- Gaz Classifieds 150514Document5 pagesGaz Classifieds 150514Digital MediaNo ratings yet

- Soal UTS 1-1Document2 pagesSoal UTS 1-1Fitri AnnaNo ratings yet

- Highwaymaintenance M KennyDocument28 pagesHighwaymaintenance M KennyEbsa KelifaNo ratings yet

- National Crane NBT40: Operator ManualDocument128 pagesNational Crane NBT40: Operator ManualAlex Sandro Borges Pereira100% (1)

- Legislative Decree 271 - 99Document14 pagesLegislative Decree 271 - 99volgNo ratings yet

- Specific Poa - TX Blank FormDocument1 pageSpecific Poa - TX Blank FormTyler BealsNo ratings yet

- Participating Stations Sep 2020 PDFDocument3 pagesParticipating Stations Sep 2020 PDFمحمد ﺫﻭﻟﻔﮑﺮ محمد بصيNo ratings yet

- Gas DesighDocument81 pagesGas DesighNetra Nanda100% (1)

- 2006 5 Citroen c4 63714 PDFDocument218 pages2006 5 Citroen c4 63714 PDFMuhammad ShahidNo ratings yet

- New Insignia Prices FRDocument24 pagesNew Insignia Prices FRNikos Anta TagalhsNo ratings yet

- Svenborg Disc BrakesDocument112 pagesSvenborg Disc BrakesvsarrNo ratings yet

- R&I Seat Belt Buckle Front #2Document2 pagesR&I Seat Belt Buckle Front #2Pablo LoboNo ratings yet